light FORD SUPER DUTY 2009 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 103, PDF Size: 0.75 MB

Page 4 of 103

•On F-Super Duty vehicles (6.4L engine),a frame-mounted

Horizontal Fuel Conditioner Module (HFCM)

•an engine-mounted secondary fuel filter

•a unit injector for each cylinder

The FCM/HFCM acts as a primary fuel filter/water separator which

removes both water and impurities from the fuel. The engine mounted

filter filters finer impurities from the diesel fuel. The engine-mounted

fuel filter and the FCM/HFCM filter should be changed at the

recommended service interval. Refer to thescheduled maintenance

informationin this supplement for more information.

F-Super Duty

E-Series

The FCM/HFCM should be drained at regular intervals or when the

WATER IN FUEL light illuminates in the instrument cluster.

The fuel injectors are located in the center of the combustion chambers

in the cylinder head between the rocker arm assemblies. The glow plug

system and fuel injection system are controlled through the Powertrain

Control Module (PCM) and Fuel Injection Control Module (FICM) (6.0L

engine only).

Fuel is drawn from the fuel tank by a frame-mounted electric fuel pump.

The fuel pump provides pressurized fuel to the engine and is

electronically controlled by the fuel pump PCM relay. The fuel pump

contains a pressure relief valve for overpressure protection in the event

of restricted flow.

Engine protection mode

Ford diesel engines are equipped with engine protection and emission

control systems. These systems monitor critical temperatures and

pressures, and modify engine operation accordingly. These features are

intended to modify engine performance characteristics. If these modified

engine performance characteristics persist for an extended period or the

service engine soon (

) or powertrain malfunction/reduced

power/electronic throttle control light (

) is illuminated, seek service

from your authorized dealer.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Introduction

4

Page 7 of 103

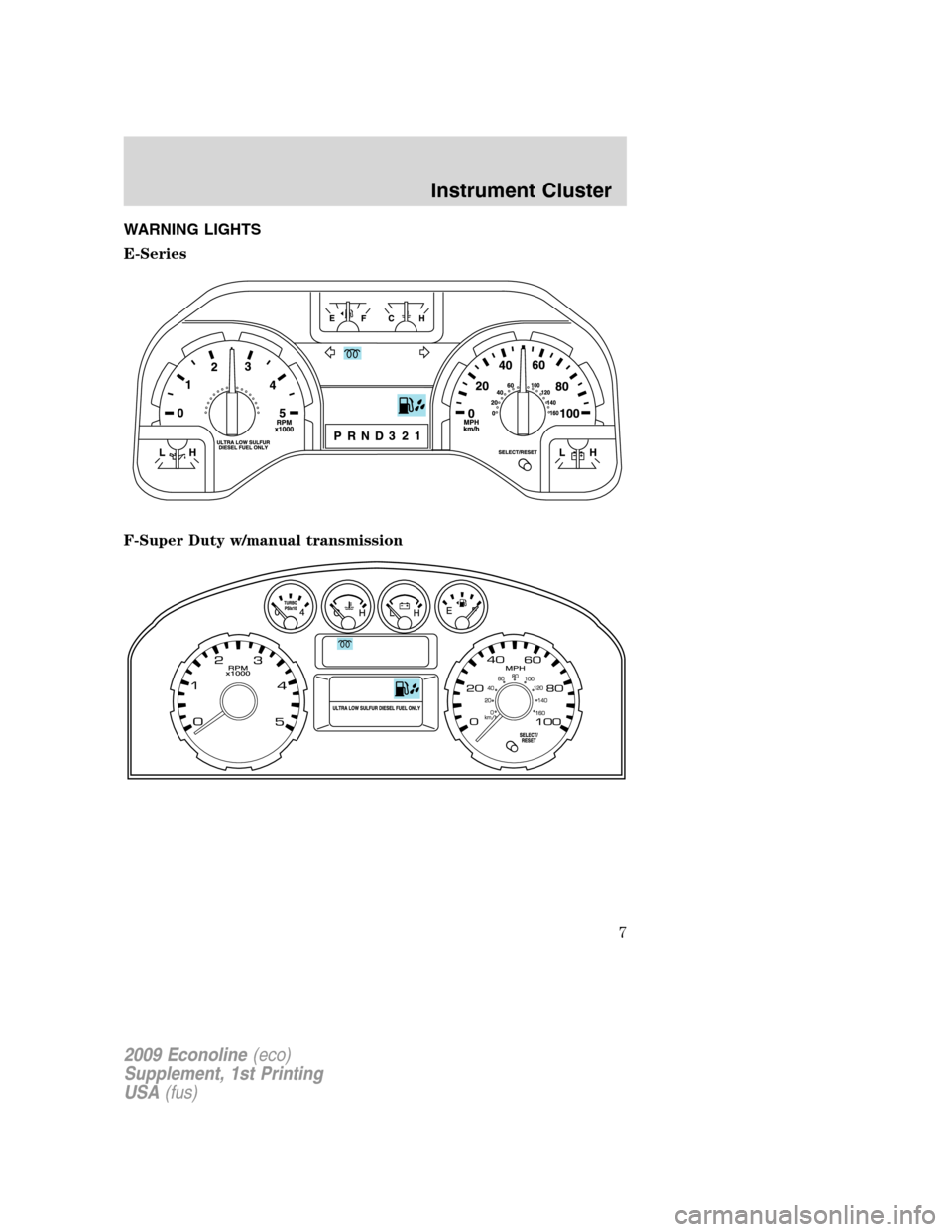

WARNING LIGHTS

E-Series

F-Super Duty w/manual transmission

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Instrument Cluster

7

Page 8 of 103

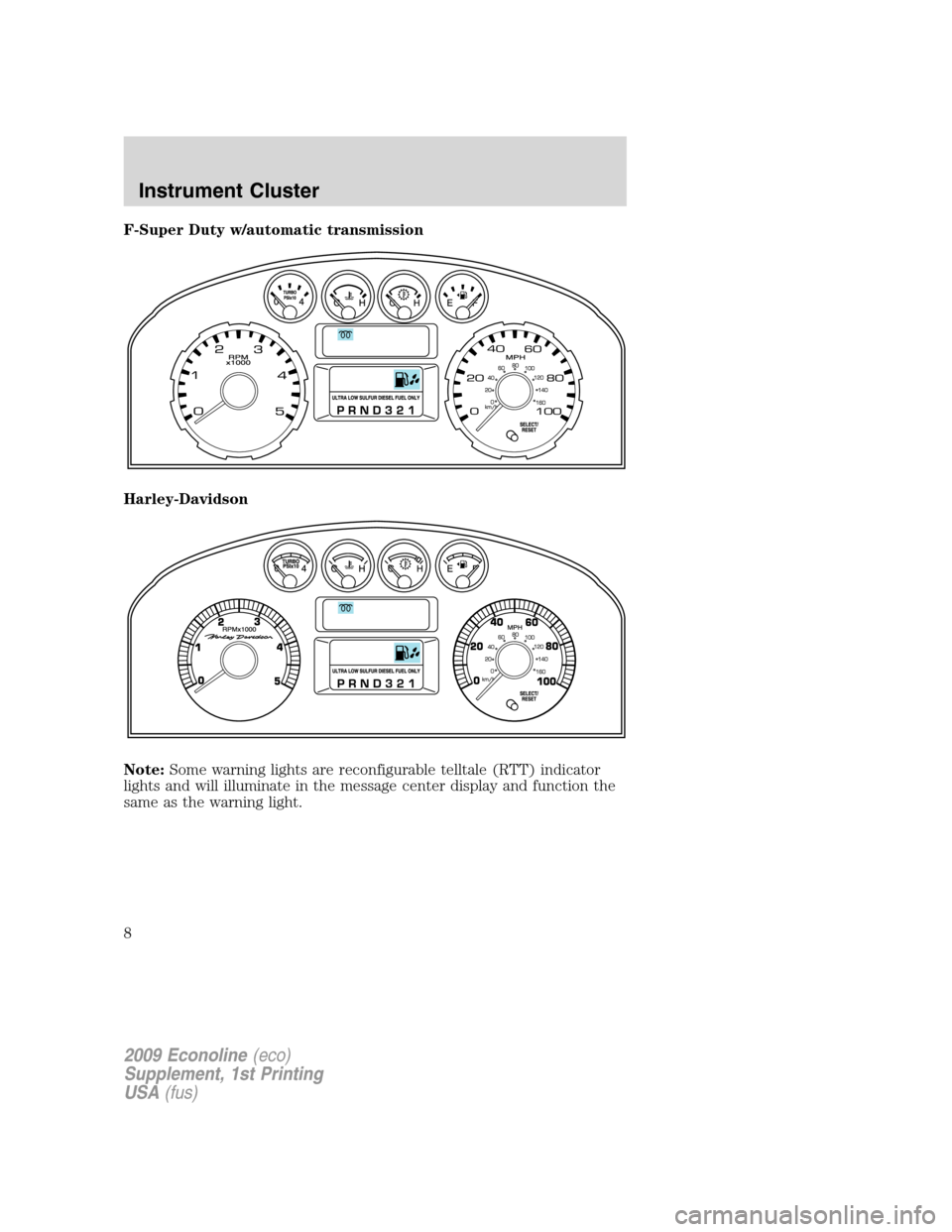

F-Super Duty w/automatic transmission

Harley-Davidson

Note:Some warning lights are reconfigurable telltale (RTT) indicator

lights and will illuminate in the message center display and function the

same as the warning light.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Instrument Cluster

8

Page 9 of 103

Glow plug pre-heat indicator:

With the key in the on position,

the

light will illuminate if glow

plug heat is necessary as a starting aid. Wait until the light goes off

before starting. Refer toCold weather startingin theDrivingchapter

of this supplement. After the engine starts, the light should turn on. The

light should always illuminate at least momentarily when the engine is

cold and the ignition is turned to on. If it does not illuminate, the glow

plug system should be checked and repaired promptly to avoid difficulty

in cold starting.

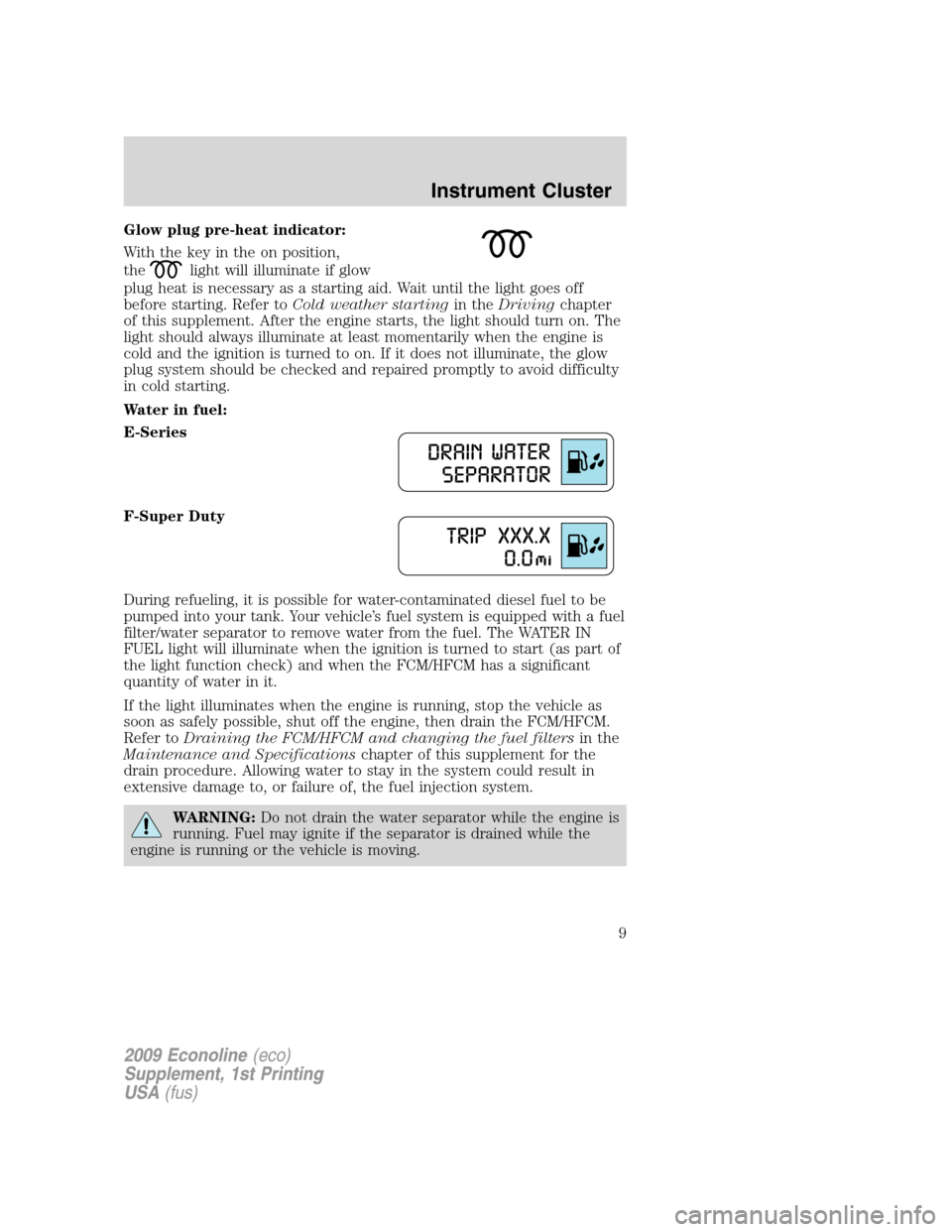

Water in fuel:

E-Series

F-Super Duty

During refueling, it is possible for water-contaminated diesel fuel to be

pumped into your tank. Your vehicle’s fuel system is equipped with a fuel

filter/water separator to remove water from the fuel. The WATER IN

FUEL light will illuminate when the ignition is turned to start (as part of

the light function check) and when the FCM/HFCM has a significant

quantity of water in it.

If the light illuminates when the engine is running, stop the vehicle as

soon as safely possible, shut off the engine, then drain the FCM/HFCM.

Refer toDraining the FCM/HFCM and changing the fuel filtersin the

Maintenance and Specificationschapter of this supplement for the

drain procedure. Allowing water to stay in the system could result in

extensive damage to, or failure of, the fuel injection system.

WARNING:Do not drain the water separator while the engine is

running. Fuel may ignite if the separator is drained while the

engine is running or the vehicle is moving.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Instrument Cluster

9

Page 13 of 103

•The timer can be reset by changing the position of the accelerator

pedal, brake pedal or the park brake within the final 30 seconds.

•When the timer reaches zero, the engine shuts down and the message

center will displayENGINE TURNED OFF.

•One minute after the engine has shut down, the electrical system will

simulate key off, even though the ignition is still in the on position,

initiating normal accessory delay period.

•The ignition must be moved to the off position to reset the system

before restarting the vehicle.

Note:The engine idle shutdown idle timer will not start if:

•The engine is operating in power take-off (PTO) mode.

•The engine coolant temperature is below 60°F (16°C).

•The exhaust emission control device (DPF) is regenerating.

STOPPING THE ENGINE

Turn the ignition to the OFF position.

On E-Series vehicles,

to prolong engine life (after extended high speed

or maximum GVW operation), it is recommended that a hot engine be idled

for 7–10 minutes which will allow the turbocharged engine to cool down.

On F-Super Duty vehicles,to prolong engine life (especially after

extended high speed, high ambient temperature, or high GVW/GCW

operation), it is recommended that a hot engine be idled for 3-5 minutes

which will allow the turbocharged engine to cool down.

COLD WEATHER OPERATION

Changing to a lighter grade engine oil also makes starting easier under

these conditions. Refer toEngine oil specificationsin theMaintenance

and Specificationschapter of this supplement.

At temperatures below 20°F (–7°C), number 2–D diesel fuel may thicken

enough to clog the fuel filter. Your vehicle is equipped with either an

FCM (E-Series) or an HFCM (F-Super Duty) which acts as a fuel

filter/water separator to keep the wax melted which will help prevent

fuel filter clogging. However, if the engine starts but stalls after a short

time and will not restart, the fuel filter(s) may be clogged. For best

results in cold weather, use Number 1–D diesel fuel or “winterized”

Number 2–D diesel fuel which has an additive to minimize wax

formation. If you have problems operating on biodiesel during cold

weather, you may need to use a diesel fuel with lower biodiesel content,

try another brand, or discontinue the use of biodiesel.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Driving

13

Page 24 of 103

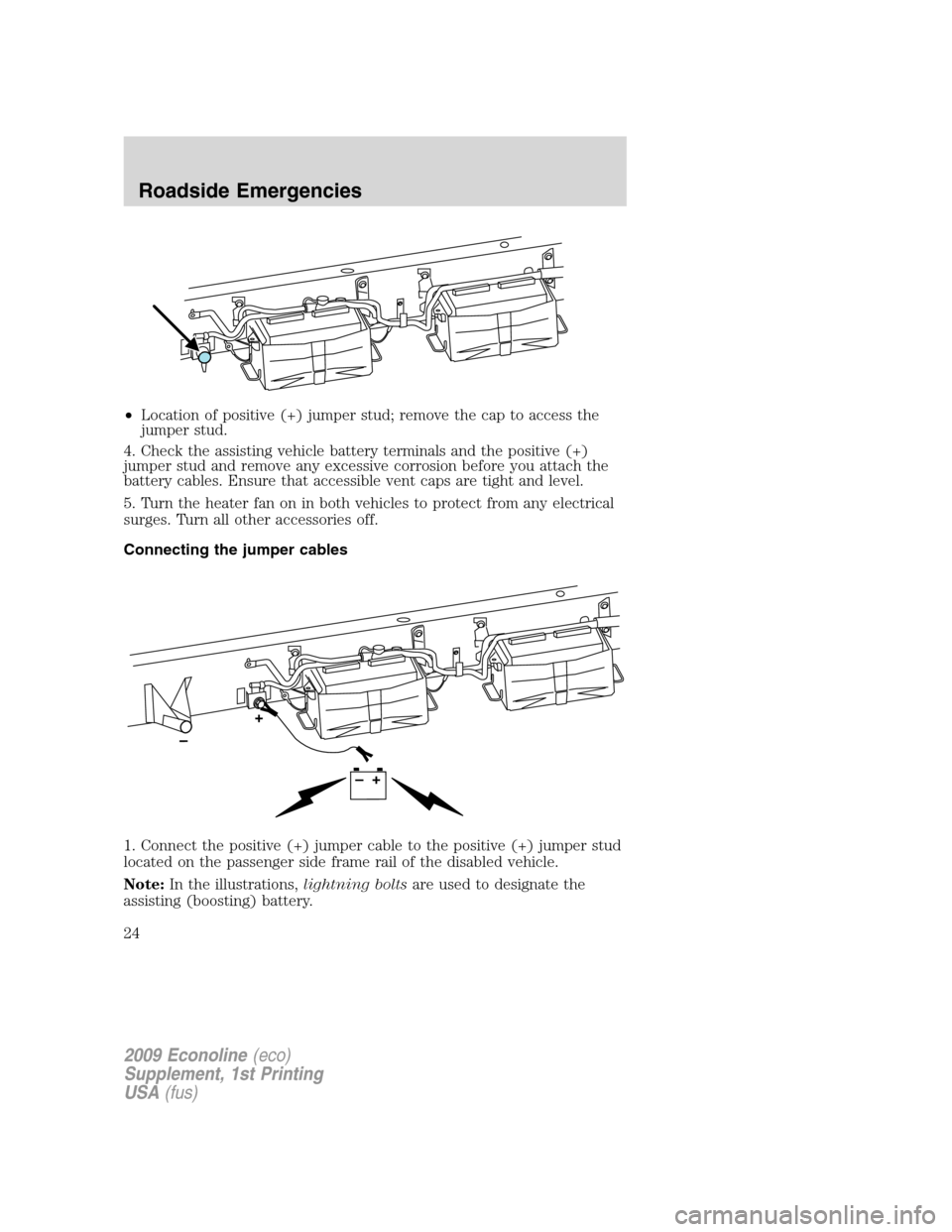

•Location of positive (+) jumper stud; remove the cap to access the

jumper stud.

4. Check the assisting vehicle battery terminals and the positive (+)

jumper stud and remove any excessive corrosion before you attach the

battery cables. Ensure that accessible vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) jumper stud

located on the passenger side frame rail of the disabled vehicle.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

24

Page 27 of 103

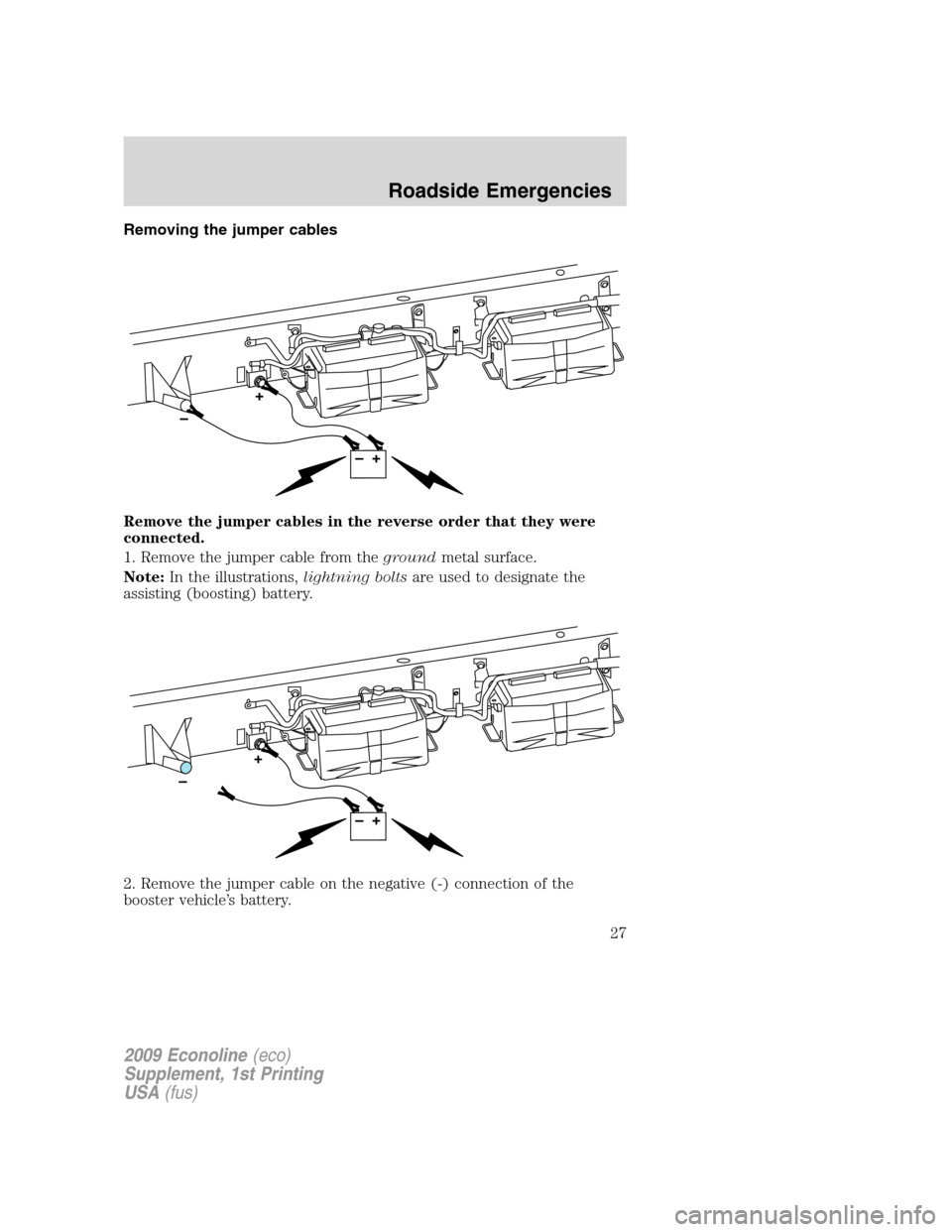

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

27

Page 29 of 103

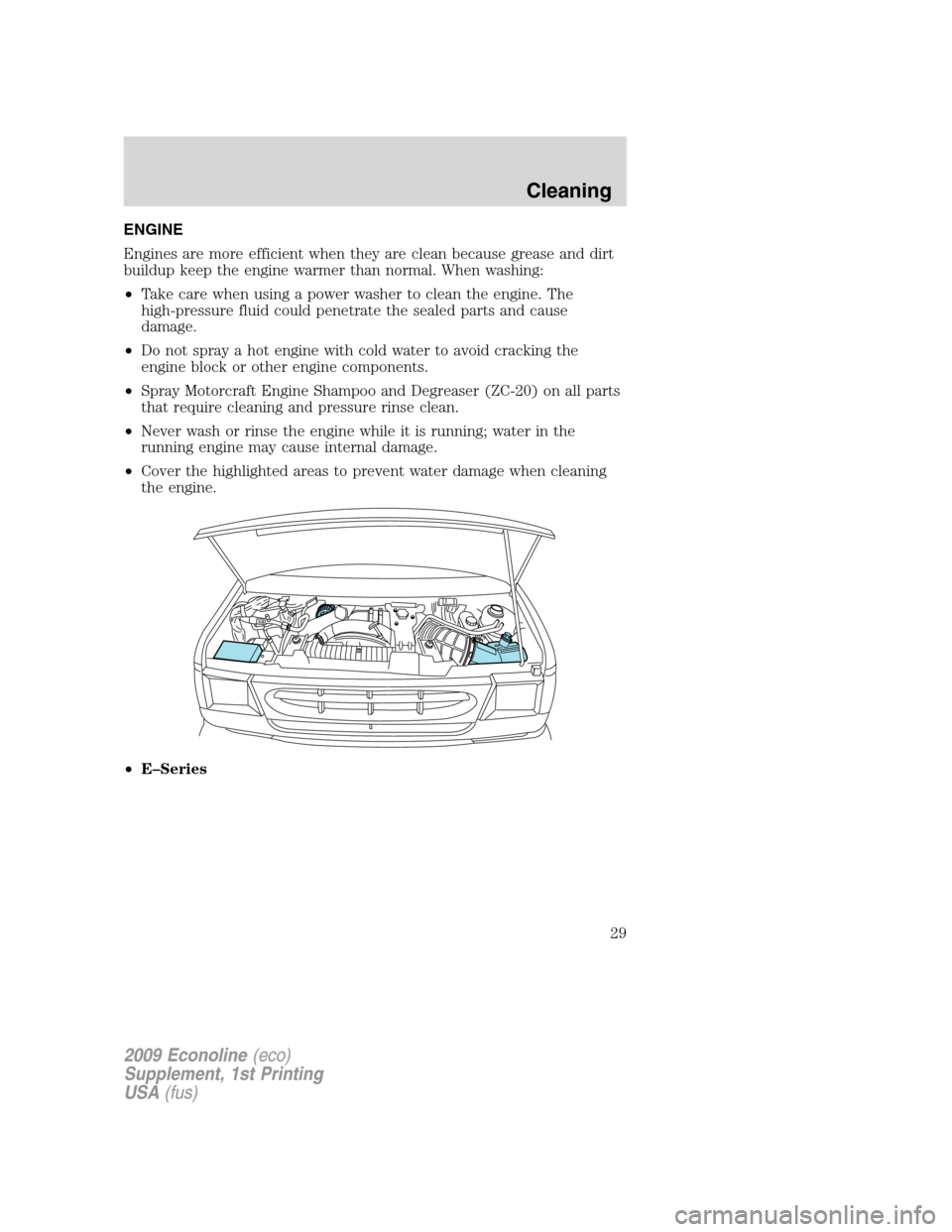

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

•Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

•Cover the highlighted areas to prevent water damage when cleaning

the engine.

•E–Series

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Cleaning

29

Page 34 of 103

The horizontal fuel conditioner module (HFCM) is located on the

frame-rail under the driver-side floorboard near the transmission.

SCHEDULED MAINTENANCE

The scheduled maintenance services in thescheduled maintenance

informationof this supplement are required because they are

considered essential to the life and performance of your vehicle.

Use only recommended fuel, lubricants, fluids and service parts

conforming to Ford specifications. Motorcraft parts are designed and

built for best performance in your vehicle.

FUEL REQUIREMENTS - CHOOSING THE RIGHT FUEL: VEHICLES

OPERATED WHERE ULTRA LOW SULFUR DIESEL FUEL IS

REQUIRED (UNITED STATES/CANADA/PUERTO RICO/U.S. VIRGIN

ISLANDS AND OTHER LOCALES)

Use only Ultra Low Sulfur (15 ppm Sulfur Maximum) number 1-D

or 2-D diesel fuel (also known as ULSD) in your 6.4L diesel

engine.The engine and exhaust system were designed to only use this

fuel. Look for theULTRA-LOW SULFUR HIGHWAY DIESEL FUEL

(15 ppm Sulfur Maximum)label on fuel pumps when purchasing your

fuel.

Using low sulfur diesel fuel (16-500 ppm) or high sulfur diesel

fuel (greater than 500 ppm) in a 6.4L diesel engine designed to

use only Ultra Low Sulfur Diesel fuel will cause certain emission

components to malfunction which may also cause the Service

Engine Soon(

)light to illuminate indicating an

emissions-related concern.

Number 1-D or winter blend number 2-D fuel is recommended at

temperatures below 20°F (-7°C) (seeCold weather operationin the

Drivingchapter of this supplement).

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

34

Page 39 of 103

Fuel filler cap

Your fuel tank filler cap has an indexed design with a 1/4 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise until it spins off.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it clicks at least once.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The vehicle warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

WARNING:The fuel system may be under pressure. If the fuel

filler cap is venting vapor or if you hear a hissing sound, wait

until it stops before completely removing the fuel filler cap. Otherwise,

fuel may spray out and injure you or others.

WARNING:If you do not use the proper fuel filler cap,

excessive pressure or vacuum in the fuel tank may damage the

fuel system or cause the fuel cap to disengage in a collision, which may

result in possible personal injury.

FUEL FILTER/WATER SEPARATOR

Fuel Conditioner Module (FCM - E-Series)

The vehicle is equipped with a Fuel Conditioning Module (FCM) located

on the driver-side of the vehicle next to the transmission case.

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 cc) of water accumulates in the module.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

39