check engine FORD SUPER DUTY 2009 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 103, PDF Size: 0.75 MB

Page 3 of 103

Important notice

Ford vehicles are suitable for producing ambulances only if equipped

with the Ford ambulance preparation package. In addition, Ford urges

ambulance manufacturers to follow the recommendation of theFord

Incomplete Vehicle Manual, Ford Truck Body Builder’s Layout Book

(and pertinent supplements) and theQualified Vehicle Modifiers

Guidelines.Using a Ford vehicle without the Ford ambulance

preparation package to produce an ambulance voids the Ford warranty

and could result in elevated underbody temperatures, fuel

overpressurization and the risk of fuel expulsion and fires. To determine

whether the vehicle is equipped with the Ford ambulance preparation

package, inspect the information plate on the driver’s side door pillar.

Contact the manufacturer of your vehicle to determine whether the

ambulance manufacturer’s followed Ford’s recommendations.

WARNINGS

Throughout this guide, you will find warnings identified by the

symbol

. Warnings remind you to be especially careful to reduce the

risk of personal injury.

NEW VEHICLE BREAK-IN

Your vehicle does not need an extensive break-in. Try not to drive

continuously at the same speed for the first 1,000 miles (1,600 km) of

new vehicle operation. Vary your speed to allow parts to adjust

themselves to other parts.

Drive your new vehicle at least 500 miles (800 km) before towing a

trailer. Make sure you use the specified engine oil by checking the engine

oil specification chart underEngine oilin theMaintenance and

Specificationschapter.

Do not add friction modifier compounds or special break-in oils during

the first few thousand miles (kilometers) of operation, since these

additives may prevent piston ring seating. SeeEngine oilin the

Maintenance and Specificationschapter of this supplement for more

information on oil usage.

DIESEL ENGINE INFORMATION

The Diesel engine fuel system consists of:

•On E-Series vehicles (6.0L engine),a Diesel Fuel Conditioner

Module (DFCM) mounted on the driver-side frame rail next to the

transmission

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Introduction

3

Page 9 of 103

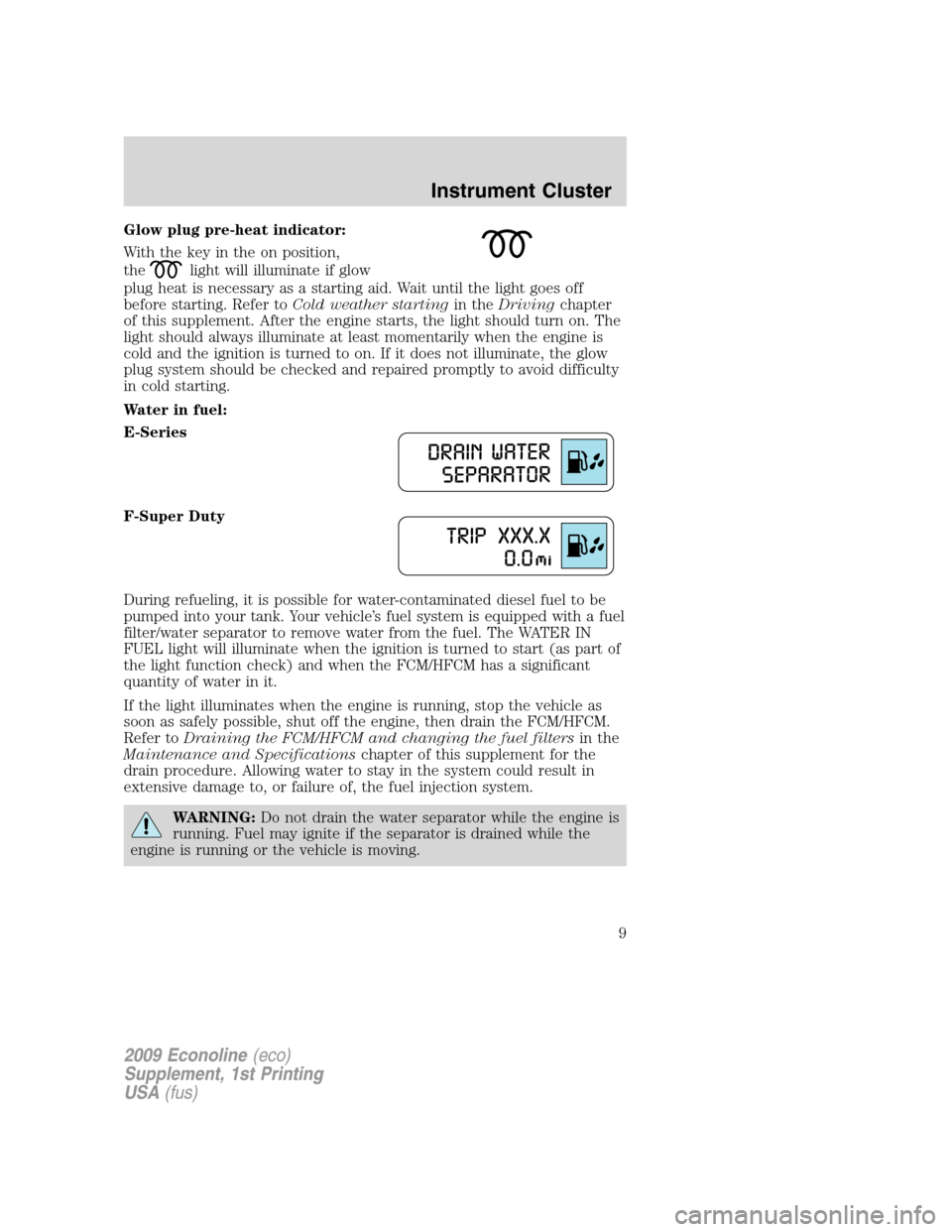

Glow plug pre-heat indicator:

With the key in the on position,

the

light will illuminate if glow

plug heat is necessary as a starting aid. Wait until the light goes off

before starting. Refer toCold weather startingin theDrivingchapter

of this supplement. After the engine starts, the light should turn on. The

light should always illuminate at least momentarily when the engine is

cold and the ignition is turned to on. If it does not illuminate, the glow

plug system should be checked and repaired promptly to avoid difficulty

in cold starting.

Water in fuel:

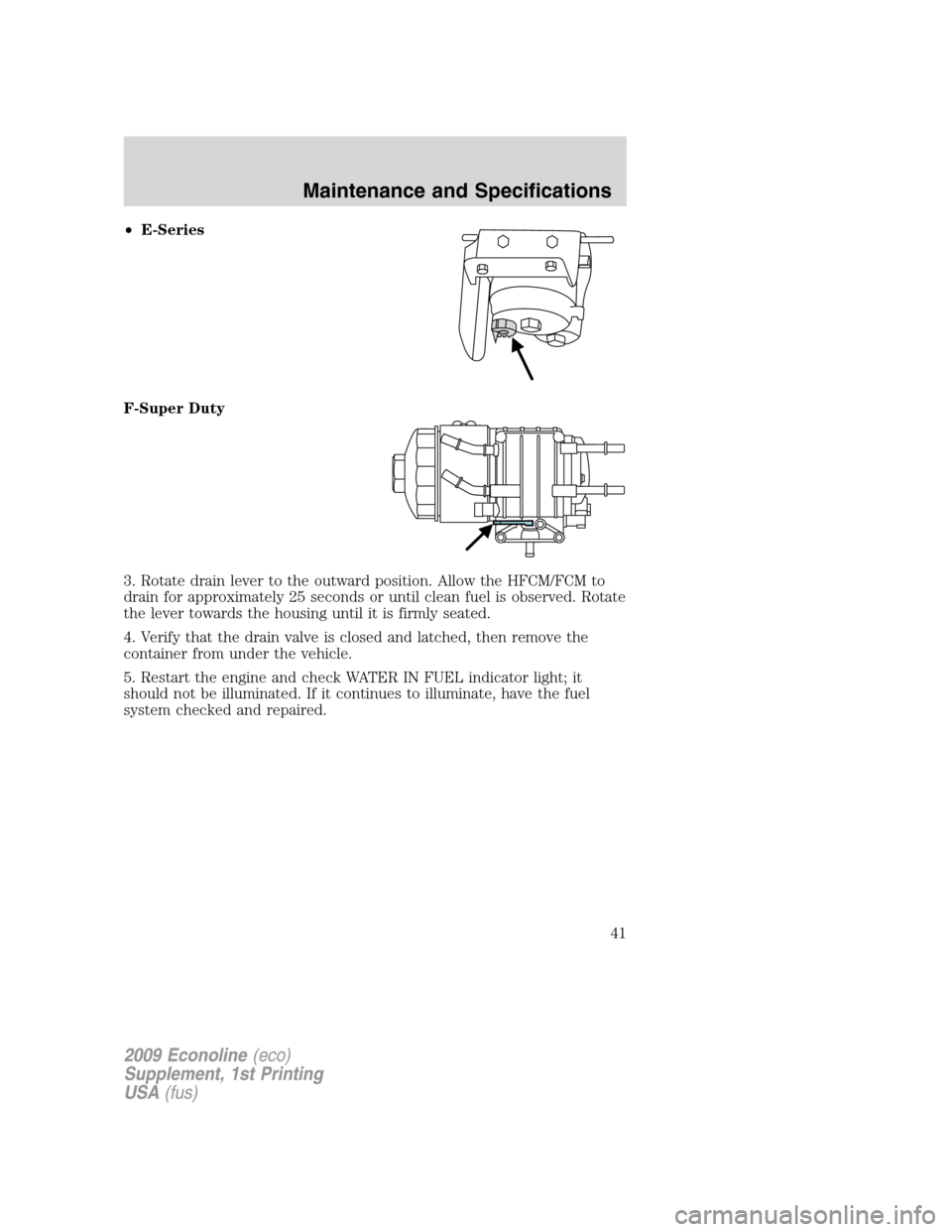

E-Series

F-Super Duty

During refueling, it is possible for water-contaminated diesel fuel to be

pumped into your tank. Your vehicle’s fuel system is equipped with a fuel

filter/water separator to remove water from the fuel. The WATER IN

FUEL light will illuminate when the ignition is turned to start (as part of

the light function check) and when the FCM/HFCM has a significant

quantity of water in it.

If the light illuminates when the engine is running, stop the vehicle as

soon as safely possible, shut off the engine, then drain the FCM/HFCM.

Refer toDraining the FCM/HFCM and changing the fuel filtersin the

Maintenance and Specificationschapter of this supplement for the

drain procedure. Allowing water to stay in the system could result in

extensive damage to, or failure of, the fuel injection system.

WARNING:Do not drain the water separator while the engine is

running. Fuel may ignite if the separator is drained while the

engine is running or the vehicle is moving.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Instrument Cluster

9

Page 14 of 103

Your vehicle is also equipped with a bypass relief valve, located in the

fuel tank pick-up boot, which provides fuel flow to the engine if the fuel

pickup should become plugged by ice or wax. To allow the bypass valve

to function and avoid engine fuel starvation, it is recommended that,

during cold weather operation 32°F (0°C) or below, the fuel level in your

tank should not be allowed to drop below

1�4full. This will help prevent

air from entering the fuel system and stalling the engine.

In cold weather below 32°F (0°C), the engine will slowly increase to a

higher idle speed if left idling in P (Park). As the engine warms-up, the

engine sound level will decrease due to the activation of PCM-controlled

sound reduction features.

If your vehicle is operated in a heavy snow storm or blowing snow

conditions, the engine air induction may become partially clogged with

snow and/or ice. If this occurs, the engine may experience a significant

reduction in power output. At the earliest opportunity, clear all the snow

and/or ice away from inside the air filter assembly. Take the top off the

assembly, leaving the air filter in, and remove any snow or ice.

In order to operate the engine in temperatures of 32°F (0°C) or lower,

read the following instructions:

•Make sure that the batteries are of sufficient size and are fully

charged. Check other electrical components to make sure they are in

optimum condition.

•Use Motorcraft Premium Gold Engine Coolant solution at the

concentration recommended to protect the engine against damage

from freezing.

•Try to keep the fuel tank full as much as possible at the end of

operation to prevent condensation in the fuel system.

•Make sure you use proper cold weather engine oil and that it is at its

proper level. Also, if necessary, make sure to follow the engine oil and

filter change schedule found under theSpecial operating conditions

section in thescheduled maintenance guideinformation.

•At temperatures of -10°F (-23°C) or below, it is recommended that

you use an engine block heater to improve cold engine starting.

•If operating in arctic temperatures of -20°F (-29°C) or lower, consult

your truck dealer for information about special cold weather

equipment and precautions.

Note:Idling in cold weather will not heat the engine to its normal

operating temperature. Long periods of idling in cold weather can cause

a buildup of heavy deposits of carbon and rust on valve stems causing

them to stick, which in turn, can cause valve train damage.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Driving

14

Page 16 of 103

produce “coking” or “wet stacking”, which is common to all diesel

engines when idling for extended periods during cold ambient

temperatures.

•Your vehicle may have a factory option for a Stationary Elevated Idle

Control (SEIC) through dash-mounted Upfitter switches will allow the

operator to elevate the idle rpm for extended idle periods, as well as

aftermarket equipment such as PTO operation. This feature must be

configured even if ordered from the factory. See your authorized

dealer for required upfitting.

Operation in snow

Vehicle operation in heavy snowfall or extreme rain conditions may feed

excessive amounts of snow/water into the air intake system. This could

plug/soak the air filter with snow and may cause the engine to lose

power and possibly shut down.

Either of these conditions may cause the CHECK AIR FILTER message

to appear in the message center.

You may not need to change the air filter and the vehicle may be driven

up to 200 miles (320 km) under the following conditions:

•Snow:At the earliest opportunity, open the hood and clear all the

snow and ice from the air filter housing inlet (do NOT remove the air

filter) and reset the air filter restriction gauge.

•Wet:The air filter will dry after about 15–30 minutes at highway

speeds. At the earliest opportunity, open the hood and reset the air

filter restriction gauge.

Refer toAir filter and restriction gaugein theMaintenance and

Specificationschapter of this supplement for more information.

Operation in standing water

Ingestion of water into the diesel engine can result in immediate and

severe damage to the engine. If driving through water, slow down to

avoid splashing water into the intake. If the engine stalls, and ingestion

of water into the engine is suspected, do not try to restart the engine.

Consult your dealer for service immediately.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Driving

16

Page 41 of 103

•E-Series

F-Super Duty

3. Rotate drain lever to the outward position. Allow the HFCM/FCM to

drain for approximately 25 seconds or until clean fuel is observed. Rotate

the lever towards the housing until it is firmly seated.

4. Verify that the drain valve is closed and latched, then remove the

container from under the vehicle.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

41

Page 44 of 103

Installation - both

The engine will not run properly if the fuel filter is not installed

in housing.

1. Install the new fuel filter and cap seal into the fuel filter housing.

Refer toMotorcraft Part Numberslater in this chapter for the fuel filter

part number.

2. Tighten cap onto fuel filter housing slowly, allowing fuel to soak into

the fuel filter element. Tighten cap until it contacts the housing.

Turn the ignition key to on for 30 seconds, then turn it to off. Do this a

total of six times in a row to purge any trapped air from the fuel system.

Replace the filter bowl O-ring with new seal (included in filter kit) every

time you service the filter.

After filter service, a no start or rough running engine may indicate that

air is entering the system through the filter bowl seal or drain. Make sure

the drain lever is pointing rearward and stowed against the HFCM case.

Using a fuel which has more than average impurities may require

the fuel filter to be replaced more frequently than the service

interval specifies.

ENGINE OIL

Checking the engine oil level

Because it is normal to add some oil between oil changes, check your

engine oil level each time you stop for fuel. To check the engine oil level

consistently and accurately, the following procedure is recommended:

1. Have engine at normal operating temperature (at least into the

NORMAL range on the engine coolant temperature gauge).

2. Park the vehicle on a level surface, then turn off the engine and open

the hood.

3. Allow at least20 minutesafter engine shutdown to ensure that the

oil contained in the upper parts of the engine has returned to the oil

pan.

4. Protecting yourself from engine heat, pull out the dipstick, wipe it

clean and reinsert fully.

5. Read oil level on both sides of dipstick and use highest level (reading)

for the actual engine oil level.

6. Maintain the oil level between MIN and MAX or the ADD and

OPERATING RANGE on the dipstick by adding oil as required. The

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

44

Page 48 of 103

•use of biodiesel, up to and including 5% Biodiesel (B5)

•use of high sulfur diesel fuel

If you are operating your vehicle under any of these conditions, change

engine oil and filter every 5,000 miles (8,000 km).

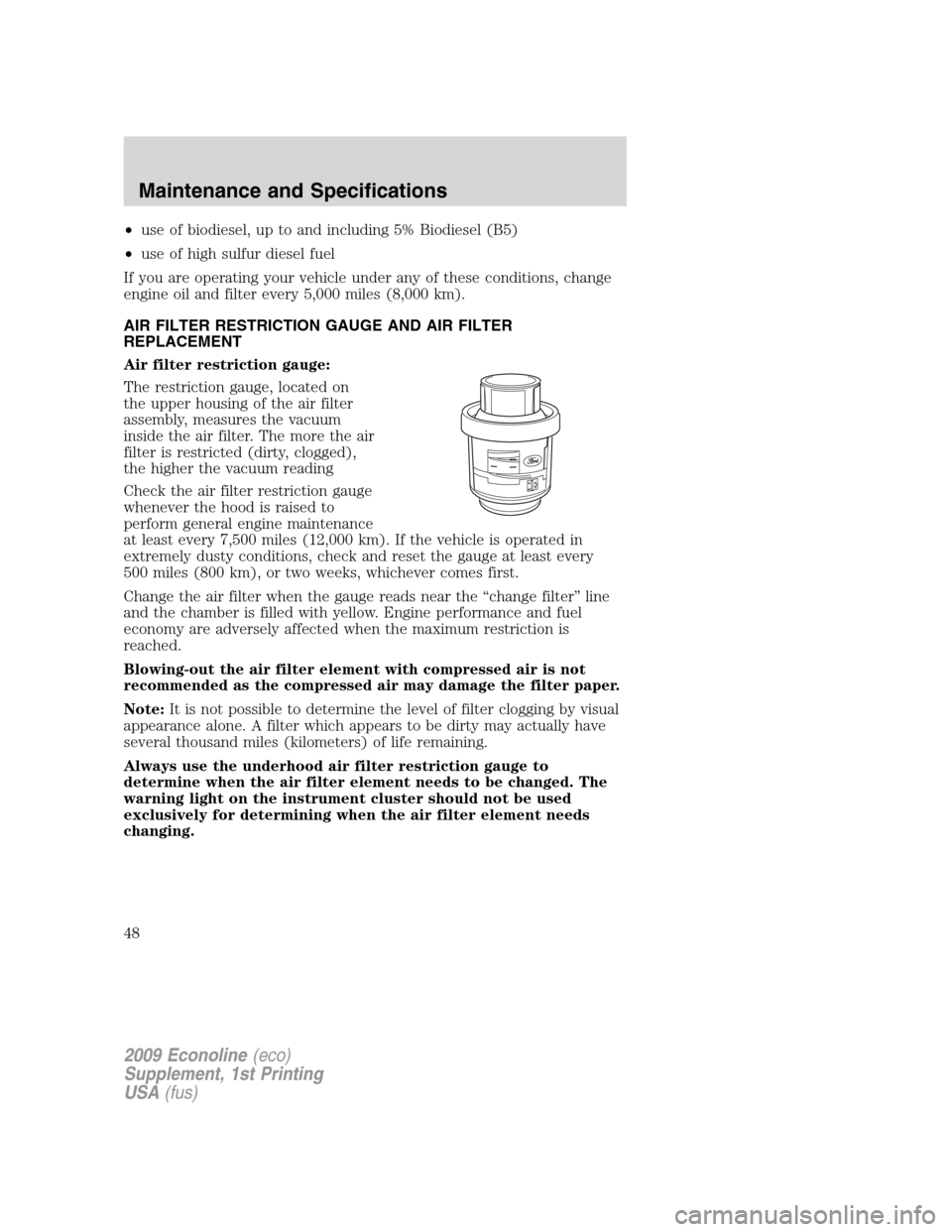

AIR FILTER RESTRICTION GAUGE AND AIR FILTER

REPLACEMENT

Air filter restriction gauge:

The restriction gauge, located on

the upper housing of the air filter

assembly, measures the vacuum

inside the air filter. The more the air

filter is restricted (dirty, clogged),

the higher the vacuum reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km). If the vehicle is operated in

extremely dusty conditions, check and reset the gauge at least every

500 miles (800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads near the “change filter” line

and the chamber is filled with yellow. Engine performance and fuel

economy are adversely affected when the maximum restriction is

reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

48

Page 49 of 103

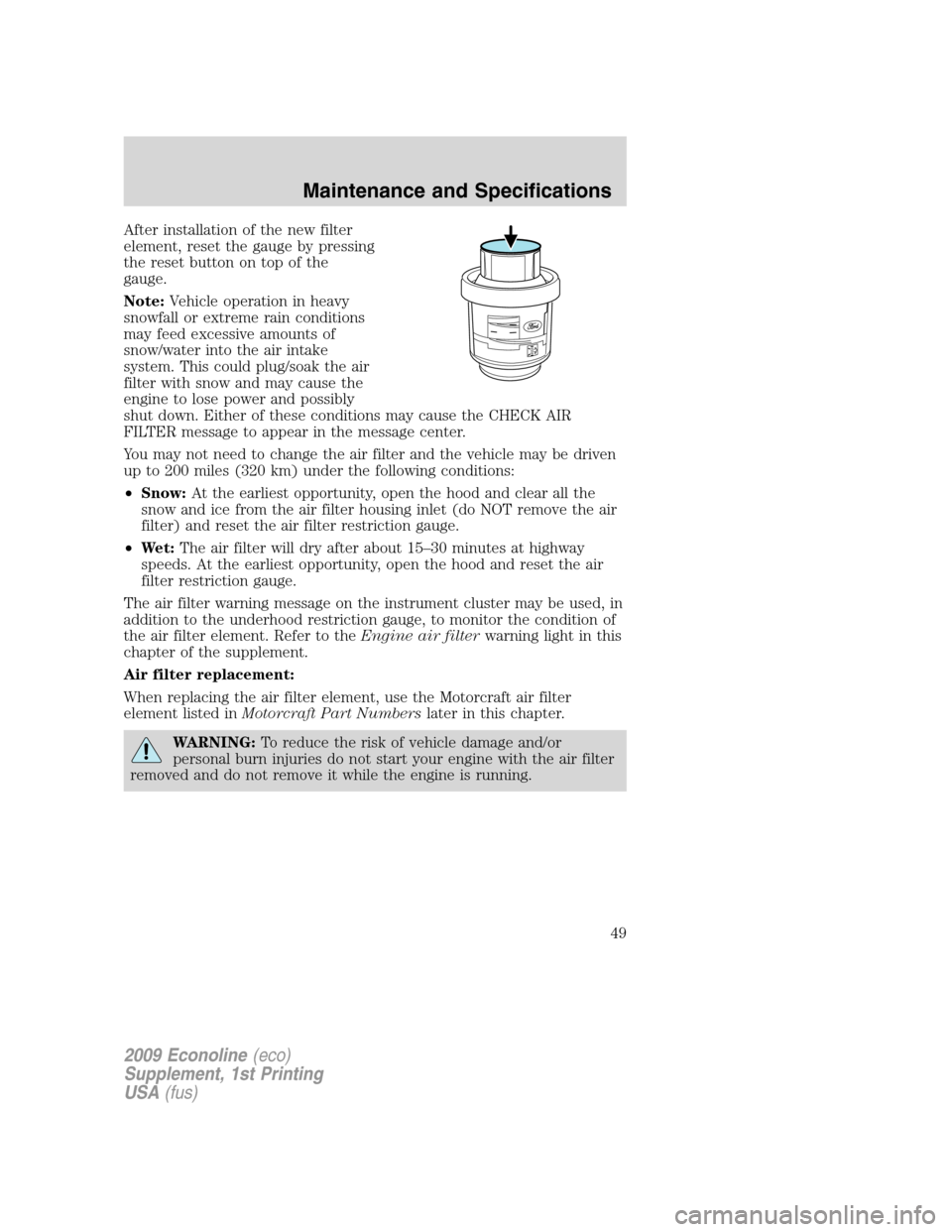

After installation of the new filter

element, reset the gauge by pressing

the reset button on top of the

gauge.

Note:Vehicle operation in heavy

snowfall or extreme rain conditions

may feed excessive amounts of

snow/water into the air intake

system. This could plug/soak the air

filter with snow and may cause the

engine to lose power and possibly

shut down. Either of these conditions may cause the CHECK AIR

FILTER message to appear in the message center.

You may not need to change the air filter and the vehicle may be driven

up to 200 miles (320 km) under the following conditions:

•Snow:At the earliest opportunity, open the hood and clear all the

snow and ice from the air filter housing inlet (do NOT remove the air

filter) and reset the air filter restriction gauge.

•Wet:The air filter will dry after about 15–30 minutes at highway

speeds. At the earliest opportunity, open the hood and reset the air

filter restriction gauge.

The air filter warning message on the instrument cluster may be used, in

addition to the underhood restriction gauge, to monitor the condition of

the air filter element. Refer to theEngine air filterwarning light in this

chapter of the supplement.

Air filter replacement:

When replacing the air filter element, use the Motorcraft air filter

element listed inMotorcraft Part Numberslater in this chapter.

WARNING:To reduce the risk of vehicle damage and/or

personal burn injuries do not start your engine with the air filter

removed and do not remove it while the engine is running.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

49

Page 54 of 103

Do not remove or alter the original equipment floor covering or

insulation between it and the metal floor of the vehicle. The floor

covering and insulation protect occupants of the vehicle from the engine

and exhaust system heat and noise. On vehicles with no original

equipment floor covering insulation, do not carry passengers in a manner

that permits prolonged skin contact with the metal floor. Provide

adequate insulation.

NOISE EMISSIONS WARRANTY, PROHIBITED TAMPERING ACTS

AND MAINTENANCE

On January 1, 1978, Federal regulation became effective governing the

noise emission on trucks over 10,000 lbs. (4,536 kg) GVWR (Gross

Vehicle Weight Rating). The following statements concerning prohibited

tampering acts and maintenance, and the noise warranty found in the

Warranty Guide, are applicable to complete chassis cabs over

10,000 lbs. (4,536 kg) GVWR.

Tampering with noise control system prohibited

Federal law prohibits the following acts or the causing thereof: (1) The

removal or rendering inoperative by any person other than for purposes

of maintenance, repair or replacement of any device or element of design

incorporated into any new vehicle for the purpose of noise control prior

to its sale or delivery to the ultimate purchaser or while it is in use, or

(2) the use of the vehicle after such device or element of design has

been removed or rendered inoperative by any person.

Among those acts which the U.S. Environmental Protection Agency may

presume to constitute tampering are the acts listed below:

•Removal of hood blanket, fender apron absorbers, fender apron

barriers, underbody noise shields or acoustically absorptive material.

•Tampering or rendering inoperative the engine speed governor, so as

to allow engine speed to exceed manufacturer’s specifications.

The complexity of the diesel engine makes it so the owner is discouraged

from attempting to perform maintenance other than the services

described in this supplement.

If you experience difficult starting, rough idling, excessive exhaust

smoke, a decrease in engine performance or excess fuel consumption,

perform the following checks:

•a plugged air inlet system or engine air filter element.

•water in the fuel filter/water separator.

•a clogged fuel filter.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

54

Page 55 of 103

•contaminated fuel.

•air in the fuel system, due to loose connections.

•an open or pinched sensor hose.

•low engine oil level.

•wrong fuel or oil viscosity for climactic conditions.

If these checks do not help you correct the engine performance problem

you are experiencing, consult an authorized dealer.

FUELING

WARNING:Do not use starting fluid such as ether or gasoline

in the diesel air intake system. Such fluids can cause immediate

explosive damage to the engine and possible personal injury.

If you fuel your vehicle at a truck stop, you may notice that the fuel

nozzle may shut off every 5–10 seconds. This is due to the flow rates

being designed for larger heavy duty trucks. You may have to fuel at a

slower rate (don’t depress the nozzle trigger fully).

Do not run your diesel vehicle out of fuel as this will allow air to enter

the fuel system which will make restarting difficult. The engine is

designed to run roughly as the fuel tank nears Empty. This is a warning

to the driver to add fuel as soon as possible. Longer engine cranking

time may be required once air is in the fuel system. If air enters the fuel

system (either through running the fuel tank(s) empty or during a fuel

filter change), the engine will self-purge the trapped air once it starts

running. The engine may run roughly and produce white smoke while air

is in the fuel system; this is normal and should stop after a short time.

MINOR TROUBLESHOOTING GUIDE

Air purge procedure

Turn the key on for 30 seconds, then turn off. Repeat procedure four or

five times.

If the engine won’t crank

Turn on the headlights. If the lights are dim, do not go on at all or when

the ignition is turned to START the lights become dim or go out, the

battery connections may be loose or corroded, or the battery may be

discharged. If there is a clicking or stuttering sound coming from the

engine compartment when you turn the key to START, this may also

indicate a loose or corroded battery connection.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

55