fuel FORD SUPER DUTY 2017 4.G Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2017 4.GPages: 636, PDF Size: 10.56 MB

Page 329 of 636

7. Replace the dipstick and remove it

again to check the oil level. See

Engine Oil Dipstick (page 324).

8. Make sure that the oil level is between

the maximum and minimum marks. If

the oil level is at the minimum mark,

add oil immediately. See

Capacities

and Specifications (page 428).

9. If the oil level is correct, replace the dipstick and make sure it is fully seated.

Note: Do not remove the dipstick when the

engine is running.

Note: If the oil level is between the

maximum and minimum marks, the oil level

is acceptable. Do not add oil.

Note: The oil consumption of new engines

reaches its normal level after approximately

3,000 mi (5,000 km)

.

Adding Engine Oil WARNING

Do not remove the filler cap when

the engine is running.

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that may

not be covered by the vehicle Warranty. Only use oils certified for diesel engines by

the American Petroleum Institute (API).

An oil with this trademark symbol

conforms to the current engine and

emission system protection standards and

fuel economy requirements of the

International Lubricants Specification

Advisory Committee (ILSAC), comprised

of U.S. and Japanese automobile

manufacturers.

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap. See Under Hood Overview

(page 321).

Turn it counterclockwise and remove

it.

3. Add engine oil that meets Ford specifications. See

Capacities and

Specifications (page 428). You may

have to use a funnel to pour the engine

oil into the opening.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately.

CHANGING THE ENGINE OIL

AND OIL FILTER WARNINGS

Do not handle a hot oil filter with

bare hands.

326

Super Duty (TFE) Canada/United States of America, enUSA, First Printing MaintenanceE163371

Page 330 of 636

WARNINGS

Continuous contact with used motor

oil has caused cancer in laboratory

mice. Protect your skin by washing

with soap and water. If your vehicle is equipped with a diesel

engine, an Intelligent Oil Life Monitor™

calculates the proper oil change service

interval. When the information display

indicates: OIL CHANGE REQUIRED, change

the engine oil and oil filter. See

Information Displays (page 111).

The engine oil filter protects your engine

by filtering harmful, abrasive or sludge

particles and particles significantly smaller

than most available will-fit filters. See

Motorcraft Parts

(page 414).

1. Unscrew the oil filter and oil pan drain plug and wait for the oil to drain.

2. Replace the filter.

3. Reinstall the oil pan drain plug.

4. Refill the engine with new oil. See Capacities and Specifications (page

428

).

5. For diesel engines, you need to reset the Intelligent Oil Life Monitor™. See

Information Displays

(page 111).

Engine lubrication for severe

service operation

The following conditions define severe

operation for which engine operation with

SAE 5W-40 API CJ-4 is recommended. Oil

and oil filter change intervals will be

determined by the Intelligent Oil Life

Monitor™ as noted previously.

• Frequent or extended idling (over 10

minutes per hour of normal driving).

• Low-speed operation/stationary use.

• If vehicle is operated in sustained

ambient temperatures below

-9°F

(-23°C) or above 100°F (38°C). •

Frequent low-speed operation,

consistent heavy traffic less than

25 mph (40 km/h)

.

• Operating in severe dust conditions.

• Operating the vehicle off road.

• Towing a trailer over

1,000 mi

(1,600 km).

• Sustained, high-speed driving at Gross

Vehicle Weight Rating (maximum

loaded weight for vehicle operation).

• Use of fuels with sulfur content other

than ultra-low sulfur diesel (ULSD).

• Use of high-sulfur diesel fuel.

CHANGING THE COALESCER

FILTER ELEMENT WARNING

Do not dispose of engine oil or oil

filters in the household refuse or the

public sewage system. Use an

authorized waste disposal facility. Do not clean or recondition the filter

element.

We recommend that you demand the use

of genuine Ford and Motorcraft® parts

whenever your vehicle requires scheduled

maintenance or repair. Use the correct

specification filter element. See

Motorcraft Parts

(page 415).

Note: Operating your vehicle without a filter

element or with an unapproved filter

element may result in damage to the turbo

charger or exchanger and could lead to

engine damage that may not be covered by

the vehicle Warranty.

327

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance

Page 340 of 636

Coolant Change

At specific mileage intervals, as listed in

the scheduled maintenance information,

the coolant should be changed. The

information display may display a message

to change coolant at this time. Add

prediluted coolant approved to the correct

specification. See Capacities and

Specifications (page 411).

Engine-driven Cooling Fan (Fan

Clutch)

Your vehicle may have an engine driven

cooling fan drive (also called a fan clutch).

This fan drive changes the fan speed to

match the vehicle ’s changing cooling air

flow requirements. Fan speed, fan noise

level and fuel consumption all will increase

based on the driving conditions that

include trailer towing, hill climbing, heavy

loads, high speed and high ambient

temperature, individually or in combination.

The fan drive is designed to provide the

minimum fan speed (and resulting

minimum fan noise and fuel consumption)

required to meet the ever changing vehicle

cooling air flow requirements. You will hear

the amount of fan noise increasing and

decreasing as the engine power

requirements and vehicle driving conditions

change as you drive. This is to be expected

as being normal to the operation of your

vehicle. High levels of fan noise might also

be heard when your engine is first started,

and should normally decrease after driving

for a short time.

AUTOMATIC TRANSMISSION

FLUID CHECK

Have an authorized dealer check and

change the transmission fluid and filter at

the correct service interval. See

Scheduled Maintenance

(page 567). Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials may

affect transmission operation and result

in damage to internal transmission

components.

Checking Automatic Transmission

Fluid

For scheduled intervals of the fluid checks

and changes, See

Scheduled

Maintenance (page 567). Your

transmission does not consume fluid.

However, the fluid level should be checked

if the transmission is not working properly,

i.e., if the transmission slips or shifts slowly

or if you notice some sign of fluid leakage.

Automatic transmission fluid expands

when warmed. To obtain an accurate fluid

check, drive the vehicle until it is at normal

operating temperature (approximately

19 mi (30 km)

). Verify that the

transmission fluid temperature gauge,

located on the instrument cluster, is within

normal range.

1. Drive the vehicle

19 mi (30 km)until it

reaches normal operating temperature.

2. Park the vehicle on a level surface and

engage the parking brake.

3. With the engine running, parking brake

engaged and your foot on the brake

pedal, move the gearshift lever through

all of the gear ranges. Allow sufficient

time for each gear to engage.

4. Latch the gearshift lever in P and leave

the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag. If

necessary, refer to the Under Hood

Overview in this chapter for the

location of the dipstick.

337

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance

Page 345 of 636

State or local regulations on volatile

organic compounds may restrict the use

of methanol, a common windshield washer

antifreeze additive. Washer fluids

containing non-methanol antifreeze

agents should be used only if they provide

cold weather protection without damaging

the vehicle

’s paint finish, wiper blades or

washer system.

DRAINING THE FUEL FILTER

WATER TRAP - 6.7L DIESEL WARNING

Do not dispose of fuel in the

household refuse or the public

sewage system. Use an authorized

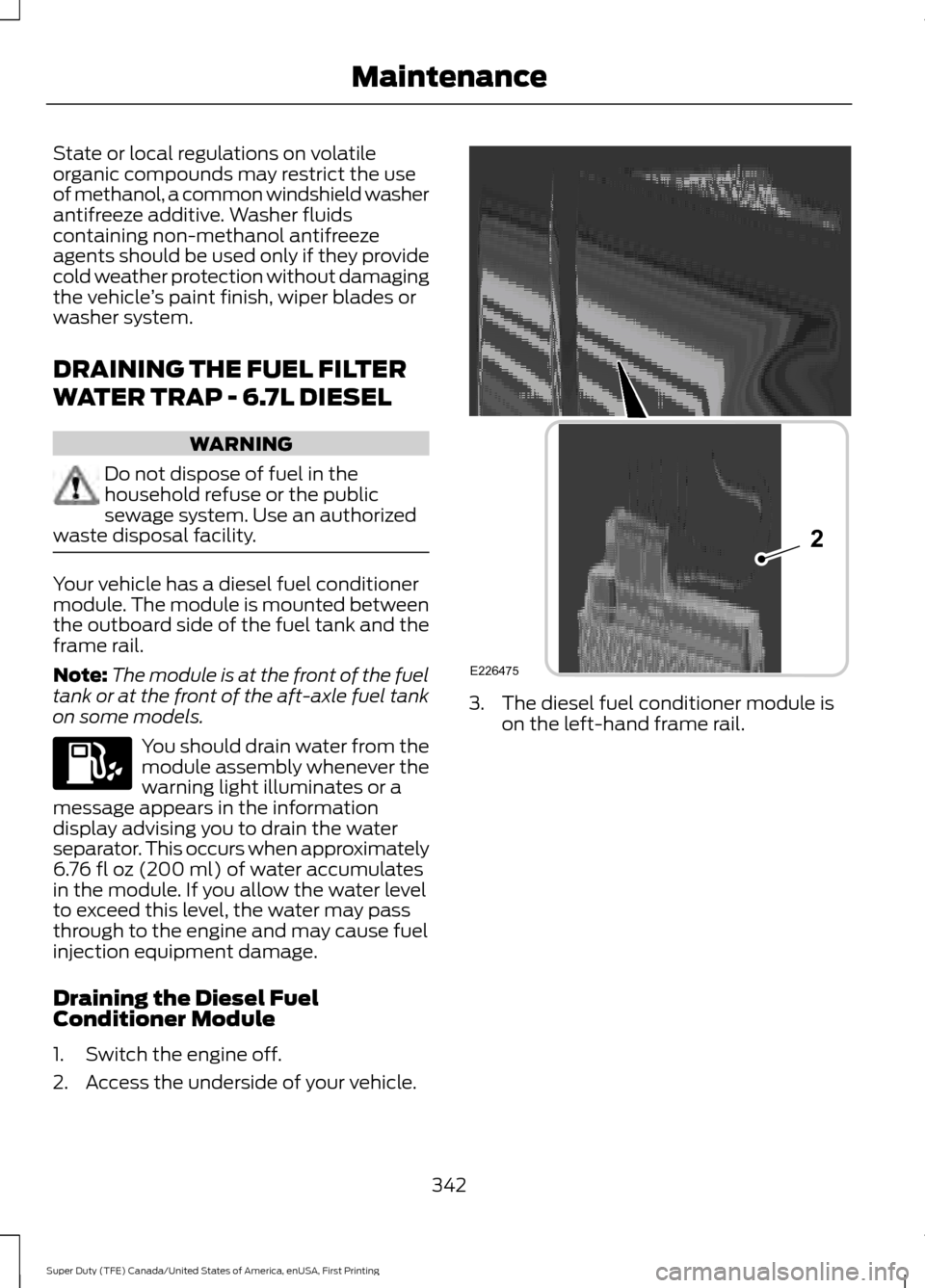

waste disposal facility. Your vehicle has a diesel fuel conditioner

module. The module is mounted between

the outboard side of the fuel tank and the

frame rail.

Note:

The module is at the front of the fuel

tank or at the front of the aft-axle fuel tank

on some models. You should drain water from the

module assembly whenever the

warning light illuminates or a

message appears in the information

display advising you to drain the water

separator. This occurs when approximately

6.76 fl oz (200 ml) of water accumulates

in the module. If you allow the water level

to exceed this level, the water may pass

through to the engine and may cause fuel

injection equipment damage.

Draining the Diesel Fuel

Conditioner Module

1. Switch the engine off.

2. Access the underside of your vehicle. 3. The diesel fuel conditioner module is

on the left-hand frame rail.

342

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance E226475

2

Page 346 of 636

4. Drain the diesel fuel conditioner

module. Turn the drain plug

counterclockwise until it stops. Do not

use any tools to loosen the drain plug.

Drain the filter, approximately 0.5 gal

(2 L), into an appropriate container. Do

not re-use the fuel drained from the

module.

5. Tighten the drain plug, turn it clockwise

until it stops and you feel a strong

resistance. Do not use any tools to

tighten the drain plug.

6. Switch the ignition off for 30 seconds and then switch the ignition off. Repeat

this operation six times in a row to

purge any trapped air from the fuel

system. FUEL FILTER - 6.2L/6.8L

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed.

CHANGING THE 12V BATTERY

WARNINGS

Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide correct

ventilation. When lifting a plastic-cased battery,

excessive pressure on the end walls

could cause acid to flow through the

vent caps, resulting in personal injury and

damage to the vehicle or battery. Lift the

battery with a battery carrier or with your

hands on opposite corners. Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands after

handling.

343

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance3

E226212

Page 347 of 636

WARNINGS

This vehicle may be fitted with more

than one battery. Removing the

battery cables from only one battery

does not disconnect your vehicle electrical

system. Make sure you disconnect the

battery cables from all batteries when

disconnecting power. Failure to do so may

cause serious personal injury or property

damage. Your vehicle is fitted with a Motorcraft

maintenance-free battery which normally

does not require additional water.

When a battery replacement is required,

you must use a recommended

replacement battery that matches the

electrical requirements of the vehicle.

Note:

After cleaning or replacing the

battery, make sure you reinstall the battery

cover or shield.

Note: If you add electrical accessories or

components to the vehicle, it may adversely

affect the low voltage battery performance

and durability. This may also affect the

performance of other electrical systems in

the vehicle.

For longer, trouble-free operation, keep the

top of the battery clean and dry.

If you see any corrosion on the battery or

terminals, remove the cables from the

terminals and clean with a wire brush. You

can neutralize the acid with a solution of

baking soda and water. Because your vehicle

’s engine is

electronically controlled by a computer,

some control conditions are maintained

by power from the battery. When the

battery is disconnected or a new battery

is installed, the engine must relearn its idle

and fuel trim strategy for optimum

driveability and performance. Flexible fuel

vehicles (FFV) must also relearn the

ethanol content of the fuel for optimum

driveability and performance.

To restore the settings, do the following:

1. Apply the parking brake.

2. Shift into park (P) or neutral (N).

3. Switch off all accessories.

4. Press the brake pedal and start your vehicle.

5. Run the engine until it reaches normal operating temperature. While the

engine is warming up, complete the

following: Reset the clock. See Audio

System (page 435). Reset the power

windows bounce-back feature. See

Windows and Mirrors

(page 95).

Reset the radio station presets. See

Audio System

(page 435).

6. Allow the engine to idle for at least one

minute.

7. Drive the vehicle at least 10 mi (16 km)

to completely relearn the idle trim and

fuel trim strategy.

Note: If you do not allow the engine to

relearn the idle and fuel trim strategy, the

idle quality of your vehicle may be adversely

affected until the engine computer

eventually relearns the idle trim and fuel

trim strategy.

Note: For flexible fuel vehicles, if you are

operating on E85, you may experience poor

starts or an inability to start the engine and

driveability problems until the fuel trim and

ethanol content have been relearned.

344

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance

Page 358 of 636

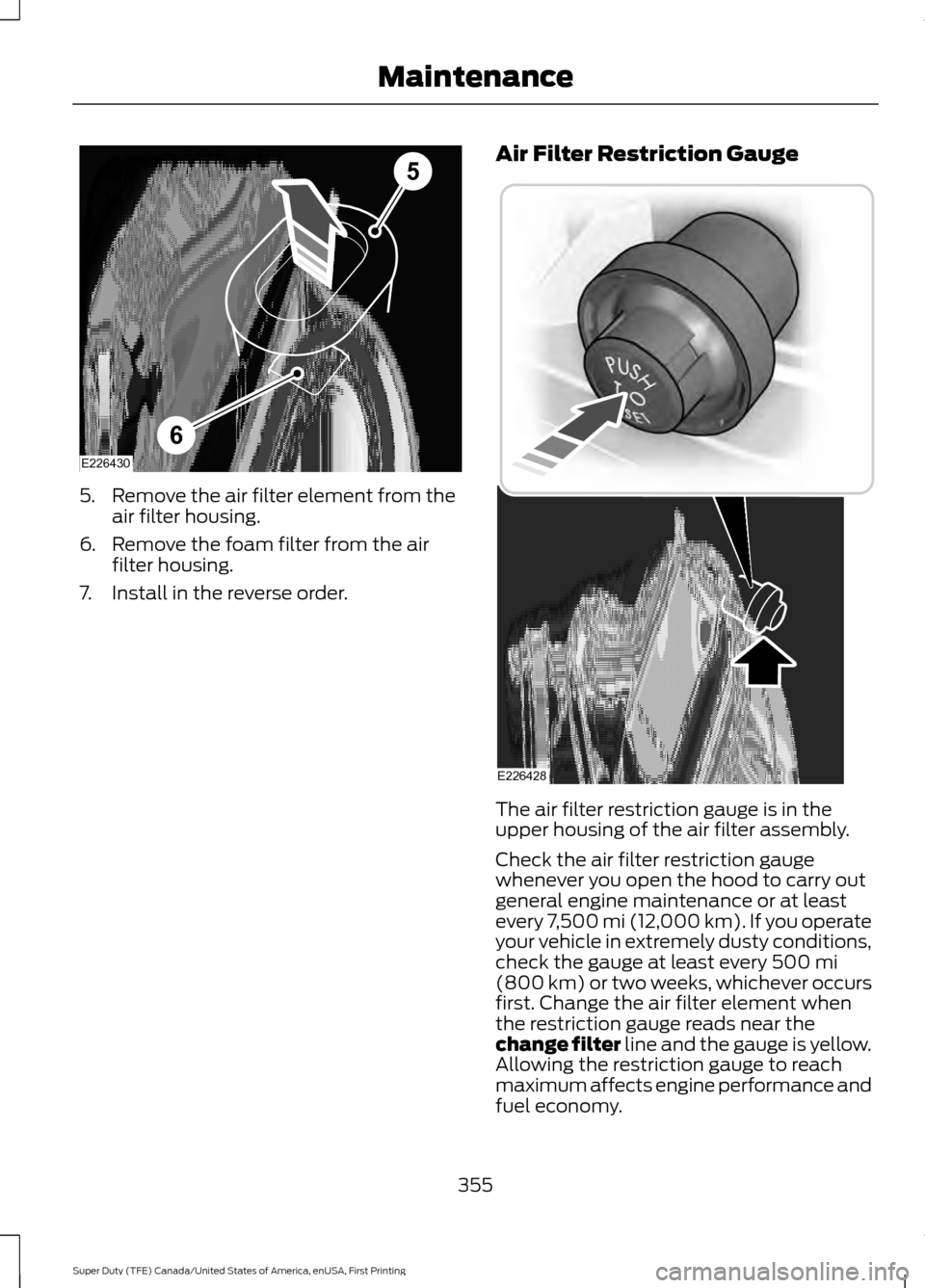

5.

Remove the air filter element from the

air filter housing.

6. Remove the foam filter from the air filter housing.

7. Install in the reverse order. Air Filter Restriction Gauge

The air filter restriction gauge is in the

upper housing of the air filter assembly.

Check the air filter restriction gauge

whenever you open the hood to carry out

general engine maintenance or at least

every 7,500 mi (12,000 km). If you operate

your vehicle in extremely dusty conditions,

check the gauge at least every 500 mi

(800 km) or two weeks, whichever occurs

first. Change the air filter element when

the restriction gauge reads near the

change filter line and the gauge is yellow.

Allowing the restriction gauge to reach

maximum affects engine performance and

fuel economy.

355

Super Duty (TFE) Canada/United States of America, enUSA, First Printing MaintenanceE226430

5

6 E226428

Page 359 of 636

Operating your vehicle in heavy snowfall

or extreme rain conditions may allow

excessive amounts of snow or water into

the air intake system. This could restrict air

flow and cause the engine to lose power

or shut down.

After installing a new air filter element, you

must reset the gauge by pressing the reset

button.

After operating your vehicle during in heavy

snowfall or extreme rain, do the following:

•

Snow: At the earliest opportunity, open

the hood and clear any snow and ice

from the air filter housing inlet and

reset the air filter restriction gauge.

• Extreme rain: The air filter element

dries out after approximately 15– 30

minutes of driving at highway speeds.

At the earliest opportunity, open the

hood and reset the air filter restriction

gauge.

Note: Do not remove the foam filter.

CHANGING THE ENGINE-

MOUNTED AND DIESEL FUEL

CONDITIONER MODULE FUEL

FILTERS - 6.7L DIESEL WARNING

Do not dispose of fuel in the

household refuse or the public

sewage system. Use an authorized

waste disposal facility. Your vehicle has two fuel filters. The first

filter mounts on top of the engine on the

left-hand side. The second filter is inside

the diesel fuel conditioner module. The

module is mounted between the outboard

side of the fuel tank and the frame rail.

Note:

The module is at the front of the fuel

tank or at the front of the aft-axle fuel tank

on some models. Regular fuel filter changes are an

important part of engine maintenance;

failing to keep with the scheduled

maintenance could lead to engine

performance issues and fuel injection

system damage. See Scheduled

Maintenance (page 567).

Use only recommended service parts

conforming to specifications. See

Motorcraft Parts

(page 415).

Note: Using fuel that has high levels of

impurities may require more frequent filter

replacements than the service interval

specifies.

Diesel Fuel Conditioner Module

Filter

Removal

1. Access the underside of your vehicle. 356

Super Duty (TFE) Canada/United States of America, enUSA, First Printing MaintenanceE226475

2

Page 360 of 636

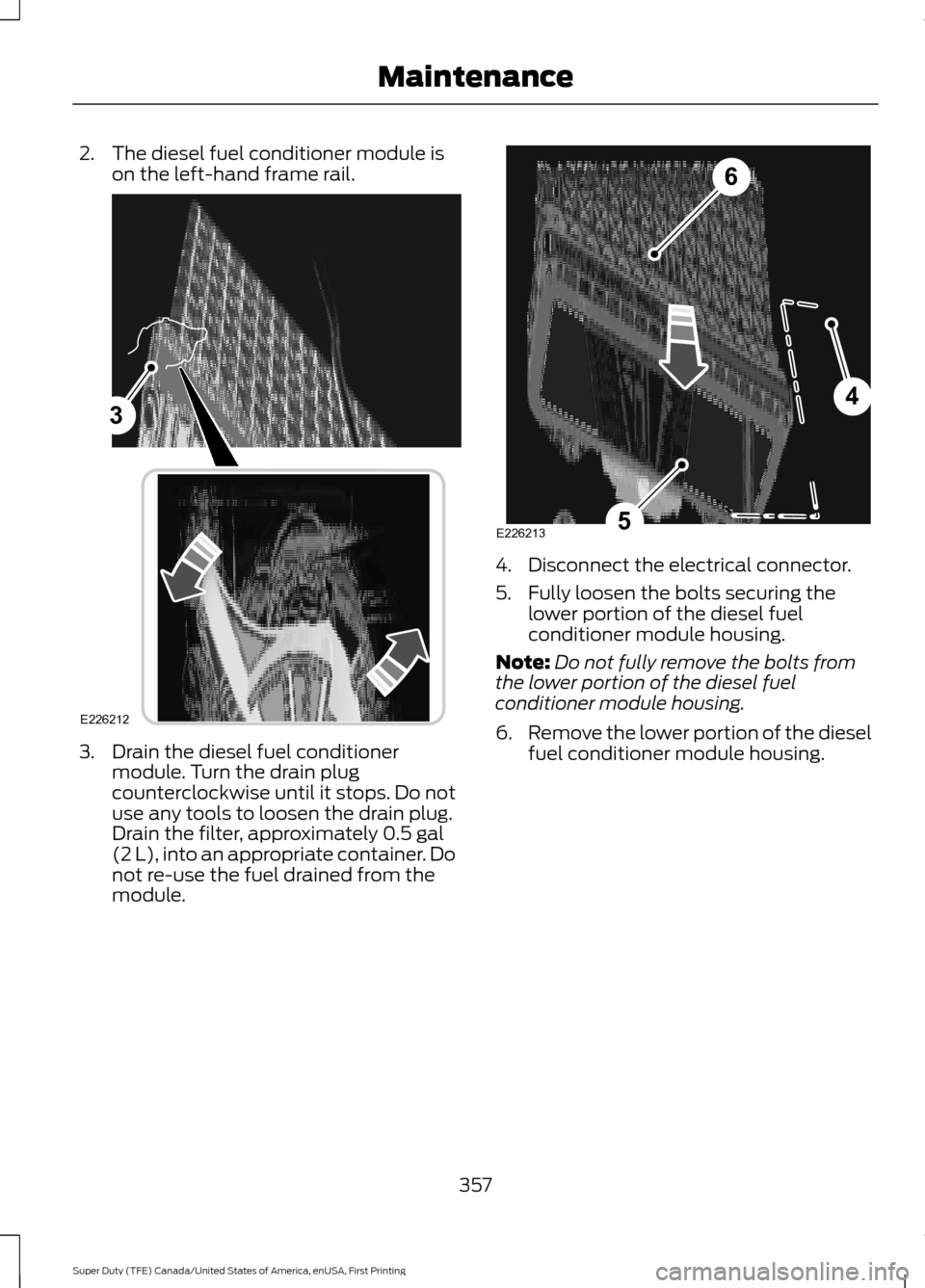

2. The diesel fuel conditioner module is

on the left-hand frame rail. 3. Drain the diesel fuel conditioner

module. Turn the drain plug

counterclockwise until it stops. Do not

use any tools to loosen the drain plug.

Drain the filter, approximately 0.5 gal

(2 L), into an appropriate container. Do

not re-use the fuel drained from the

module. 4. Disconnect the electrical connector.

5. Fully loosen the bolts securing the

lower portion of the diesel fuel

conditioner module housing.

Note: Do not fully remove the bolts from

the lower portion of the diesel fuel

conditioner module housing.

6. Remove the lower portion of the diesel

fuel conditioner module housing.

357

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance3

E226212 4

5

6

E226213

Page 361 of 636

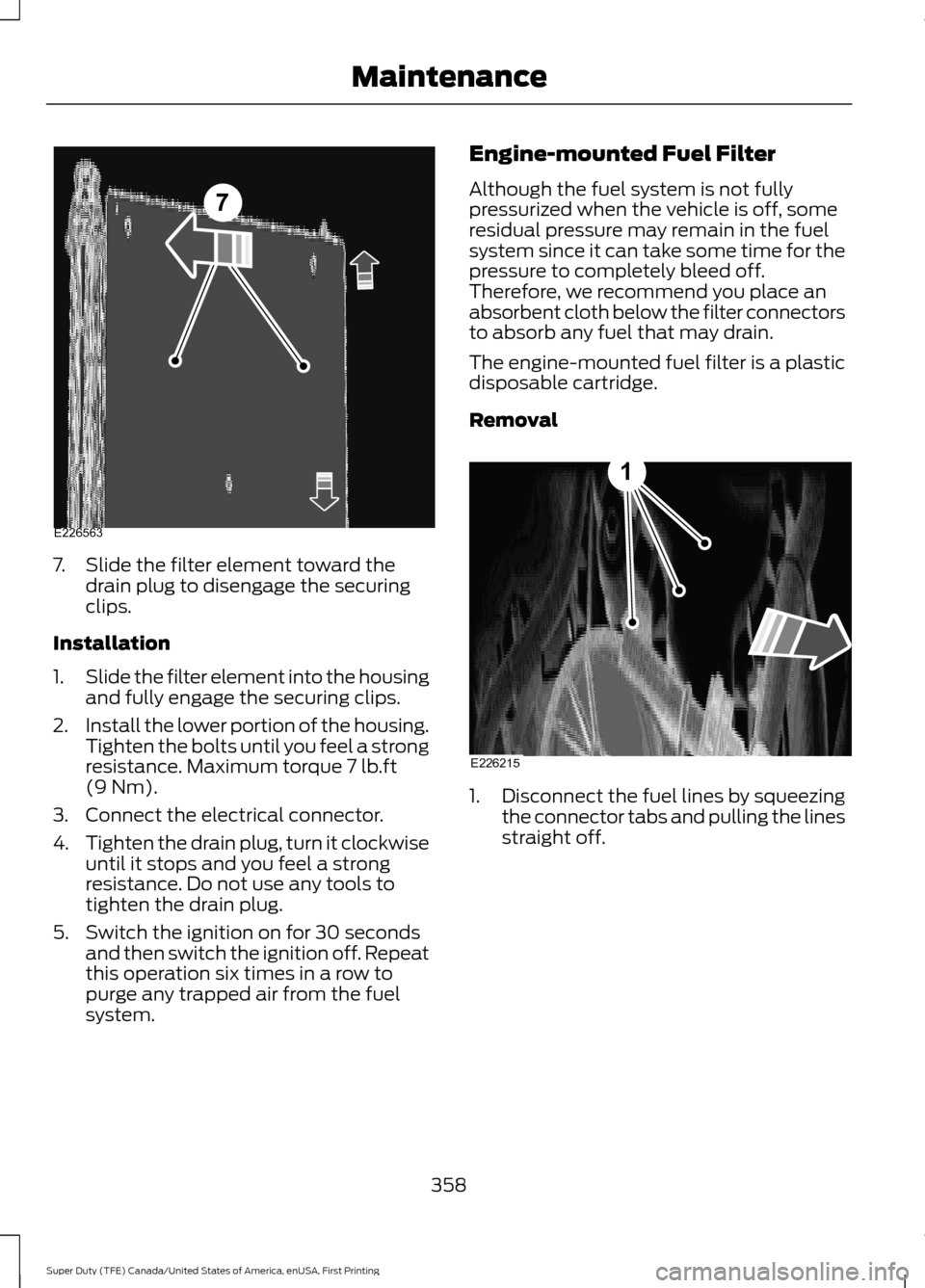

7. Slide the filter element toward the

drain plug to disengage the securing

clips.

Installation

1. Slide the filter element into the housing

and fully engage the securing clips.

2. Install the lower portion of the housing.

Tighten the bolts until you feel a strong

resistance. Maximum torque 7 lb.ft

(9 Nm).

3. Connect the electrical connector.

4. Tighten the drain plug, turn it clockwise

until it stops and you feel a strong

resistance. Do not use any tools to

tighten the drain plug.

5. Switch the ignition on for 30 seconds and then switch the ignition off. Repeat

this operation six times in a row to

purge any trapped air from the fuel

system. Engine-mounted Fuel Filter

Although the fuel system is not fully

pressurized when the vehicle is off, some

residual pressure may remain in the fuel

system since it can take some time for the

pressure to completely bleed off.

Therefore, we recommend you place an

absorbent cloth below the filter connectors

to absorb any fuel that may drain.

The engine-mounted fuel filter is a plastic

disposable cartridge.

Removal

1.

Disconnect the fuel lines by squeezing

the connector tabs and pulling the lines

straight off.

358

Super Duty (TFE) Canada/United States of America, enUSA, First Printing Maintenance7

E226563 E226215

1