FORD SUPER DUTY 2017 4.G Owners Manual

Manufacturer: FORD, Model Year: 2017, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2017 4.GPages: 636, PDF Size: 10.56 MB

Page 411 of 636

Stowing the Flat or Spare Tire

Note:

Failure to follow spare tire stowage

instructions may result in failure of cable or

loss of spare tire.

Note: If you are stowing a tire that requires

reattaching it to the vehicle with a tether,

perform these steps first, then proceed with

the following steps.

1. Place the tire on end with the valve stem facing toward the front of the

vehicle.

2. Place the tether into the bolt holes in the wheel and attach the lug nut using

the lug wrench. 3. Lay the tire on the ground with the

valve stem facing up.

4. Slide the wheel partially under the vehicle and install the retainer through

the wheel center. Pull on the cable to

align the components at the end of the

cable.

5. Turn the jack handle clockwise until the tire is raised to its stowed position

underneath the vehicle. The effort to

turn the jack handle increases

significantly and the spare tire carrier

ratchets or slips when the tire is raised

to the maximum tightness. Tighten to

the best of your ability, to the point

where the ratchet/slip occurs, if

possible. The spare tire carrier will not

allow you to overtighten. If the spare

tire carrier ratchets or slips with little

effort, take the vehicle to your

authorized dealer for assistance at your

earliest convenience.

6. Check that the tire lies flat against the frame and is properly tightened. Try to

push or pull, then turn the tire to be

sure it will not move. Loosen and

retighten, if necessary. Failure to

properly stow the spare tire may result

in failure of the winch cable and loss

of the tire.

408

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Wheels and TiresE162825 E162826 E162800

Page 412 of 636

7.

Repeat this tightness check procedure

when servicing the spare tire pressure

(every six months, per scheduled

maintenance information), or at any

time that the spare tire is disturbed through service of other components.

8. If removed, install the spare tire lock into the bumper drive tube with the

spare tire lock key and jack handle.

TECHNICAL SPECIFICATIONS

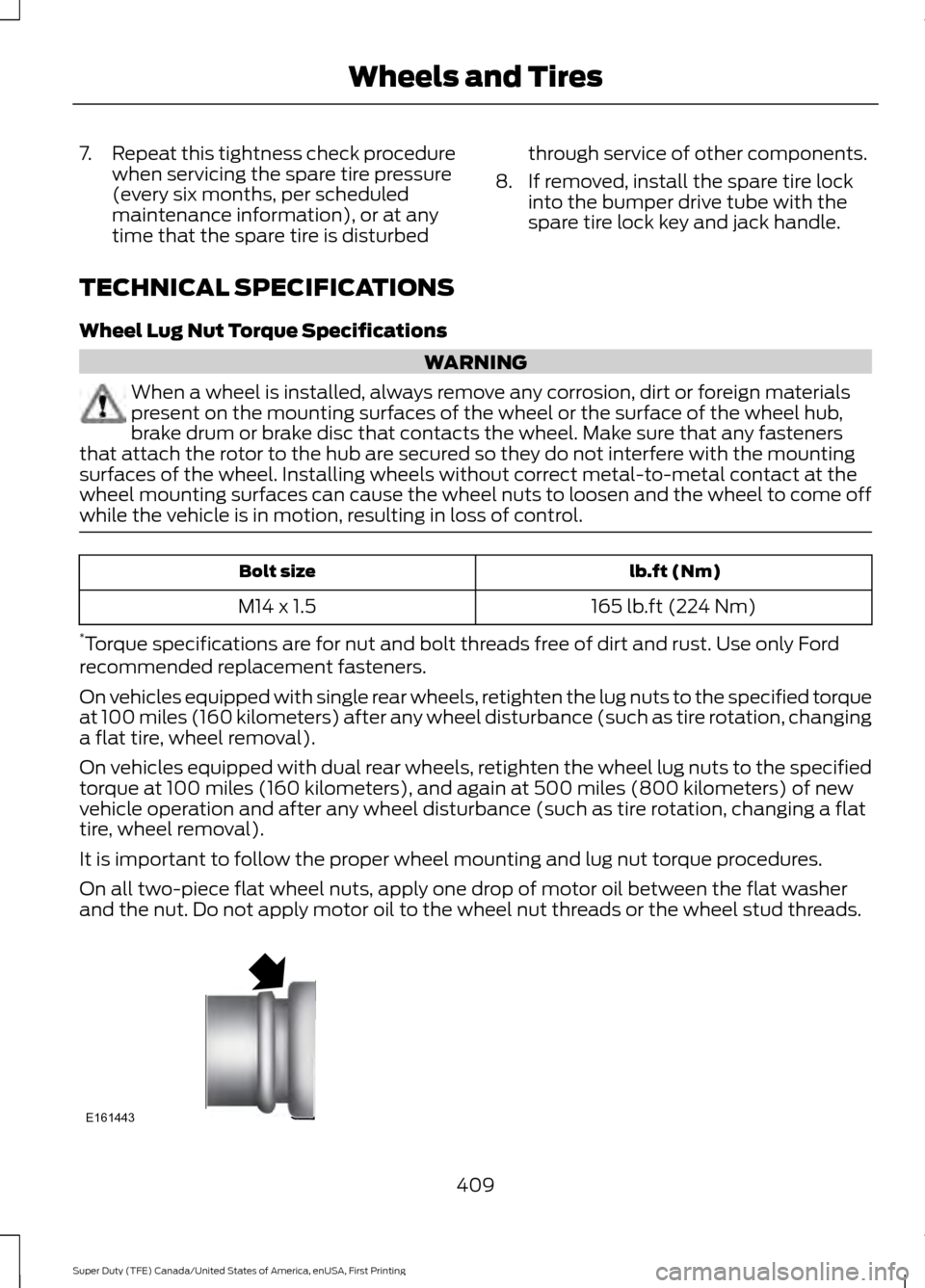

Wheel Lug Nut Torque Specifications WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materials

present on the mounting surfaces of the wheel or the surface of the wheel hub,

brake drum or brake disc that contacts the wheel. Make sure that any fasteners

that attach the rotor to the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off

while the vehicle is in motion, resulting in loss of control. lb.ft (Nm)

Bolt size

165 lb.ft (224 Nm)

M14 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust. Use only Ford

recommended replacement fasteners.

On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque

at 100 miles (160 kilometers) after any wheel disturbance (such as tire rotation, changing

a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified

torque at 100 miles (160 kilometers), and again at 500 miles (800 kilometers) of new

vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat

tire, wheel removal).

It is important to follow the proper wheel mounting and lug nut torque procedures.

On all two-piece flat wheel nuts, apply one drop of motor oil between the flat washer

and the nut. Do not apply motor oil to the wheel nut threads or the wheel stud threads. 409

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Wheels and TiresE161443

Page 413 of 636

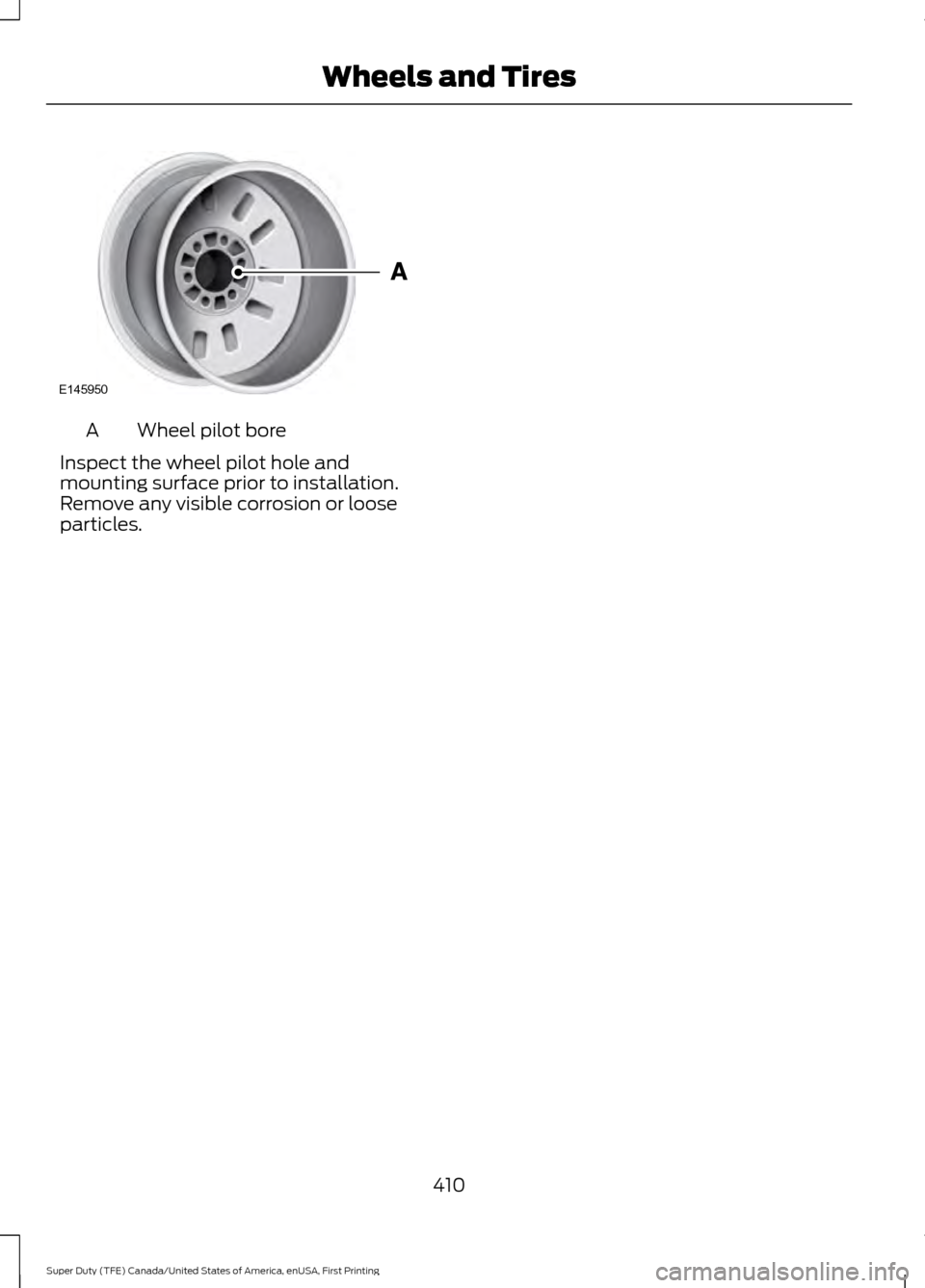

Wheel pilot bore

A

Inspect the wheel pilot hole and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

410

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Wheels and TiresE145950

Page 414 of 636

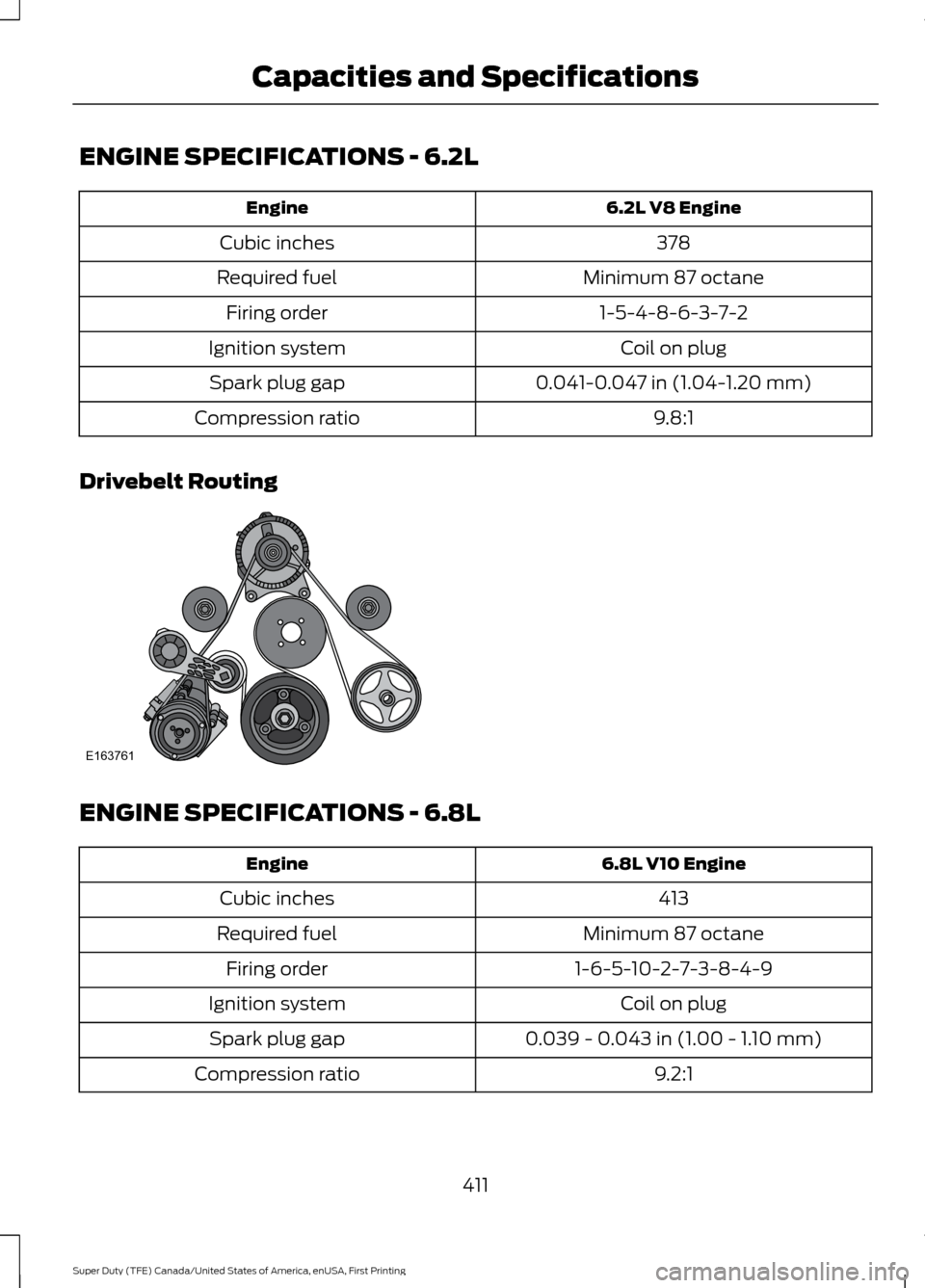

ENGINE SPECIFICATIONS - 6.2L

6.2L V8 Engine

Engine

378

Cubic inches

Minimum 87 octane

Required fuel

1-5-4-8-6-3-7-2

Firing order

Coil on plug

Ignition system

0.041-0.047 in (1.04-1.20 mm)

Spark plug gap

9.8:1

Compression ratio

Drivebelt Routing ENGINE SPECIFICATIONS - 6.8L

6.8L V10 Engine

Engine

413

Cubic inches

Minimum 87 octane

Required fuel

1-6-5-10-2-7-3-8-4-9

Firing order

Coil on plug

Ignition system

0.039 - 0.043 in (1.00 - 1.10 mm)

Spark plug gap

9.2:1

Compression ratio

411

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and SpecificationsE163761

Page 415 of 636

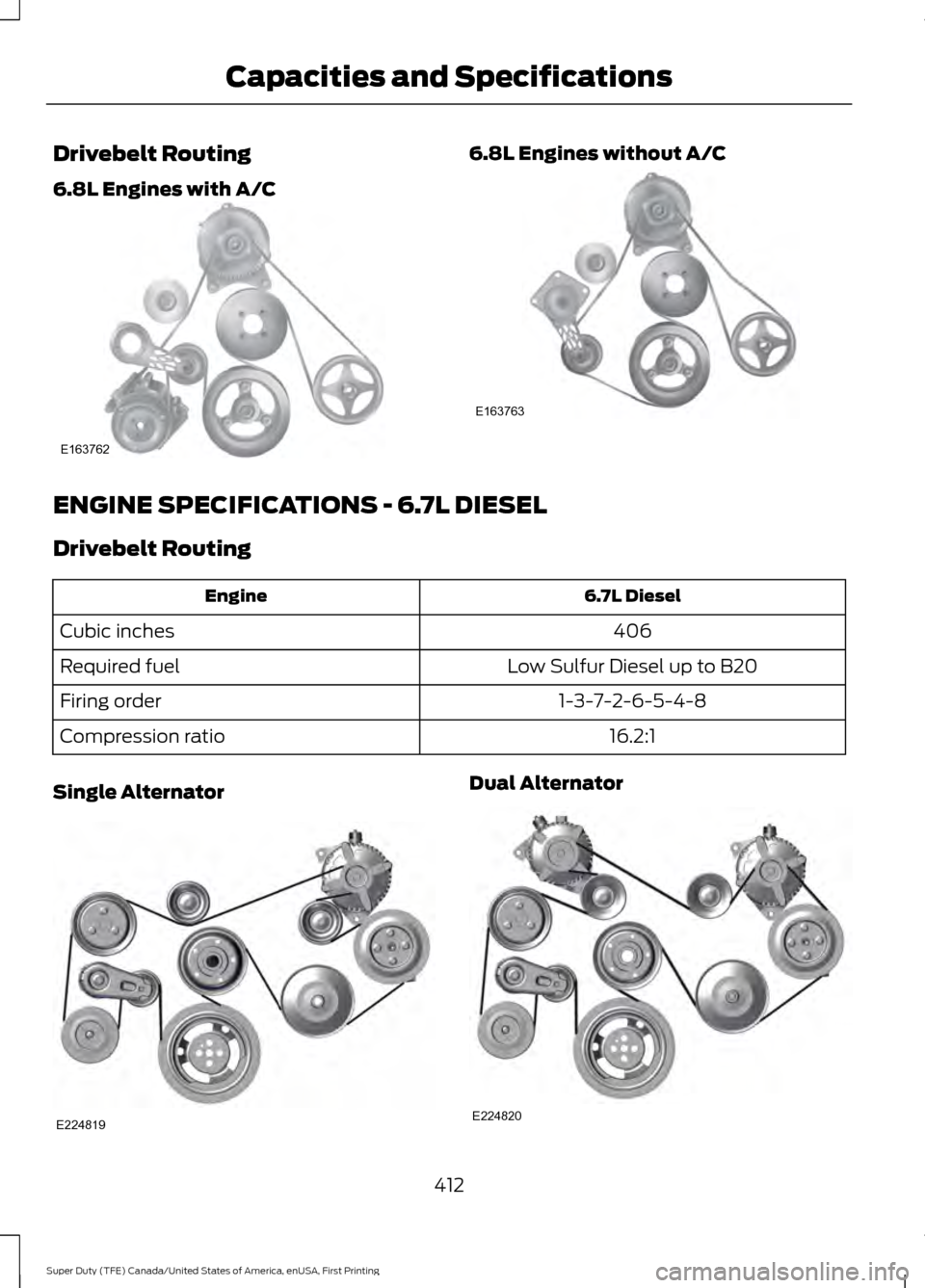

Drivebelt Routing

6.8L Engines with A/C 6.8L Engines without A/C

ENGINE SPECIFICATIONS - 6.7L DIESEL

Drivebelt Routing

6.7L Diesel

Engine

406

Cubic inches

Low Sulfur Diesel up to B20

Required fuel

1-3-7-2-6-5-4-8

Firing order

16.2:1

Compression ratio

Single Alternator Dual Alternator

412

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and SpecificationsE163762 E163763 E224819 E224820

Page 416 of 636

MOTORCRAFT PARTS - 6.2L

Motorcraft Part number

Component

FA-1883

Air filter element

FL-820-S

Oil filter

BXT-65-650

Battery (XL)

BXT-65-750

Battery (all except XL)

SP-526

Spark plugs-platinum

WW-2242

Windshield wiper blade

FT-187

Transmission fluid filter

FP-79

Cabin air filter

For scheduled maintenance, we recommend Motorcraft® replacement parts available

at your Ford dealer or at fordparts.com. These parts meet or exceed Ford Motor Company ’s

specifications and are engineered for your vehicle. Use of other parts may impact vehicle

performance, emissions and durability. Your warranty may be void for any damage related

to use of other parts.

If a Motorcraft® oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the

appropriate intervals. See Scheduled Maintenance (page 567).

413

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 417 of 636

MOTORCRAFT PARTS - 6.8L

Motorcraft Part number

Component

FA-1883

Air filter element.

FL-820-S

Oil filter.

BXT-65-650

Battery (XL).

BXT-65-750

Battery (all except XL).

SP-509

Spark plugs-platinum.

WW-2242

Windshield wiper blade.

FP-79

Cabin air filter.

For scheduled maintenance, we recommend Motorcraft® replacement parts available

at your Ford dealer or at fordparts.com. These parts meet or exceed Ford Motor Company ’s

specifications and are engineered for your vehicle. Use of other parts may impact vehicle

performance, emissions and durability. Your warranty may be void for any damage related

to use of other parts.

If a Motorcraft® oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36/USC-D.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the

appropriate intervals. See Normal Scheduled Maintenance (page 570).

414

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 418 of 636

MOTORCRAFT PARTS - 6.7L DIESEL

Motorcraft Part number

Component

FL-2051S

Engine oil filter

FA-1909

Foam pre-filter

FA-1902

Air filter

FG-1147

Fuel filter

BXT-65-750

Battery (Two)

WW-2242

Windshield wiper blade

FP-79

Cabin air filter

FT-187

Transmission filter

For scheduled maintenance, we recommend Motorcraft® replacement parts available

at your Ford dealer or at fordparts.com. These parts meet or exceed Ford Motor Company ’s

specifications and are engineered for your vehicle. Use of other parts may impact vehicle

performance, emissions and durability. Your warranty may be void for any damage related

to use of other parts.

If a Motorcraft® oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36.

415

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 419 of 636

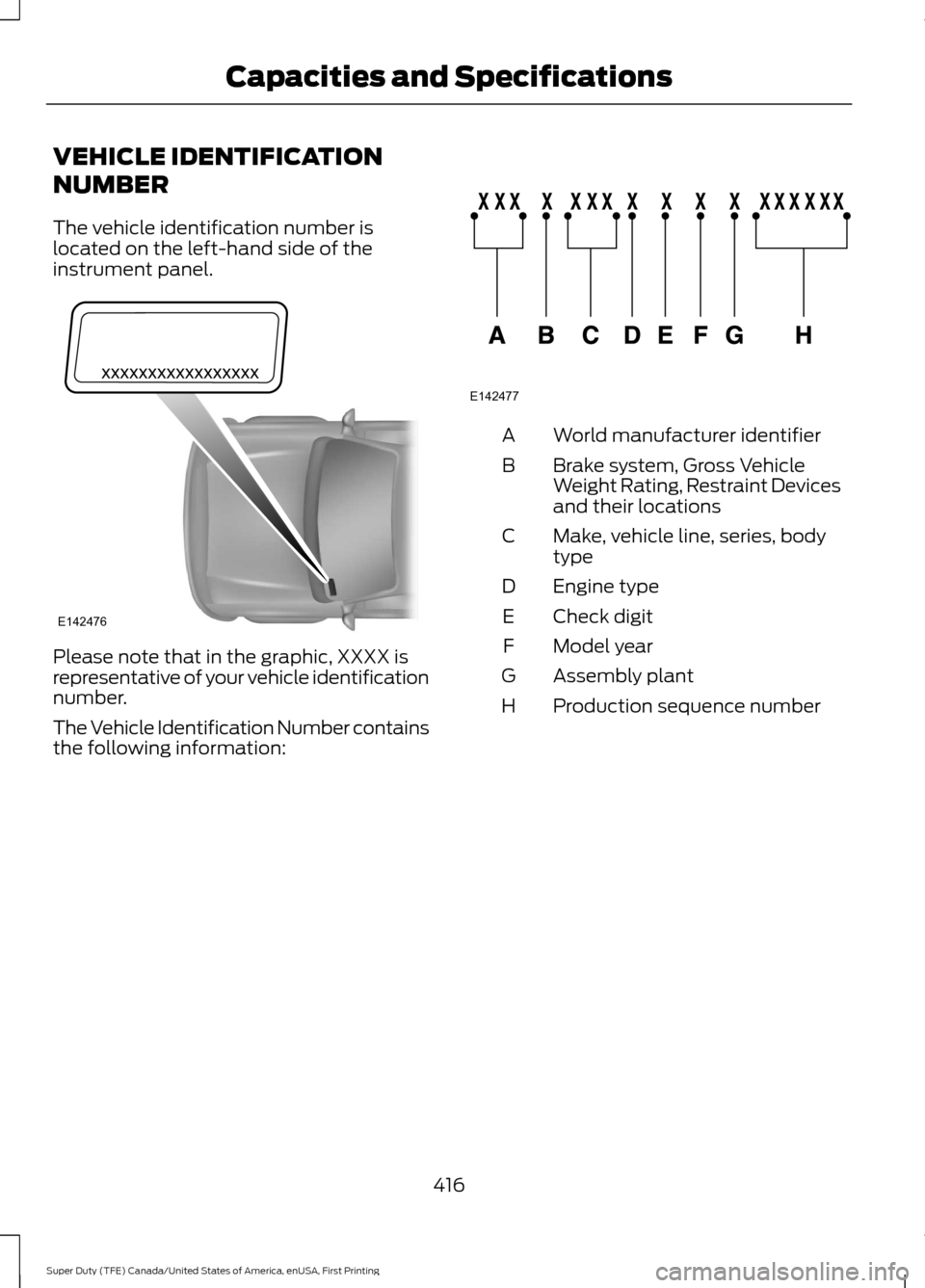

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number is

located on the left-hand side of the

instrument panel.

Please note that in the graphic, XXXX is

representative of your vehicle identification

number.

The Vehicle Identification Number contains

the following information: World manufacturer identifier

A

Brake system, Gross Vehicle

Weight Rating, Restraint Devices

and their locations

B

Make, vehicle line, series, body

type

C

Engine type

D

Check digit

E

Model year

F

Assembly plant

G

Production sequence number

H

416

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and SpecificationsE142476 E142477

Page 420 of 636

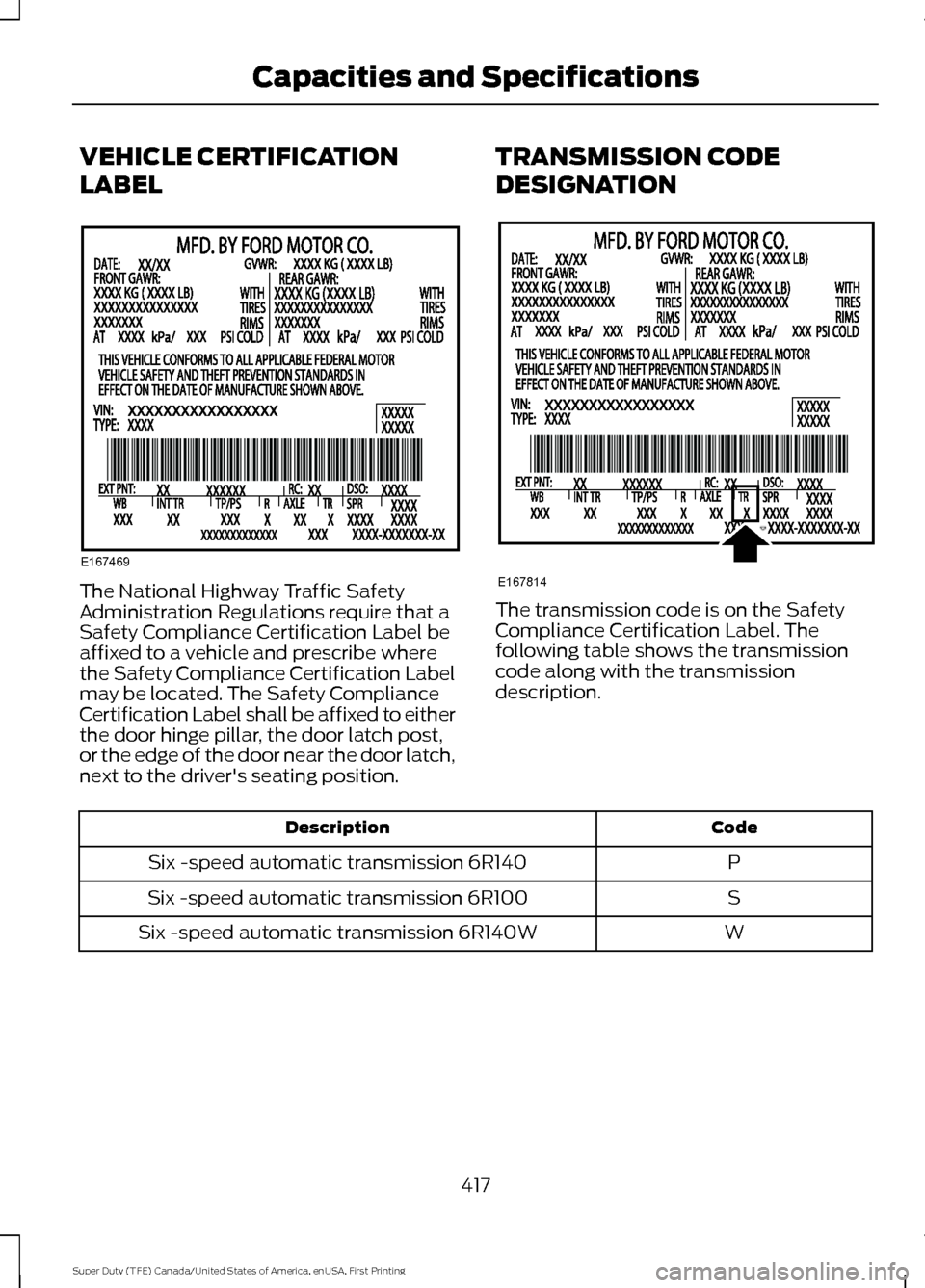

VEHICLE CERTIFICATION

LABEL

The National Highway Traffic Safety

Administration Regulations require that a

Safety Compliance Certification Label be

affixed to a vehicle and prescribe where

the Safety Compliance Certification Label

may be located. The Safety Compliance

Certification Label shall be affixed to either

the door hinge pillar, the door latch post,

or the edge of the door near the door latch,

next to the driver's seating position.

TRANSMISSION CODE

DESIGNATION The transmission code is on the Safety

Compliance Certification Label. The

following table shows the transmission

code along with the transmission

description.

Code

Description

P

Six -speed automatic transmission 6R140

S

Six -speed automatic transmission 6R100

W

Six -speed automatic transmission 6R140W

417

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Capacities and SpecificationsE167469 E167814