horn FORD SUPER DUTY 2017 4.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2017 4.GPages: 636, PDF Size: 10.56 MB

Page 400 of 636

12.

Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

13. Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label (affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver's seating position)

or Tire Label located on the B-Pillar

or the edge of the driver's door.

Trailer Tire Pressure Monitoring

System (If Equipped)

Note: Additional equipment may be

required for your vehicle to support trailer

tire pressure monitoring. See your authorized

dealer for more information.

Note: The trailer tire pressure monitoring

system is not a substitute for proper tire

maintenance. It is your responsibility to

maintain correct tire pressures at all times.

Note: If a trailer tire is repaired, replaced or

broken down for service, the screw and valve

on the trailer tire pressure sensor should be

replaced. See your authorized dealer for

details. The trailer tire pressure monitoring system

is an added safety feature that allows you

to view your trailer tire pressures through

the information display. See

General

Information (page 111). Tire pressure

sensors are mounted into each tire on your

trailer. The sensors send a message to your

vehicle indicating the current trailer tire

pressure.

If the trailer tire pressure monitoring

system detects that a tire is low, a warning

message appears in the information

display. The trailer tire pressure status

screen in the information display highlights

the tire with a low pressure.

The main function of the trailer tire

pressure monitoring system is to warn you

when your trailer tires need air. It can also

warn you in the event the system is no

longer capable of functioning as intended.

See

Information Messages (page 128).

When a Temporary Spare or New Tire

is Installed

If you have replaced a trailer tire with a new

or spare tire, a warning message appears

and pressure readings are no longer

displayed for that tire.

To restore the full function of the trailer

tire pressure monitoring system:

• Have the damaged wheel and tire

assembly repaired and remounted to

your trailer.

• Install the trailer tire pressure

monitoring sensor into the new wheel

and tire assembly.

• Perform the trailer tire pressure

monitoring system reset procedure.

Trailer Tire Pressure Monitoring

System Reset Procedure

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation, or when a new trailer tire

pressure sensor is installed into a trailer tire.

397

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Wheels and TiresE235807

Page 572 of 636

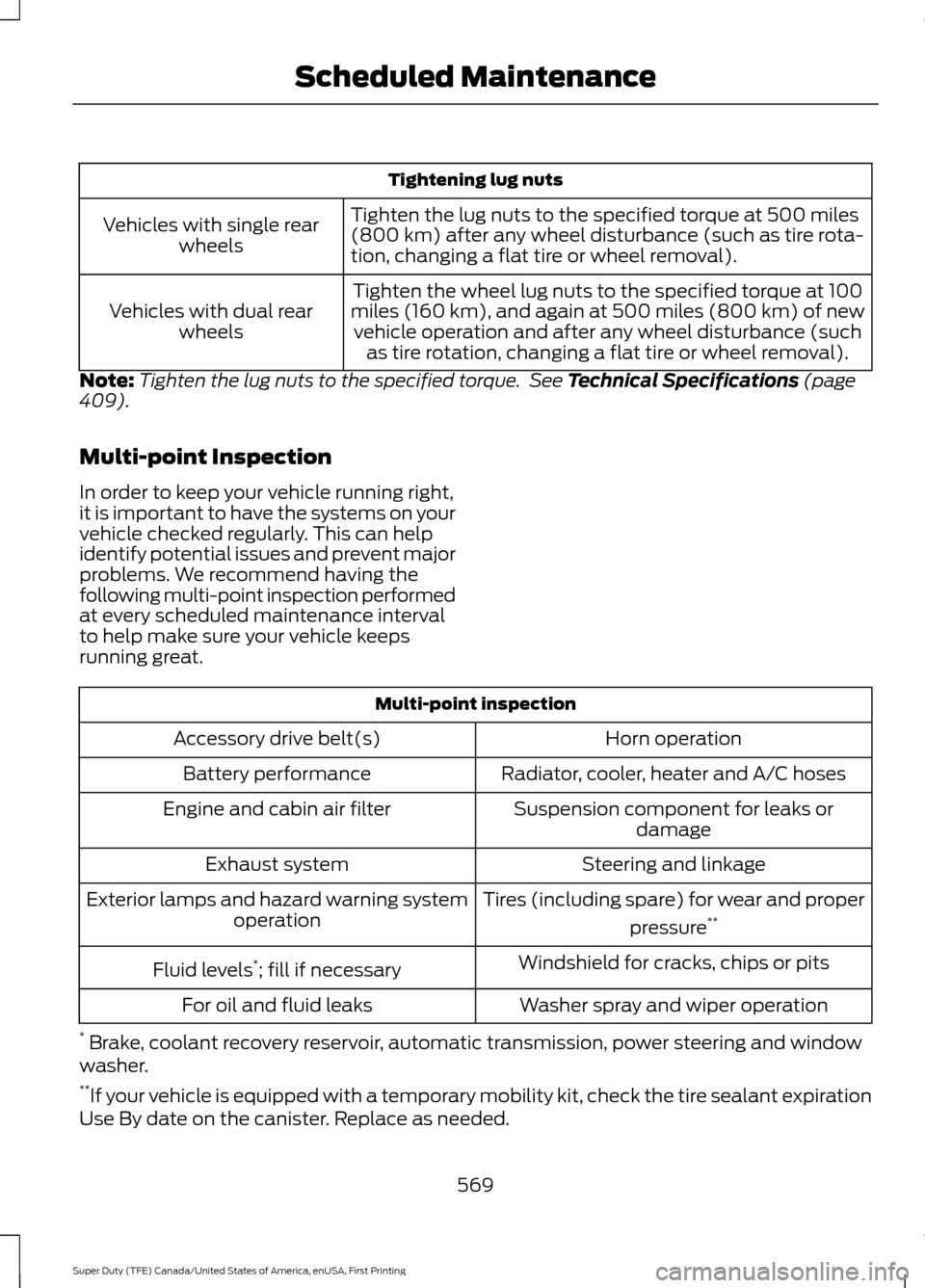

Tightening lug nuts

Tighten the lug nuts to the specified torque at 500 miles

(800 km) after any wheel disturbance (such as tire rota-

tion, changing a flat tire or wheel removal).

Vehicles with single rear

wheels

Tighten the wheel lug nuts to the specified torque at 100

miles (160 km), and again at 500 miles (800 km) of new vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat tire or wheel removal).

Vehicles with dual rear

wheels

Note: Tighten the lug nuts to the specified torque. See Technical Specifications (page

409).

Multi-point Inspection

In order to keep your vehicle running right,

it is important to have the systems on your

vehicle checked regularly. This can help

identify potential issues and prevent major

problems. We recommend having the

following multi-point inspection performed

at every scheduled maintenance interval

to help make sure your vehicle keeps

running great. Multi-point inspection

Horn operation

Accessory drive belt(s)

Radiator, cooler, heater and A/C hoses

Battery performance

Suspension component for leaks ordamage

Engine and cabin air filter

Steering and linkage

Exhaust system

Tires (including spare) for wear and properpressure**

Exterior lamps and hazard warning system

operation

Windshield for cracks, chips or pits

Fluid levels *

; fill if necessary

Washer spray and wiper operation

For oil and fluid leaks

* Brake, coolant recovery reservoir, automatic transmission, power steering and window

washer.

** If your vehicle is equipped with a temporary mobility kit, check the tire sealant expiration

Use By date on the canister. Replace as needed.

569

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Scheduled Maintenance