coolant level FORD SUPER DUTY 2017 4.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2017 4.GPages: 636, PDF Size: 10.56 MB

Page 339 of 636

If you drive in extremely hot climates:

•

You can decrease the coolant

concentration to 40%.

• Coolant concentrations below 40%

decrease the freeze and corrosion

protection characteristics of the

coolant and may cause engine

damage.

Vehicles driven year-round in non-extreme

climates should use prediluted engine

coolant for optimum cooling system and

engine protection.

Checking Coolant Corrosion

Inhibitor Additive Strength

At specific mileage intervals as listed in the

scheduled maintenance information

chapter, the coolant corrosion inhibitor

additive should be checked. An information

message may display in the optional

information display at this time. The

purpose of checking is to verify the correct

engine coolant concentration (freeze point

protection) and corrosion inhibitor additive

level (strength) of the coolant for

maximum engine performance and

protection.

Three products are available to confirm

the life and health of the coolant, one tool,

a test kit and a coolant inhibitor additive: •

Robinair® Coolant and Battery

Refractometer 75240 –

Recommended refractometer to test

coolant concentration. (Rotunda tool

part number: ROB75240).

• Rotunda 328-R071–ELC (Antifreeze

Coolant ELC Contamination Kit)

–

Evaluates the corrosion inhibitor

additive strength. Note the first step is

to verify the vehicle ’s coolant

concentration is in the correct range of

40 – 60%. Coolant concentrations

outside this range will not provide valid

test results. If the report results in a

pass, for example the cooling system

does not show excessive

contamination, the corrosion inhibitor

additive strength is sufficient, and no

action is required. If the report results

as insufficient (does not pass), the

corrosion inhibitor additive strength of

the coolant is too low. If the engine

cooling system corrosion inhibitor

additive strength is low, add

47 fl oz

(1.4 L) of Motorcraft Specialty Orange

Engine Coolant Revitalizer. If the

secondary cooling system corrosion

inhibitor additive strength is low, add

16 fl oz (0.47 L) of Motorcraft Specialty

Orange Engine Coolant Revitalizer.

• Motorcraft Specialty Orange Engine

Coolant Revitalizer

– Additive to

boost the corrosion inhibitor level

based upon the test results of the

Antifreeze Coolant ELC Contamination

Kit. The Revitalizer may be added two

times over the life of the coolant. If

additional dosages are required, the

cooling system must be flushed and

refilled per the instructions in the

Workshop Manual.

Make sure to follow the proper coolant and

additive specifications. See

Capacities

and Specifications (page 411).

336

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance

Page 340 of 636

Coolant Change

At specific mileage intervals, as listed in

the scheduled maintenance information,

the coolant should be changed. The

information display may display a message

to change coolant at this time. Add

prediluted coolant approved to the correct

specification. See Capacities and

Specifications (page 411).

Engine-driven Cooling Fan (Fan

Clutch)

Your vehicle may have an engine driven

cooling fan drive (also called a fan clutch).

This fan drive changes the fan speed to

match the vehicle ’s changing cooling air

flow requirements. Fan speed, fan noise

level and fuel consumption all will increase

based on the driving conditions that

include trailer towing, hill climbing, heavy

loads, high speed and high ambient

temperature, individually or in combination.

The fan drive is designed to provide the

minimum fan speed (and resulting

minimum fan noise and fuel consumption)

required to meet the ever changing vehicle

cooling air flow requirements. You will hear

the amount of fan noise increasing and

decreasing as the engine power

requirements and vehicle driving conditions

change as you drive. This is to be expected

as being normal to the operation of your

vehicle. High levels of fan noise might also

be heard when your engine is first started,

and should normally decrease after driving

for a short time.

AUTOMATIC TRANSMISSION

FLUID CHECK

Have an authorized dealer check and

change the transmission fluid and filter at

the correct service interval. See

Scheduled Maintenance

(page 567). Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials may

affect transmission operation and result

in damage to internal transmission

components.

Checking Automatic Transmission

Fluid

For scheduled intervals of the fluid checks

and changes, See

Scheduled

Maintenance (page 567). Your

transmission does not consume fluid.

However, the fluid level should be checked

if the transmission is not working properly,

i.e., if the transmission slips or shifts slowly

or if you notice some sign of fluid leakage.

Automatic transmission fluid expands

when warmed. To obtain an accurate fluid

check, drive the vehicle until it is at normal

operating temperature (approximately

19 mi (30 km)

). Verify that the

transmission fluid temperature gauge,

located on the instrument cluster, is within

normal range.

1. Drive the vehicle

19 mi (30 km)until it

reaches normal operating temperature.

2. Park the vehicle on a level surface and

engage the parking brake.

3. With the engine running, parking brake

engaged and your foot on the brake

pedal, move the gearshift lever through

all of the gear ranges. Allow sufficient

time for each gear to engage.

4. Latch the gearshift lever in P and leave

the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag. If

necessary, refer to the Under Hood

Overview in this chapter for the

location of the dipstick.

337

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance

Page 371 of 636

Engine

•

Change the engine oil and filter prior to

storage because used engine oil

contains contaminates which may

cause engine damage.

• Start the engine every 15 days for a

minimum of 15 minutes. Run at fast idle

with the climate controls set to defrost

until the engine reaches normal

operating temperature.

• With your foot on the brake, shift

through all the gears while the engine

is running.

• We recommend that you change the

engine oil before you use your vehicle

again.

Fuel system

• Fill the fuel tank with high-quality fuel

until the first automatic shutoff of the

fuel pump nozzle.

Cooling system

• Protect against freezing temperatures.

• When removing your vehicle from

storage, check coolant fluid level.

Confirm that there are no cooling

system leaks and that fluid is at the

recommended level.

Battery

• Check and recharge as necessary. Keep

connections clean.

• If storing your vehicle for more than 30

days without recharging the battery,

we recommend that you disconnect

the battery cables to maintain battery

charge for quick starting.

Note: It is necessary to reset memory

features if battery cables are disconnected. Brakes

•

Make sure the brakes and parking brake

release fully.

Tires

• Maintain recommended air pressure.

Miscellaneous

• Make sure all linkages, cables, levers

and pins under your vehicle are covered

with grease to prevent rust.

• Move vehicles at least 25 ft (7.5 m)

every 15 days to lubricate working parts

and prevent corrosion.

Removing Vehicle From Storage

When your vehicle is ready to come out of

storage, do the following:

• Wash your vehicle to remove any dirt

or grease film build-up on window

surfaces.

• Check windshield wipers for any

deterioration.

• Check under the hood for any foreign

material that may have collected

during storage such as mice or squirrel

nests.

• Check the exhaust for any foreign

material that may have collected

during storage.

• Check tire pressures and set tire

inflation per the Tire Label.

• Check brake pedal operation. Drive

your vehicle

15 ft (4.5 m) back and

forth to remove rust build-up.

• Check fluid levels (including coolant,

oil and gas) to make sure there are no

leaks, and fluids are at recommended

levels.

• If you remove the battery, clean the

battery cable ends and check for

damage.

368

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Vehicle Care

Page 432 of 636

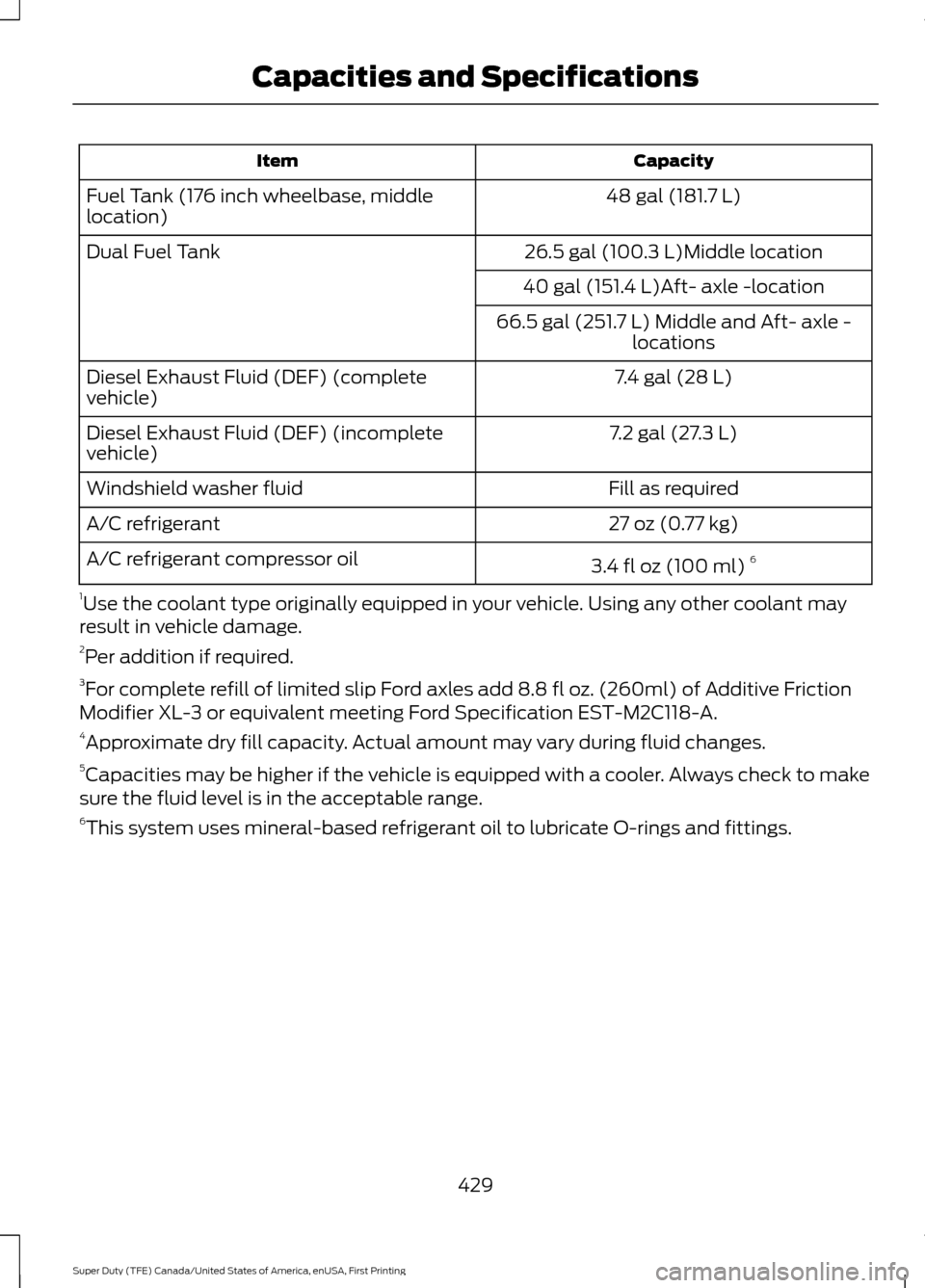

Capacity

Item

48 gal (181.7 L)

Fuel Tank (176 inch wheelbase, middle

location)

26.5 gal (100.3 L)Middle location

Dual Fuel Tank

40 gal (151.4 L)

Aft- axle -location

66.5 gal (251.7 L)

Middle and Aft- axle -

locations

7.4 gal (28 L)

Diesel Exhaust Fluid (DEF) (complete

vehicle)

7.2 gal (27.3 L)

Diesel Exhaust Fluid (DEF) (incomplete

vehicle)

Fill as required

Windshield washer fluid

27 oz (0.77 kg)

A/C refrigerant

3.4 fl oz (100 ml)6

A/C refrigerant compressor oil

1 Use the coolant type originally equipped in your vehicle. Using any other coolant may

result in vehicle damage.

2 Per addition if required.

3 For complete refill of limited slip Ford axles add 8.8 fl oz. (260ml) of Additive Friction

Modifier XL-3 or equivalent meeting Ford Specification EST-M2C118-A.

4 Approximate dry fill capacity. Actual amount may vary during fluid changes.

5 Capacities may be higher if the vehicle is equipped with a cooler. Always check to make

sure the fluid level is in the acceptable range.

6 This system uses mineral-based refrigerant oil to lubricate O-rings and fittings.

429

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 572 of 636

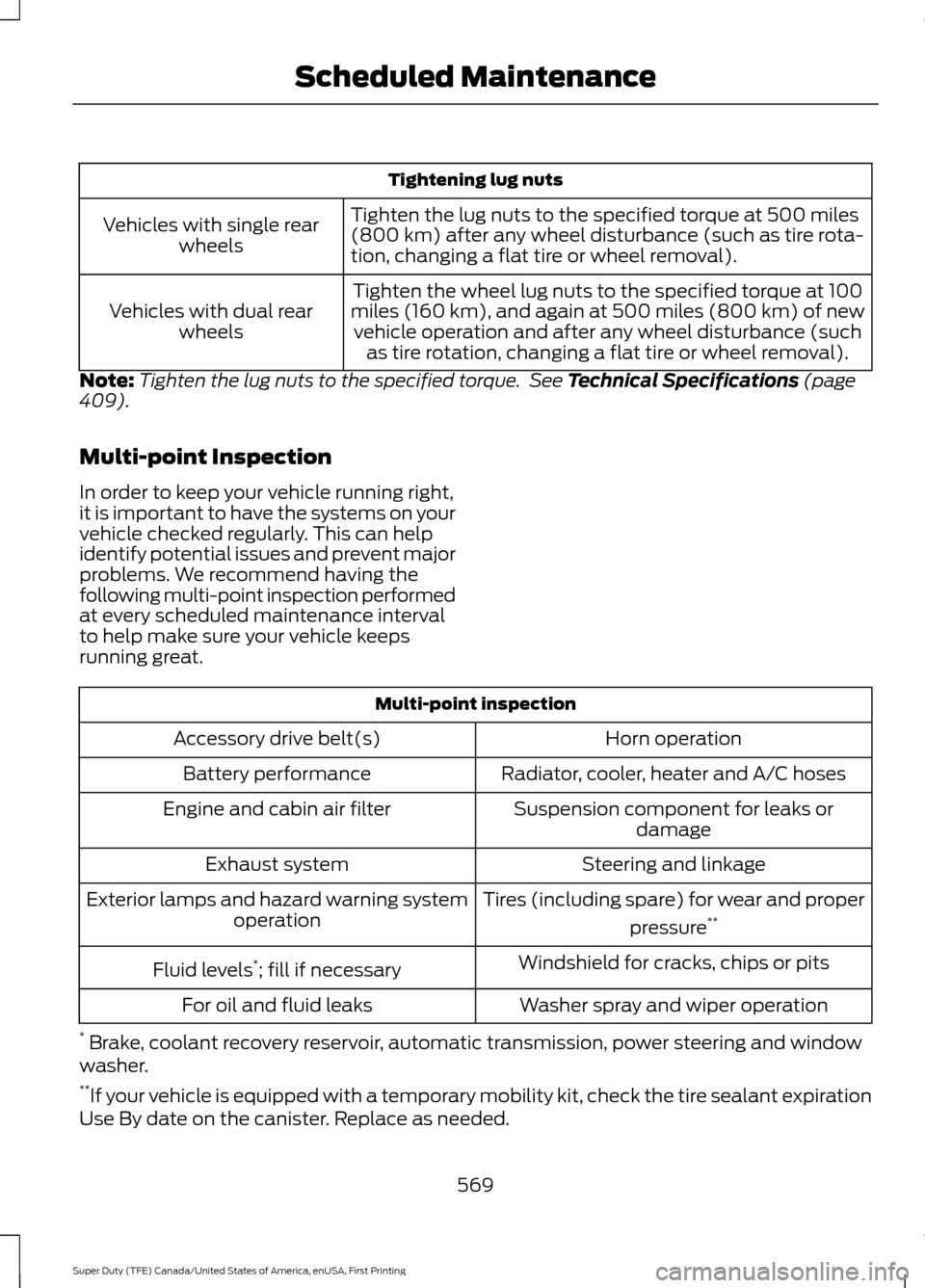

Tightening lug nuts

Tighten the lug nuts to the specified torque at 500 miles

(800 km) after any wheel disturbance (such as tire rota-

tion, changing a flat tire or wheel removal).

Vehicles with single rear

wheels

Tighten the wheel lug nuts to the specified torque at 100

miles (160 km), and again at 500 miles (800 km) of new vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat tire or wheel removal).

Vehicles with dual rear

wheels

Note: Tighten the lug nuts to the specified torque. See Technical Specifications (page

409).

Multi-point Inspection

In order to keep your vehicle running right,

it is important to have the systems on your

vehicle checked regularly. This can help

identify potential issues and prevent major

problems. We recommend having the

following multi-point inspection performed

at every scheduled maintenance interval

to help make sure your vehicle keeps

running great. Multi-point inspection

Horn operation

Accessory drive belt(s)

Radiator, cooler, heater and A/C hoses

Battery performance

Suspension component for leaks ordamage

Engine and cabin air filter

Steering and linkage

Exhaust system

Tires (including spare) for wear and properpressure**

Exterior lamps and hazard warning system

operation

Windshield for cracks, chips or pits

Fluid levels *

; fill if necessary

Washer spray and wiper operation

For oil and fluid leaks

* Brake, coolant recovery reservoir, automatic transmission, power steering and window

washer.

** If your vehicle is equipped with a temporary mobility kit, check the tire sealant expiration

Use By date on the canister. Replace as needed.

569

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Scheduled Maintenance

Page 573 of 636

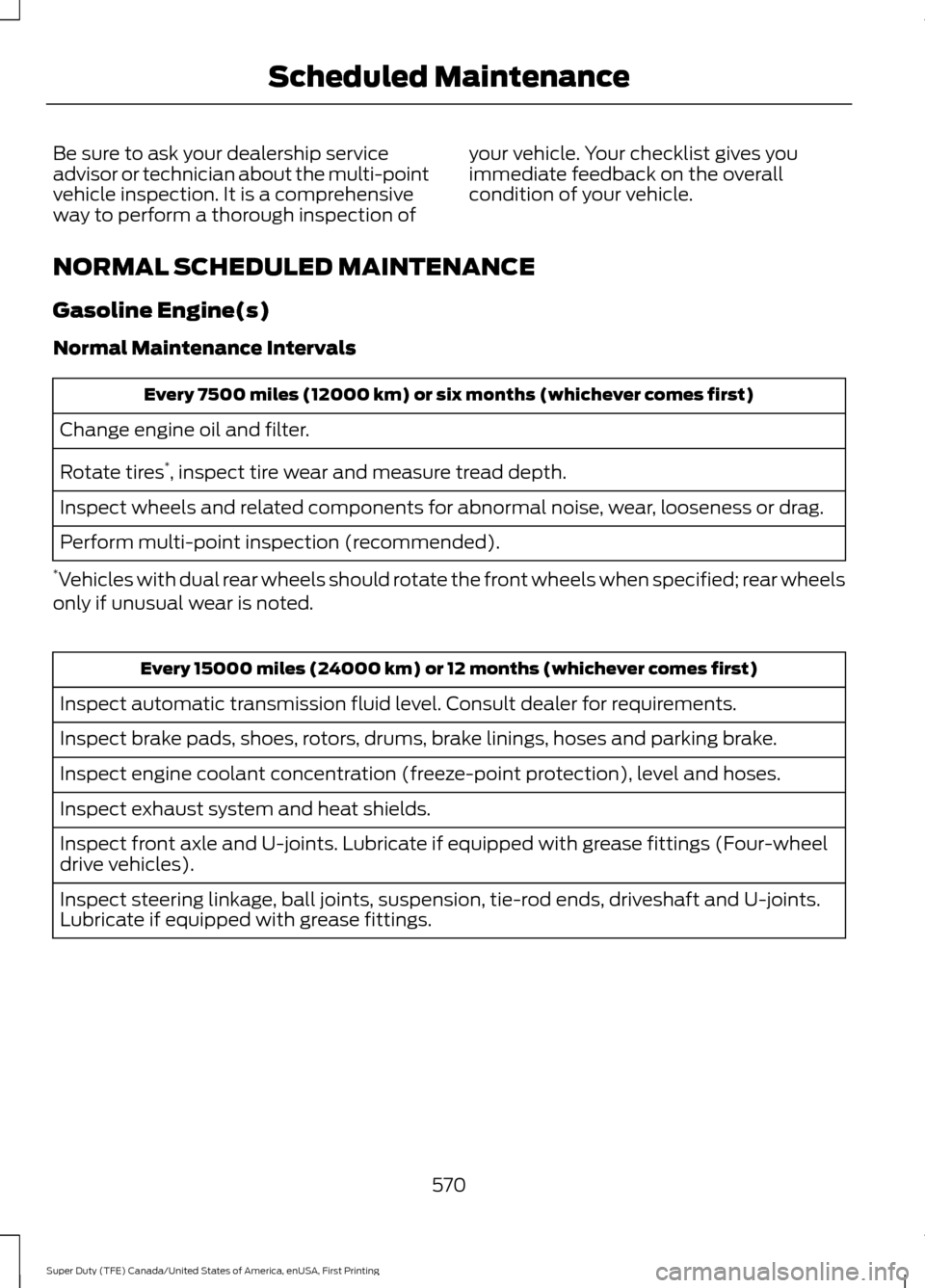

Be sure to ask your dealership service

advisor or technician about the multi-point

vehicle inspection. It is a comprehensive

way to perform a thorough inspection of

your vehicle. Your checklist gives you

immediate feedback on the overall

condition of your vehicle.

NORMAL SCHEDULED MAINTENANCE

Gasoline Engine(s)

Normal Maintenance Intervals Every 7500 miles (12000 km) or six months (whichever comes first)

Change engine oil and filter.

Rotate tires *

, inspect tire wear and measure tread depth.

Inspect wheels and related components for abnormal noise, wear, looseness or drag.

Perform multi-point inspection (recommended).

* Vehicles with dual rear wheels should rotate the front wheels when specified; rear wheels

only if unusual wear is noted. Every 15000 miles (24000 km) or 12 months (whichever comes first)

Inspect automatic transmission fluid level. Consult dealer for requirements.

Inspect brake pads, shoes, rotors, drums, brake linings, hoses and parking brake.

Inspect engine coolant concentration (freeze-point protection), level and hoses.

Inspect exhaust system and heat shields.

Inspect front axle and U-joints. Lubricate if equipped with grease fittings (Four-wheel

drive vehicles).

Inspect steering linkage, ball joints, suspension, tie-rod ends, driveshaft and U-joints.

Lubricate if equipped with grease fittings.

570

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Scheduled Maintenance

Page 576 of 636

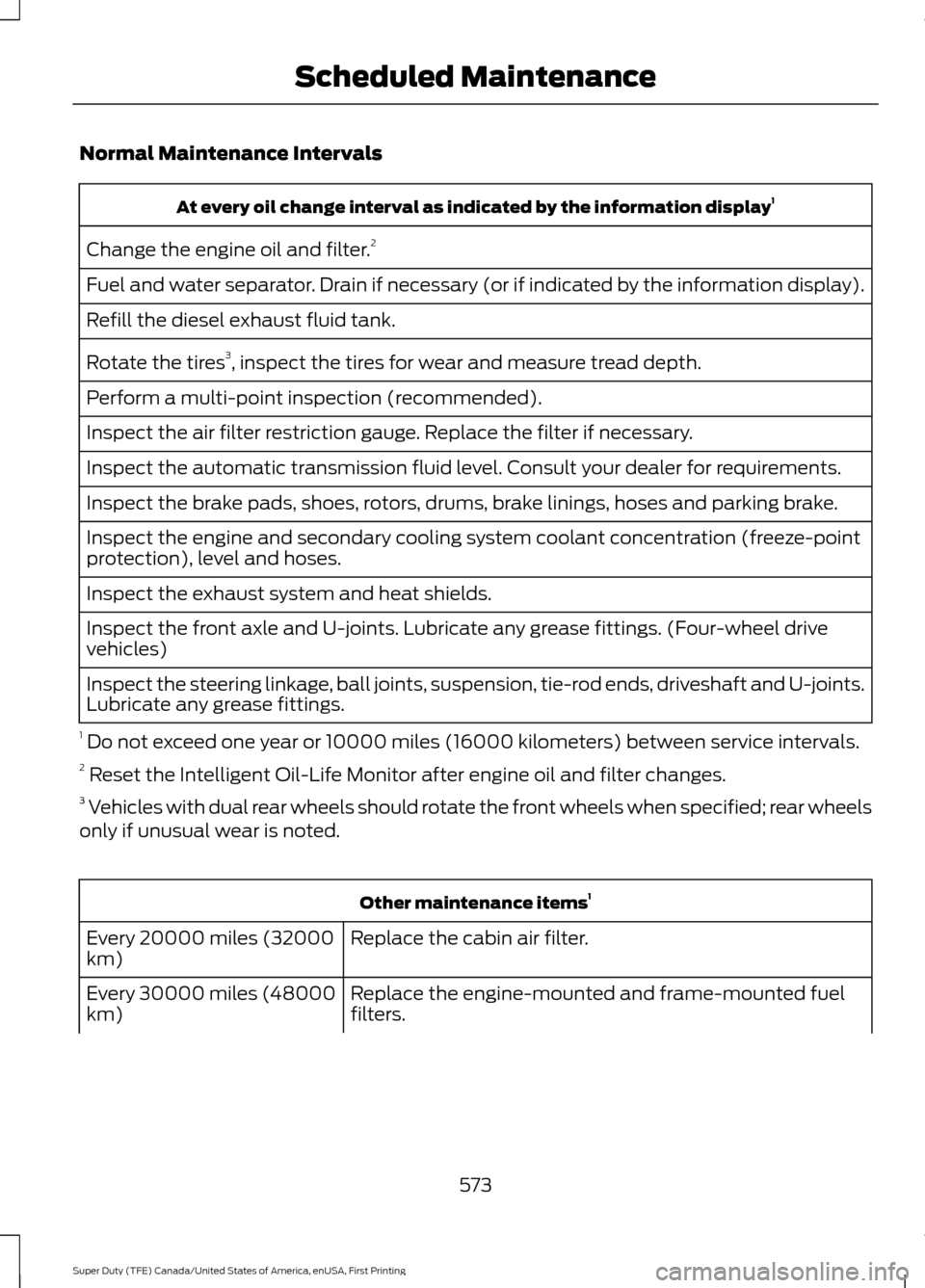

Normal Maintenance Intervals

At every oil change interval as indicated by the information display

1

Change the engine oil and filter. 2

Fuel and water separator. Drain if necessary (or if indicated by the information display).

Refill the diesel exhaust fluid tank.

Rotate the tires 3

, inspect the tires for wear and measure tread depth.

Perform a multi-point inspection (recommended).

Inspect the air filter restriction gauge. Replace the filter if necessary.

Inspect the automatic transmission fluid level. Consult your dealer for requirements.

Inspect the brake pads, shoes, rotors, drums, brake linings, hoses and parking brake.

Inspect the engine and secondary cooling system coolant concentration (freeze-point

protection), level and hoses.

Inspect the exhaust system and heat shields.

Inspect the front axle and U-joints. Lubricate any grease fittings. (Four-wheel drive

vehicles)

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and U-joints.

Lubricate any grease fittings.

1 Do not exceed one year or 10000 miles (16000 kilometers) between service intervals.

2 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes.

3 Vehicles with dual rear wheels should rotate the front wheels when specified; rear wheels

only if unusual wear is noted. Other maintenance items

1

Replace the cabin air filter.

Every 20000 miles (32000

km)

Replace the engine-mounted and frame-mounted fuel

filters.

Every 30000 miles (48000

km)

573

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Scheduled Maintenance

Page 577 of 636

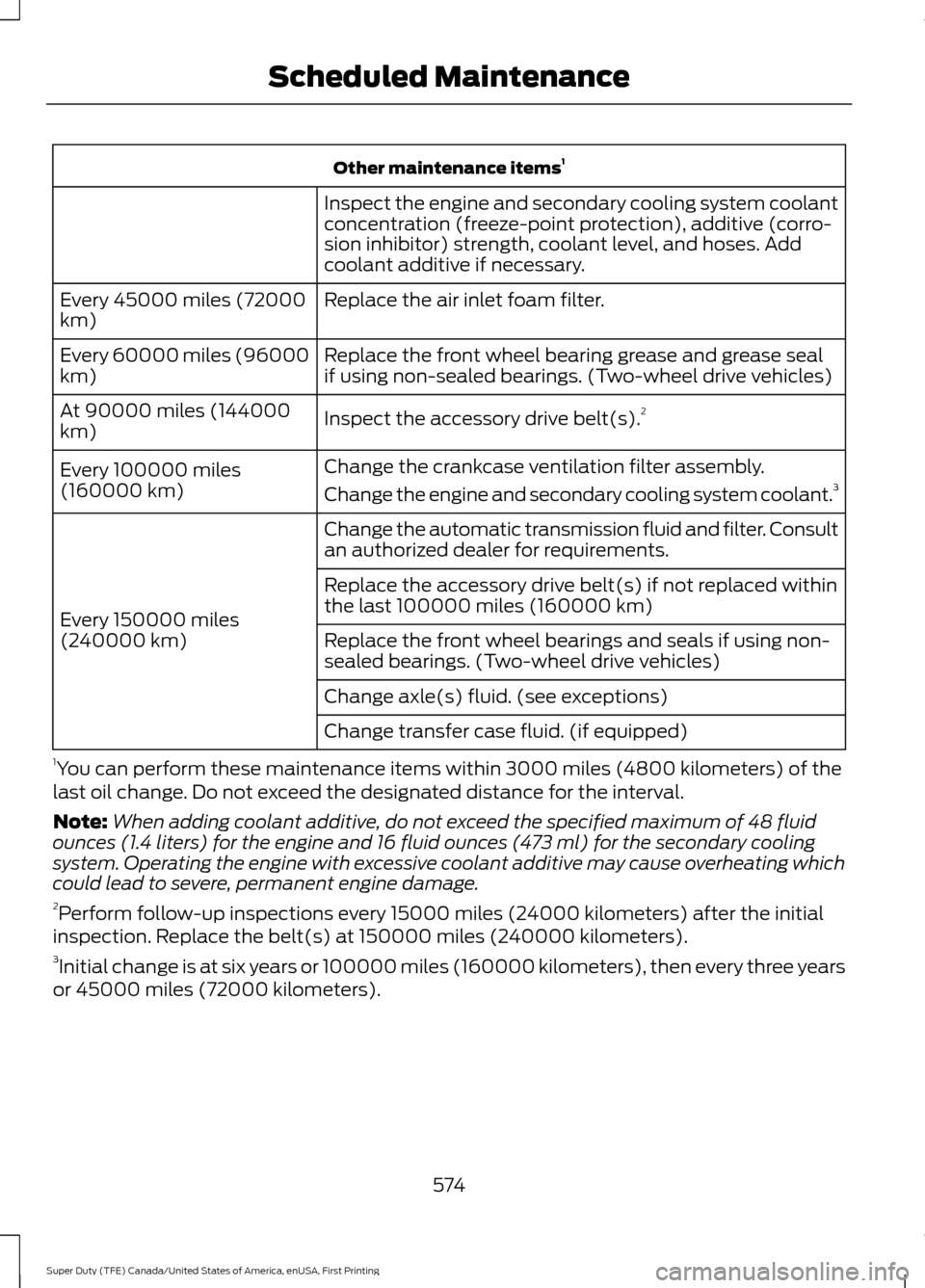

Other maintenance items

1

Inspect the engine and secondary cooling system coolant

concentration (freeze-point protection), additive (corro-

sion inhibitor) strength, coolant level, and hoses. Add

coolant additive if necessary.

Replace the air inlet foam filter.

Every 45000 miles (72000

km)

Replace the front wheel bearing grease and grease seal

if using non-sealed bearings. (Two-wheel drive vehicles)

Every 60000 miles (96000

km)

Inspect the accessory drive belt(s). 2

At 90000 miles (144000

km)

Change the crankcase ventilation filter assembly.

Every 100000 miles

(160000 km) Change the engine and secondary cooling system coolant. 3

Change the automatic transmission fluid and filter. Consult

an authorized dealer for requirements.

Every 150000 miles

(240000 km) Replace the accessory drive belt(s) if not replaced within

the last 100000 miles (160000 km)

Replace the front wheel bearings and seals if using non-

sealed bearings. (Two-wheel drive vehicles)

Change axle(s) fluid. (see exceptions)

Change transfer case fluid. (if equipped)

1 You can perform these maintenance items within 3000 miles (4800 kilometers) of the

last oil change. Do not exceed the designated distance for the interval.

Note: When adding coolant additive, do not exceed the specified maximum of 48 fluid

ounces (1.4 liters) for the engine and 16 fluid ounces (473 ml) for the secondary cooling

system. Operating the engine with excessive coolant additive may cause overheating which

could lead to severe, permanent engine damage.

2 Perform follow-up inspections every 15000 miles (24000 kilometers) after the initial

inspection. Replace the belt(s) at 150000 miles (240000 kilometers).

3 Initial change is at six years or 100000 miles (160000 kilometers), then every three years

or 45000 miles (72000 kilometers).

574

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Scheduled Maintenance