maintenance reset FORD SUPER DUTY 2021 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2021, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2021Pages: 666, PDF Size: 8.48 MB

Page 383 of 666

4. Press the brake pedal and start your

vehicle.

5. Run the engine until it reaches normal operating temperature. While the

engine is warming up, complete the

following: Reset the clock. Reset the

power windows bounce-back feature.

See Windows and Mirrors (page 95).

Reset the radio station presets. See

Audio System

(page 488).

6. Allow the engine to idle for at least one

minute.

7. Drive the vehicle at least 10 mi (16 km)

to completely relearn the idle trim and

fuel trim strategy.

Note: If you do not allow the engine to

relearn the idle and fuel trim strategy, the

idle quality of your vehicle may be adversely

affected until the engine computer

eventually relearns the idle trim and fuel

trim strategy.

Note: For flexible fuel vehicles, if you are

operating on E85, you may experience poor

starts or an inability to start the engine and

driveability problems until the fuel trim and

ethanol content have been relearned.

Make sure that you dispose of old batteries

in an environmentally friendly way. Seek

advice from your local authority about

recycling old batteries.

If storing your vehicle for more than 30

days without recharging the battery, we

recommend that you disconnect the

negative battery cable to maintain battery

charge for quick starting.

Battery Management System

(If

Equipped)

The battery management system monitors

battery conditions and takes actions to

extend battery life. If excessive battery

drain is detected, the system temporarily

disables some electrical systems to

protect the battery. Systems included are:

•

Heated rear window.

• Heated seats.

• Climate control.

• Heated steering wheel.

• Audio unit.

• Navigation system.

A message may appear in the information

displays to alert you that battery

protection actions are active. These

messages are only for notification that an

action is taking place, and not intended to

indicate an electrical problem or that the

battery requires replacement.

After battery replacement, or in some

cases after charging the battery with an

external charger, the battery management

system requires eight hours of vehicle sleep

time to relearn the battery state of charge.

During this time your vehicle must remain

fully locked with the ignition switched off.

Note: Prior to relearning the battery state

of charge, the battery management system

may temporarily disable some electrical

systems.

Electrical Accessory Installation

To make sure the battery management

system works correctly, do not connect an

electrical device ground connection

directly to the battery negative post. This

can cause inaccurate measurements of

the battery condition and potential

incorrect system operation.

Note: If you add electrical accessories or

components to the vehicle, it may adversely

affect battery performance and durability.

This may also affect the performance of

other electrical systems in the vehicle.

380

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Maintenance

Page 422 of 666

Wheel misalignment in the front

or the rear can cause uneven and

rapid treadwear of your tires and

should be corrected by an

authorized dealer. Front-wheel

drive vehicles and those with an

independent rear suspension may

require alignment of all four

wheels.

The tires should also be balanced

periodically. An unbalanced tire

and wheel assembly may result in

irregular tire wear.

Tire Rotation

WARNING: If the tire label

shows different tire pressures for

the front and rear tires and the

vehicle has a tire pressure

monitoring system, then you

need to update the settings for

the system sensors. Always

perform the system reset

procedure after tire rotation. If

you do not reset the system, it

may not provide a low tire

pressure warning when

necessary.

Note: If your tires show uneven

wear ask an authorized dealer to

check for and correct any wheel

misalignment, tire imbalance or

mechanical problem involved

before tire rotation. Note:

Your vehicle may be

equipped with a dissimilar spare

wheel and tire assembly. A

dissimilar spare wheel and tire

assembly is defined as a spare

wheel and tire assembly that is

different in brand, size or

appearance from the road tires and

wheels. If you have a dissimilar

spare wheel and tire assembly it is

intended for temporary use only

and should not be used in a tire

rotation.

Note: After having your tires

rotated, inflation pressure must be

checked and adjusted to the

vehicle requirements.

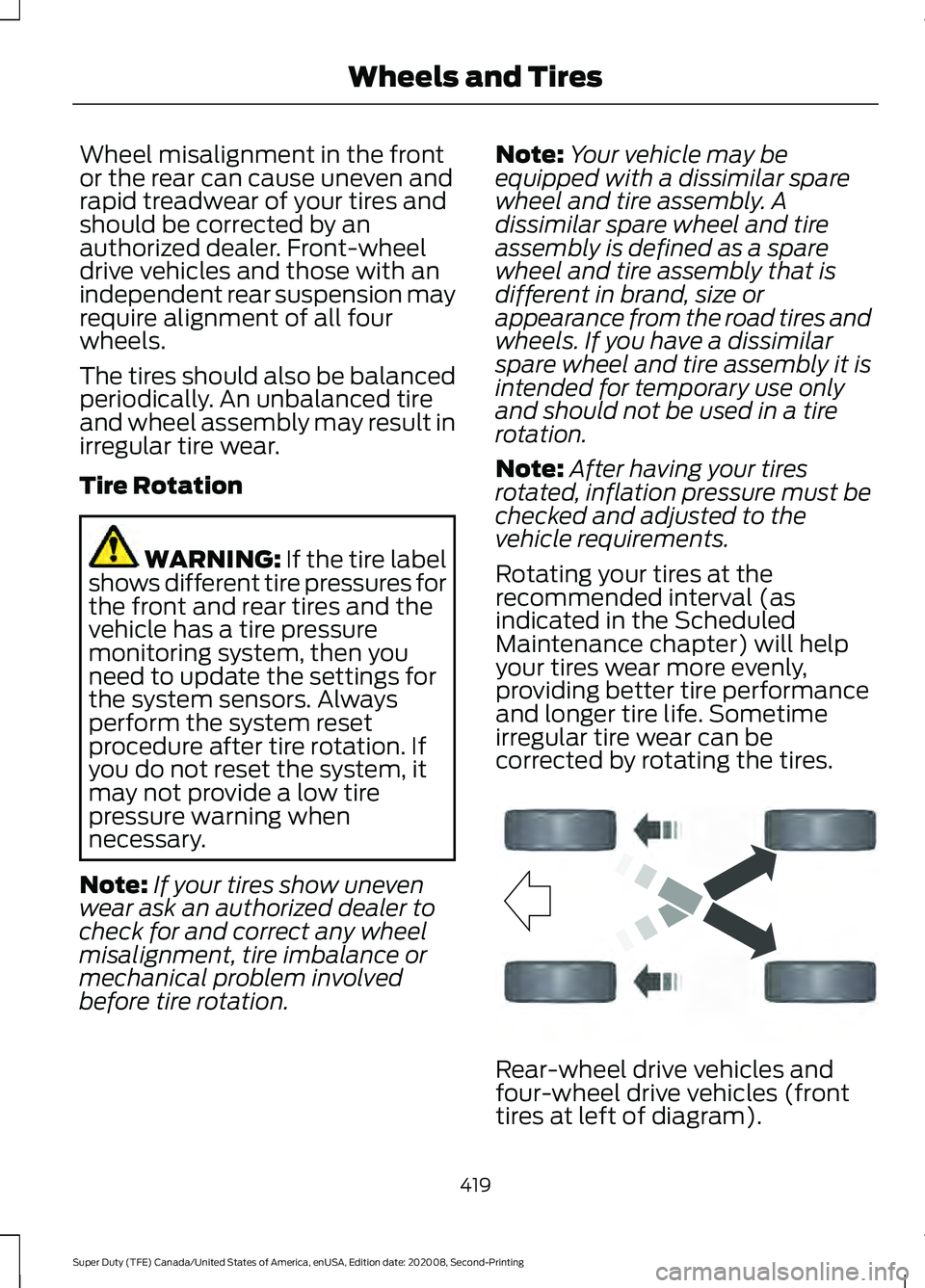

Rotating your tires at the

recommended interval (as

indicated in the Scheduled

Maintenance chapter) will help

your tires wear more evenly,

providing better tire performance

and longer tire life. Sometime

irregular tire wear can be

corrected by rotating the tires. Rear-wheel drive vehicles and

four-wheel drive vehicles (front

tires at left of diagram).

419

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Wheels and TiresE142548

Page 431 of 666

12.

Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

13. Set all six tires to the recommended air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

Trailer Tire Pressure Monitoring

System (If Equipped)

Note: Additional equipment may be

required for your vehicle to support trailer

tire pressure monitoring. See your authorized

dealer for more information.

Note: The trailer tire pressure monitoring

system is not a substitute for proper tire

maintenance. It is your responsibility to

maintain correct tire pressures at all times.

Note: If a trailer tire is repaired, replaced or

broken down for service, the screw and valve

on the trailer tire pressure sensor should be

replaced. See your authorized dealer for

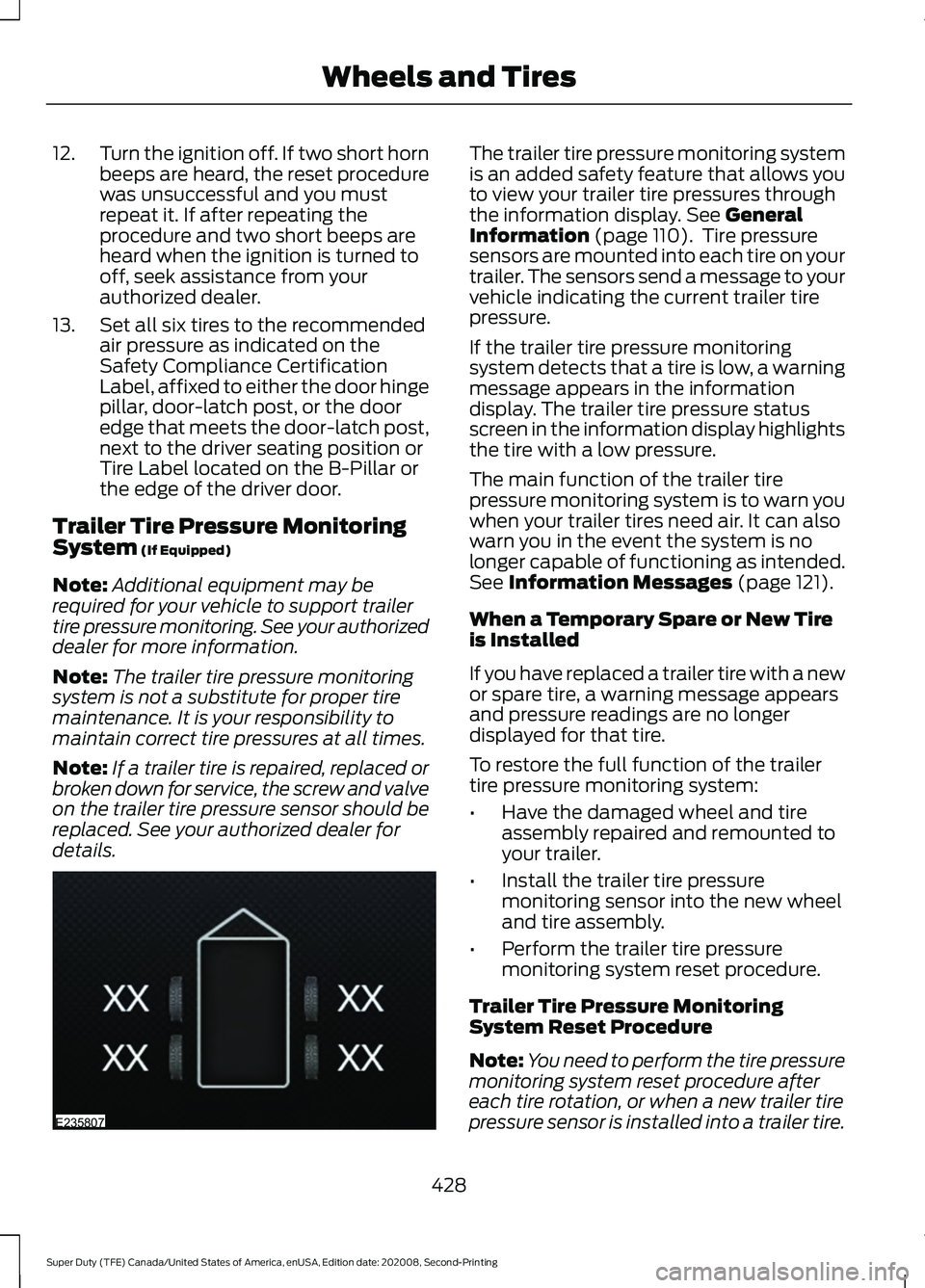

details. The trailer tire pressure monitoring system

is an added safety feature that allows you

to view your trailer tire pressures through

the information display.

See General

Information (page 110). Tire pressure

sensors are mounted into each tire on your

trailer. The sensors send a message to your

vehicle indicating the current trailer tire

pressure.

If the trailer tire pressure monitoring

system detects that a tire is low, a warning

message appears in the information

display. The trailer tire pressure status

screen in the information display highlights

the tire with a low pressure.

The main function of the trailer tire

pressure monitoring system is to warn you

when your trailer tires need air. It can also

warn you in the event the system is no

longer capable of functioning as intended.

See

Information Messages (page 121).

When a Temporary Spare or New Tire

is Installed

If you have replaced a trailer tire with a new

or spare tire, a warning message appears

and pressure readings are no longer

displayed for that tire.

To restore the full function of the trailer

tire pressure monitoring system:

• Have the damaged wheel and tire

assembly repaired and remounted to

your trailer.

• Install the trailer tire pressure

monitoring sensor into the new wheel

and tire assembly.

• Perform the trailer tire pressure

monitoring system reset procedure.

Trailer Tire Pressure Monitoring

System Reset Procedure

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation, or when a new trailer tire

pressure sensor is installed into a trailer tire.

428

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Wheels and TiresE235807

Page 569 of 666

When the oil change message appears in

the information display, it is time for an oil

change. Make sure you perform the oil

change within two weeks or 500 mi

(800 km) of the message appearing. Make

sure you reset the Intelligent Oil-Life

Monitor after each oil change. See

Oil

Change Indicator Reset (page 356).

If your information display resets

prematurely or becomes inoperative, you

should perform the oil change interval at

six months or

5,000 mi (8,000 km) from

your last oil change. Never exceed one year

or

10,000 mi (16,000 km) between oil

change intervals.

You can drive high performance vehicles

in such a way that may lead to higher oil

consumption this includes extended time

at high engine speeds, high loads, engine

braking, hard cornering maneuvers, track

and off-road usage. Under these

conditions, oil consumption of

approximately 1 quart per 500 miles (1 liter

per 800 km) is possible. As a result, you

need to check the engine oil level at every

refueling and adjust to maintain proper

levels to avoid engine damage.

Your vehicle is very sophisticated and built

with multiple, complex, performance

systems. Every manufacturer develops

these systems using different

specifications and performance features.

That is why it is important to rely upon your

dealership to properly diagnose and repair

your vehicle.

We have recommended maintenance

intervals for various parts and component

systems based upon engineering testing.

We rely upon this testing to determine the

most appropriate mileage for replacement

of oils and fluids to protect your vehicle at

the lowest overall cost to you and

recommends against maintenance

schedules that deviate from the scheduled

maintenance information. We strongly recommend the use of only

our genuine or our authorized

re-manufactured replacement parts

engineered for your vehicle.

Additives and Chemicals

This owner's manual and our Workshop

Manual list the recommended additives

and chemicals for your vehicle. We do not

recommend using chemicals or additives

not approved by us as part of your vehicle

’s

normal maintenance. Please consult your

warranty information.

Oils, Fluids and Flushing

In many cases, fluid discoloration is a

normal operating characteristic and, by

itself, does not necessarily indicate a

concern or that the fluid needs to be

changed. However, a qualified expert, such

as the factory-trained technicians at your

dealership, should inspect discolored fluids

that also show signs of overheating or

foreign material contamination

immediately.

Make sure to change your vehicle ’s oils and

fluids at the specified intervals or in

conjunction with a repair. Flushing is a

viable way to change fluid for many vehicle

sub-systems during scheduled

maintenance. It is critical that systems are

flushed only with new fluid that is the same

as that required to fill and operate the

system or using our approved flushing

chemical.

Owner Checks and Services

Make sure you perform the following basic

maintenance checks and inspections every

month or at six-month intervals.

566

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Scheduled Maintenance

Page 573 of 666

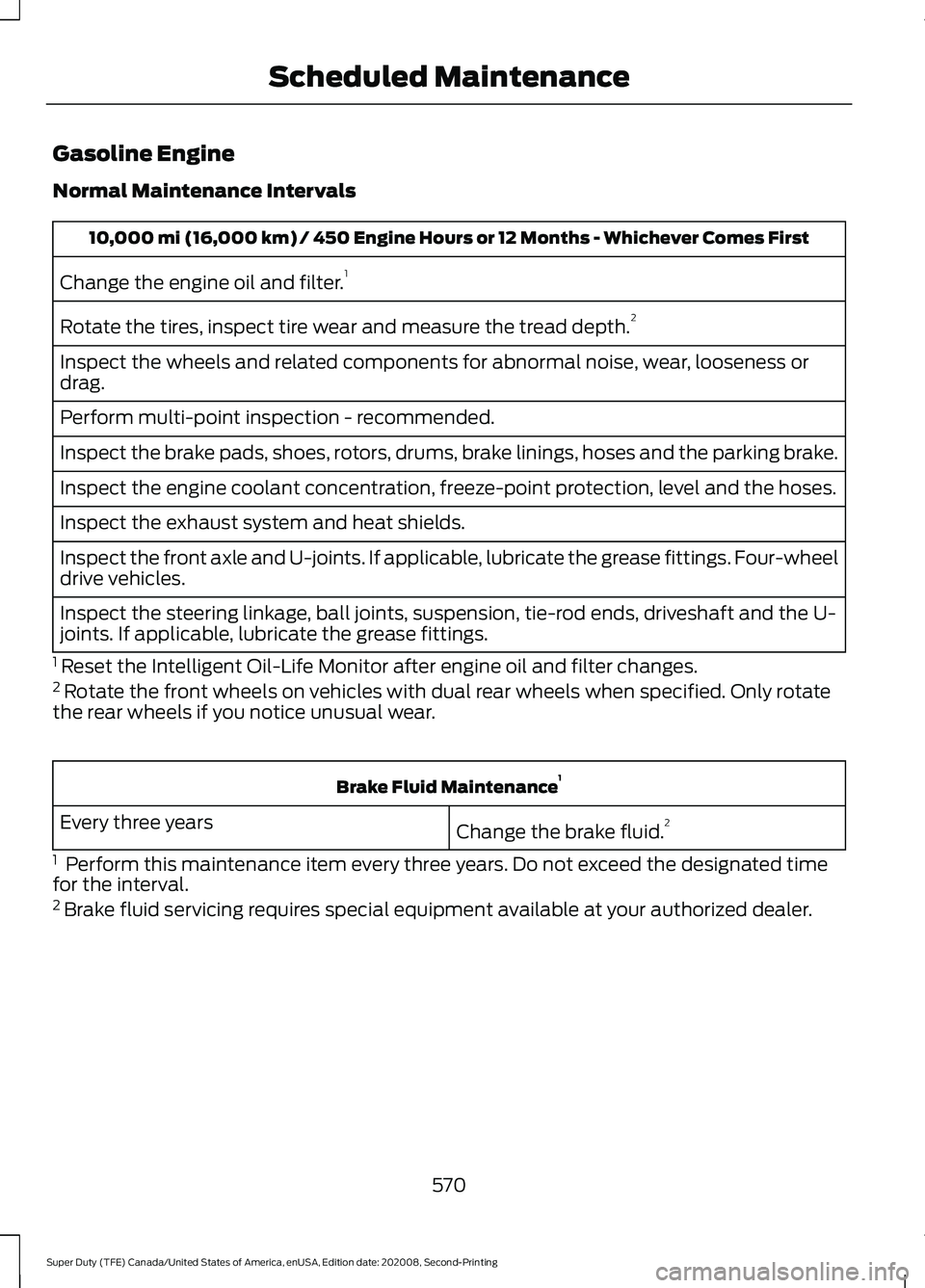

Gasoline Engine

Normal Maintenance Intervals

10,000 mi (16,000 km) / 450 Engine Hours or 12 Months - Whichever Comes First

Change the engine oil and filter. 1

Rotate the tires, inspect tire wear and measure the tread depth. 2

Inspect the wheels and related components for abnormal noise, wear, looseness or

drag.

Perform multi-point inspection - recommended.

Inspect the brake pads, shoes, rotors, drums, brake linings, hoses and the parking brake.

Inspect the engine coolant concentration, freeze-point protection, level and the hoses.

Inspect the exhaust system and heat shields.

Inspect the front axle and U-joints. If applicable, lubricate the grease fittings. Four-wheel

drive vehicles.

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and the U-

joints. If applicable, lubricate the grease fittings.

1 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes.

2 Rotate the front wheels on vehicles with dual rear wheels when specified. Only rotate

the rear wheels if you notice unusual wear. Brake Fluid Maintenance

1

Change the brake fluid. 2

Every three years

1 Perform this maintenance item every three years. Do not exceed the designated time

for the interval.

2 Brake fluid servicing requires special equipment available at your authorized dealer.

570

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Scheduled Maintenance

Page 575 of 666

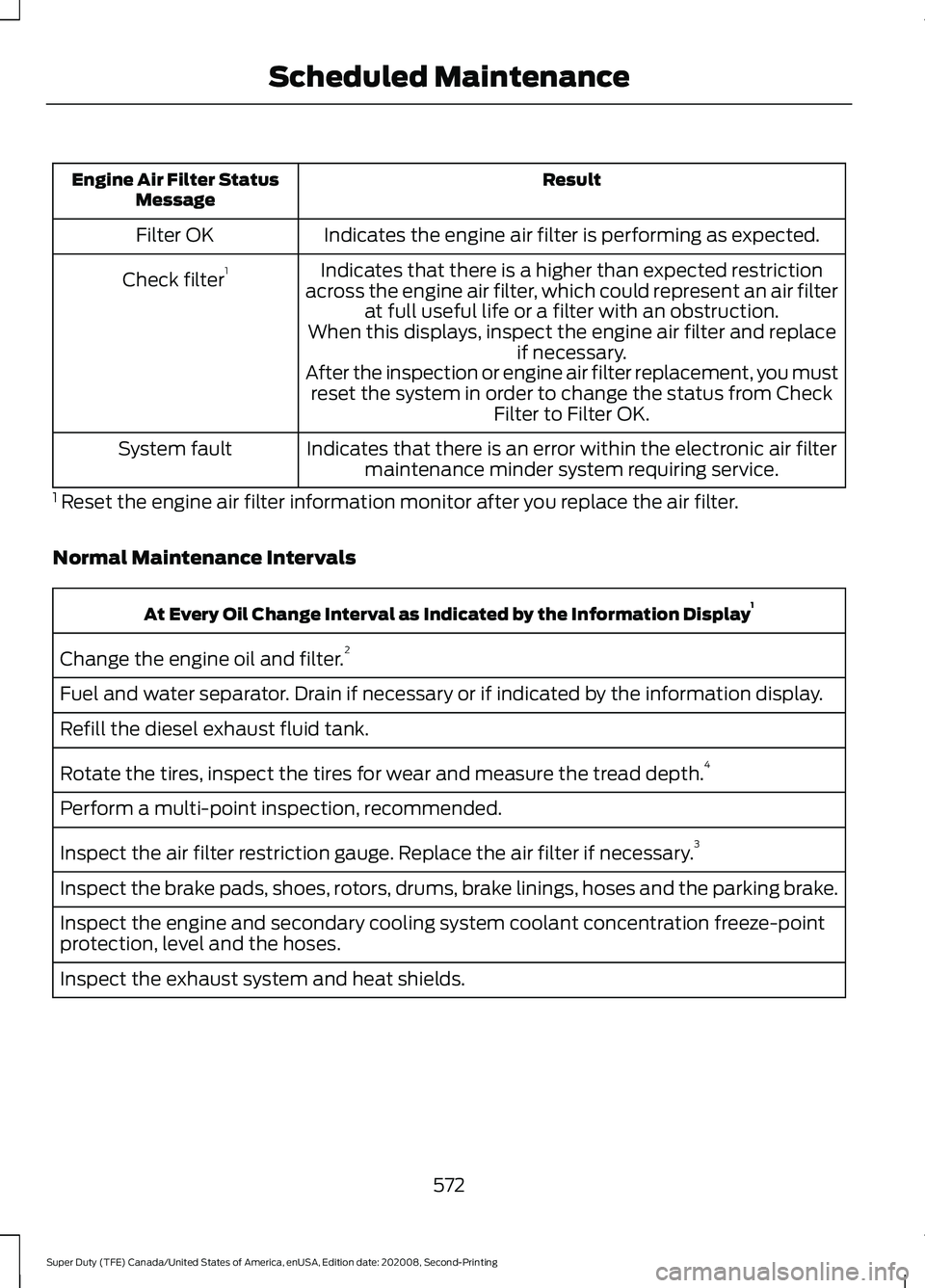

Result

Engine Air Filter Status

Message

Indicates the engine air filter is performing as expected.

Filter OK

Indicates that there is a higher than expected restriction

across the engine air filter, which could represent an air filter at full useful life or a filter with an obstruction.

Check filter

1

When this displays, inspect the engine air filter and replace if necessary.

After the inspection or engine air filter replacement, you must reset the system in order to change the status from Check Filter to Filter OK.

Indicates that there is an error within the electronic air filter maintenance minder system requiring service.

System fault

1 Reset the engine air filter information monitor after you replace the air filter.

Normal Maintenance Intervals At Every Oil Change Interval as Indicated by the Information Display

1

Change the engine oil and filter. 2

Fuel and water separator. Drain if necessary or if indicated by the information display.

Refill the diesel exhaust fluid tank.

Rotate the tires, inspect the tires for wear and measure the tread depth. 4

Perform a multi-point inspection, recommended.

Inspect the air filter restriction gauge. Replace the air filter if necessary. 3

Inspect the brake pads, shoes, rotors, drums, brake linings, hoses and the parking brake.

Inspect the engine and secondary cooling system coolant concentration freeze-point

protection, level and the hoses.

Inspect the exhaust system and heat shields.

572

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Scheduled Maintenance

Page 576 of 666

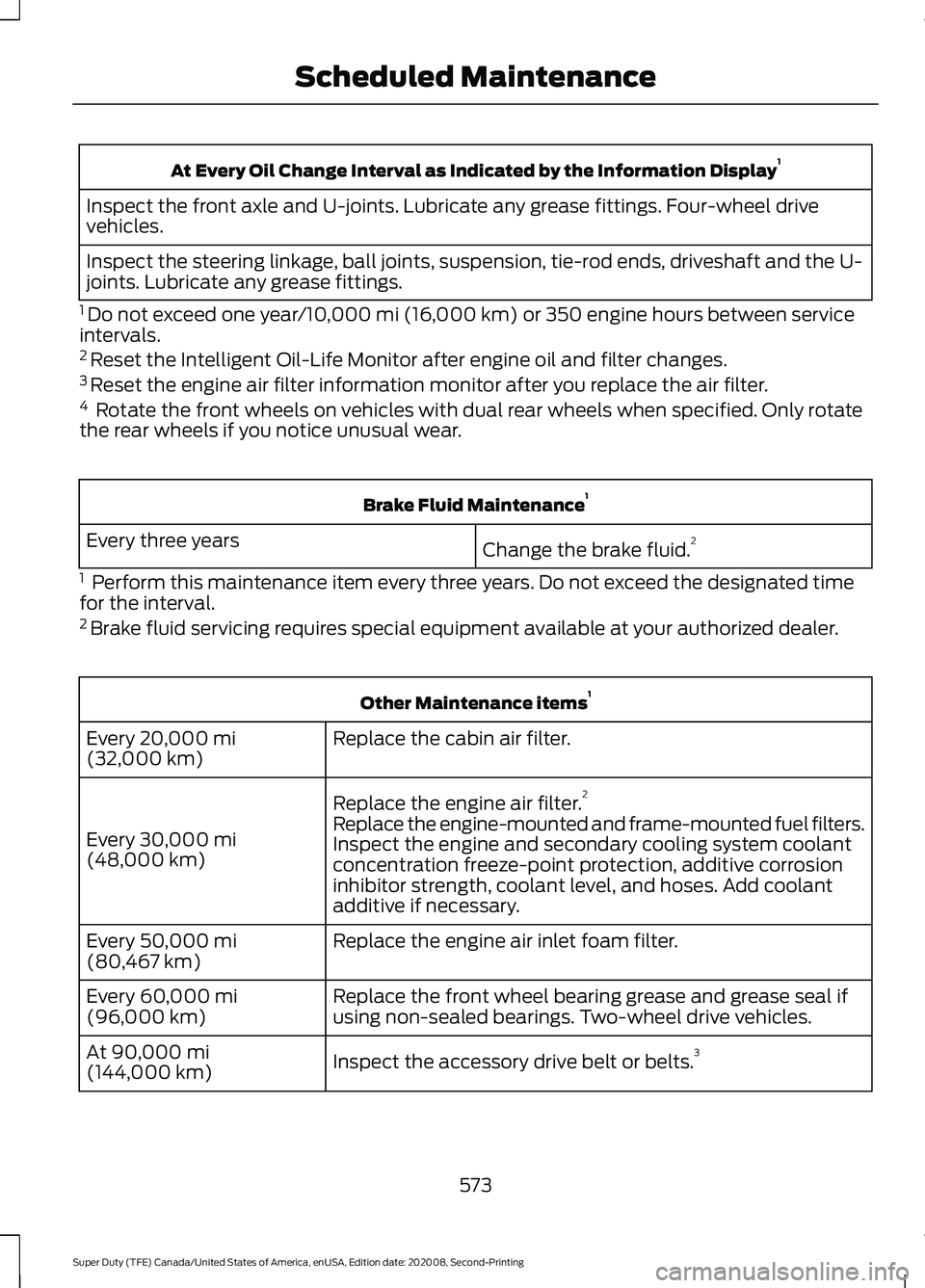

At Every Oil Change Interval as Indicated by the Information Display

1

Inspect the front axle and U-joints. Lubricate any grease fittings. Four-wheel drive

vehicles.

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and the U-

joints. Lubricate any grease fittings.

1 Do not exceed one year/10,000 mi (16,000 km) or 350 engine hours between service

intervals.

2 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes.

3 Reset the engine air filter information monitor after you replace the air filter.

4 Rotate the front wheels on vehicles with dual rear wheels when specified. Only rotate

the rear wheels if you notice unusual wear. Brake Fluid Maintenance

1

Change the brake fluid. 2

Every three years

1 Perform this maintenance item every three years. Do not exceed the designated time

for the interval.

2 Brake fluid servicing requires special equipment available at your authorized dealer. Other Maintenance items

1

Replace the cabin air filter.

Every

20,000 mi

(32,000 km)

Replace the engine air filter. 2

Every

30,000 mi

(48,000 km) Replace the engine-mounted and frame-mounted fuel filters.

Inspect the engine and secondary cooling system coolant

concentration freeze-point protection, additive corrosion

inhibitor strength, coolant level, and hoses. Add coolant

additive if necessary.

Replace the engine air inlet foam filter.

Every

50,000 mi

(80,467 km)

Replace the front wheel bearing grease and grease seal if

using non-sealed bearings. Two-wheel drive vehicles.

Every

60,000 mi

(96,000 km)

Inspect the accessory drive belt or belts. 3

At

90,000 mi

(144,000 km)

573

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Scheduled Maintenance

Page 577 of 666

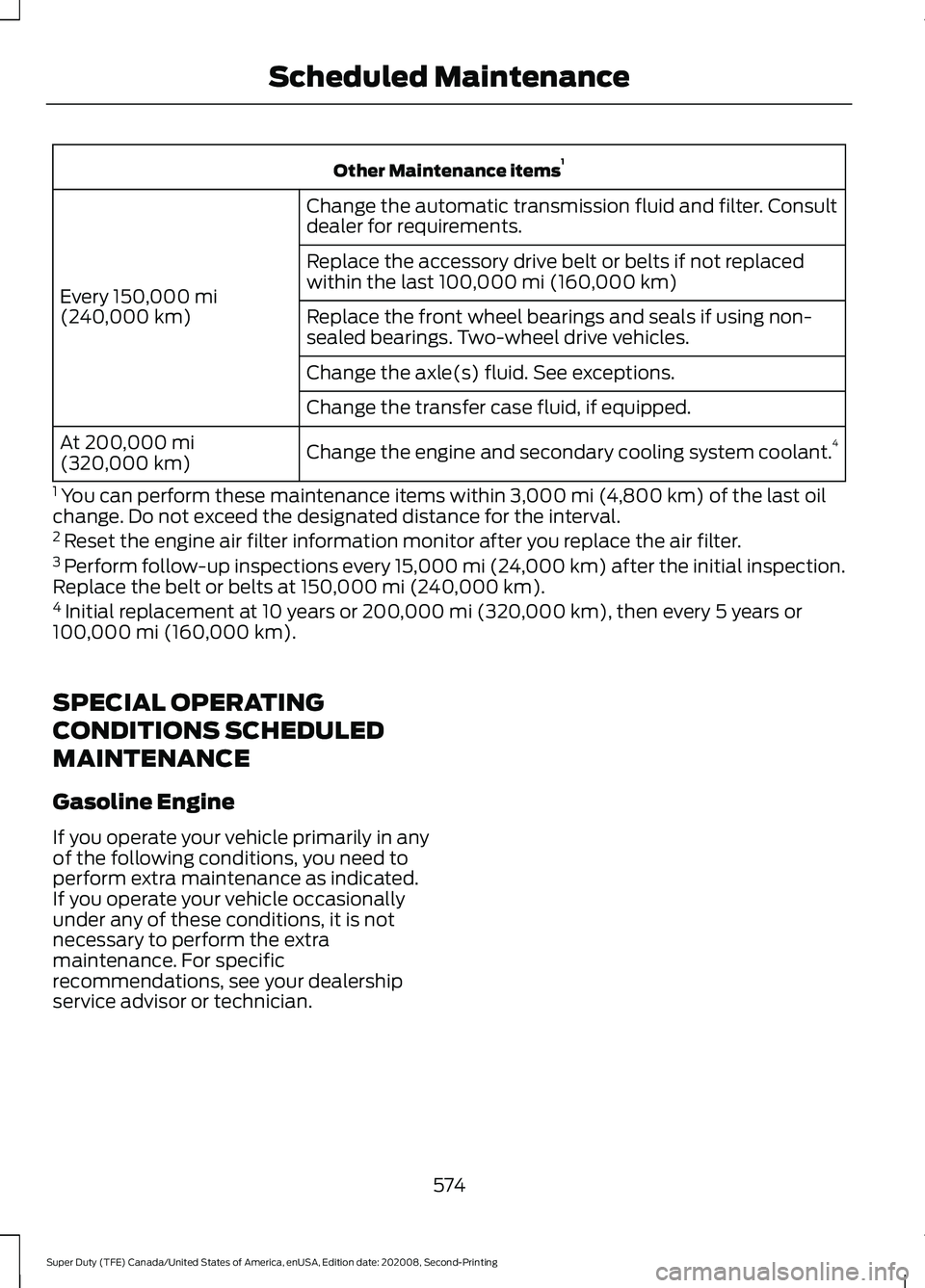

Other Maintenance items

1

Change the automatic transmission fluid and filter. Consult

dealer for requirements.

Every 150,000 mi

(240,000 km) Replace the accessory drive belt or belts if not replaced

within the last 100,000 mi (160,000 km)

Replace the front wheel bearings and seals if using non-

sealed bearings. Two-wheel drive vehicles.

Change the axle(s) fluid. See exceptions.

Change the transfer case fluid, if equipped.

Change the engine and secondary cooling system coolant. 4

At

200,000 mi

(320,000 km)

1 You can perform these maintenance items within

3,000 mi (4,800 km) of the last oil

change. Do not exceed the designated distance for the interval.

2 Reset the engine air filter information monitor after you replace the air filter.

3 Perform follow-up inspections every 15,000 mi (24,000 km) after the initial inspection.

Replace the belt or belts at

150,000 mi (240,000 km).

4 Initial replacement at 10 years or 200,000 mi (320,000 km), then every 5 years or

100,000 mi (160,000 km).

SPECIAL OPERATING

CONDITIONS SCHEDULED

MAINTENANCE

Gasoline Engine

If you operate your vehicle primarily in any

of the following conditions, you need to

perform extra maintenance as indicated.

If you operate your vehicle occasionally

under any of these conditions, it is not

necessary to perform the extra

maintenance. For specific

recommendations, see your dealership

service advisor or technician.

574

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Scheduled Maintenance

Page 584 of 666

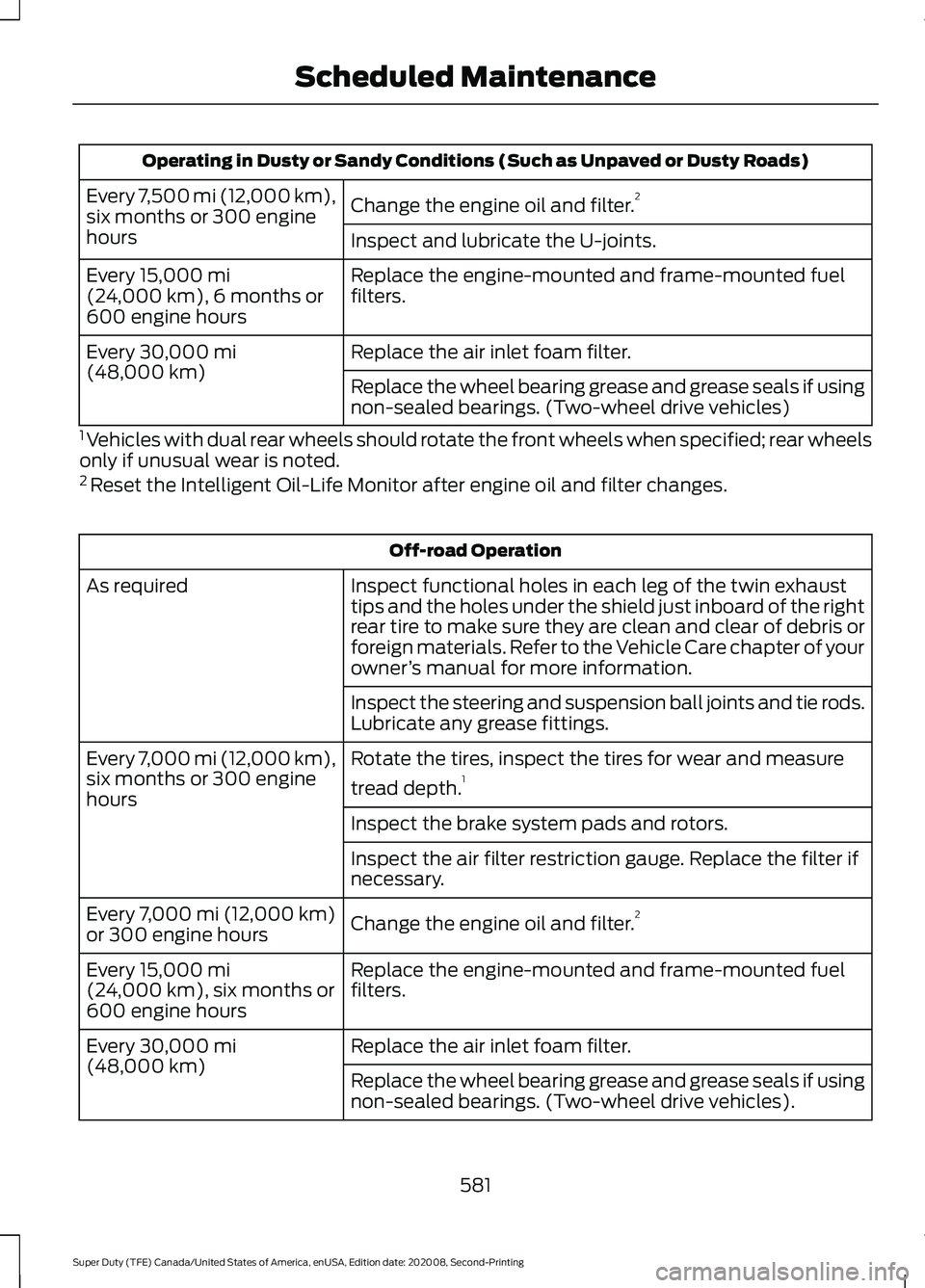

Operating in Dusty or Sandy Conditions (Such as Unpaved or Dusty Roads)

Change the engine oil and filter. 2

Every 7,500 mi (12,000 km),

six months or 300 engine

hours

Inspect and lubricate the U-joints.

Replace the engine-mounted and frame-mounted fuel

filters.

Every 15,000 mi

(24,000 km), 6 months or

600 engine hours

Replace the air inlet foam filter.

Every

30,000 mi

(48,000 km) Replace the wheel bearing grease and grease seals if using

non-sealed bearings. (Two-wheel drive vehicles)

1 Vehicles with dual rear wheels should rotate the front wheels when specified; rear wheels

only if unusual wear is noted.

2 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes. Off-road Operation

Inspect functional holes in each leg of the twin exhaust

tips and the holes under the shield just inboard of the right

rear tire to make sure they are clean and clear of debris or

foreign materials. Refer to the Vehicle Care chapter of your

owner ’s manual for more information.

As required

Inspect the steering and suspension ball joints and tie rods.

Lubricate any grease fittings.

Rotate the tires, inspect the tires for wear and measure

tread depth.1

Every 7,000 mi (12,000 km),

six months or 300 engine

hours

Inspect the brake system pads and rotors.

Inspect the air filter restriction gauge. Replace the filter if

necessary.

Change the engine oil and filter. 2

Every 7,000 mi (12,000 km)

or 300 engine hours

Replace the engine-mounted and frame-mounted fuel

filters.

Every

15,000 mi

(24,000 km), six months or

600 engine hours

Replace the air inlet foam filter.

Every

30,000 mi

(48,000 km) Replace the wheel bearing grease and grease seals if using

non-sealed bearings. (Two-wheel drive vehicles).

581

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Scheduled Maintenance

Page 585 of 666

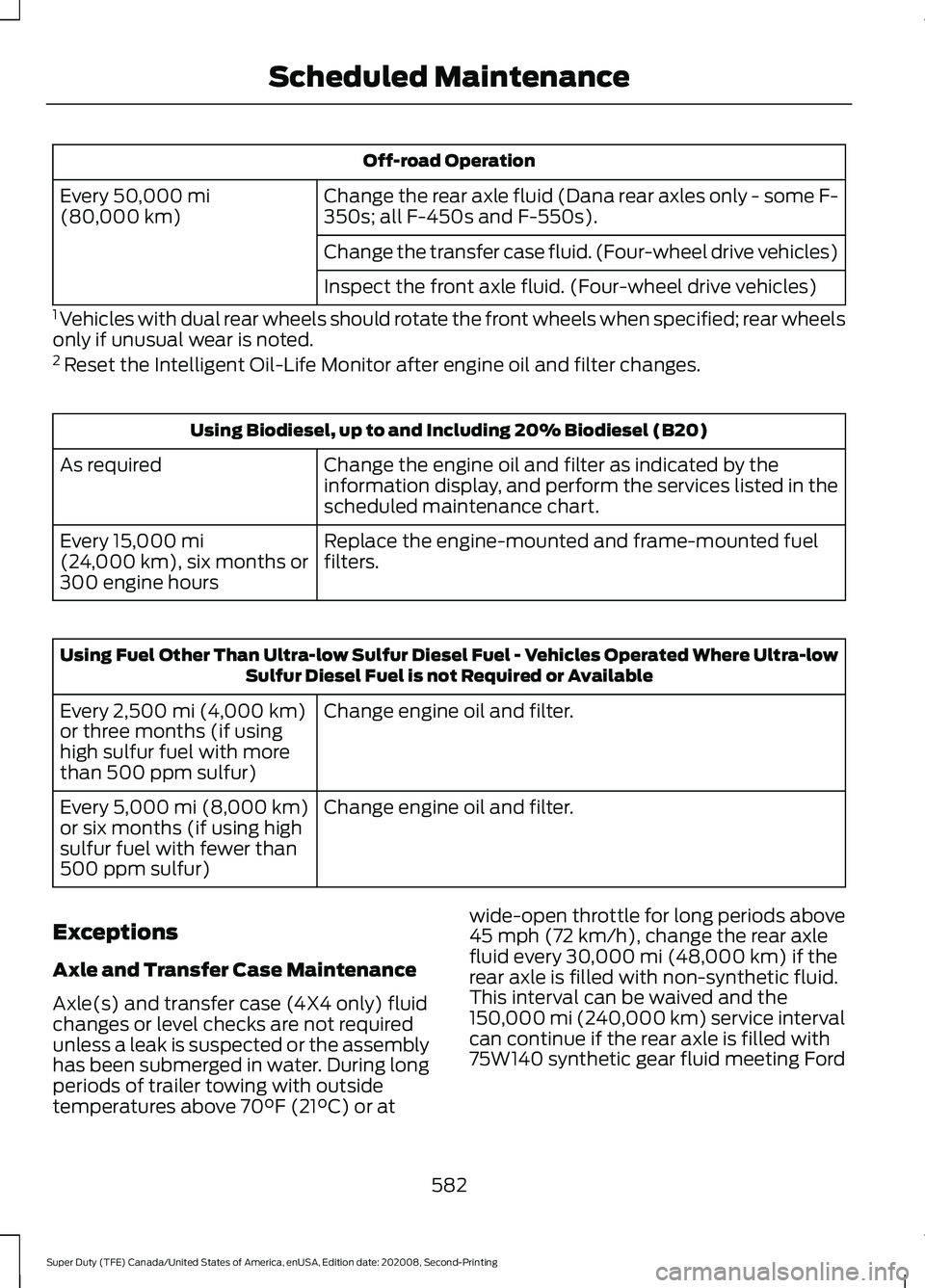

Off-road Operation

Change the rear axle fluid (Dana rear axles only - some F-

350s; all F-450s and F-550s).

Every 50,000 mi

(80,000 km)

Change the transfer case fluid. (Four-wheel drive vehicles)

Inspect the front axle fluid. (Four-wheel drive vehicles)

1 Vehicles with dual rear wheels should rotate the front wheels when specified; rear wheels

only if unusual wear is noted.

2 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes. Using Biodiesel, up to and Including 20% Biodiesel (B20)

Change the engine oil and filter as indicated by the

information display, and perform the services listed in the

scheduled maintenance chart.

As required

Replace the engine-mounted and frame-mounted fuel

filters.

Every

15,000 mi

(24,000 km), six months or

300 engine hours Using Fuel Other Than Ultra-low Sulfur Diesel Fuel - Vehicles Operated Where Ultra-low

Sulfur Diesel Fuel is not Required or Available

Change engine oil and filter.

Every

2,500 mi (4,000 km)

or three months (if using

high sulfur fuel with more

than 500 ppm sulfur)

Change engine oil and filter.

Every

5,000 mi (8,000 km)

or six months (if using high

sulfur fuel with fewer than

500 ppm sulfur)

Exceptions

Axle and Transfer Case Maintenance

Axle(s) and transfer case (4X4 only) fluid

changes or level checks are not required

unless a leak is suspected or the assembly

has been submerged in water. During long

periods of trailer towing with outside

temperatures above

70°F (21°C) or at wide-open throttle for long periods above

45 mph (72 km/h)

, change the rear axle

fluid every 30,000 mi (48,000 km) if the

rear axle is filled with non-synthetic fluid.

This interval can be waived and the

150,000 mi (240,000 km) service interval

can continue if the rear axle is filled with

75W140 synthetic gear fluid meeting Ford

582

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Second-Printing Scheduled Maintenance