FORD SUPER DUTY 2009 2.G Diesel Supplement Manual

Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 103, PDF Size: 0.75 MB

Page 31 of 103

WARNING:Failure to maintain the functional holes, in the

tailpipe section of the exhaust, clean and free of debris or

foreign material may result in the holes becoming blocked or plugged.

Do not modify or remove the tail-pipe section. Blocked or plugged

holes or removal/modification of the system could result in elevated

exhaust gas temperatures which may result in vehicle/property damage

or personal injury

WARNING:The normal operating temperature of the exhaust

system is very high. Never work around or attempt to repair any

part of the exhaust system until it has cooled. Use special care when

working around the diesel oxidation catalytic converter and/or the

diesel particulate filter (DPF). The diesel oxidation catalytic converter

and/or the DPF heats up to a high temperature after only a short

period of engine operation and can stay hot even after the engine is

turned off. Failure to follow these instructions may result in personal

injury.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Cleaning

31

Page 32 of 103

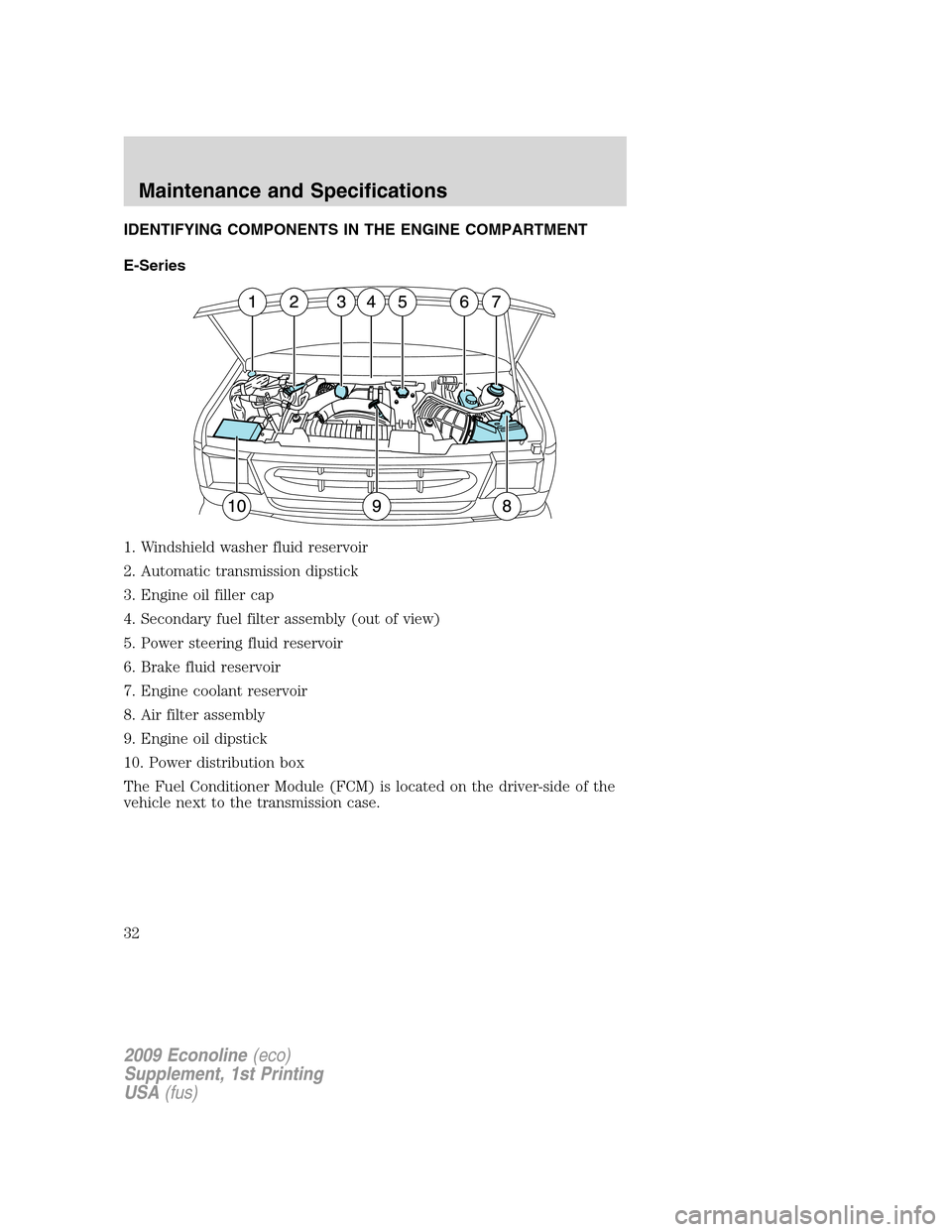

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

E-Series

1. Windshield washer fluid reservoir

2. Automatic transmission dipstick

3. Engine oil filler cap

4. Secondary fuel filter assembly (out of view)

5. Power steering fluid reservoir

6. Brake fluid reservoir

7. Engine coolant reservoir

8. Air filter assembly

9. Engine oil dipstick

10. Power distribution box

The Fuel Conditioner Module (FCM) is located on the driver-side of the

vehicle next to the transmission case.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

32

Page 33 of 103

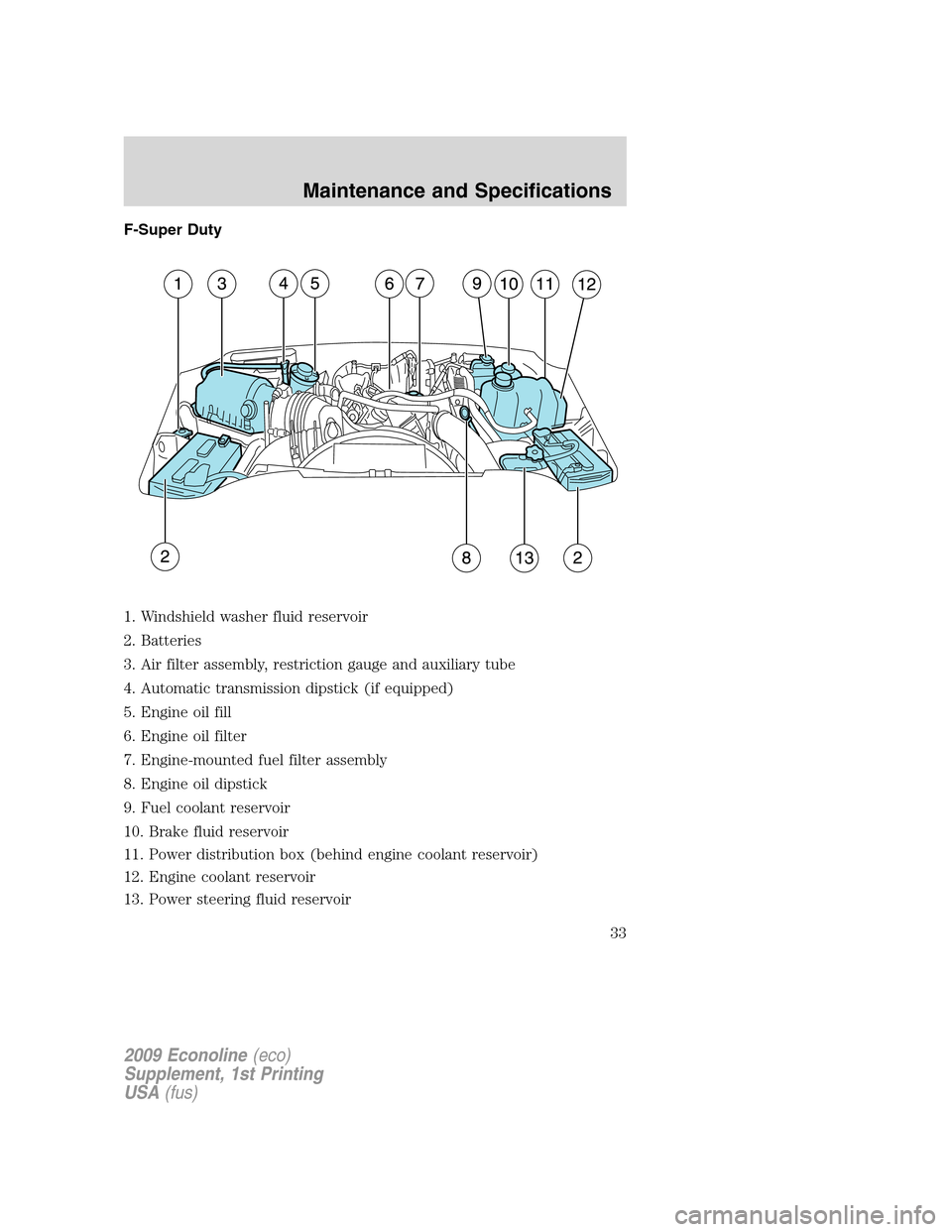

F-Super Duty

1. Windshield washer fluid reservoir

2. Batteries

3. Air filter assembly, restriction gauge and auxiliary tube

4. Automatic transmission dipstick (if equipped)

5. Engine oil fill

6. Engine oil filter

7. Engine-mounted fuel filter assembly

8. Engine oil dipstick

9. Fuel coolant reservoir

10. Brake fluid reservoir

11. Power distribution box (behind engine coolant reservoir)

12. Engine coolant reservoir

13. Power steering fluid reservoir

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

33

Page 34 of 103

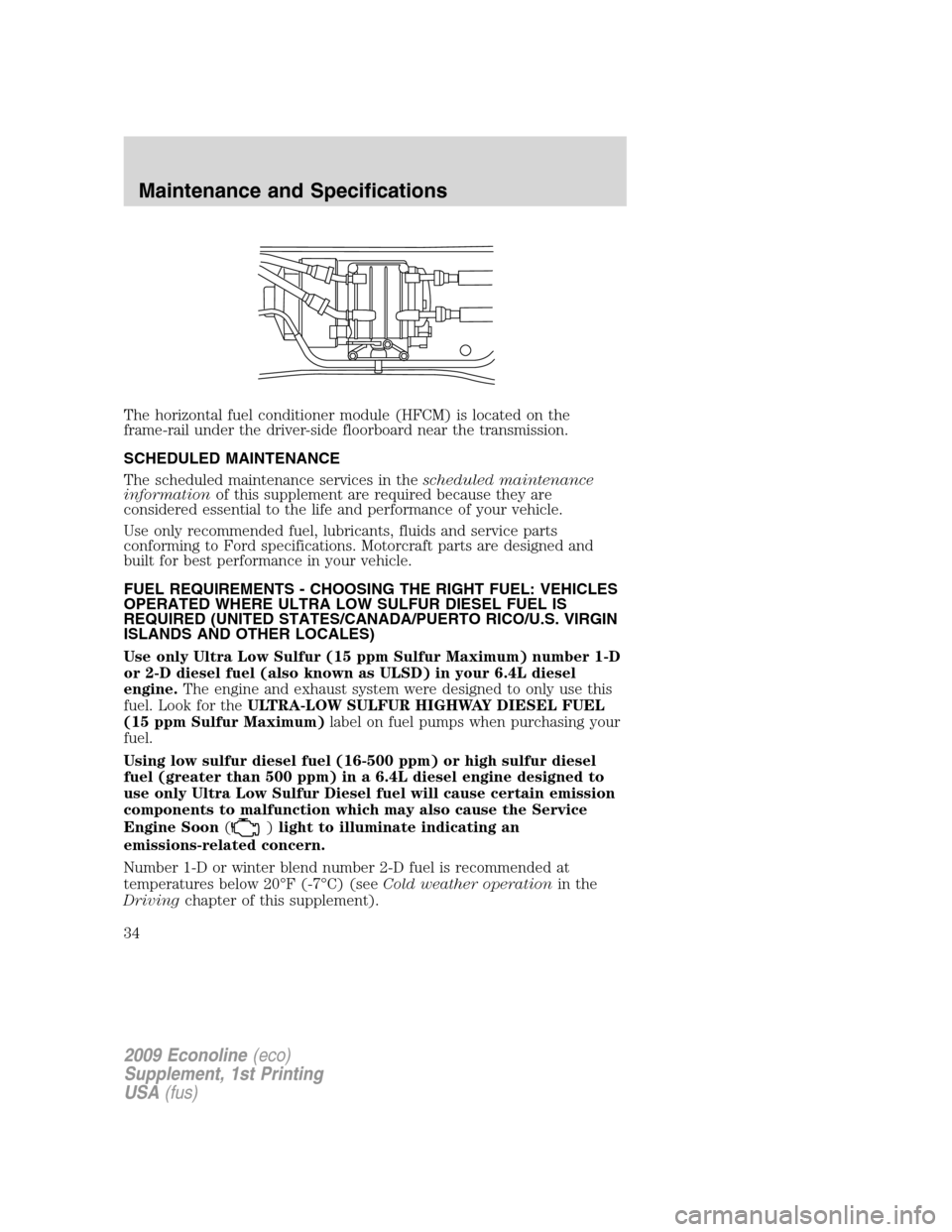

The horizontal fuel conditioner module (HFCM) is located on the

frame-rail under the driver-side floorboard near the transmission.

SCHEDULED MAINTENANCE

The scheduled maintenance services in thescheduled maintenance

informationof this supplement are required because they are

considered essential to the life and performance of your vehicle.

Use only recommended fuel, lubricants, fluids and service parts

conforming to Ford specifications. Motorcraft parts are designed and

built for best performance in your vehicle.

FUEL REQUIREMENTS - CHOOSING THE RIGHT FUEL: VEHICLES

OPERATED WHERE ULTRA LOW SULFUR DIESEL FUEL IS

REQUIRED (UNITED STATES/CANADA/PUERTO RICO/U.S. VIRGIN

ISLANDS AND OTHER LOCALES)

Use only Ultra Low Sulfur (15 ppm Sulfur Maximum) number 1-D

or 2-D diesel fuel (also known as ULSD) in your 6.4L diesel

engine.The engine and exhaust system were designed to only use this

fuel. Look for theULTRA-LOW SULFUR HIGHWAY DIESEL FUEL

(15 ppm Sulfur Maximum)label on fuel pumps when purchasing your

fuel.

Using low sulfur diesel fuel (16-500 ppm) or high sulfur diesel

fuel (greater than 500 ppm) in a 6.4L diesel engine designed to

use only Ultra Low Sulfur Diesel fuel will cause certain emission

components to malfunction which may also cause the Service

Engine Soon(

)light to illuminate indicating an

emissions-related concern.

Number 1-D or winter blend number 2-D fuel is recommended at

temperatures below 20°F (-7°C) (seeCold weather operationin the

Drivingchapter of this supplement).

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

34

Page 35 of 103

BIODIESEL

Diesel fuel containing no more than 5% biodiesel may be used. To help

achieve acceptable engine performance and durability, it is important to

only use biodiesel of good quality in your diesel engine. At a minimum,

the biodiesel should comply with ASTM D6751 or an equivalent

specification.

Use of biodiesel in concentrations greater than 5% may cause damage to

your vehicles fuel system components such as fuel tank, fuel lines, fuel

pump, fuel sender and fuel injectors. Concentrations greater than 5% can

also cause fuel filter restrictions that may result in a lack of power and

or fuel pump and fuel injector failure.

Look for a label on the fuel pump to confirm the amount of biodiesel

contained in a diesel fuel. Biodiesel content is often indicated with the

letter “B” followed by the percent of biodiesel in the fuel. For example,

B5 indicates a fuel containing 5% biodiesel. Ask the service station

attendant to confirm the biodiesel content of a diesel fuel if you do not

see a label on the fuel pump.

Biodiesel should not be stored in the fuel tank for more than three

months. If your vehicle will be parked or stored for more than three

months, then your vehicle should be drained and filled with a diesel fuel

not containing biodiesel.

During cold weather, if you have problems operating on biodiesel, you

may need to use a diesel fuel with lower biodiesel content, try another

brand, or discontinue the use of biodiesel.

Biodiesel use may affect the recommended oil change intervals. Refer to

theSpecial Operating Conditionssection in theschedule

maintenance guidefor more information about oil change intervals and

other maintenance when operating on biodiesel.

Biodiesel fuel is a product that has been converted from renewable fuel

sources, including vegetable oil, animal fat and cooking oil. Raw or

refined vegetable oil, animal fat, cooking oil or recycled greases should

not be used.

Do not use home heating oil, agricultural fuel or any diesel fuel

not intended for highway use. Damage to the fuel injection

system, engine and exhaust catalyst can occur if an improper fuel

is used. Do not add gasoline, gasohol or alcohol to diesel fuel.

This practice creates a serious fire hazard and engine

performance problems.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

35

Page 36 of 103

FUEL REQUIREMENTS - CHOOSING THE RIGHT FUEL: VEHICLES

OPERATED WHERE ULTRA LOW SULFUR DIESEL FUEL IS NOT

REQUIRED

For a 6.4L engine to operate reliably on low sulfur or high sulfur diesel

fuel, the 6.4L engine must be a high sulfur configured engine or a ULSD

fuel-configured engine that has been retrofitted for high sulfur diesel fuel

use.

Use only a 6.4L diesel engine that has been configured for use

with high sulfur diesel fuel in markets with diesel fuel that has

sulfur content greater than 15 ppm. Using low sulfur diesel fuel

(16–500 ppm) or high sulfur diesel fuel (greater than 500 ppm) in

a 6.4L diesel engine designed to use only Ultra Low Sulfur Diesel

fuel increases the likelihood of engine oil dilution with fuel which

may lead to major engine damage. Engine damage from using the

improper type of fuel is not covered under your warranty.

Vehicles with 6.4L engines configured for use with high sulfur diesel fuel

will only be made available for sale in countries where ULSD fuel is not

available or mandated by the government. Vehicles originally sold in a

ULSD fuel market that are subsequently exported to non-ULSD fuel

markets will need to be retrofitted (at the customer’s expense) in order

to be reliably operated on non-ULSD fuel.

Vehicles equipped with a 6.0L engine that are operated in a market that

does not require ULSD fuel may be operated on higher sulfur fuel

without any engine fuel system or emissions-related concerns.

Number 1-D or winter blend number 2-D fuel is recommended at

temperatures below 20°F (-7°C) (seeCold weather operationin the

Drivingchapter of this supplement).

BIODIESEL

Diesel fuel containing no more than 5% biodiesel may be used. To help

achieve acceptable engine performance and durability, it is important to

only use biodiesel of good quality in your diesel engine. At a minimum,

the biodiesel should comply with ASTM D6751 or an equivalent

specification.

Use of biodiesel in concentrations greater than 5% may cause damage to

your vehicles fuel system components such as fuel tank, fuel lines, fuel

pump, fuel sender and fuel injectors. Concentrations greater than 5% can

also cause fuel filter restrictions that may result in a lack of power and

or fuel pump and fuel injector failure.

Look for a label on the fuel pump to confirm the amount of biodiesel

contained in a diesel fuel. Biodiesel content is often indicated with the

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

36

Page 37 of 103

letter “B” followed by the percent of biodiesel in the fuel. For example,

B5 indicates a fuel containing 5% biodiesel. Ask the service station

attendant to confirm the biodiesel content of a diesel fuel if you do not

see a label on the fuel pump.

Biodiesel should not be stored in the fuel tank for more than three

months. If your vehicle will be parked or stored for more than three

months, then your vehicle should be drained and filled with a diesel fuel

not containing biodiesel.

During cold weather, if you have problems operating on biodiesel, you

may need to use a diesel fuel with lower biodiesel content, try another

brand, or discontinue the use of biodiesel.

Biodiesel use may affect the recommended oil change intervals. Refer to

theSpecial Operating Conditionssection in theschedule

maintenance guidefor more information about oil change intervals and

other maintenance when operating on biodiesel.

Biodiesel fuel is a product that has been converted from renewable fuel

sources, including vegetable oil, animal fat and cooking oil. Raw or

refined vegetable oil, animal fat, cooking oil or recycled greases should

not be used.

Do not use home heating oil, agricultural fuel or any diesel fuel

not intended for highway use. Damage to the fuel injection

system, engine and exhaust catalyst can occur if an improper fuel

is used. Do not add gasoline, gasohol or alcohol to diesel fuel.

This practice creates a serious fire hazard and engine

performance problems.

Fuel quality

It should not be necessary to add any aftermarket additives to your fuel

tank if you use a properly formulated diesel fuel that meets the ASTM D

975 industry specification. Aftermarket additives can damage the injector

system or engine. Repairs to correct the effects of using an aftermarket

product in your fuel may not be covered by your warranty.

Do not blend used engine oil with diesel fuel under any

circumstances.Blending used oil with the fuel will significantly increase

your vehicle’s exhaust emissions and reduce engine life due to increased

internal wear.

Many of the world’s automakers approved the World-wide Fuel Charter

that recommends diesel fuel specifications to provide improved

performance and emission control system protection for your vehicle.

Diesel fuel that meets the World-wide Fuel Charter should be used when

available. Ask your fuel supplier about fuel that meets the World-wide

Fuel Charter.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

37

Page 38 of 103

Diesel fuel conditioner

Additives that will improve fuel cetane numbers may be used to

verify/enhance fuel quality. Use Motorcraft Cetane Booster &

Performance Improver, PM-22-A (U.S.) / PM-22-B (Canada) or

equivalent. The customer warranty may be void from using additives that

do not meet or exceed Ford specifications.

Do not use alcohol based additives to correct fuel gelling. This may

result in damage to the fuel injectors/system. Use Motorcraft Anti-Gel &

Performance Improver, PM-23-A (U.S.) / PM-23-B (Canada) or

equivalent. The customer warranty may be void from using additives that

do not meet or exceed Ford specifications.

Note:This ultra-low sulfur formulation is designed to meet the emissions

standards for the 6.4L engine and is backward compatible as well (i.e.,

can be used in Ford 6.9L, 7.3L, and 6.0L diesel engines).

Fueling tips

If the engine fails to start in 30 seconds, turn the key to the off position

and wait 30 seconds before trying again.

Truck stops have pumps and nozzles designed for larger, heavy-duty

trucks. When refueling at truck stops: if the nozzle shuts off repeatedly

when refueling, wait 5–10 seconds; then use a slower rate of flow (don’t

depress the nozzle trigger as far).

If air is allowed to enter the fuel system (during fuel filter change or if

you run out of fuel) the engine will purge the trapped air as it runs. The

engine may run rough and produce white smoke while air is in the

system. This is normal and should correct itself in a short time.

An engine that suddenly becomes noisy or operates poorly after a fuel fill

could be using substandard fuel (i.e., high water content, low cetane

rating or gasoline in the fuel). Diesel fuel should be purchased from a

reputable station which sells a large amount of diesel fuel.

Care should be taken whenever diesel fuel is stored. Use only clean,

approved containers which will prevent the entry of dirt or water.

Diesel fuel must not be stored in a galvanized container. The fuel will

dissolve the zinc in a galvanized container. The zinc will then remain in

the solution until it is run through the engine where it will be deposited

in the fuel injectors causing expensive-to-repair damage.

Diesel fuel dispensing nozzle fill rate

This truck is equipped with a fuel fill pipe which is able to accept fuel up

to 20 gallons per minute from an 1

1�8” fuel dispensing nozzle. Pumping

fuel at greater flow rates may result in premature nozzle shut-off or

spitback.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

38

Page 39 of 103

Fuel filler cap

Your fuel tank filler cap has an indexed design with a 1/4 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise until it spins off.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it clicks at least once.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The vehicle warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

WARNING:The fuel system may be under pressure. If the fuel

filler cap is venting vapor or if you hear a hissing sound, wait

until it stops before completely removing the fuel filler cap. Otherwise,

fuel may spray out and injure you or others.

WARNING:If you do not use the proper fuel filler cap,

excessive pressure or vacuum in the fuel tank may damage the

fuel system or cause the fuel cap to disengage in a collision, which may

result in possible personal injury.

FUEL FILTER/WATER SEPARATOR

Fuel Conditioner Module (FCM - E-Series)

The vehicle is equipped with a Fuel Conditioning Module (FCM) located

on the driver-side of the vehicle next to the transmission case.

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 cc) of water accumulates in the module.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

39

Page 40 of 103

Horizontal Fuel Conditioner Module (HFCM - F-Super Duty)

The vehicle is equipped with a Horizontal Fuel Conditioning Module

(HFCM) located on the frame-rail under the driver-side floorboard near

the transmission

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 cc) of

water accumulates in the module.

DRAINING THE HFCM AND CHANGING THE ENGINE AND

VEHICLE FUEL FILTERS

Your vehicle is equipped with two fuel filters; one is mounted on top of

the engine.On F-Super Duty,the second filter, inside the HFCM, is

mounted inside the frame rail under the driver-side floorboard near the

transmission.On E-Series,the second filter, inside the FCM, is mounted

on the driver-side of the vehicle next to the transmission case.On all

vehicles,both filters should be replaced at the same time. Regular fuel

filter changes are an important part of engine maintenance; failing to

keep with the scheduled maintenance could lead to engine performance

issues and/or fuel injection system damage. Refer to theScheduled

Maintenance Guidechapter of this supplement for more information.

Refer toMotorcraft Part Numberslater in this chapter for the fuel filter

replacement part number. This part number includes filters and seals for

both the engine-mounted and frame-mounted filters.

1. Stop the vehicle andshut offthe engine.

WARNING:The vehicle must be stopped with the engine off

when draining the HFCM/FCM. Fuel may ignite if the separator

is drained while the engine is running or vehicle is moving.

2. Locate the HFCM and place an appropriate container under the drain

port (see illustration).

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

40