battery FORD SUPER DUTY 2009 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 103, PDF Size: 0.75 MB

Page 23 of 103

JUMP STARTING YOUR VEHICLE (E-SERIES ONLY)

The following procedure is for E-Series vehicles only. F-Super

Duty vehicles equipped with the 6.4L diesel engine can be jump

started using the same procedure as a gasoline engine; refer to

yourOwner’s Guidefor the jump starting procedure.

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; damage to the

automatic transmission may result.

Preparing your vehicle

When the batteries are disconnected or new batteries are installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the batteries of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the passenger side of the disabled

vehicle making sure the two vehiclesdo nottouch. Set the parking

brake on both vehicles.

Note:This vehicle has two frame-mounted batteries located on the

passenger side frame rail, behind the front passenger door. A battery

positive (+) jumper stud is located on the frame rail behind the rear

most battery box.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

23

Page 24 of 103

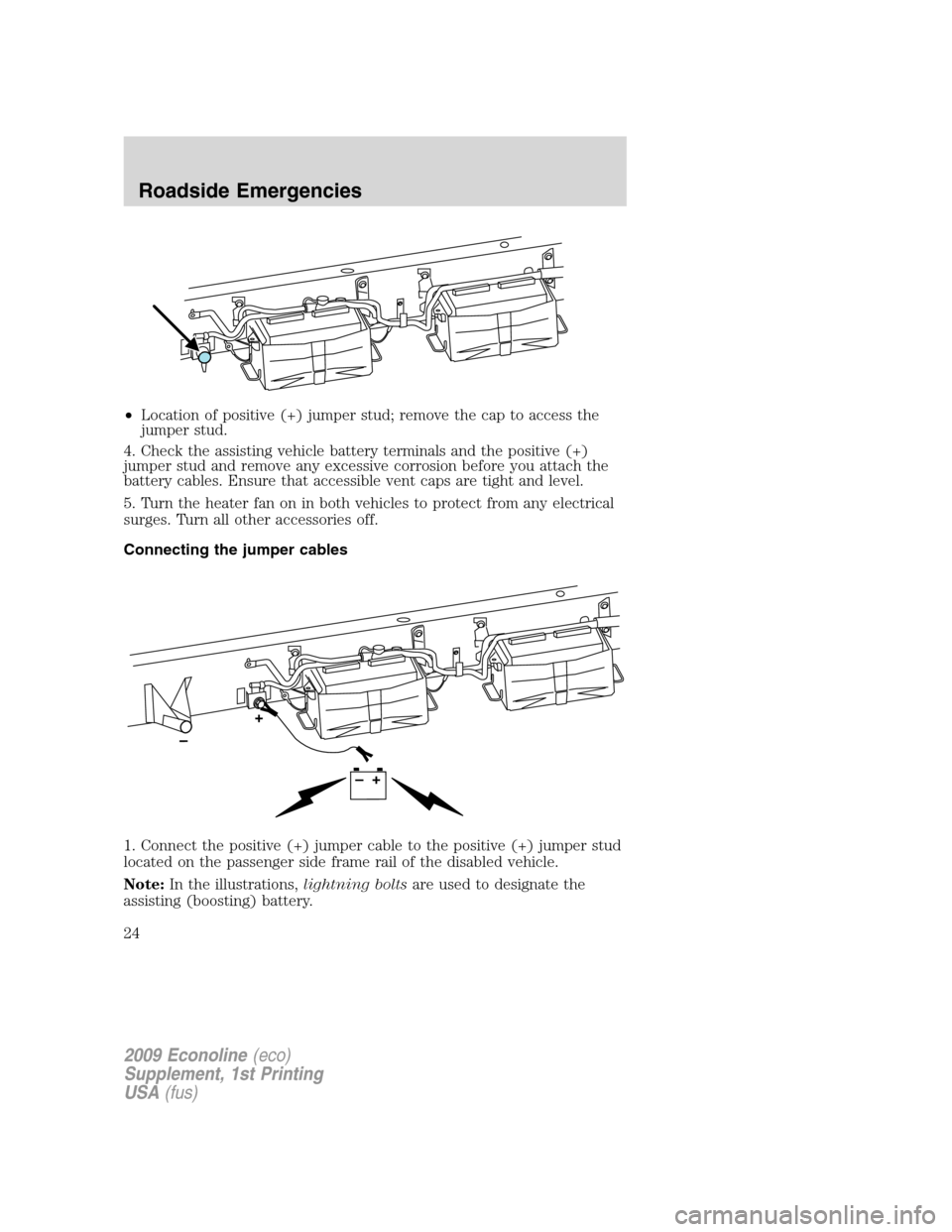

•Location of positive (+) jumper stud; remove the cap to access the

jumper stud.

4. Check the assisting vehicle battery terminals and the positive (+)

jumper stud and remove any excessive corrosion before you attach the

battery cables. Ensure that accessible vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

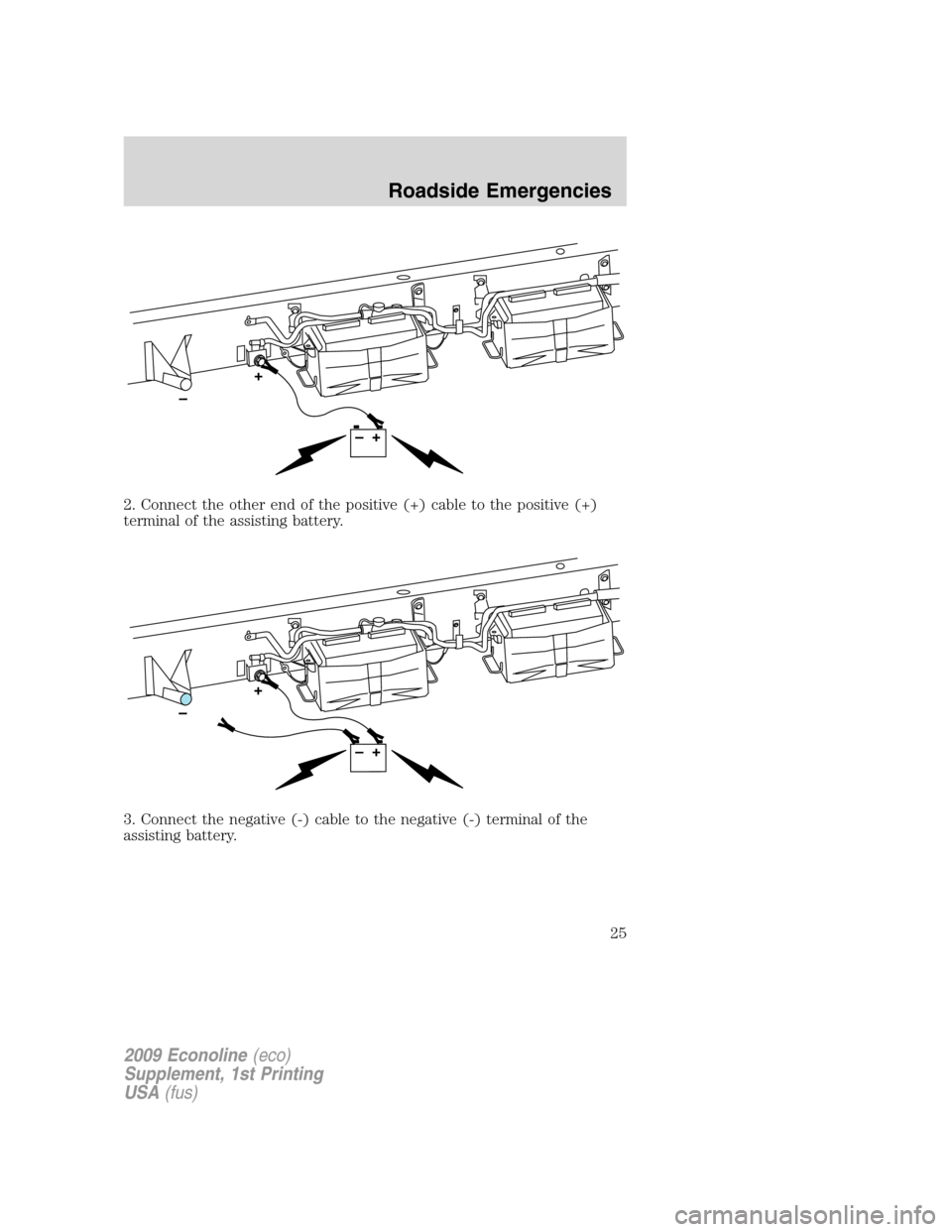

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) jumper stud

located on the passenger side frame rail of the disabled vehicle.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

24

Page 25 of 103

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

25

Page 26 of 103

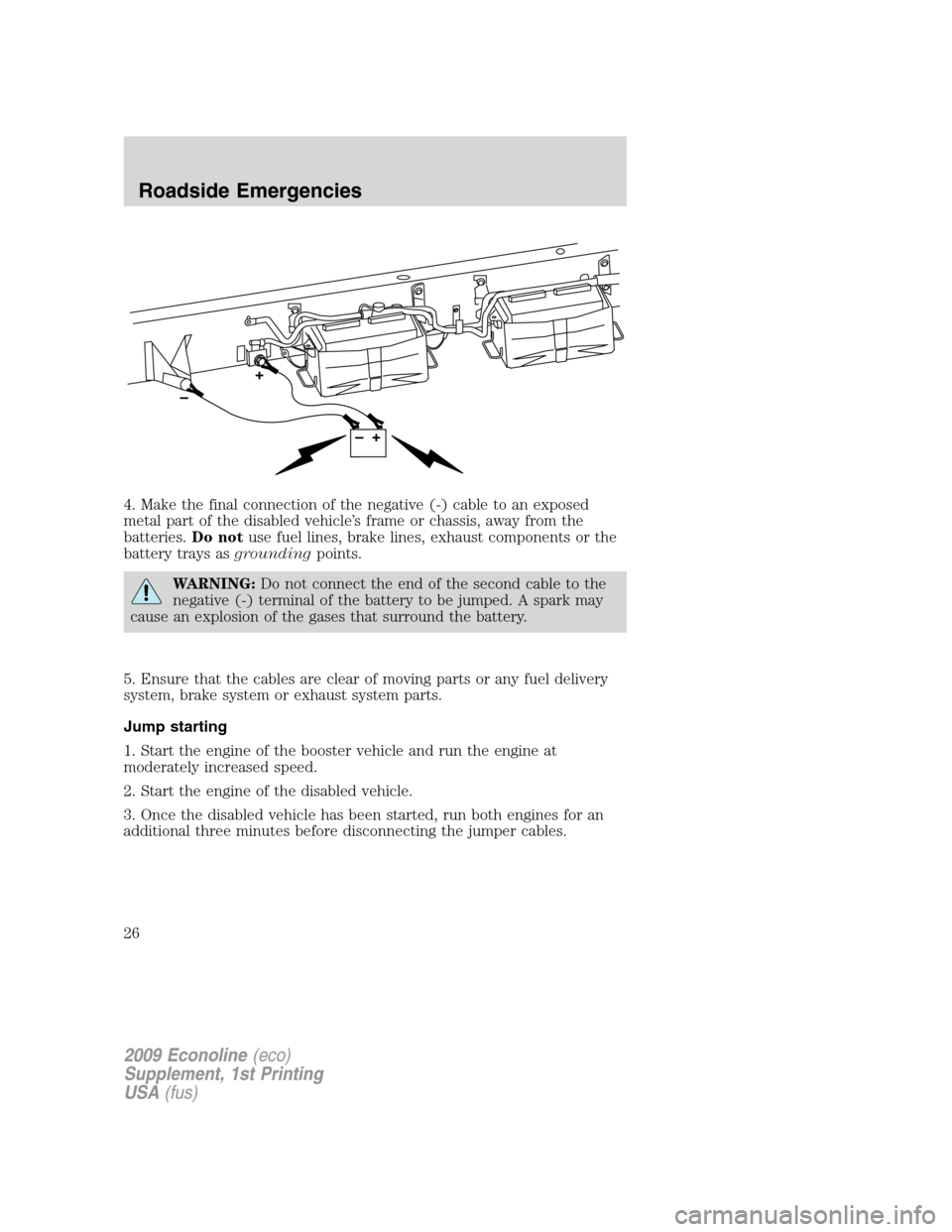

4. Make the final connection of the negative (-) cable to an exposed

metal part of the disabled vehicle’s frame or chassis, away from the

batteries.Do notuse fuel lines, brake lines, exhaust components or the

battery trays asgroundingpoints.

WARNING:Do not connect the end of the second cable to the

negative (-) terminal of the battery to be jumped. A spark may

cause an explosion of the gases that surround the battery.

5. Ensure that the cables are clear of moving parts or any fuel delivery

system, brake system or exhaust system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

26

Page 27 of 103

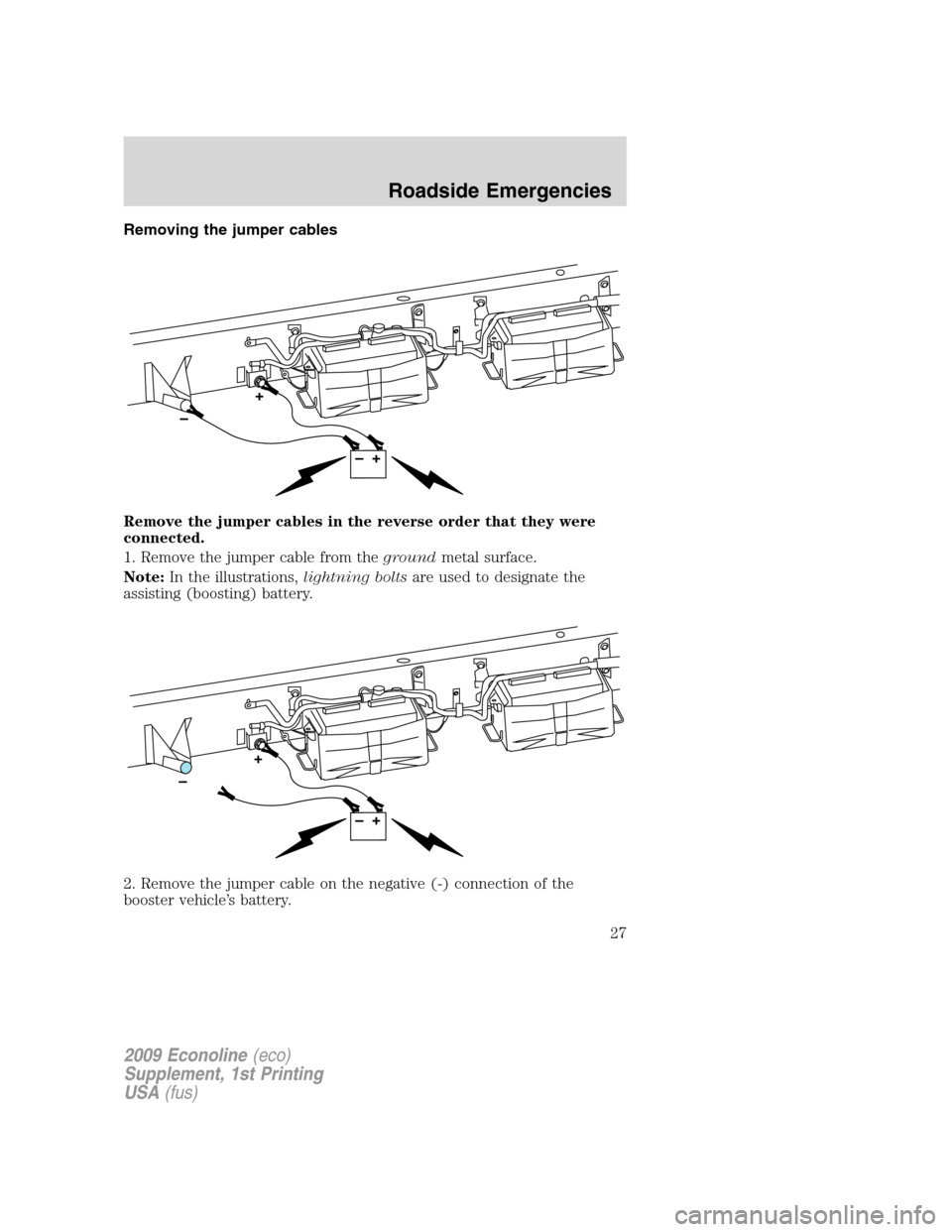

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

27

Page 28 of 103

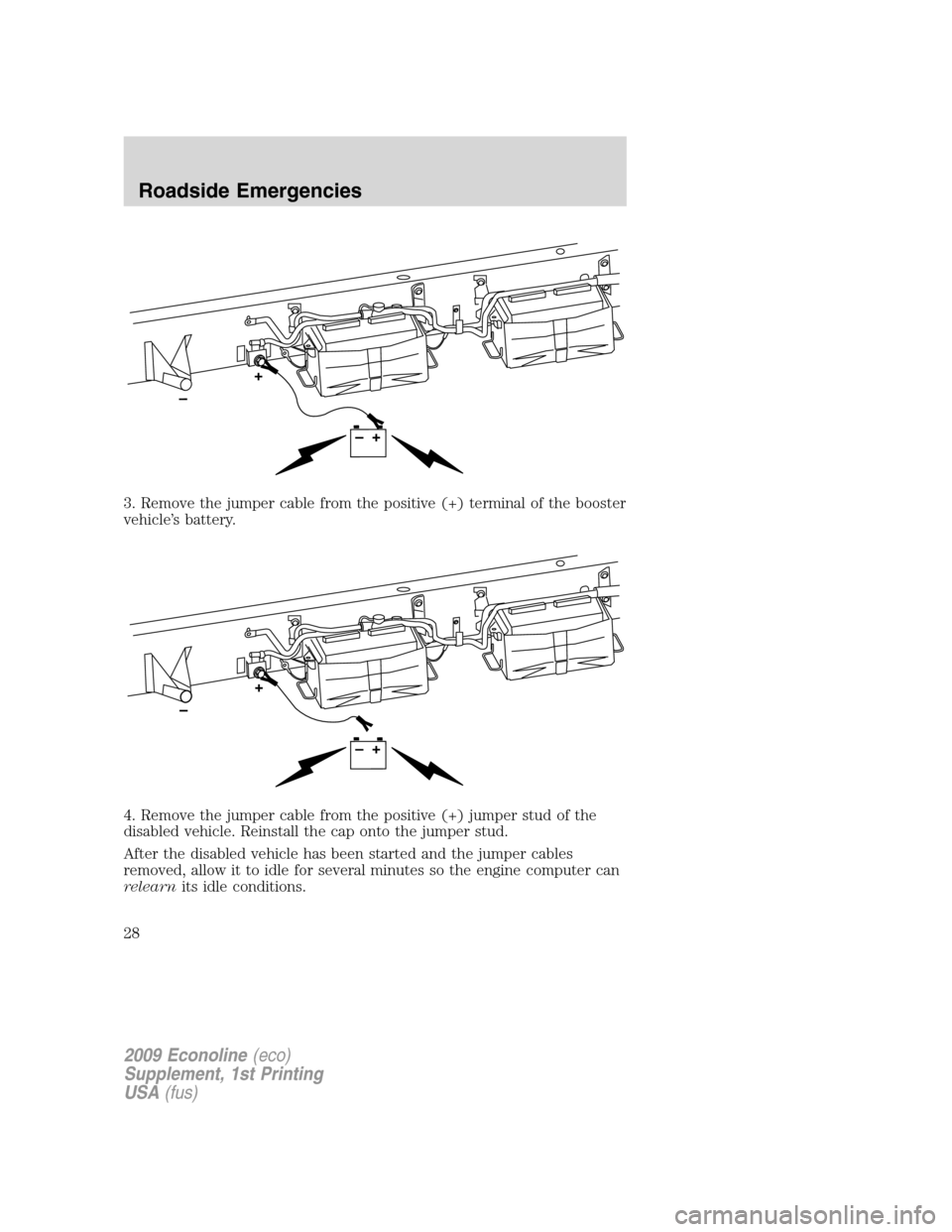

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) jumper stud of the

disabled vehicle. Reinstall the cap onto the jumper stud.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

28

Page 55 of 103

•contaminated fuel.

•air in the fuel system, due to loose connections.

•an open or pinched sensor hose.

•low engine oil level.

•wrong fuel or oil viscosity for climactic conditions.

If these checks do not help you correct the engine performance problem

you are experiencing, consult an authorized dealer.

FUELING

WARNING:Do not use starting fluid such as ether or gasoline

in the diesel air intake system. Such fluids can cause immediate

explosive damage to the engine and possible personal injury.

If you fuel your vehicle at a truck stop, you may notice that the fuel

nozzle may shut off every 5–10 seconds. This is due to the flow rates

being designed for larger heavy duty trucks. You may have to fuel at a

slower rate (don’t depress the nozzle trigger fully).

Do not run your diesel vehicle out of fuel as this will allow air to enter

the fuel system which will make restarting difficult. The engine is

designed to run roughly as the fuel tank nears Empty. This is a warning

to the driver to add fuel as soon as possible. Longer engine cranking

time may be required once air is in the fuel system. If air enters the fuel

system (either through running the fuel tank(s) empty or during a fuel

filter change), the engine will self-purge the trapped air once it starts

running. The engine may run roughly and produce white smoke while air

is in the fuel system; this is normal and should stop after a short time.

MINOR TROUBLESHOOTING GUIDE

Air purge procedure

Turn the key on for 30 seconds, then turn off. Repeat procedure four or

five times.

If the engine won’t crank

Turn on the headlights. If the lights are dim, do not go on at all or when

the ignition is turned to START the lights become dim or go out, the

battery connections may be loose or corroded, or the battery may be

discharged. If there is a clicking or stuttering sound coming from the

engine compartment when you turn the key to START, this may also

indicate a loose or corroded battery connection.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

55

Page 56 of 103

Check the battery connections at the battery posts, cable connection to

the engine grounding point and at the starter connection.

If a discharged battery is suspected, have it checked and corrected.

WARNING:Battery posts, terminals and related accessories

contain lead and lead compounds.Wash hands after handling.

•For vehicles with manual transmissions,the clutch pedalmustbe

fully depressed in order for the starter to operate.

•For vehicles with automatic transmissions,the gearshift lever

must be in P (Park) or N (Neutral) in order for the starter to operate.

•Try operating the starter switch several times. Should the switch be

corroded, this operation may clean the contacts or make the switch

temporarily operable until you can reach the dealer.

•If all electrical connections are tight and you need assistance to start,

refer toJump startingin theRoadside Emergencieschapter of your

Owner’s Guide(F-Super Duty) or refer to theJump startingsection

in theRoadside Emergencieschapter of this supplement (E-Series).

If engine cranks but won’t start

Prolonged starter cranking (in excess of 30 seconds) could cause

damage to the starter motor.

•Check the fuel gauge. You may be out of fuel. If the gauge shows that

there is fuel in the tank, the trouble may be in the electrical system or

the fuel system. If equipped with an auxiliary tank, be sure that the

tank control switch is set for the tank with fuel and not on an empty

tank.

•Leaving the ignition key turned to ON for over two minutes without

starting may make starting difficult because the glow plugs will cease

activation. Reset the system by turning the ignition key to OFF and

then back to ON again.

If the engine runs hot

The following could cause the engine to overheat:

•Lack of coolant.

•Dirty cooling system.

•Plugged radiator fins, charge air cooler, A/C condenser and/or oil

cooler.

•Driving with frozen coolant.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

56

Page 57 of 103

•Sticking thermostat.

•Overloading or pulling heavy trailers during hot weather.

•Grill or radiator air blockage.

•Slipping or missing drive belt.

•Plugged or very dirty air filter.

If fuses burn out

Burned-out or blown fuses usually indicate an electrical short-circuit,

although a fuse may occasionally burn out from vibration. Insert a second

fuse. If this fuse immediately burns out and you cannot locate the cause,

return your vehicle to your dealer for a circuit check.

WARNING:Replacement fuses and circuit breakers must always

be the same rating as the original equipment shown. Never

replace a fuse or circuit breaker with one of a higher rating. Higher

rated fuses or circuit breakers could allow circuit overloading in the

event of a circuit malfunction, resulting in severe vehicle damage or

personal injury due to fire.

Refer to theOwner’s Guidefor replacement of fuses.

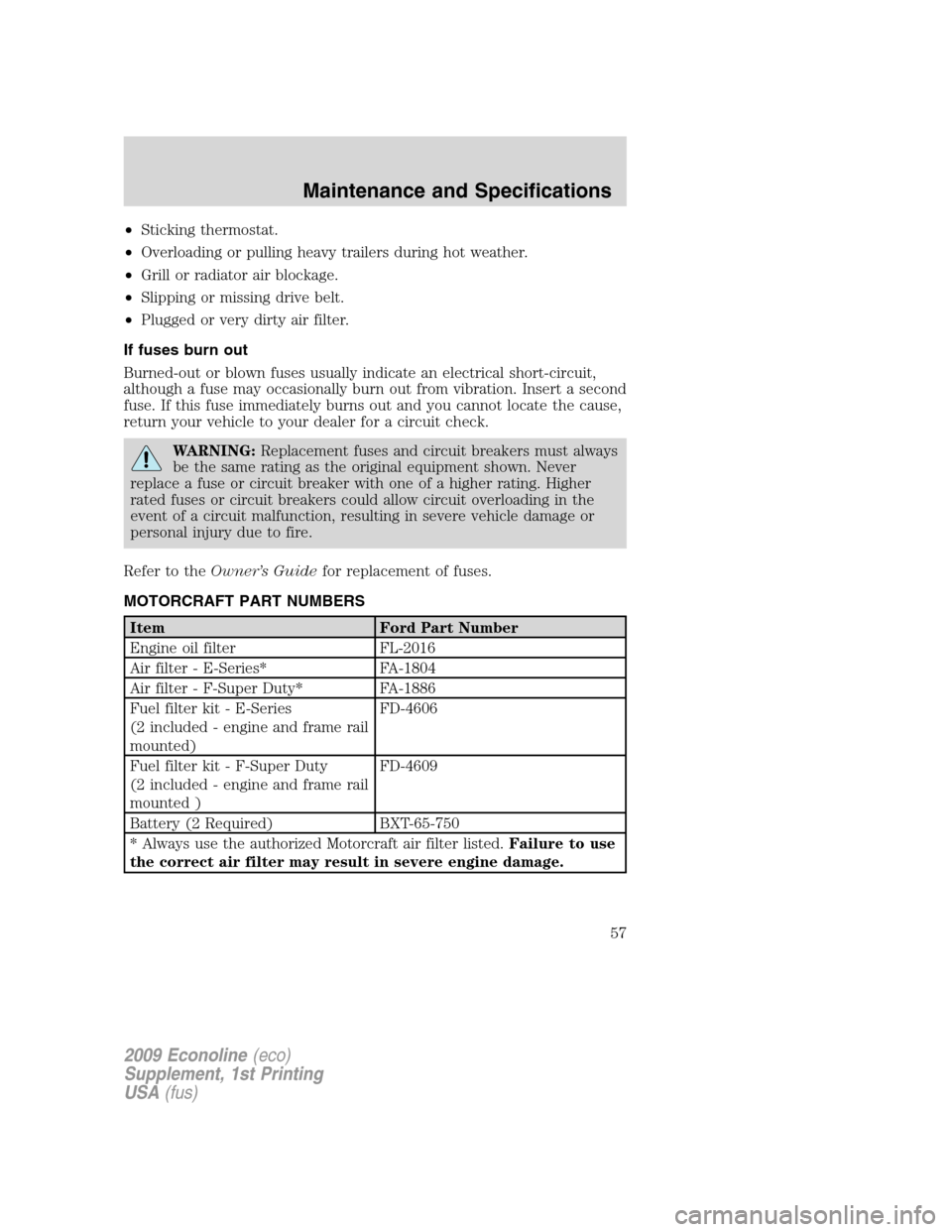

MOTORCRAFT PART NUMBERS

Item Ford Part Number

Engine oil filter FL-2016

Air filter - E-Series* FA-1804

Air filter - F-Super Duty* FA-1886

Fuel filter kit - E-Series

(2 included - engine and frame rail

mounted)FD-4606

Fuel filter kit - F-Super Duty

(2 included - engine and frame rail

mounted )FD-4609

Battery (2 Required) BXT-65-750

* Always use the authorized Motorcraft air filter listed.Failure to use

the correct air filter may result in severe engine damage.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

57

Page 62 of 103

A proper repair begins with a thorough system check. A Factory

Authorized Systems Check can ONLY be found at a Ford dealership. In

some circumstances, the technician may need to request your

authorization to perform additional operations to determine the final

diagnosis. The technician’s goal is to ensure that your vehicle is fixed

right the first time, at the best value to you.

The following list represents several of the Factory Authorized Systems

Checks available at participating Ford dealers:

•Air Conditioning

•Service Engine Soon Light

•All Wheel Drive and4X4

•Automatic Transmission

•Engine Cooling and Cabin Heating

•Steering and Suspension

•Charge/Start/Battery

•Wheel Alignment

•Anti-Lock Brake System

Genuine Ford and Motorcraft Replacement Parts

Ford dealerships stock Ford and Motorcraft branded replacement parts.

These parts meet or exceed Ford Motor Company’s specifications, and

we stand behind them. Maintenance parts installed at your Ford

dealership carry a nationwide, 12 months, 12,000 mile (20,000 km) parts

and labor limited warranty. Your dealer can give you details.

Value Shopping for Your Vehicle’s Maintenance Needs

Your dealership recognizes the competitive landscape of maintenance and

light repair automotive services. With factory-trained technicians, and

one-stop service from routine maintenance like oil changes and tire

rotations to repairs like brake service, check out the value your Ford

dealers can offer.

WHICH MAINTENANCE SCHEDULE SHOULD YOU FOLLOW?

Owner Checks and Services

Refer to Mileage Intervals for Additional Checks and Services

Certain basic maintenance checks and inspections should be performed

by the owner or a service technician at the intervals indicated. Service

information and supporting specifications are provided in theOwner’s

Guide.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Scheduled Maintenance: General Information

62