lock FORD SUPER DUTY 2013 3.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2013, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2013 3.GPages: 95, PDF Size: 2.42 MB

Page 9 of 95

STARTING THE ENGINE

Read all starting instructions carefully before you start your vehicle.

For temperatures below 32°F (0°C), the use of the correct grade engine

oil is essential for proper operation. Refer toEngine oil specifications

in theMaintenancechapter for more information.

Your vehicle may be equipped with a cold weather starting strategy that

prevents severe engine damage by assisting in engine lubrication

warm-up. In extremely cold ambient temperatures, this strategy activates

and prevents the accelerator pedal from being used for 30 seconds after

starting the vehicle. By not allowing the accelerator pedal to be used, the

engine oil is allowed to properly lubricate the bearings preventing engine

damage due to lack of proper lubrication. After the 30 second warm-up

period, the accelerator pedal will be operational again as long as the

pedal is not being pressed when the 30 second time limit expires. When

starting the engine in extremely cold temperatures (-15°F [–26°C]), it is

recommended to allow the engine to idle for several minutes before

driving the vehicle.

Make sure the gearshift lever is in P (Park) and the parking brake is fully

set before you turn the key. Do not press the accelerator during starting.

Cold Weather Starting

WARNING:Do not use starting fluid, such as ether, in the air

intake system (see air filter decal). Such fluid could cause

immediate explosive damage to the engine and possible personal injury.

WARNING:Do not add gasoline, gasohol or alcohol to diesel

fuel. This practice creates a serious fire hazard and causes

engine performance problems.

It is recommended that the engine block heater be used for starting

when the temperature is -10°F (-23°C) or colder. Refer toEngine block

heater (if equipped)in theStarting and Stopping the Enginechapter

of yourOwner’s Manual.

When operating in cold weather, Motorcraft® cetane improvers or

non-alcohol-based cetane improvers from a reputable manufacturer may

be used as needed.

Starting and Stopping the Engine

8

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 12 of 95

In cold weather below 32°F (0°C), the engine may slowly increase to a

higher idle speed if left idling in P (Park). As the engine warms-up, the

engine sound level decreases due to the activation of PCM-controlled

sound reduction features.

If your vehicle is operated in a heavy snow storm or blowing snow

conditions, the engine air induction may become partially clogged with

snow and/or ice. If this occurs, the engine may experience a significant

reduction in power output. At the earliest opportunity, clear all the snow

and/or ice away from inside the air filter assembly. Remove the air

cleaner cover and the pleated paper filter, leaving the foam filter in and

remove any snow or ice. Make sure the foam filter is installed correctly

in place. Remove any debris, snow and/or ice on the foam filter by

brushing the surface with soft brush. Do not use water, solvents, or a

hard brush for cleaning the foam filter.

In order to operate the engine in temperatures of 32°F (0°C) or lower,

read the following instructions:

•Make sure that the batteries are of sufficient size and are fully

charged. Check other electrical components to make sure they are in

optimum condition.

•Use the proper coolant solution at the concentration recommended to

protect the engine against damage from freezing.

•Try to keep the fuel tank full as much as possible at the end of

operation to prevent condensation in the fuel system.

•Make sure you use proper cold weather engine oil and that it is at its

proper level. Also, if necessary, make sure to follow the engine oil and

filter change schedule found under theSpecial operating conditions

section listed in thescheduled maintenance information.

•At temperatures of -10°F (-23°C) or below, it is recommended that

you use an engine block heater to improve cold engine starting.

•If operating in arctic temperatures of -20°F (-29°C) or lower, consult

your truck dealer for information about special cold weather

equipment and precautions.

The following cold weather idling guidelines are recommended:

•Motorcraft® cetane improvers or non-alcohol-based cetane improvers

from a reputable manufacturer may be used as needed.

•Maintain the engine cooling system properly.

•Avoid shutting the engine down after an extensive idling period. Drive

the vehicle for several miles with the engine at normal operating

temperatures under a moderate load.

•Consider using an engine block heater.

•For extended idle times use an approved idle speed increase device.

Starting and Stopping the Engine

11

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 13 of 95

Winter Operating Tips for Arctic Operation -20°F (-29°C) and Below

The following information is provided as a guideline only, and is not

intended to be the only source of possible solutions in resolving extreme

cold temperature issues.

Starting Aids:

WARNING:Do not use starting fluid, such as ether, in the air

intake system (see air filter decal). Such fluid could cause

immediate explosive damage to the engine and possible personal injury.

The use of the factory engine block heater assists in engine starting in

extreme cold ambient temperatures. Refer toEngine block heaterin the

Starting and Stopping the Enginechapter of yourOwner’s Manual.

Idle Control:

•Your vehicle may have a factory option for a stationary elevated idle

control (SEIC) through dash-mounted upfitter switches which allows

the operator to elevate the idle rpm for extended idle periods, as well

as aftermarket equipment such as PTO operation. This feature must

be configured even if ordered from the factory. See your authorized

dealer for required upfitting.

Operation in Snow and Rain

Vehicle operation in heavy snowfall or extreme rain conditions may feed

excessive amounts of snow/water into the air intake system. This could

plug/soak the air filter with snow and may cause the engine to lose

power and possibly shut down.

The following actions are recommended after operating the vehicle up to

200 miles (320 kilometers) in snowfall or extreme rain:

•Snow:At the earliest opportunity, open the hood and clear all the

snow and ice from the air filter housing inlet (do not remove the

foam filter) and reset the air filter restriction gauge.Note:Removal

of the foam filter degrades vehicle performance during snow and hot

weather conditions.

•Extreme rain:The air filter dries after about 15–30 minutes at

highway speeds. At the earliest opportunity, open the hood and reset

the air filter restriction gauge.

Refer toAir filter and restriction gaugein theMaintenancechapter of

this supplement for more information.

Starting and Stopping the Engine

12

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 14 of 95

Operation in Standing Water

Ingestion of water into the diesel engine can result in immediate and

severe damage to the engine. If driving through water, slow down to

avoid splashing water into the intake. If the engine stalls, and ingestion

of water into the engine is suspected, do not try to restart the engine.

Consult your dealer for service immediately.

The fuel tank is vented to atmosphere by valves on top of the tank and

through the fuel cap. If water reaches this level water may be pulled into

the fuel tank. Water in the fuel can cause performance issues and

damage the fuel injection system.

Engine Block Heater (If Equipped)

Refer to theStarting and Stopping the Enginechapter in your

Owner’s Manual.

Rapid Heat Supplemental Heating System (If Equipped)

Note:Additional aftermarket electrical loads operated during engine

warm up may impact the performance of the rapid heat supplemental

heater.

The optional rapid heat feature is an electrically powered device that is

designed to provide supplemental heat during engine warm up. For

maximum effectiveness mid to low blower speed is recommended during

initial warm up. When operating in automatic mode (when equipped) the

climate control unit determines the appropriate blower speed for existing

conditions.

Starting and Stopping the Engine

13

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 19 of 95

Care should be taken whenever diesel fuel is stored. Use only clean,

approved containers which will prevent the entry of dirt or water.

Diesel fuel must not be stored in a galvanized container. The fuel will

dissolve the zinc in a galvanized container. The zinc will then remain in

the solution until it is run through the engine where it will be deposited

in the fuel injectors causing expensive-to-repair damage.

Diesel fuel dispensing nozzle fill rate

This truck is equipped with a fuel fill pipe which is able to accept fuel up

to 20 gallons per minute from a 1

1�8fuel dispensing nozzle. Pumping fuel

at greater flow rates may result in premature nozzle shut-off or spitback.

Fuel filler cap

WARNING:The fuel system may be under pressure. If the fuel

filler cap is venting vapor or if you hear a hissing sound, wait

until it stops before completely removing the fuel filler cap. Otherwise,

fuel may spray out and injure you or others.

WARNING:If you do not use the proper fuel filler cap,

excessive pressure or vacuum in the fuel tank may damage the

fuel system or cause the fuel cap to disengage in a collision, which may

result in possible personal injury.

Note:If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The vehicle warranty may be void

for any damage to the fuel tank or fuel system if the correct genuine

Ford or Motorcraft® fuel filler cap is not used.

Your fuel tank filler cap has an indexed design with a 1/4 turn on/off feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise until it spins off.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it clicks at least once.

Fuel and Refueling

18

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 25 of 95

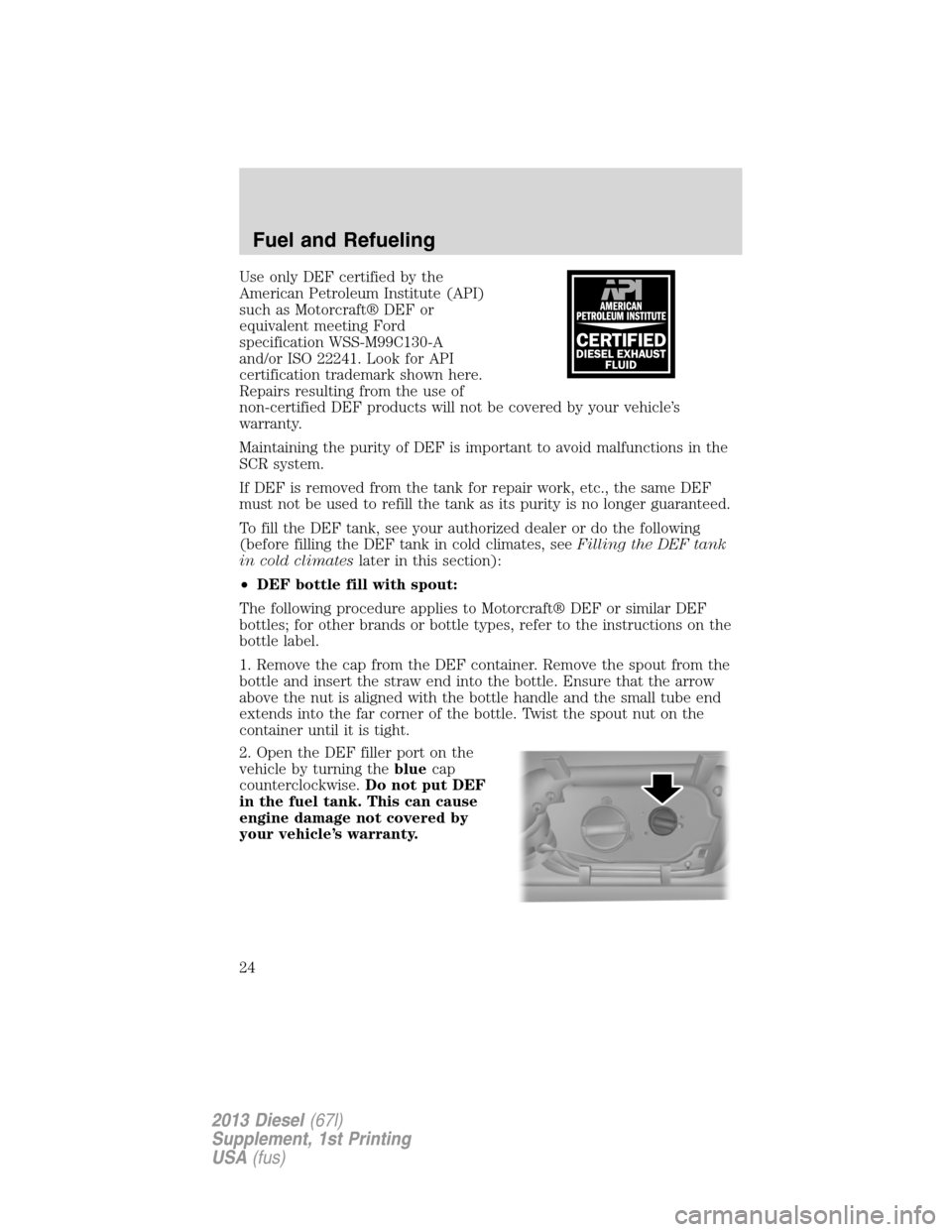

Use only DEF certified by the

American Petroleum Institute (API)

such as Motorcraft® DEF or

equivalent meeting Ford

specification WSS-M99C130-A

and/or ISO 22241. Look for API

certification trademark shown here.

Repairs resulting from the use of

non-certified DEF products will not be covered by your vehicle’s

warranty.

Maintaining the purity of DEF is important to avoid malfunctions in the

SCR system.

If DEF is removed from the tank for repair work, etc., the same DEF

must not be used to refill the tank as its purity is no longer guaranteed.

To fill the DEF tank, see your authorized dealer or do the following

(before filling the DEF tank in cold climates, seeFilling the DEF tank

in cold climateslater in this section):

•DEF bottle fill with spout:

The following procedure applies to Motorcraft® DEF or similar DEF

bottles; for other brands or bottle types, refer to the instructions on the

bottle label.

1. Remove the cap from the DEF container. Remove the spout from the

bottle and insert the straw end into the bottle. Ensure that the arrow

above the nut is aligned with the bottle handle and the small tube end

extends into the far corner of the bottle. Twist the spout nut on the

container until it is tight.

2. Open the DEF filler port on the

vehicle by turning thebluecap

counterclockwise.Do not put DEF

in the fuel tank. This can cause

engine damage not covered by

your vehicle’s warranty.

Fuel and Refueling

24

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 32 of 95

3. Rotate the drain counterclockwise

until the O-ring is visible. Allow the

DFCM to drain for approximately

25 seconds or until clean fuel is

observed. Rotate the drain clockwise

to tighten it. If no liquid drains, the

drain may be clogged. Have the

DFCM serviced by your authorized

dealer.

4. Make sure that the drain valve is fully tightened, then remove the

container from under the vehicle.

5. Restart the engine. TheWATER IN FUEL DRAIN FILTERor

WATER IN FUEL DRAIN FILTER SEE MANUALmessage and light

should not be illuminated. If they continues to illuminate, have the fuel

system checked and repaired.

LOW FUEL PRESSURE MESSAGE

The engine is equipped with a low fuel pressure detection system. If the

message center displays:LOW FUEL PRESSUREthe following

explains why and what to do:

•Cold start or cold operation (below 32°F (0°C): If this message

appears during a cold start or during cold operation up to 10 minutes

after the initial cold start, monitor the message center. If it disappears

and does not re-appear after the engine has fully warmed up, the low

fuel pressure message is most likely caused by waxed or gelled fuel.

Do not use alcohol based additives to correct fuel gelling. This may

result in damage to the fuel injectors/systems. Use an anti-gel additive

as listed in theCapacities and Specificationschapter. The customer

warranty may be void from using additives that do not meet or exceed

Ford specifications.

If the low fuel pressure message persistently appears after re-fueling

during the cold start and cold operation conditions defined previously

and then disappear when the engine has fully warmed up, consider

different fuel sources.

•Low fuel operation: If the message appears when the vehicle is warm

and during low fuel tank level operation, i.e. the tank level is at or

very near empty, refuel the vehicle and operate the vehicle. If the

message reappears after fueling, see below. If the message does not

come back, the low fuel pressure condition was due to low fuel levels

in the fuel tank.

Fuel and Refueling

31

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 33 of 95

•Normal operation: If the message appears during normal operation

when the vehicle / engine is fully warm, and fuel level is not low, the

fuel filters must be changed regardless of the maintenance schedule

interval.

•If replacement of the fuel filter does not remedy the low fuel pressure

message during normal operation as defined above, take the vehicle to

your authorized dealer.

CHANGING THE ENGINE-MOUNTED AND DFCM FUEL FILTERS

Your vehicle is equipped with two fuel filters; one is mounted on top of

the driver’s side of the engine and the second filter, inside the DFCM, is

mounted on the frame rail under the driver-side floorboard near the

transmission. Both filters should be replaced at the same time. Regular

fuel filter changes are an important part of engine maintenance; failing to

keep with the scheduled maintenance could lead to engine performance

issues and/or fuel injection system damage. Refer to thescheduled

maintenance informationof this supplement for more information.

Refer toMotorcraft part numbersin theMaintenancechapter for the

fuel filter replacement part number. This part number includes filters

and seals for both the engine-mounted and frame-mounted filters.

Removal - DFCM filter

The DFCM filter is located in the lower portion of the DFCM housing.

1. Drain the DFCM. SeeFuel filter/water separatorin theFuel and

Refuelingchapter.

To install the new DFCM filter, seeInstallation – DFCM filterin the

Fuel and Refuelingchapter.

2. Remove the lower portion of the

DFCM housing (filter bowl) by

turning it counterclockwise using a

32 mm socket.

Note:Depending on the amount

seal swelling, removal of the filter

bowl may be noisy and require some

effort. Replace the seal prior to

reinstalling the filter/bowl to

improve assembly.

3. Remove and discard the old fuel filter element.

4. Carefully clean the mating surfaces using a lint-free rag.

Fuel and Refueling

32

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 34 of 95

Installation – DFCM filter

1. Install the new filter into the filter bowl tabs and replace the seal on

the DFCM header (top portion of DFCM). Refer toMotorcraft part

numbersin theMaintenancechapter for the fuel filter kit part number.

2. Lube O-ring with lubricant packet in the filter kit. This will assist in

making sure the filter gets properly tightened.

3. Reinstall the lower portion of the

housing by slowly turning it

clockwise onto DFCM housing,

allowing fuel to soak into the fuel

filter element. Tighten the lower

housing until it contacts the

mechanical stop.

Note:The engine will not run

properly if the DFCM fuel filter is

not installed in the housing or if the

filter bowl is not tightened to the

mechanical stop.

The system will need to be purged of air after removal/changing of the

filter. SeePurging air from the fuel system after DFCM and engine

mounted fuel filter replacementfollowing.

Removal - Engine-mounted fuel filter

The engine-mounted fuel filter is a plastic disposable cartridge. To

remove it, do the following:

1. Disconnect both fuel lines by

squeezing the connector tabs and

pulling the lines straight off.

Note:Although the fuel system is

not fully pressurized when the

vehicle is off, some residual

pressure may remain in the fuel

system since it can take some time

for the pressure to completely bleed

off. Therefore, it is recommended to

place a shop rag below the filter

connectors to absorb the small amount of fuel that will drain.

Fuel and Refueling

33

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)

Page 35 of 95

2. Rotate the filter fully

counterclockwise until the peg is at

the far end of the slot.

3. Pull the filter straight up from the bracket and discard the filter.

Installation – Engine-mounted fuel filter

1. Install the new filter into the filter bracket. Turn the filter clockwise to

lock it in place.

2. Reconnect both fuel lines.

Using a fuel which has more than average impurities may require

the fuel filter to be replaced more frequently than the service

interval specifies.

The system will need to be purged of air after removal/changing of the

filter. SeePurging air from the fuel system after DFCM and

engine-mounted fuel filter replacementfollowing.

Purging air from the fuel system after DFCM and engine mounted

fuel filter replacement

Turn the ignition key to on for 30 seconds, then turn it to off. Do this a

total of six times in a row to purge any trapped air from the fuel system.

After filter service, a no start or rough running engine may indicate that

air is entering the system through the filter bowl seal or drain. Make sure

the drain is tight and the filter bowl has been tightened to the

mechanical stop.

DIESEL EXHAUST SYSTEM: OXIDATION CATALYST/DIESEL

PARTICULATE FILTER SYSTEM

Your vehicle is equipped with a diesel particulate filter (DPF). The DPF

is an inline filter in the exhaust system which reduces carbon emissions

by trapping exhaust particles before they reach the tailpipe. The DPF

looks similar to a traditional exhaust catalyst, except larger, and is part

of the exhaust system under the vehicle. The DPF is coupled to a diesel

oxidation catalyst, that reduces the amount of harmful exhaust emitted

Fuel and Refueling

34

2013 Diesel(67l)

Supplement, 1st Printing

USA(fus)