headlamp FORD SUPER DUTY 2013 3.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2013, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2013 3.GPages: 563, PDF Size: 7.27 MB

Page 271 of 563

Transmission operation while plowing

WARNING:Do not spin the wheels at over 35 mph (55 km/h).

The tires may fail and injure a passenger or bystander.

•Shift transfer case to4L(4WD Low) when plowing in small areas at

speeds below 5 mph (8 km/h).

•Shift transfer case to4H(4WD High) when plowing larger areas or

light snow at higher speeds. Do not exceed 15 mph (24 km/h).

•Do not shift the transmission from a forward gear toR(Reverse) until

the engine is at idle and the wheels are stopped.

•If the vehicle is stuck, shift the transmission in a steady motion

between forward and reverse gears. Do not rock the vehicle for more

than a minute. The transmission and tires may be damaged or the

engine can overheat.

Outside Air Temperature While Plowing

The outside air temperature reading can be inaccurate while plowing

with your vehicle due to the sensor air flow being blocked by the plow

blade.

A Ford Wiring Kit (XXXX-XXXXX-XX) is available to relocated the OAT

sensor to the plow blade frame below the headlamp to provide accurate

outside air temperature readings.

VEHICLE USED AS A STATIONARY POWER SOURCE

Auxiliary equipment called power take-off, or PTO, is often added to the

engine or transmission to operate utility equipment. Examples include a

wheel-lift for tow trucks, cranes, tools for construction or tire service,

and pumping fluids. PTO applications draw auxiliary horsepower from

the powertrain, often while the vehicle is stationary. In this condition,

there is limited cooling air flow through the radiator and around the

vehicle that normally occurs when a vehicle is moving. The aftermarket

PTO system installer, having the most knowledge of the final application,

is responsible for determining whether additional chassis heat protection

or powertrain cooling is required, and alerting the user to the safe and

proper operation.

Ford Super Duty Vehicles are approved for use as a stationary (including

split shaft capability) or mobile power source, within limits and operating

guidelines detailed in theFord Truck Body Builders Layout Book,

found at www.fleet.ford.com/truckbbas, and through the Ford Truck

Body Builders Advisory Service.

270Driving Hints

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

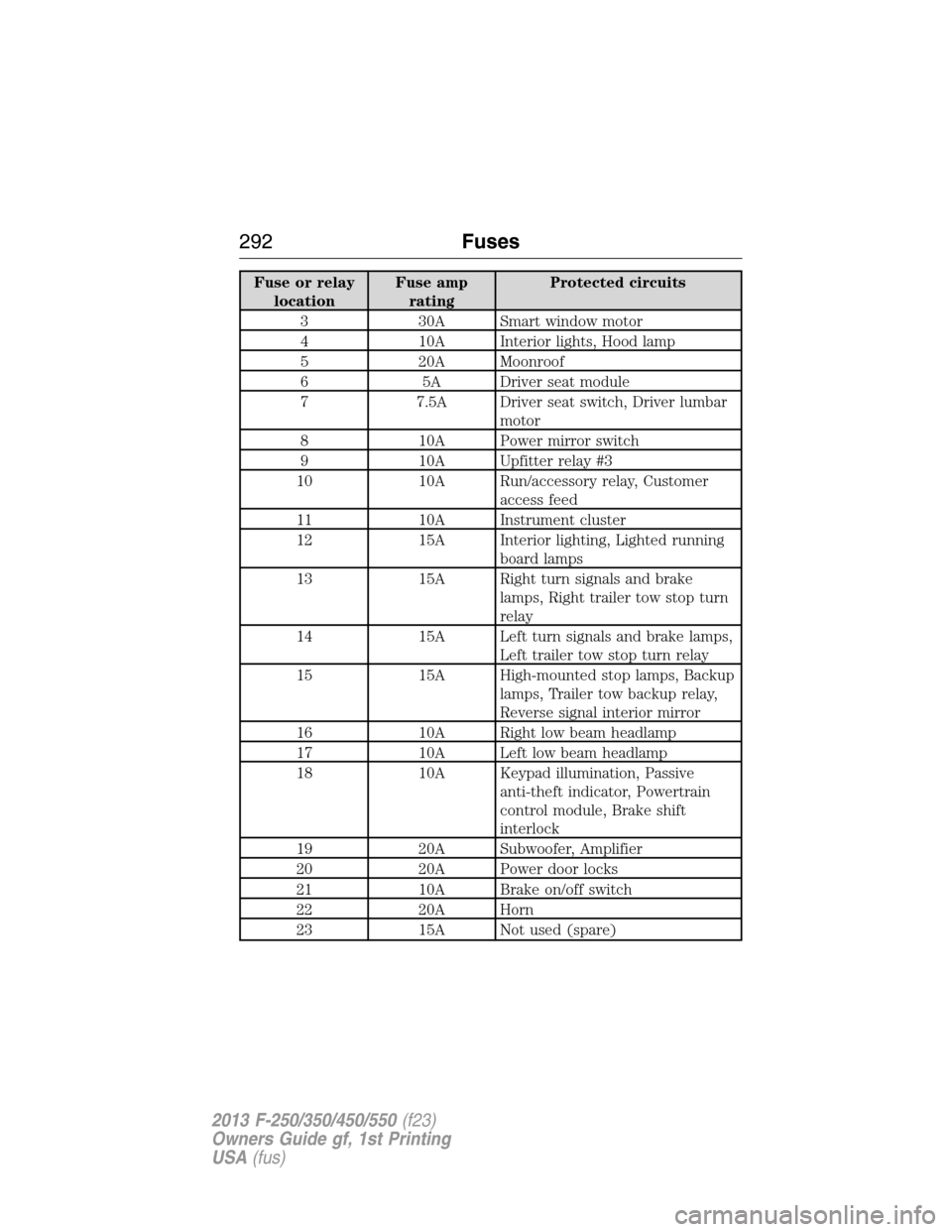

Page 293 of 563

Fuse or relay

locationFuse amp

ratingProtected circuits

3 30A Smart window motor

4 10A Interior lights, Hood lamp

5 20A Moonroof

6 5A Driver seat module

7 7.5A Driver seat switch, Driver lumbar

motor

8 10A Power mirror switch

9 10A Upfitter relay #3

10 10A Run/accessory relay, Customer

access feed

11 10A Instrument cluster

12 15A Interior lighting, Lighted running

board lamps

13 15A Right turn signals and brake

lamps, Right trailer tow stop turn

relay

14 15A Left turn signals and brake lamps,

Left trailer tow stop turn relay

15 15A High-mounted stop lamps, Backup

lamps, Trailer tow backup relay,

Reverse signal interior mirror

16 10A Right low beam headlamp

17 10A Left low beam headlamp

18 10A Keypad illumination, Passive

anti-theft indicator, Powertrain

control module, Brake shift

interlock

19 20A Subwoofer, Amplifier

20 20A Power door locks

21 10A Brake on/off switch

22 20A Horn

23 15A Not used (spare)

292Fuses

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

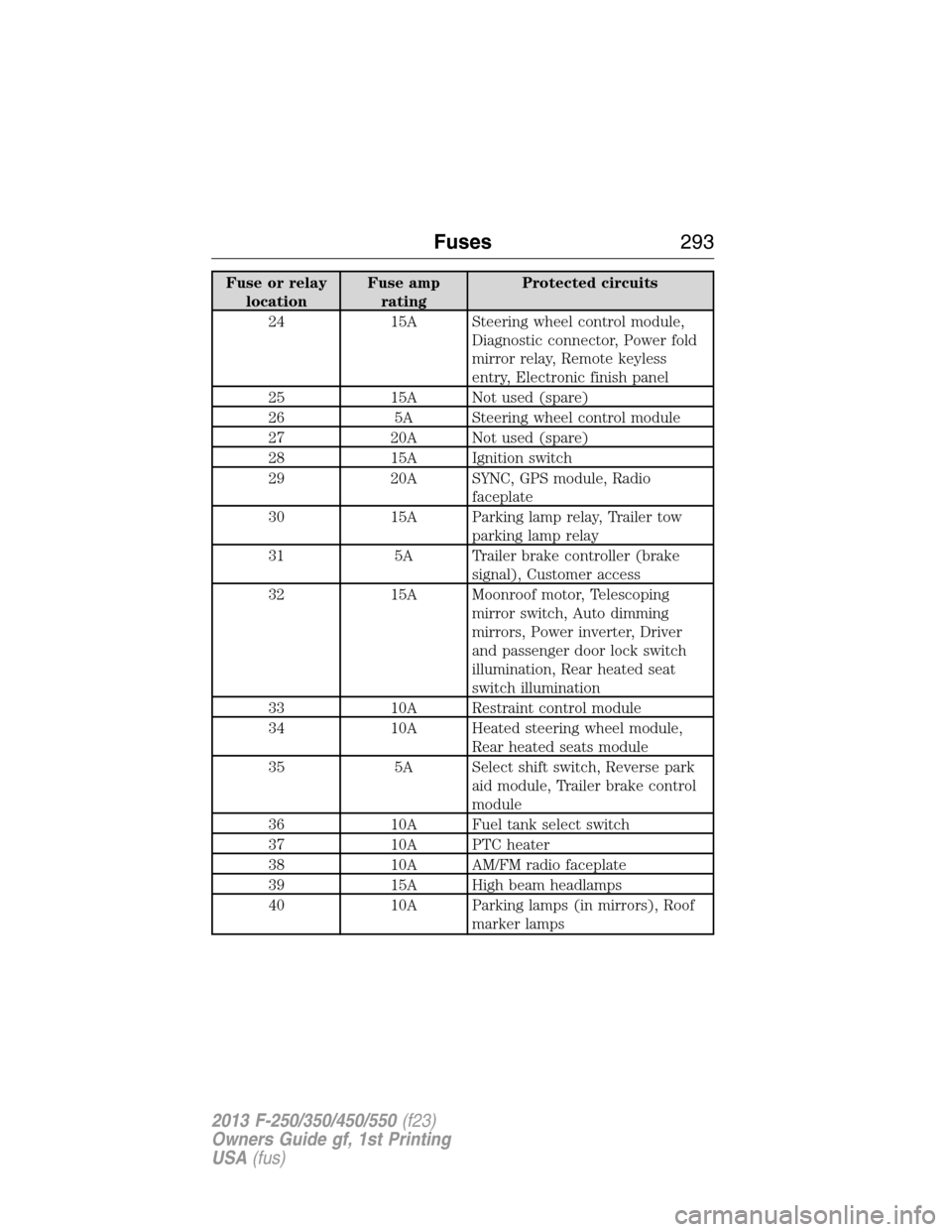

Page 294 of 563

Fuse or relay

locationFuse amp

ratingProtected circuits

24 15A Steering wheel control module,

Diagnostic connector, Power fold

mirror relay, Remote keyless

entry, Electronic finish panel

25 15A Not used (spare)

26 5A Steering wheel control module

27 20A Not used (spare)

28 15A Ignition switch

29 20A SYNC, GPS module, Radio

faceplate

30 15A Parking lamp relay, Trailer tow

parking lamp relay

31 5A Trailer brake controller (brake

signal), Customer access

32 15A Moonroof motor, Telescoping

mirror switch, Auto dimming

mirrors, Power inverter, Driver

and passenger door lock switch

illumination, Rear heated seat

switch illumination

33 10A Restraint control module

34 10A Heated steering wheel module,

Rear heated seats module

35 5A Select shift switch, Reverse park

aid module, Trailer brake control

module

36 10A Fuel tank select switch

37 10A PTC heater

38 10A AM/FM radio faceplate

39 15A High beam headlamps

40 10A Parking lamps (in mirrors), Roof

marker lamps

Fuses293

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

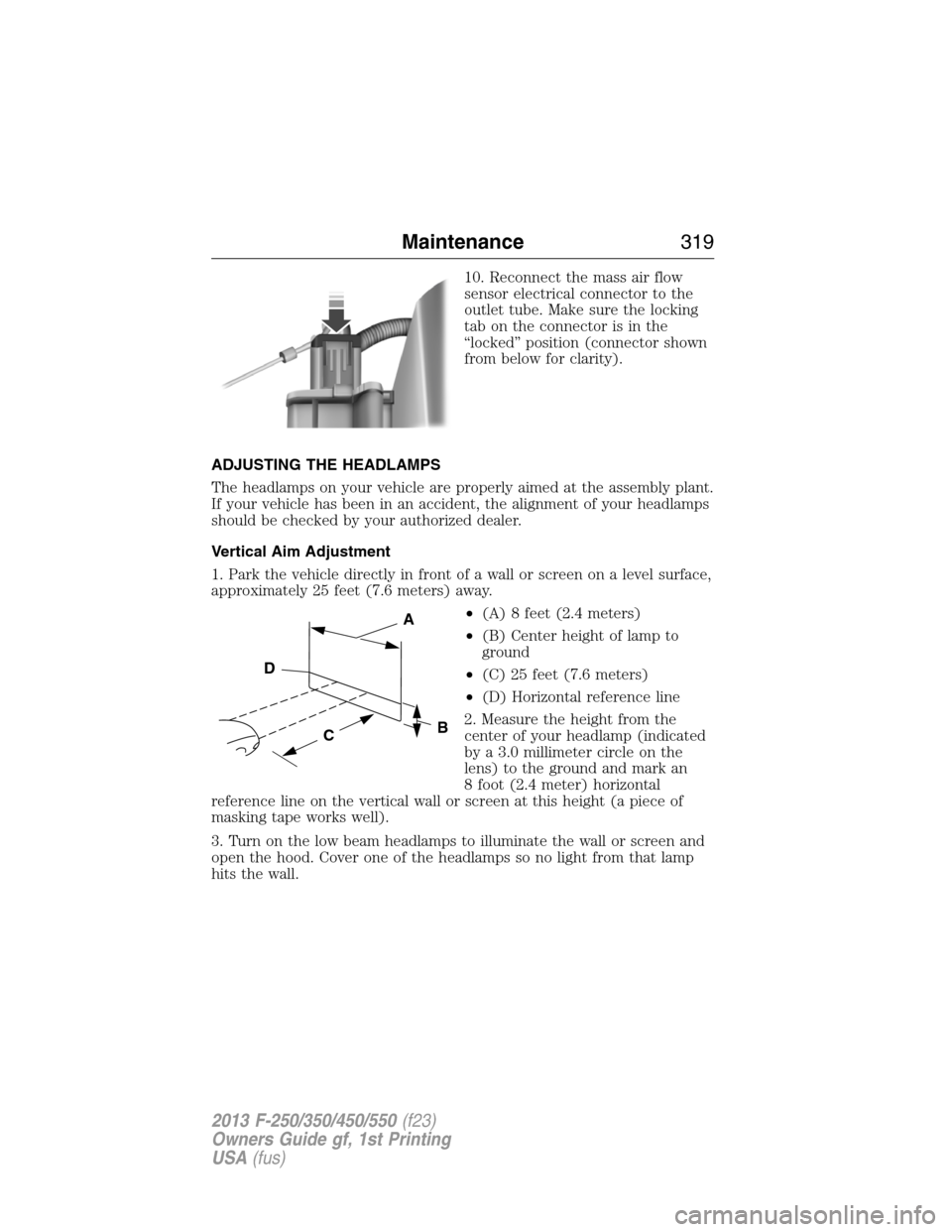

Page 320 of 563

10. Reconnect the mass air flow

sensor electrical connector to the

outlet tube. Make sure the locking

tab on the connector is in the

“locked” position (connector shown

from below for clarity).

ADJUSTING THE HEADLAMPS

The headlamps on your vehicle are properly aimed at the assembly plant.

If your vehicle has been in an accident, the alignment of your headlamps

should be checked by your authorized dealer.

Vertical Aim Adjustment

1. Park the vehicle directly in front of a wall or screen on a level surface,

approximately 25 feet (7.6 meters) away.

•(A) 8 feet (2.4 meters)

•(B) Center height of lamp to

ground

•(C) 25 feet (7.6 meters)

•(D) Horizontal reference line

2. Measure the height from the

center of your headlamp (indicated

by a 3.0 millimeter circle on the

lens) to the ground and mark an

8 foot (2.4 meter) horizontal

reference line on the vertical wall or screen at this height (a piece of

masking tape works well).

3. Turn on the low beam headlamps to illuminate the wall or screen and

open the hood. Cover one of the headlamps so no light from that lamp

hits the wall.

C

A

B

D

Maintenance319

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

Page 321 of 563

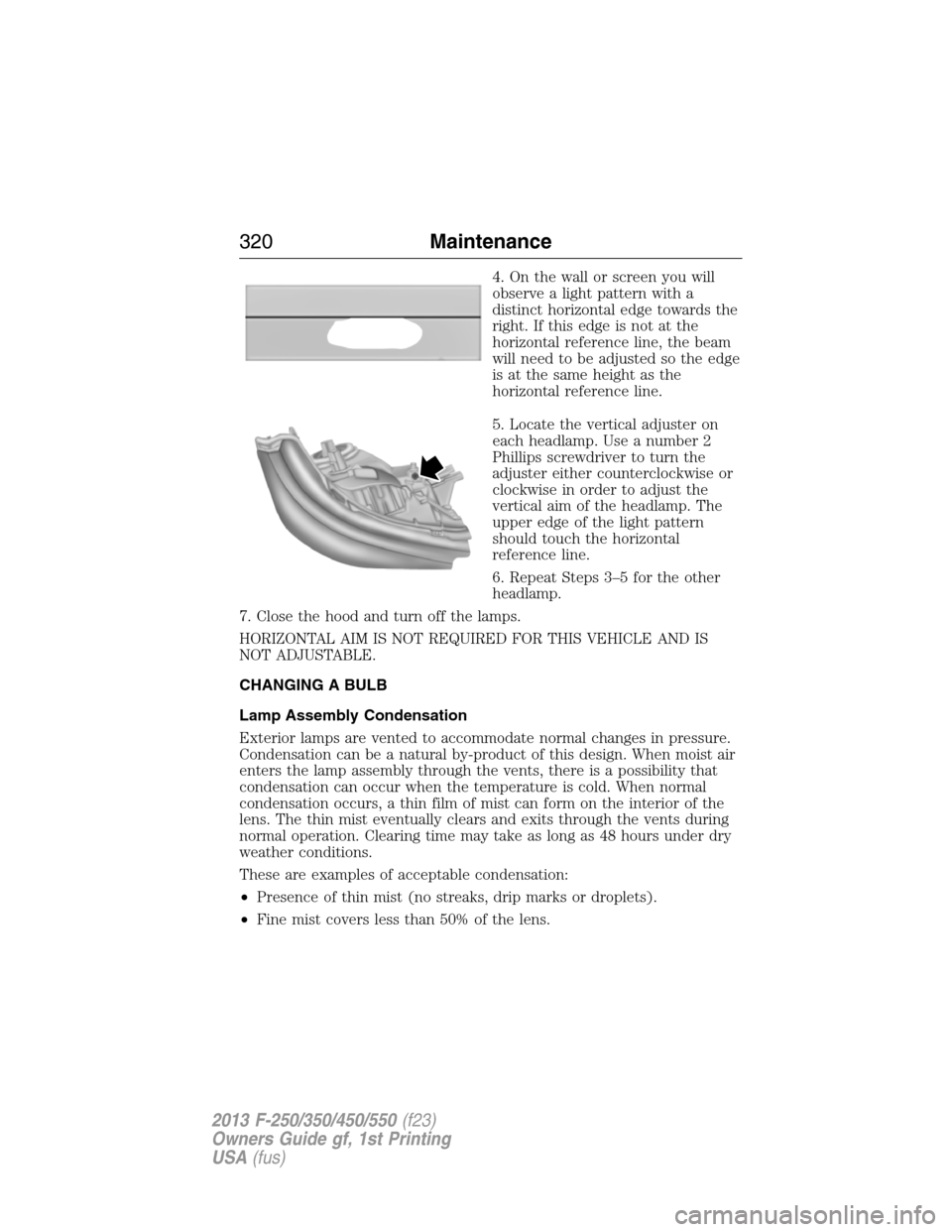

4. On the wall or screen you will

observe a light pattern with a

distinct horizontal edge towards the

right. If this edge is not at the

horizontal reference line, the beam

will need to be adjusted so the edge

is at the same height as the

horizontal reference line.

5. Locate the vertical adjuster on

each headlamp. Use a number 2

Phillips screwdriver to turn the

adjuster either counterclockwise or

clockwise in order to adjust the

vertical aim of the headlamp. The

upper edge of the light pattern

should touch the horizontal

reference line.

6. Repeat Steps 3–5 for the other

headlamp.

7. Close the hood and turn off the lamps.

HORIZONTAL AIM IS NOT REQUIRED FOR THIS VEHICLE AND IS

NOT ADJUSTABLE.

CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented to accommodate normal changes in pressure.

Condensation can be a natural by-product of this design. When moist air

enters the lamp assembly through the vents, there is a possibility that

condensation can occur when the temperature is cold. When normal

condensation occurs, a thin film of mist can form on the interior of the

lens. The thin mist eventually clears and exits through the vents during

normal operation. Clearing time may take as long as 48 hours under dry

weather conditions.

These are examples of acceptable condensation:

•Presence of thin mist (no streaks, drip marks or droplets).

•Fine mist covers less than 50% of the lens.

320Maintenance

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

Page 322 of 563

These are examples of unacceptable moisture (usually caused by a lamp

water leak):

•Water puddle inside the lamp.

•Large water droplets, drip marks or streaks present on the interior of

the lens.

Take your vehicle to a dealer for service if any of the above conditions of

unacceptable moisture are present.

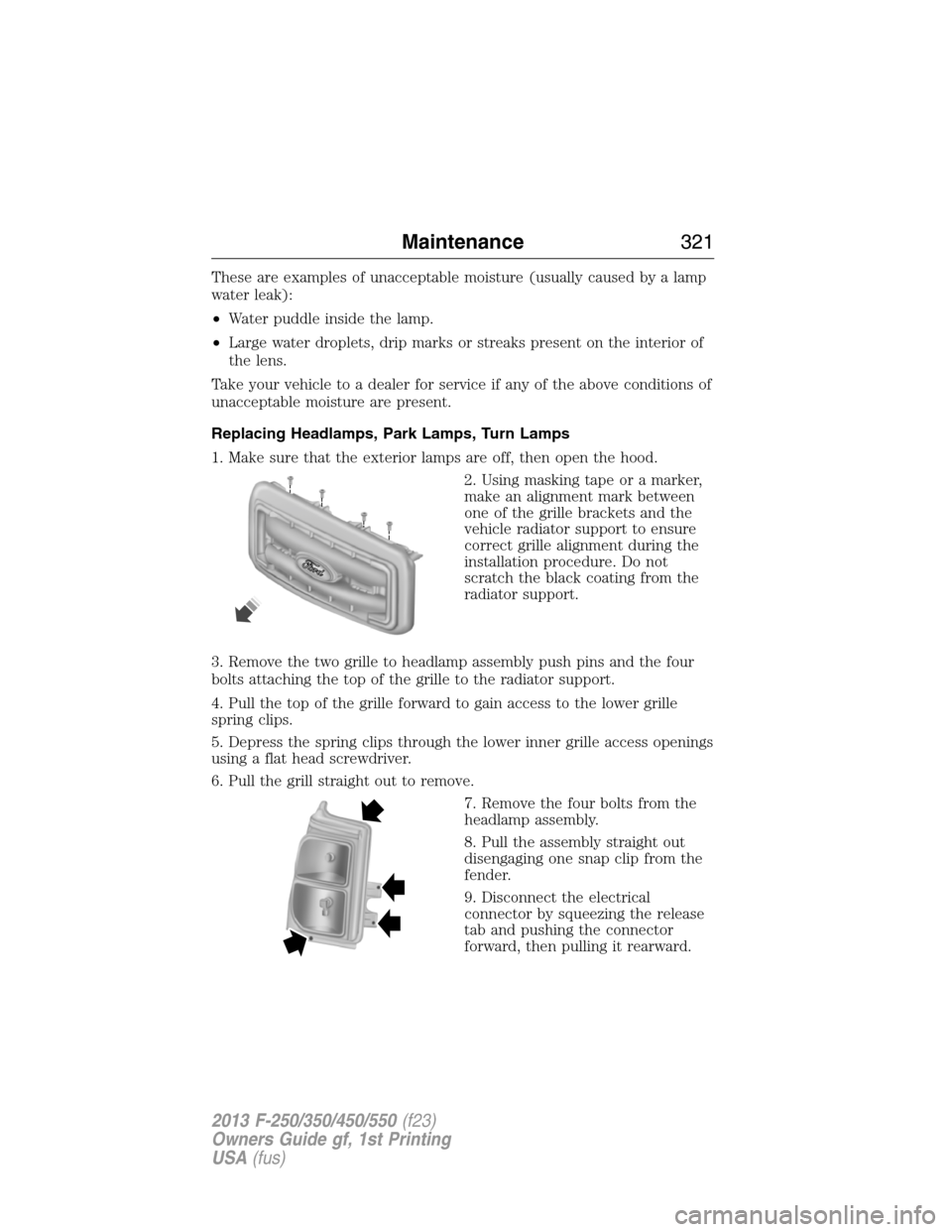

Replacing Headlamps, Park Lamps, Turn Lamps

1. Make sure that the exterior lamps are off, then open the hood.

2. Using masking tape or a marker,

make an alignment mark between

one of the grille brackets and the

vehicle radiator support to ensure

correct grille alignment during the

installation procedure. Do not

scratch the black coating from the

radiator support.

3. Remove the two grille to headlamp assembly push pins and the four

bolts attaching the top of the grille to the radiator support.

4. Pull the top of the grille forward to gain access to the lower grille

spring clips.

5. Depress the spring clips through the lower inner grille access openings

using a flat head screwdriver.

6. Pull the grill straight out to remove.

7. Remove the four bolts from the

headlamp assembly.

8. Pull the assembly straight out

disengaging one snap clip from the

fender.

9. Disconnect the electrical

connector by squeezing the release

tab and pushing the connector

forward, then pulling it rearward.

Maintenance321

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

Page 323 of 563

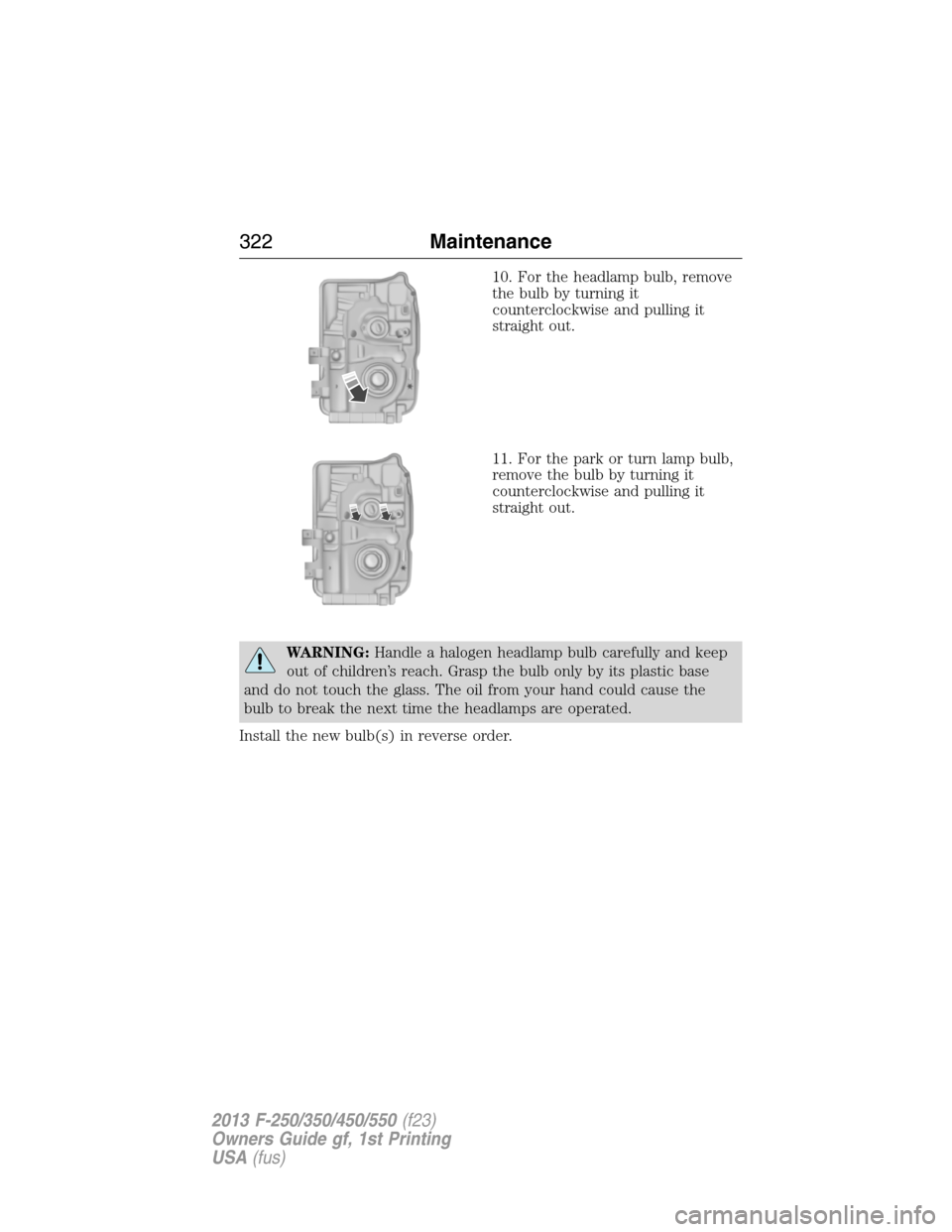

10. For the headlamp bulb, remove

the bulb by turning it

counterclockwise and pulling it

straight out.

11. For the park or turn lamp bulb,

remove the bulb by turning it

counterclockwise and pulling it

straight out.

WARNING:Handle a halogen headlamp bulb carefully and keep

out of children’s reach. Grasp the bulb only by its plastic base

and do not touch the glass. The oil from your hand could cause the

bulb to break the next time the headlamps are operated.

Install the new bulb(s) in reverse order.

322Maintenance

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

Page 324 of 563

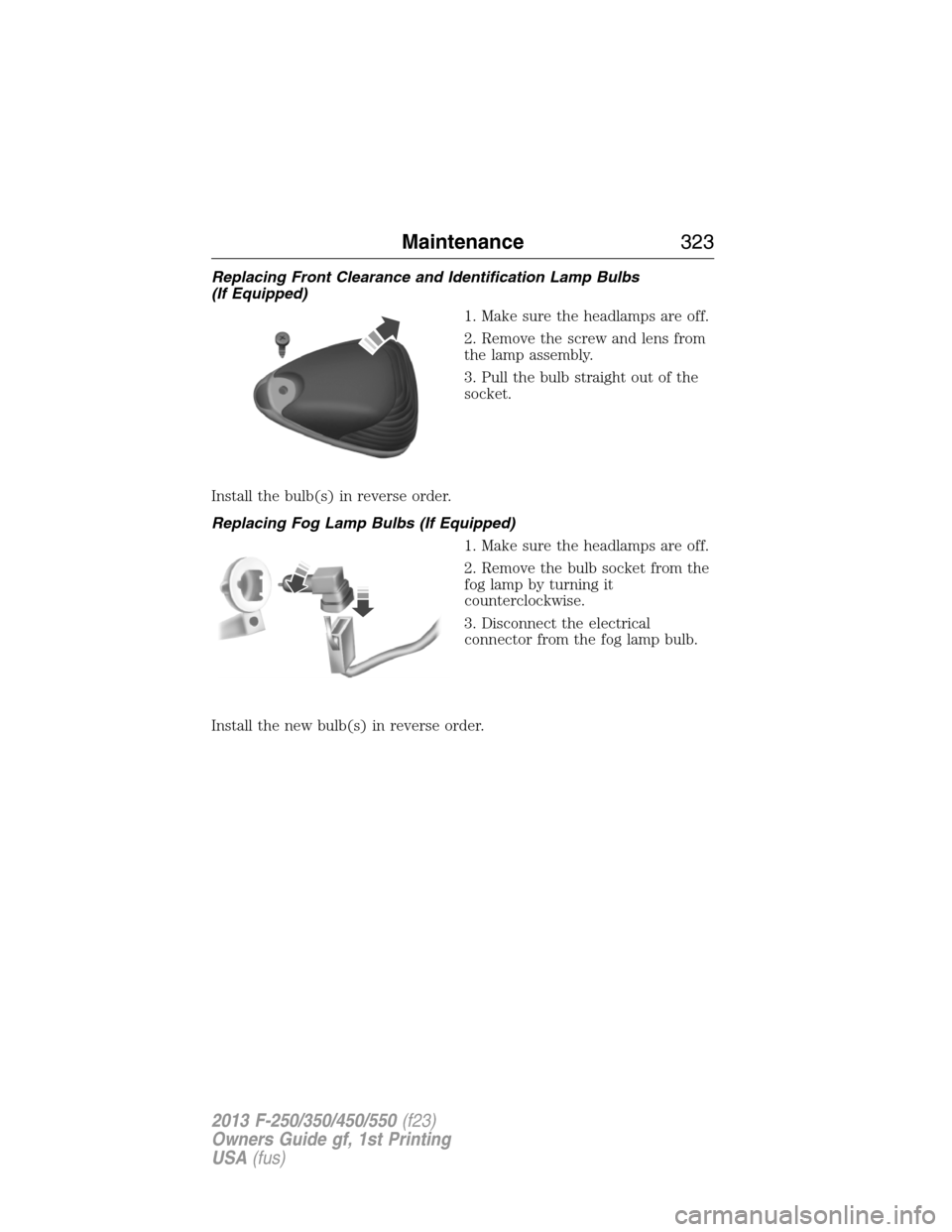

Replacing Front Clearance and Identification Lamp Bulbs

(If Equipped)

1. Make sure the headlamps are off.

2. Remove the screw and lens from

the lamp assembly.

3. Pull the bulb straight out of the

socket.

Install the bulb(s) in reverse order.

Replacing Fog Lamp Bulbs (If Equipped)

1. Make sure the headlamps are off.

2. Remove the bulb socket from the

fog lamp by turning it

counterclockwise.

3. Disconnect the electrical

connector from the fog lamp bulb.

Install the new bulb(s) in reverse order.

Maintenance323

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

Page 325 of 563

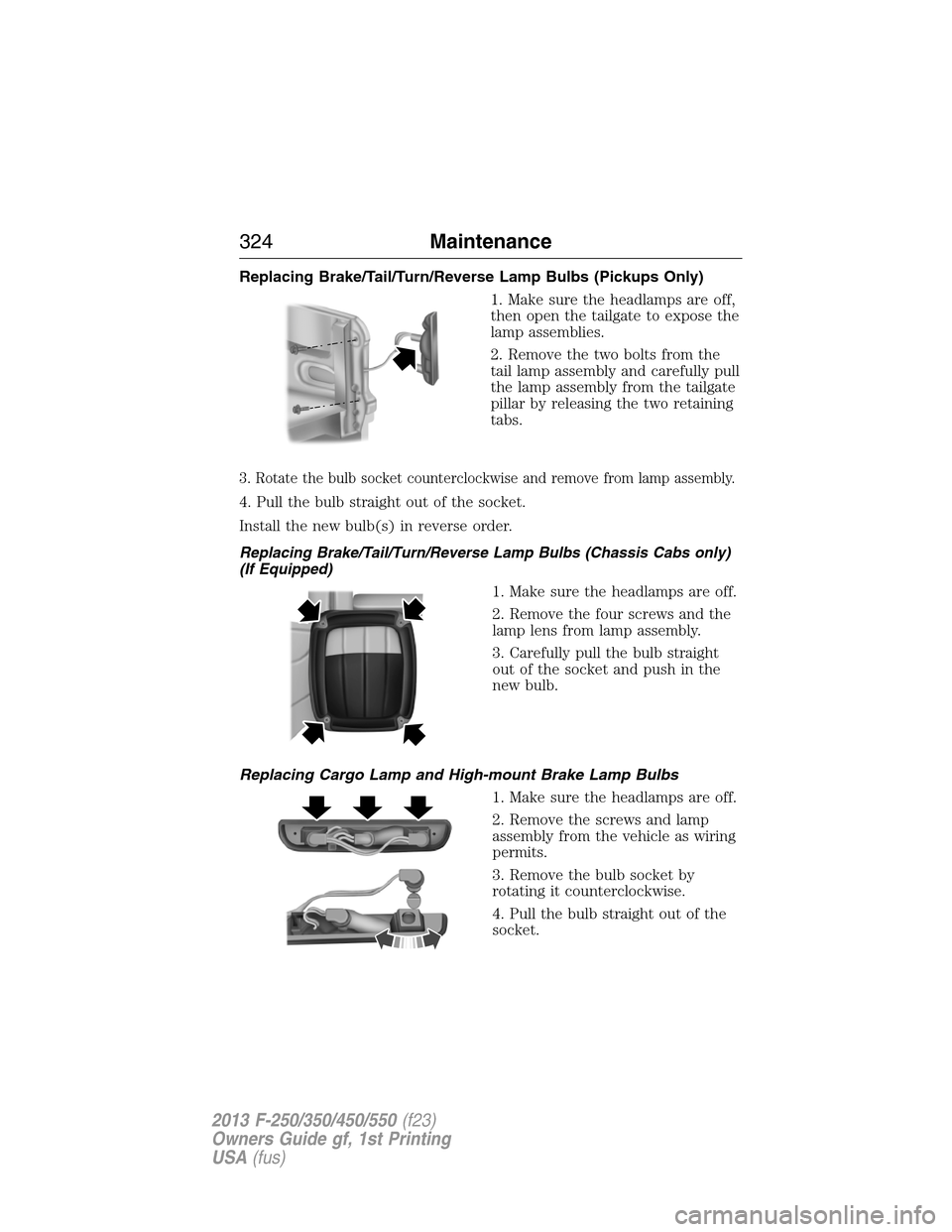

Replacing Brake/Tail/Turn/Reverse Lamp Bulbs (Pickups Only)

1. Make sure the headlamps are off,

then open the tailgate to expose the

lamp assemblies.

2. Remove the two bolts from the

tail lamp assembly and carefully pull

the lamp assembly from the tailgate

pillar by releasing the two retaining

tabs.

3. Rotate the bulb socket counterclockwise and remove from lamp assembly.

4. Pull the bulb straight out of the socket.

Install the new bulb(s) in reverse order.

Replacing Brake/Tail/Turn/Reverse Lamp Bulbs (Chassis Cabs only)

(If Equipped)

1. Make sure the headlamps are off.

2. Remove the four screws and the

lamp lens from lamp assembly.

3. Carefully pull the bulb straight

out of the socket and push in the

new bulb.

Replacing Cargo Lamp and High-mount Brake Lamp Bulbs

1. Make sure the headlamps are off.

2. Remove the screws and lamp

assembly from the vehicle as wiring

permits.

3. Remove the bulb socket by

rotating it counterclockwise.

4. Pull the bulb straight out of the

socket.

324Maintenance

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)

Page 326 of 563

Replacing License Plate Lamp Bulbs

The license plate bulbs are located

behind the rear bumper. To change

the license plate lamp bulbs:

1. Reach behind the rear bumper to

locate the bulb.

2. Twist the bulb socket

counterclockwise and carefully pull

to remove it from the lamp

assembly.

3. Pull out the old bulb from the socket and push in the new bulb.

4. Install the bulb socket in lamp assembly by turning it clockwise.

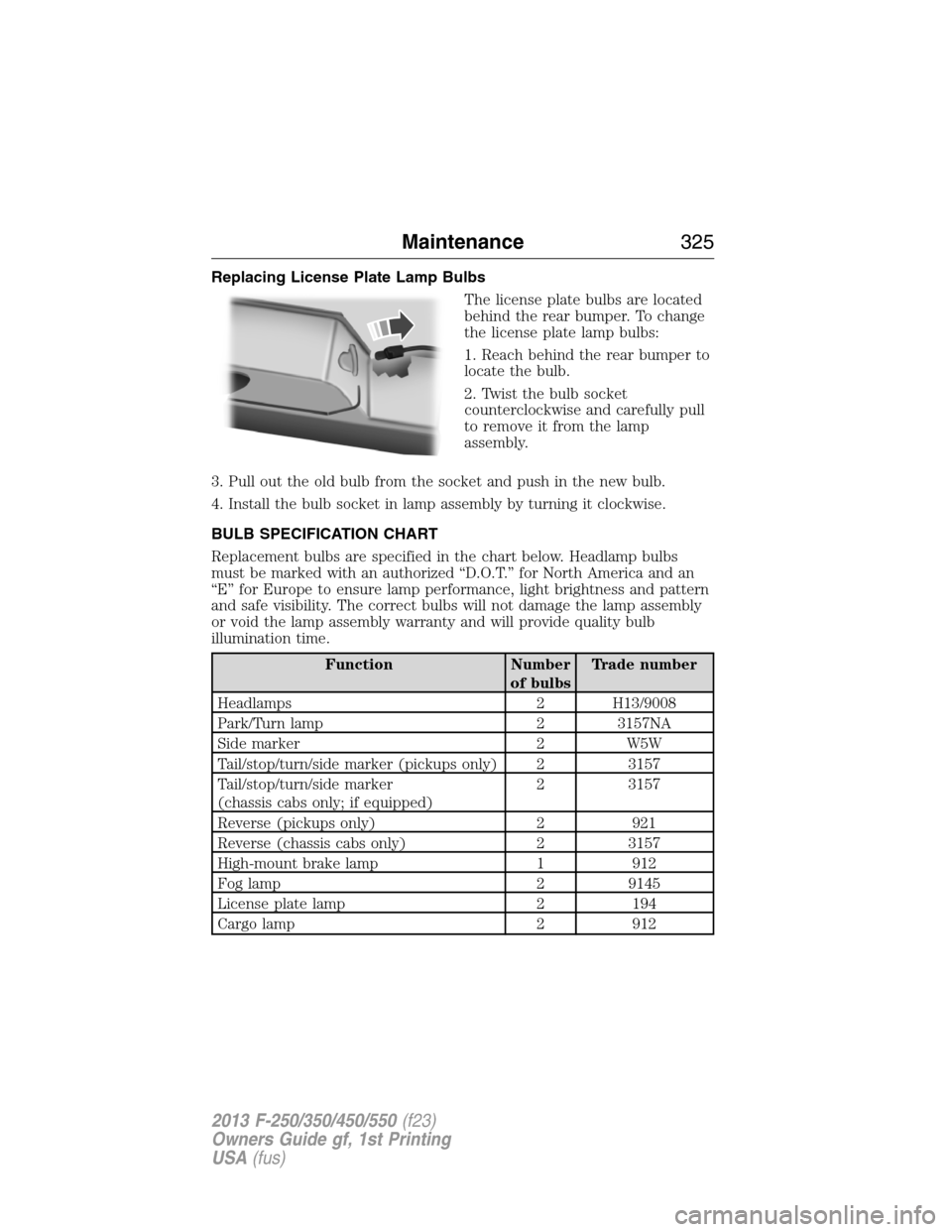

BULB SPECIFICATION CHART

Replacement bulbs are specified in the chart below. Headlamp bulbs

must be marked with an authorized “D.O.T.” for North America and an

“E” for Europe to ensure lamp performance, light brightness and pattern

and safe visibility. The correct bulbs will not damage the lamp assembly

or void the lamp assembly warranty and will provide quality bulb

illumination time.

Function Number

of bulbsTrade number

Headlamps 2 H13/9008

Park/Turn lamp 2 3157NA

Side marker 2 W5W

Tail/stop/turn/side marker (pickups only) 2 3157

Tail/stop/turn/side marker

(chassis cabs only; if equipped)2 3157

Reverse (pickups only) 2 921

Reverse (chassis cabs only) 2 3157

High-mount brake lamp 1 912

Fog lamp 2 9145

License plate lamp 2 194

Cargo lamp 2 912

Maintenance325

2013 F-250/350/450/550(f23)

Owners Guide gf, 1st Printing

USA(fus)