warning light FORD SUPER DUTY 2017 4.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2017 4.GPages: 636, PDF Size: 10.56 MB

Page 286 of 636

The active guidelines fade in and out

depending on the steering wheel position.

The active guidelines are not shown when

the steering wheel position is straight.

Always use caution while reversing.

Objects in the red zone are closest to your

vehicle and objects in the green zone are

farther away. Objects are getting closer to

your vehicle as they move from the green

zone to the yellow or red zones. Use the

side view mirrors and rear view mirror to

get better coverage on both sides and rear

of your vehicle.

Refer to the Rear View Camera section for

additional information. See Rear View

Camera (page 232).

Hitches

Note: On pick-up trucks, the trailer hitch

provided on this vehicle enhances crash

protection for the fuel system. Do not

remove!

Note: Do not cut, drill, weld or modify trailer

hitches. Modifying trailer hitches can reduce

hitch rating.

Do not use a hitch that either clamps onto

the bumper or attaches to the axle. You

must distribute the load in your trailer so

that 10-15% for conventional towing or

15-25% for fifth wheel towing of the total

weight of the trailer is on the tongue.

Hitch components (If Equipped)

The following components will be included

in certain vehicles.

• A 5/8 inch hitch pin rated to tow up to

21,000 lbs.

• A 3 inch drawbar.

• A hitch pin sleeve to be used when

mounting the 3 inch drawbar.

• A clevis pin to help keep the hitch pin

in place. Weight-distributing Hitches WARNING

Do not adjust the spring bars so that

your vehicle's rear bumper is higher

than before attaching the trailer.

Doing so will defeat the function of the

weight-distributing hitch, which may cause

unpredictable handling, and could result

in serious personal injury. When hooking-up a trailer using a

weight-distributing hitch, always use the

following procedure:

1. Park the loaded vehicle, without the

trailer, on a level surface.

2. Measure the height to the top of your vehicle's front wheel opening on the

fender. This is H1.

3. Attach the loaded trailer to your vehicle

without the weight-distributing bars

connected.

4. Measure the height to the top of your vehicle's front wheel opening on the

fender a second time. This is H2.

5. Install and adjust the tension in the weight-distributing bars so that the

height of your vehicle's front wheel

opening on the fender is approximately

halfway between H1 and H2.

6. Check that the trailer is level or slightly

nose down toward your vehicle. If not,

adjust the ball height accordingly and

repeat Steps 2-6.

283

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Towing

Page 287 of 636

Once the trailer is level or slightly nose

down toward the vehicle:

•

Lock the bar tension adjuster in place.

• Check that the trailer tongue securely

attaches and locks onto the hitch.

• Install safety chains, lighting, and trailer

brake controls as required by law or the

trailer manufacturer.

Fifth-wheel Trailer Hitch (If Equipped)

Note: The mounting pads in the bed are

specifically designed for certain fifth-wheel

trailer hitches and gooseneck ball hitches.

Do not use these mounting pads for other

purposes.

Note: Contact an authorized dealer to

purchase gooseneck and fifth-wheel hitches

that are compatible with your vehicle.

Your vehicle may be equipped with a

fifth-wheel prep package. This package

enables your vehicle to accept certain

fifth-wheel trailer hitches and gooseneck

ball hitches. The fifth-wheel trailer hitch

attaches to the four mounting pads in the

pick-up bed. An optional 7-pin trailer wiring

connector may be in the bed as well. The

gooseneck ball hitch is a separate

mounting pad from the fifth-wheel hitch,

located in the center of the bed.

Shorter pick-up boxes, such as the 6½-foot

box on the F-250 and F-350, provide less

clearance between the cab and the

fifth-wheel and gooseneck trailer

compared to longer box pick-ups, such as

an 8-foot box on the F-250 or F-350. When

selecting a trailer and tow vehicle, it is

critical to check that this combination

provides clearance between the front of

the trailer and tow vehicle for turns up to

90 degrees. Failure to follow this recommendation could result in the trailer

contacting the cab of the tow vehicle

during tight turns that are typical during

low-speed parking and turning maneuvers.

This contact could result in damage to the

trailer and tow vehicle.

Safety Chains

Note:

Do not attach safety chains to the

bumper.

Always connect the safety chains to the

frame or hook retainers of your vehicle

hitch.

To connect the safety chains, cross the

chains under the trailer tongue and allow

enough slack for turning tight corners. Do

not allow the chains to drag on the ground.

Trailer Brakes WARNING

Do not connect a trailer's hydraulic

brake system directly to your

vehicle's brake system. Your vehicle

may not have enough braking power and

your chances of having a collision greatly

increase. Electric brakes and manual, automatic or

surge-type trailer brakes are safe if you

install them properly and adjust them to

the manufacturer's specifications. The

trailer brakes must meet local and federal

regulations.

The rating for the tow vehicle's braking

system operation is at the gross vehicle

weight rating, not the gross combined

weight rating.

Separate functioning brake systems

are required for safe control of towed

vehicles and trailers weighing more

than 1500 pounds (680 kilograms)

when loaded.

284

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Towing

Page 288 of 636

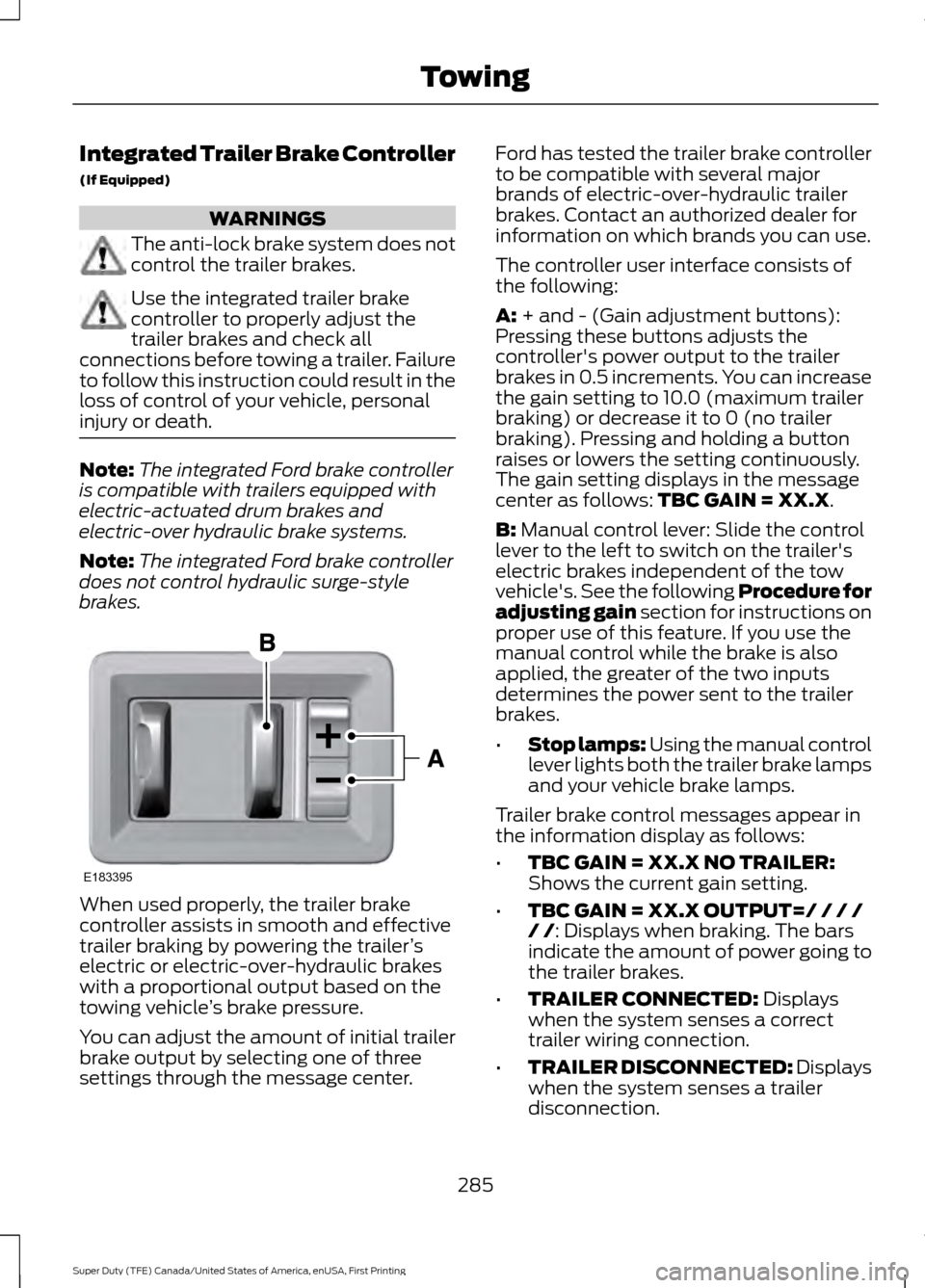

Integrated Trailer Brake Controller

(If Equipped)

WARNINGS

The anti-lock brake system does not

control the trailer brakes.

Use the integrated trailer brake

controller to properly adjust the

trailer brakes and check all

connections before towing a trailer. Failure

to follow this instruction could result in the

loss of control of your vehicle, personal

injury or death. Note:

The integrated Ford brake controller

is compatible with trailers equipped with

electric-actuated drum brakes and

electric-over hydraulic brake systems.

Note: The integrated Ford brake controller

does not control hydraulic surge-style

brakes. When used properly, the trailer brake

controller assists in smooth and effective

trailer braking by powering the trailer

’s

electric or electric-over-hydraulic brakes

with a proportional output based on the

towing vehicle ’s brake pressure.

You can adjust the amount of initial trailer

brake output by selecting one of three

settings through the message center. Ford has tested the trailer brake controller

to be compatible with several major

brands of electric-over-hydraulic trailer

brakes. Contact an authorized dealer for

information on which brands you can use.

The controller user interface consists of

the following:

A: + and - (Gain adjustment buttons):

Pressing these buttons adjusts the

controller's power output to the trailer

brakes in 0.5 increments. You can increase

the gain setting to 10.0 (maximum trailer

braking) or decrease it to 0 (no trailer

braking). Pressing and holding a button

raises or lowers the setting continuously.

The gain setting displays in the message

center as follows:

TBC GAIN = XX.X.

B:

Manual control lever: Slide the control

lever to the left to switch on the trailer's

electric brakes independent of the tow

vehicle's. See the following Procedure for

adjusting gain section for instructions on

proper use of this feature. If you use the

manual control while the brake is also

applied, the greater of the two inputs

determines the power sent to the trailer

brakes.

• Stop lamps: Using the manual control

lever lights both the trailer brake lamps

and your vehicle brake lamps.

Trailer brake control messages appear in

the information display as follows:

• TBC GAIN = XX.X NO TRAILER:

Shows the current gain setting.

• TBC GAIN = XX.X OUTPUT=/ / / /

/ /

: Displays when braking. The bars

indicate the amount of power going to

the trailer brakes.

• TRAILER CONNECTED:

Displays

when the system senses a correct

trailer wiring connection.

• TRAILER DISCONNECTED: Displays

when the system senses a trailer

disconnection.

285

Super Duty (TFE) Canada/United States of America, enUSA, First Printing TowingE183395

Page 290 of 636

If this message displays, with no trailer

connected, the problem is with your vehicle

wiring or trailer brake controller. Contact

an authorized dealer.

If the message only displays with a trailer

connected, the problem is with the trailer

wiring. Consult your trailer dealer for

assistance. This can be a short to ground

(such as a chaffed wire), short to voltage

(such as a pulled pin on trailer emergency

breakaway battery) or the trailer brakes

may be drawing too much current.

Points to Remember

Note:

Do not attempt removal of the trailer

brake controller without consulting the

Workshop Manual. Damage to the unit may

result.

• Adjust gain setting before using the

trailer brake controller.

• Adjust gain setting, using the procedure

above, whenever road, weather, trailer

or vehicle loading conditions change

from when the gain was initially set.

• Only use the manual control lever for

proper adjustment of the gain during

trailer setup. Misuse, such as

application during trailer sway, could

cause instability of trailer or tow

vehicle.

• Avoid towing in adverse weather

conditions. The trailer brake controller

does not provide anti-lock control of

the trailer wheels. Trailer wheels can

lock up on slippery surfaces, resulting

in reduced stability of trailer and tow

vehicle.

• The trailer brake controller is equipped

with a feature that reduces output at

vehicle speeds below 11 mph (18 km/h)

so trailer and vehicle braking is not jerky

or harsh. This feature is only active

when applying the brakes using your

vehicle's brake pedal, not the

controller. •

The controller interacts with the brake

control system and powertrain control

system of your vehicle to provide the

best performance on different road

conditions.

• Your vehicle's brake system and the

trailer brake system work

independently of each other. Changing

the gain setting on the controller does

not affect the operation of your

vehicle's brakes.

• When you switch the engine off, the

controller output is disabled and the

display and module shut down.

Trailer Lamps WARNING

Never connect any trailer lamp wiring

to the vehicle's tail lamp wiring; this

may damage the electrical system

resulting in fire. Contact your authorized

dealer as soon as possible for assistance

in proper trailer tow wiring installation.

Additional electrical equipment may be

required. Trailer lamps are required on most towed

vehicles. Make sure all running lights, brake

lights, turn signals and hazard lights are

working.

Before Towing a Trailer

Practice turning, stopping and backing up

to get the feel of your vehicle-trailer

combination before starting on a trip.

When turning, make wider turns so the

trailer wheels clear curbs and other

obstacles.

287

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Towing

Page 294 of 636

•

Fuel economy may decrease with lower

temperatures during the first 8– 10

miles (12 –16 kilometers) of driving.

• Driving on flat terrain offers improved

fuel economy as compared to driving

on hilly terrain.

• Transmissions give their best fuel

economy when operated in the top

cruise gear and with steady pressure

on the gas pedal.

• Four-wheel-drive operation (if

equipped) is less fuel efficient than

two-wheel-drive operation.

• Close the windows for high-speed

driving.

DRIVING THROUGH WATER WARNING

Do not drive through flowing or deep

water as you may lose control of your

vehicle.

Note:

Driving through standing water can

cause vehicle damage.

Note: Engine damage can occur if water

enters the air filter.

Before driving through standing water,

check the depth. Never drive through water

that is higher than the bottom of the wheel

hubs. When driving through standing water, drive

very slowly and do not stop your vehicle.

Your brake performance and traction may

be limited. After driving through water and

as soon as it is safe to do so:

•

Lightly press the brake pedal to dry the

brakes and to check that they work.

• Check that the horn works.

• Check that the exterior lights work.

• Turn the steering wheel to check that

the steering power assist works.

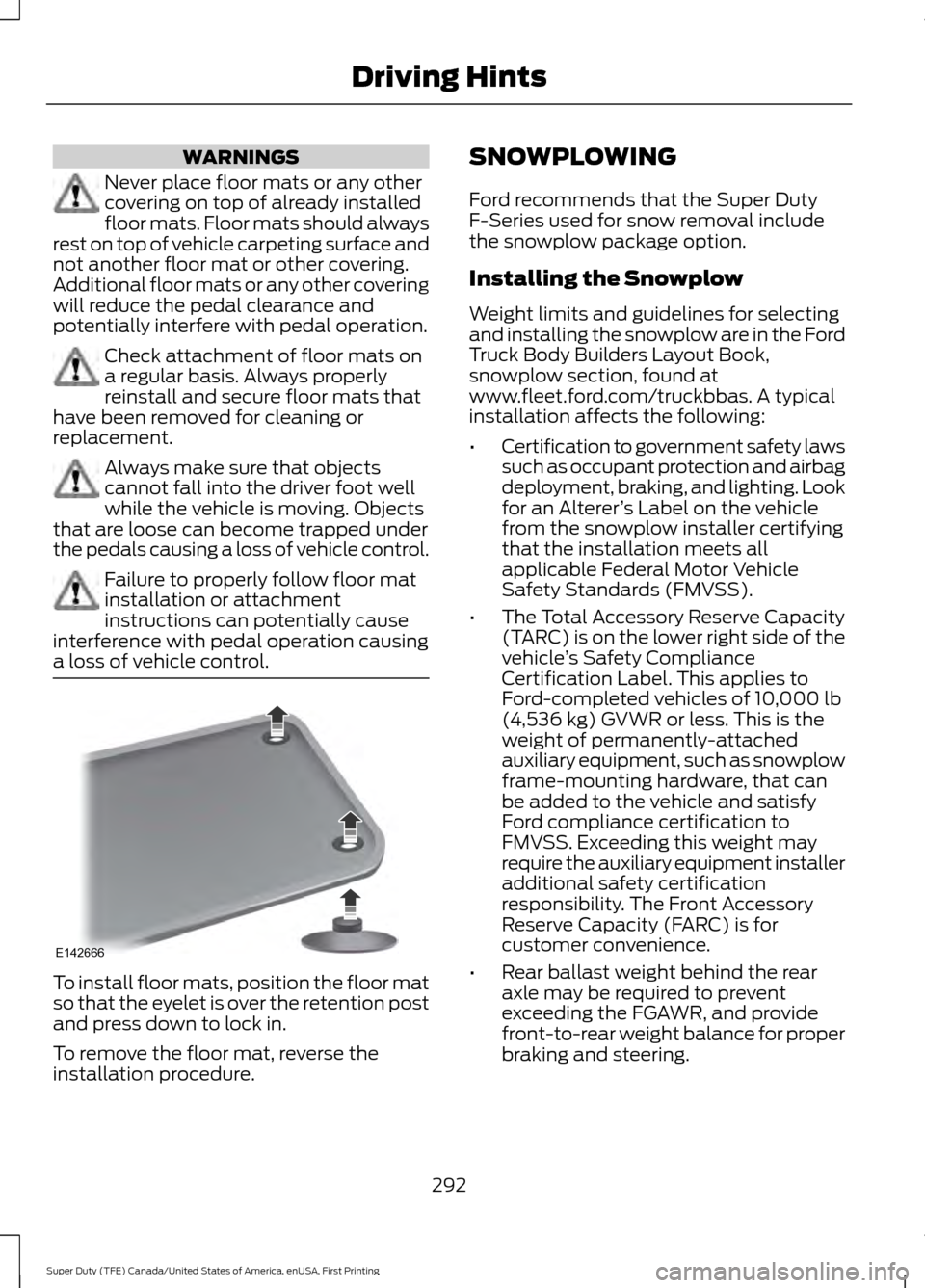

FLOOR MATS WARNINGS

Always use floor mats that are

designed to fit the foot well of your

vehicle. Only use floor mats that

leave the pedal area unobstructed. Only

use floor mats that are firmly secured to

retention posts so that they cannot slip out

of position and interfere with the pedals

or impair safe operation of your vehicle in

other ways. Pedals that cannot move freely can

cause loss of vehicle control and

increase the risk of serious personal

injury. Always make sure that the floor

mats are properly attached to the

retention posts in the carpet that are

supplied with your vehicle. Floor mats must

be properly secured to both retention posts

to make sure mats do not shift out of

position. Never place floor mats or any other

covering in the vehicle foot well that

cannot be properly secured to

prevent them from moving and interfering

with the pedals or the ability to control the

vehicle.

291

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Driving HintsE176913

Page 295 of 636

WARNINGS

Never place floor mats or any other

covering on top of already installed

floor mats. Floor mats should always

rest on top of vehicle carpeting surface and

not another floor mat or other covering.

Additional floor mats or any other covering

will reduce the pedal clearance and

potentially interfere with pedal operation. Check attachment of floor mats on

a regular basis. Always properly

reinstall and secure floor mats that

have been removed for cleaning or

replacement. Always make sure that objects

cannot fall into the driver foot well

while the vehicle is moving. Objects

that are loose can become trapped under

the pedals causing a loss of vehicle control. Failure to properly follow floor mat

installation or attachment

instructions can potentially cause

interference with pedal operation causing

a loss of vehicle control. To install floor mats, position the floor mat

so that the eyelet is over the retention post

and press down to lock in.

To remove the floor mat, reverse the

installation procedure. SNOWPLOWING

Ford recommends that the Super Duty

F-Series used for snow removal include

the snowplow package option.

Installing the Snowplow

Weight limits and guidelines for selecting

and installing the snowplow are in the Ford

Truck Body Builders Layout Book,

snowplow section, found at

www.fleet.ford.com/truckbbas. A typical

installation affects the following:

•

Certification to government safety laws

such as occupant protection and airbag

deployment, braking, and lighting. Look

for an Alterer ’s Label on the vehicle

from the snowplow installer certifying

that the installation meets all

applicable Federal Motor Vehicle

Safety Standards (FMVSS).

• The Total Accessory Reserve Capacity

(TARC) is on the lower right side of the

vehicle ’s Safety Compliance

Certification Label. This applies to

Ford-completed vehicles of 10,000 lb

(4,536 kg) GVWR or less. This is the

weight of permanently-attached

auxiliary equipment, such as snowplow

frame-mounting hardware, that can

be added to the vehicle and satisfy

Ford compliance certification to

FMVSS. Exceeding this weight may

require the auxiliary equipment installer

additional safety certification

responsibility. The Front Accessory

Reserve Capacity (FARC) is for

customer convenience.

• Rear ballast weight behind the rear

axle may be required to prevent

exceeding the FGAWR, and provide

front-to-rear weight balance for proper

braking and steering.

292

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Driving HintsE142666

Page 296 of 636

•

Front wheel toe may require

re-adjustment to prevent premature

uneven tire wear. Specifications are in

the Ford Workshop Manual.

• Headlight aim may require

re-adjustment.

• The tire air pressures recommended

for general driving are on the vehicle ’s

Safety Certification Label. The

maximum cold inflation pressure for

the tire and associated load rating is

on the tire sidewall. Tire air pressure

may require re-adjustment within these

pressure limits to accommodate the

additional weight of the snowplow

installation.

• Federal and some local regulations

require additional exterior lamps for

snowplow-equipped vehicles. Consult

your authorized dealer for additional

information.

Operating the Vehicle with the

Snowplow Attached

Note: Do not use your vehicle for snow

removal until you have driven at least

500 mi (800 km).

Ford recommends vehicle speed does not

exceed

45 mph (72 km/h) when

snowplowing.

The attached snowplow blade restricts

airflow to the radiator, and may cause the

engine to run at a higher temperature:

Attention to engine temperature is

especially important when outside

temperatures are above freezing. Angle

the blade to maximize airflow to the

radiator and monitor engine temperature

to determine whether a left or right angle

provides the best performance.

Follow the severe duty schedule in your

Scheduled Maintenance information for

engine oil and transmission fluid change

intervals. Snowplowing with your Airbag

Equipped Vehicle WARNINGS

Do not attempt to service, repair, or

modify the airbag supplemental

restraint system (SRS) or its fuses.

Contact an authorized dealer. Additional equipment for example

snowplow equipment may affect the

performance of the airbag sensors

increasing the risk of injury. Please refer to

the Body Builders Layout Book for

instructions about the appropriate

installation of additional equipment. All occupants of the vehicle,

including the driver, should always

properly wear their seatbelt, even

when provided with an airbag

supplemental restraint system (SRS). Your vehicle is equipped with a driver and

passenger airbag supplemental restraint

system. The supplemental restraint system

will activate in certain frontal and offset

frontal collisions when the vehicle sustains

sufficient frontal deceleration.

Careless or high speed driving while

plowing snow that results in sufficient

vehicle decelerations can deploy the

airbags. Such driving also increases the risk

of accidents.

Never remove or defeat the tripping

mechanisms designed into the snow

removal equipment by its manufacturer.

Doing so may cause damage to the vehicle

and the snow removal equipment as well

as possible airbag deployment.

Engine temperature while plowing

When driving with a plow, your engine may

run at a higher temperature than normal

because the attached snowplow blade will

restrict airflow to the radiator.

293

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Driving Hints

Page 297 of 636

•

If you are driving more than 15 mi

(24 km) at temperatures above

freezing, angle the plow blade either

full left or full right to provide

maximum airflow to the radiator.

• If you are driving less than

15 mi

(24 km) at speeds up to 45 mph

(72 km/h) in cold weather, you will not

need to worry about blade position to

provide maximum airflow.

Transmission operation while

plowing WARNING

Do not spin the wheels at over

34 mph (55 km/h). The tires may fail

and injure a passenger or bystander.

•

Shift transfer case to

4L (4WD Low)

when plowing in small areas at speeds

below

5 mph (8 km/h).

• Shift transfer case to

4H (4WD High)

when plowing larger areas or light snow

at higher speeds. Do not exceed 15 mph

(24 km/h)

.

• Do not shift the transmission from a

forward gear to

R (Reverse) until the

engine is at idle and the wheels have

stopped.

294

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Driving Hints

Page 301 of 636

JUMP STARTING THE VEHICLE

WARNINGS

Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide correct

ventilation. Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Use only adequately sized cables

with insulated clamps.

Preparing Your Vehicle

Do not attempt to push-start your

automatic transmission vehicle.

Note:

Attempting to push-start a vehicle

with an automatic transmission may cause

transmission damage.

Note: Use only a 12-volt supply to start your

vehicle.

Note: Do not disconnect the battery of the

disabled vehicle as this could damage the

vehicle electrical system.

Park the booster vehicle close to the hood

of the disabled vehicle, making sure the

two vehicles do not touch. Connecting the Jumper Cables WARNINGS

Do not attach the cables to fuel lines,

engine rocker covers, the intake

manifold or electrical components

as grounding points. Stay clear of moving

parts. To avoid reverse polarity

connections, make sure that you correctly

identify the positive (+) and negative (-)

terminals on both the disabled and booster

vehicles before connecting the cables. Do not attach the end of the positive

cable to the studs or L-shaped eyelet

located above the positive (+)

terminal of your vehicle ’s battery. High

current may flow through and cause

damage to the fuses. Do not connect the end of the

second cable to the negative (-)

terminal of the battery to be jumped.

A spark may cause an explosion of the

gases that surround the battery. Note:

In the illustration, the bottom vehicle

represents the booster vehicle.

298

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Roadside Emergencies

Page 332 of 636

Action and description

Message

Press and hold the OK

button until the instrument

cluster displays the

following message.

Hold OK to

Reset

Reset Successful

When the oil change indic-

ator resets the instrument

cluster displays 100%.

Remaining Life

{00}%

If the instrument cluster

displays one of the following

messages, repeat the

process.

Not Reset

Reset Cancelled

ENGINE COOLANT CHECK -

6.2L/6.8L WARNINGS

Do not add engine coolant when the

engine is hot. Steam and scalding

liquids released from a hot cooling

system can burn you badly. Also, spilling

coolant on hot engine parts can burn you. Do not put engine coolant in the

windshield washer fluid container. If

sprayed on the windshield, engine

coolant could make it difficult to see

through the windshield. To reduce the risk of personal injury,

make sure the engine is cool before

unscrewing the coolant pressure

relief cap. The cooling system is under

pressure. Steam and hot liquid can come

out forcefully when you loosen the cap

slightly. WARNINGS

Do not add coolant further than the

MAX mark.

When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance

(page 567).

Note: Make sure that the coolant level is

between the

MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the

MAX mark.

Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C). Coolant concentration should be

checked using a refractometer. We

recommend, Robinair® Coolant and

Battery Refractometer 75240 (Rotunda

tool part number: ROB75240). We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentration.

Note: Automotive fluids are not

interchangeable. Do not use coolant or

windshield washer fluid outside of its

specified function and vehicle location.

Note: Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

Adding Coolant WARNING

Never remove the coolant reservoir

cap while the engine is running or hot.

329

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance