ECU FORD TAURUS 2016 6.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: TAURUS, Model: FORD TAURUS 2016 6.GPages: 424, PDF Size: 4.04 MB

Page 242 of 424

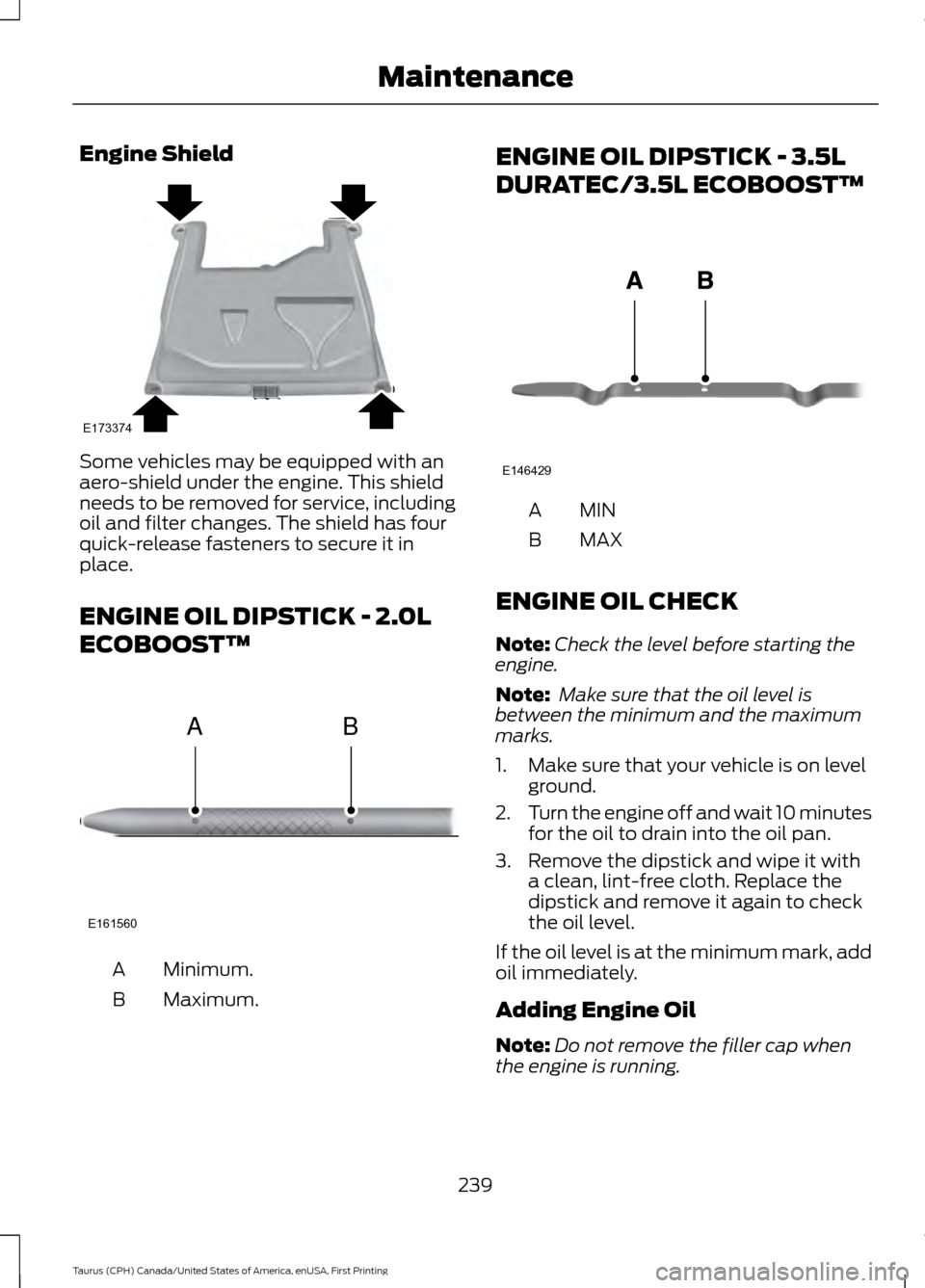

Engine Shield

Some vehicles may be equipped with an

aero-shield under the engine. This shield

needs to be removed for service, including

oil and filter changes. The shield has four

quick-release fasteners to secure it in

place.

ENGINE OIL DIPSTICK - 2.0L

ECOBOOST™

Minimum.

A

Maximum.

B ENGINE OIL DIPSTICK - 3.5L

DURATEC/3.5L ECOBOOST™

MINA

MAX

B

ENGINE OIL CHECK

Note: Check the level before starting the

engine.

Note: Make sure that the oil level is

between the minimum and the maximum

marks.

1. Make sure that your vehicle is on level ground.

2. Turn the engine off and wait 10 minutes

for the oil to drain into the oil pan.

3. Remove the dipstick and wipe it with a clean, lint-free cloth. Replace the

dipstick and remove it again to check

the oil level.

If the oil level is at the minimum mark, add

oil immediately.

Adding Engine Oil

Note: Do not remove the filler cap when

the engine is running.

239

Taurus (CPH) Canada/United States of America, enUSA, First Printing MaintenanceE173374 E161560

AB E146429

Page 257 of 424

2. Remove the screws that secure the

lamp assembly. 3. Remove the bulb.

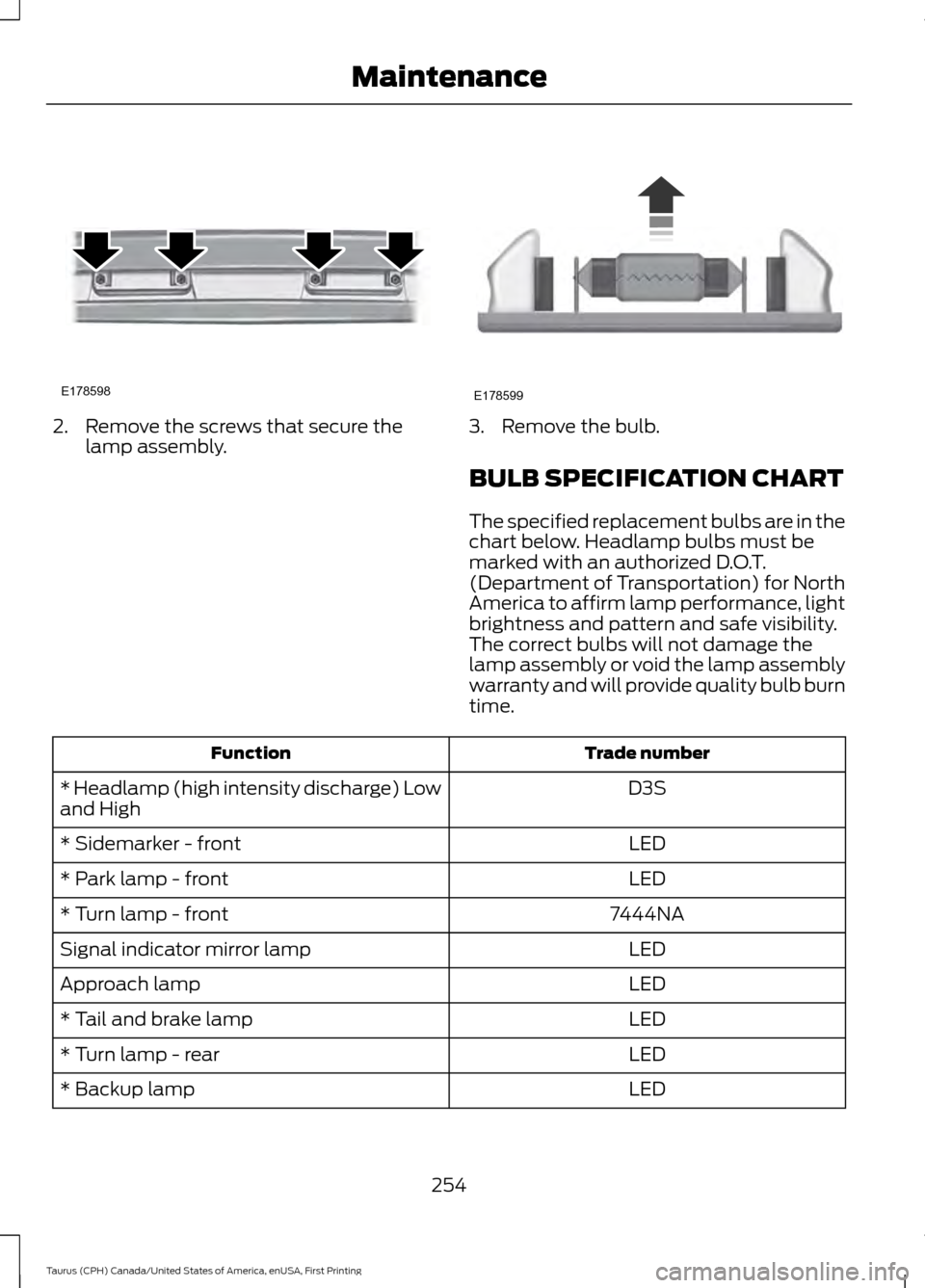

BULB SPECIFICATION CHART

The specified replacement bulbs are in the

chart below. Headlamp bulbs must be

marked with an authorized D.O.T.

(Department of Transportation) for North

America to affirm lamp performance, light

brightness and pattern and safe visibility.

The correct bulbs will not damage the

lamp assembly or void the lamp assembly

warranty and will provide quality bulb burn

time.

Trade number

Function

D3S

* Headlamp (high intensity discharge) Low

and High

LED

* Sidemarker - front

LED

* Park lamp - front

7444NA

* Turn lamp - front

LED

Signal indicator mirror lamp

LED

Approach lamp

LED

* Tail and brake lamp

LED

* Turn lamp - rear

LED

* Backup lamp

254

Taurus (CPH) Canada/United States of America, enUSA, First Printing MaintenanceE178598 E178599

Page 259 of 424

CHANGING THE ENGINE AIR

FILTER

WARNING

Do not start the engine with the air

cleaner removed. This can cause

damage not covered by the vehicle

Warranty and can result in serious injury. When changing the air filter element, use

only the air filter element listed. See

Capacities and Specifications (page

294).

For vehicles with EcoBoost engines, when

servicing the air cleaner, it is important that

no foreign material enters the air induction

system. The engine and turbocharger are

susceptible to damage from even small

particles.

Change the air filter element at the correct

interval. See

Scheduled Maintenance

(page 375).

Note: Failure to use the correct air filter

element may result in severe engine

damage. Resulting component damage

may not be covered by the vehicle Warranty.

To replace the air filter element do the

following:

1. Switch the ignition off. 2. Remove the clips that secure the air

filter housing cover.

3. Carefully lift the air filter housing cover.

4. Remove the air filter element from the

air filter housing.

5. Wipe any dirt or debris from the air filter

housing and cover to make sure no dirt

gets in the engine and that you have a

good seal.

6. Install a new air filter element.

7. Install the air filter housing cover. Be careful not to crimp the filter element

edges between the air filter housing

and cover. This could cause filter

damage and allow unfiltered air to

enter the engine if it is not properly

seated.

8. Engage the clips to secure the air filter housing cover to the air filter housing.

256

Taurus (CPH) Canada/United States of America, enUSA, First Printing MaintenanceE173520

Page 268 of 424

General Information

WARNING

Failure to follow these guidelines

could result in an increased risk of

loss of vehicle control, injury or death.

Note:

Do not use the kit if a tire has become

severely damaged by driving the vehicle with

a tire that has insufficient air pressure. Only

punctured areas located within the tire tread

can be sealed with the kit.

Do not attempt to repair punctures larger

than ¼ inch (6 millimeters) or damage to

the tire's sidewall. The tire may not

completely seal.

Loss of air pressure may adversely affect

tire performance. For this reason:

Note: Do not drive the vehicle above

50 mph (80 km/h).

Note: Do not drive further than

120 mi

(200 km). Drive only to the closest

authorized Ford dealer or tire repair shop to

have your tire inspected.

• Drive carefully and avoid abrupt

steering maneuvers.

• Periodically monitor tire inflation

pressure in the affected tire. If the tire

is losing pressure, have the vehicle

towed.

• Read the information in the Tips for

Use of the Kit section to make sure safe

operation of the kit and your vehicle.

Tips for Use of the Kit

Read the following list of tips to ensure

safe operation of the kit: •

Before operating the kit, make sure

your vehicle is safely off the road and

away from moving traffic. Turn on the

hazard lights.

• Always set the parking brake to ensure

the vehicle does not move

unexpectedly.

• Do not remove any foreign objects,

such as nails or screws, from the tire.

• When using the kit, leave the engine

running (only if the vehicle is outdoors

or in a well-ventilated area) so the

compressor does not drain the vehicle

battery.

• Do not allow the compressor to

operate continuously for more than 15

minutes. This will help prevent the

compressor from overheating.

• Never leave the kit unattended when

it is operating.

• Sealant compound contains latex.

Make sure that you use the non-latex

gloves provided to avoid an allergic

reaction.

• Keep the kit away from children.

• Only use the kit when the ambient

temperature is between

-22°F (-30°C)

and 158°F (70°C).

• Only use the sealing compound before

the use by date. The use by date is on

the lower right hand corner of the label

located on the sealant canister

(bottle). Check the use by date

regularly and replace the canister after

four years.

• Do not store the kit unsecured inside

the passenger compartment of the

vehicle as it may cause injury during a

sudden stop or crash. Always store the

kit in its original location.

• After sealant use, the tire pressure

monitoring system sensor and valve

stem on the wheel must be replaced

by an authorized Ford dealer.

265

Taurus (CPH) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 269 of 424

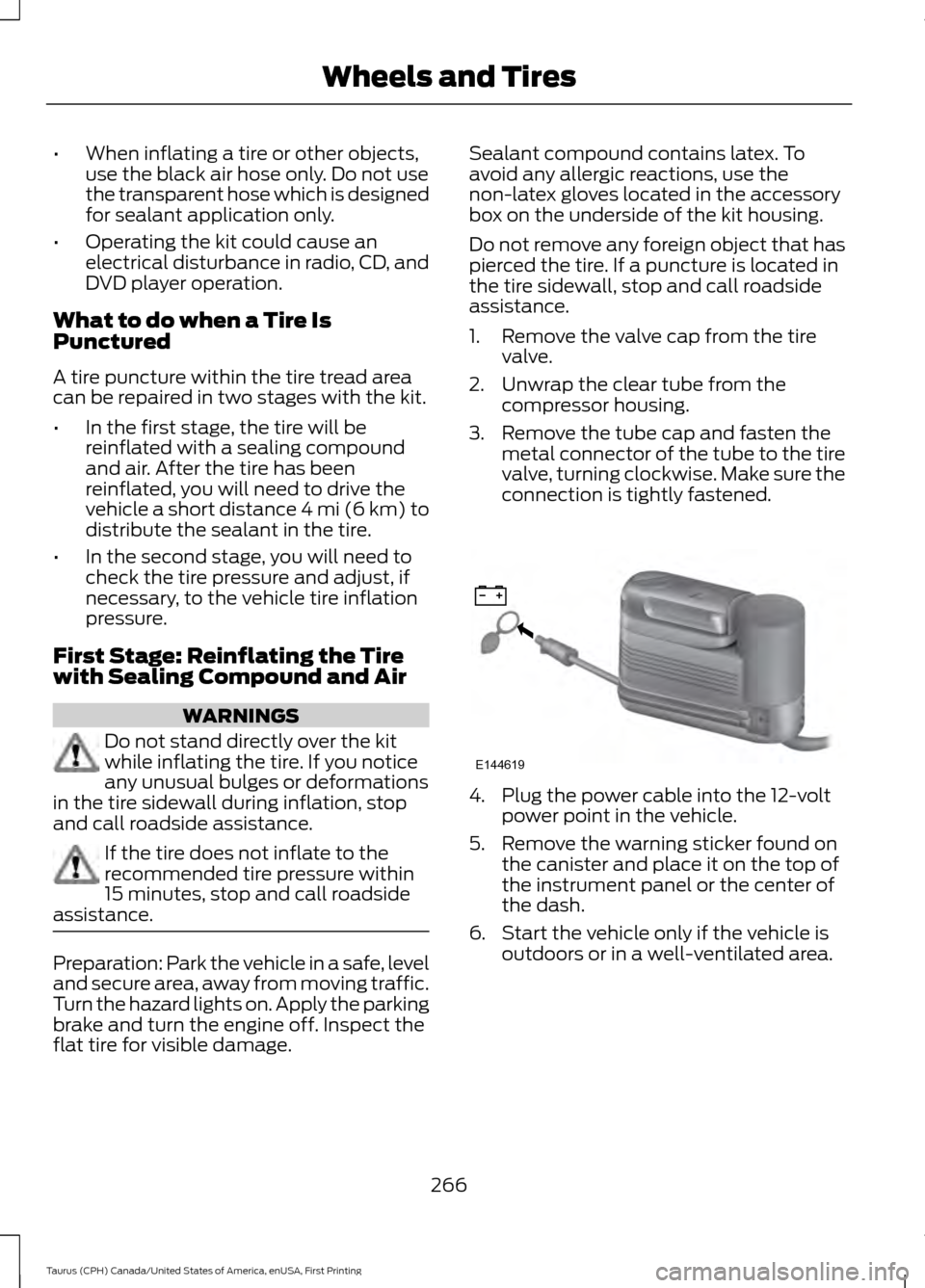

•

When inflating a tire or other objects,

use the black air hose only. Do not use

the transparent hose which is designed

for sealant application only.

• Operating the kit could cause an

electrical disturbance in radio, CD, and

DVD player operation.

What to do when a Tire Is

Punctured

A tire puncture within the tire tread area

can be repaired in two stages with the kit.

• In the first stage, the tire will be

reinflated with a sealing compound

and air. After the tire has been

reinflated, you will need to drive the

vehicle a short distance 4 mi (6 km) to

distribute the sealant in the tire.

• In the second stage, you will need to

check the tire pressure and adjust, if

necessary, to the vehicle tire inflation

pressure.

First Stage: Reinflating the Tire

with Sealing Compound and Air WARNINGS

Do not stand directly over the kit

while inflating the tire. If you notice

any unusual bulges or deformations

in the tire sidewall during inflation, stop

and call roadside assistance. If the tire does not inflate to the

recommended tire pressure within

15 minutes, stop and call roadside

assistance. Preparation: Park the vehicle in a safe, level

and secure area, away from moving traffic.

Turn the hazard lights on. Apply the parking

brake and turn the engine off. Inspect the

flat tire for visible damage. Sealant compound contains latex. To

avoid any allergic reactions, use the

non-latex gloves located in the accessory

box on the underside of the kit housing.

Do not remove any foreign object that has

pierced the tire. If a puncture is located in

the tire sidewall, stop and call roadside

assistance.

1. Remove the valve cap from the tire

valve.

2. Unwrap the clear tube from the compressor housing.

3. Remove the tube cap and fasten the metal connector of the tube to the tire

valve, turning clockwise. Make sure the

connection is tightly fastened. 4. Plug the power cable into the 12-volt

power point in the vehicle.

5. Remove the warning sticker found on the canister and place it on the top of

the instrument panel or the center of

the dash.

6. Start the vehicle only if the vehicle is outdoors or in a well-ventilated area.

266

Taurus (CPH) Canada/United States of America, enUSA, First Printing Wheels and TiresE144619

Page 287 of 424

Note:

The suspension insulation and

bumpers will help prevent vehicle damage.

Do not remove these components from your

vehicle when using snow tires and chains.

The tires on your vehicle have all-weather

treads to provide traction in rain and snow.

However, in some climates, you may need

to use snow tires and cables. If you need

to use cables, it is recommended that steel

wheels (of the same size and

specifications) be used, as cables may chip

aluminum wheels.

Follow these guidelines when using snow

tires and chains:

• If possible, avoid fully loading your

vehicle.

• Use only SAE Class S snow chains,

snow cables or equivalent on the front

axle for P235/55R18 equipped vehicles.

The use of snow chains, snow cables

or other traction assist devices that are

larger than SAE Class S may cause

damage to your vehicle ’s wheel house,

suspension and/or body.

• Do not install tire chains, cables, or

optional traction devices on the rear

tires. This could cause damage to the

vehicle ’s wheel house or body.

• Install cable chains securely, verifying

that the cables do not touch any wiring,

brake lines or fuel lines.

• Do not exceed 30 mph (48 km/h) with

tire cables on your vehicle.

• Drive cautiously. If you hear the cables

rub or bang against your vehicle, stop

and retighten the cables. If this does

not work, remove the cables to prevent

damage to your vehicle.

• Remove the tire cables when they are

no longer needed. Do not use tire

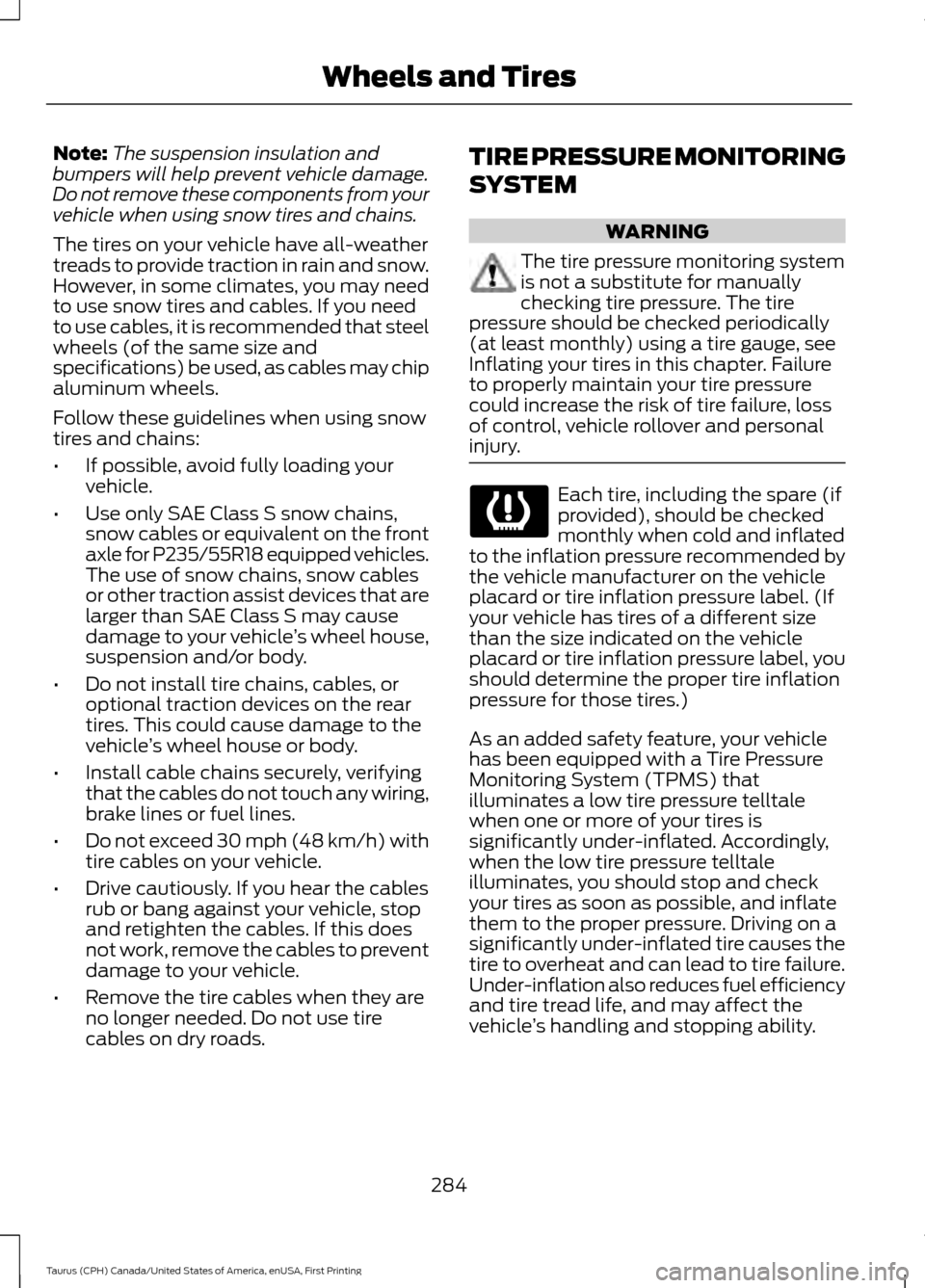

cables on dry roads. TIRE PRESSURE MONITORING

SYSTEM WARNING

The tire pressure monitoring system

is not a substitute for manually

checking tire pressure. The tire

pressure should be checked periodically

(at least monthly) using a tire gauge, see

Inflating your tires in this chapter. Failure

to properly maintain your tire pressure

could increase the risk of tire failure, loss

of control, vehicle rollover and personal

injury. Each tire, including the spare (if

provided), should be checked

monthly when cold and inflated

to the inflation pressure recommended by

the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. (If

your vehicle has tires of a different size

than the size indicated on the vehicle

placard or tire inflation pressure label, you

should determine the proper tire inflation

pressure for those tires.)

As an added safety feature, your vehicle

has been equipped with a Tire Pressure

Monitoring System (TPMS) that

illuminates a low tire pressure telltale

when one or more of your tires is

significantly under-inflated. Accordingly,

when the low tire pressure telltale

illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly under-inflated tire causes the

tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency

and tire tread life, and may affect the

vehicle ’s handling and stopping ability.

284

Taurus (CPH) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 293 of 424

WARNINGS

Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured. Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. To reduce the risk of possible serious

injury or death, do not remove the full

size spare tire from the factory

secured location. This location is necessary

to achieve police-rated 75 mph rear impact

crash-test performance. Removal

increases the risk of fuel leak in high-speed

rear impacts. Note:

Passengers should not remain in your

vehicle when the vehicle is being jacked.

Note: Jack at the specified locations to

avoid damage to the vehicle.

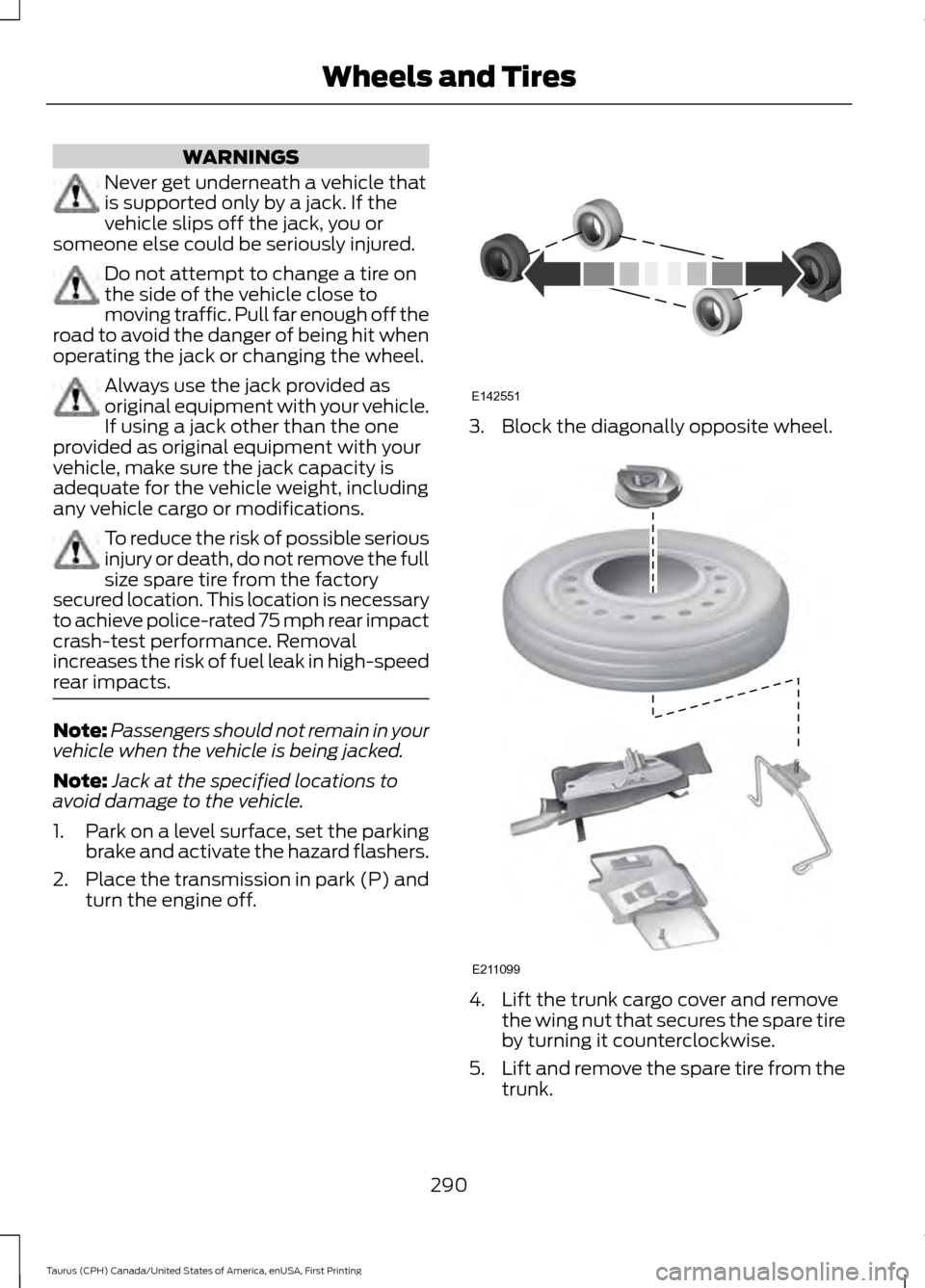

1. Park on a level surface, set the parking

brake and activate the hazard flashers.

2. Place the transmission in park (P) and

turn the engine off. 3. Block the diagonally opposite wheel.

4. Lift the trunk cargo cover and remove

the wing nut that secures the spare tire

by turning it counterclockwise.

5. Lift and remove the spare tire from the

trunk.

290

Taurus (CPH) Canada/United States of America, enUSA, First Printing Wheels and TiresE142551 E211099

Page 294 of 424

6. Remove the second wing nut that

secures the jack retention bracket by

turning it counterclockwise, then

remove the jack kit from your vehicle.

7. Remove the jack and the wrench from the felt bag. Fold down the wrench

socket used to loosen the lug nuts and

to operate the jack.

8. Loosen each wheel lug nut one-half turn counterclockwise, but do not

remove them until the wheel is raised

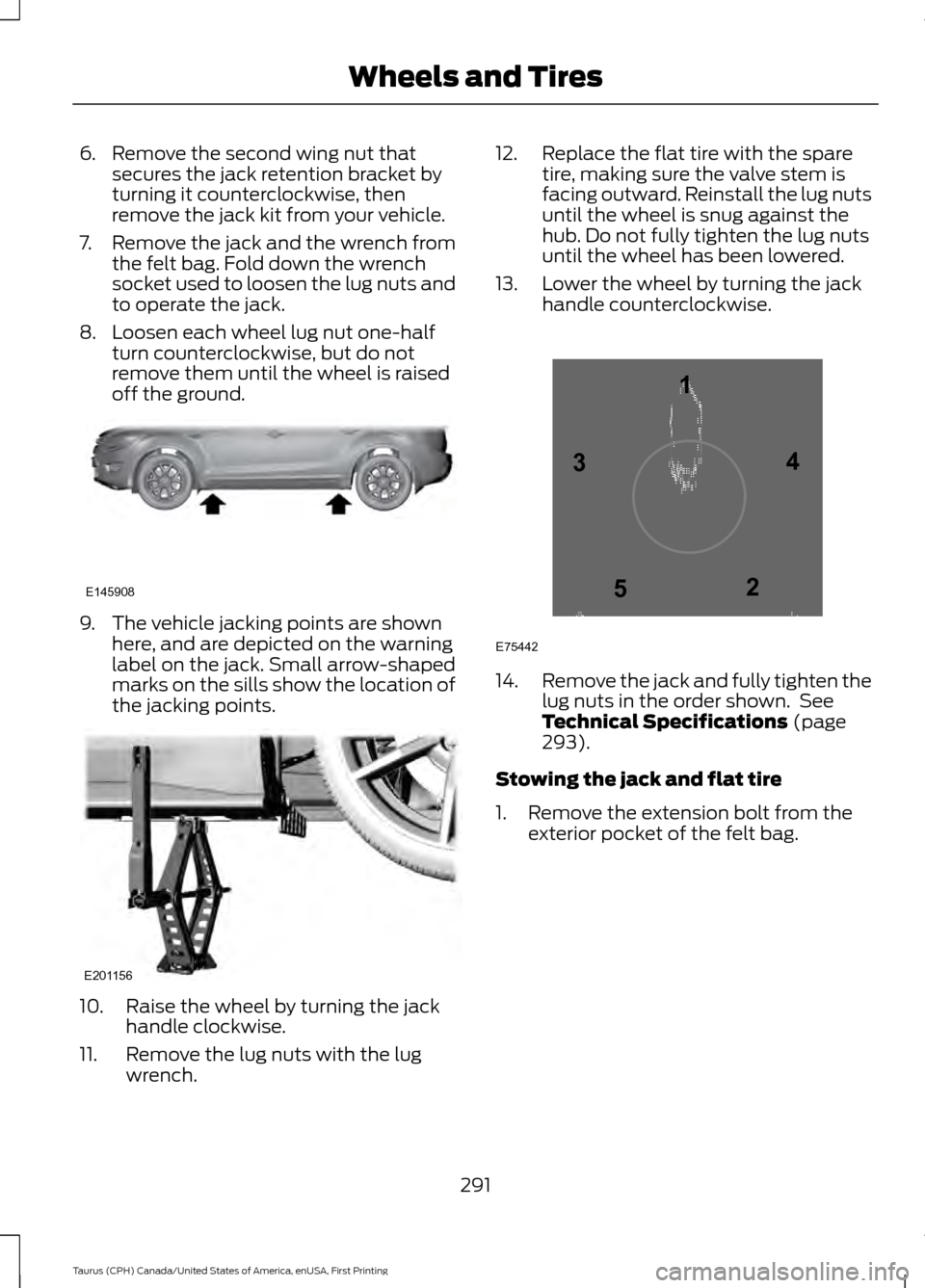

off the ground. 9. The vehicle jacking points are shown

here, and are depicted on the warning

label on the jack. Small arrow-shaped

marks on the sills show the location of

the jacking points. 10. Raise the wheel by turning the jack

handle clockwise.

11. Remove the lug nuts with the lug wrench. 12. Replace the flat tire with the spare

tire, making sure the valve stem is

facing outward. Reinstall the lug nuts

until the wheel is snug against the

hub. Do not fully tighten the lug nuts

until the wheel has been lowered.

13. Lower the wheel by turning the jack handle counterclockwise. 14.

Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page

293).

Stowing the jack and flat tire

1. Remove the extension bolt from the exterior pocket of the felt bag.

291

Taurus (CPH) Canada/United States of America, enUSA, First Printing Wheels and TiresE145908 E201156 12

3

4

5

E75442

Page 295 of 424

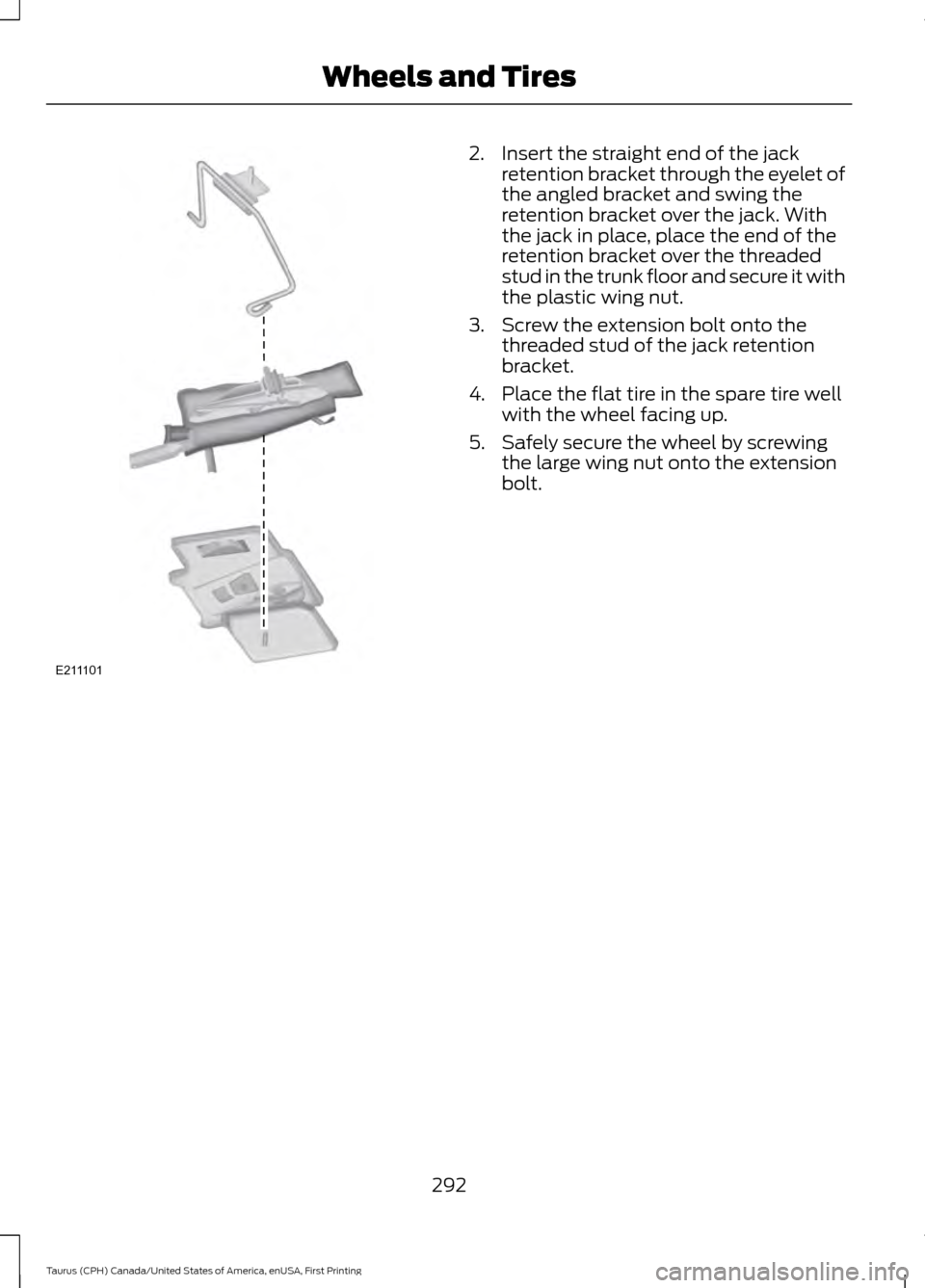

2. Insert the straight end of the jack

retention bracket through the eyelet of

the angled bracket and swing the

retention bracket over the jack. With

the jack in place, place the end of the

retention bracket over the threaded

stud in the trunk floor and secure it with

the plastic wing nut.

3. Screw the extension bolt onto the threaded stud of the jack retention

bracket.

4. Place the flat tire in the spare tire well with the wheel facing up.

5. Safely secure the wheel by screwing the large wing nut onto the extension

bolt.

292

Taurus (CPH) Canada/United States of America, enUSA, First Printing Wheels and TiresE211101

Page 296 of 424

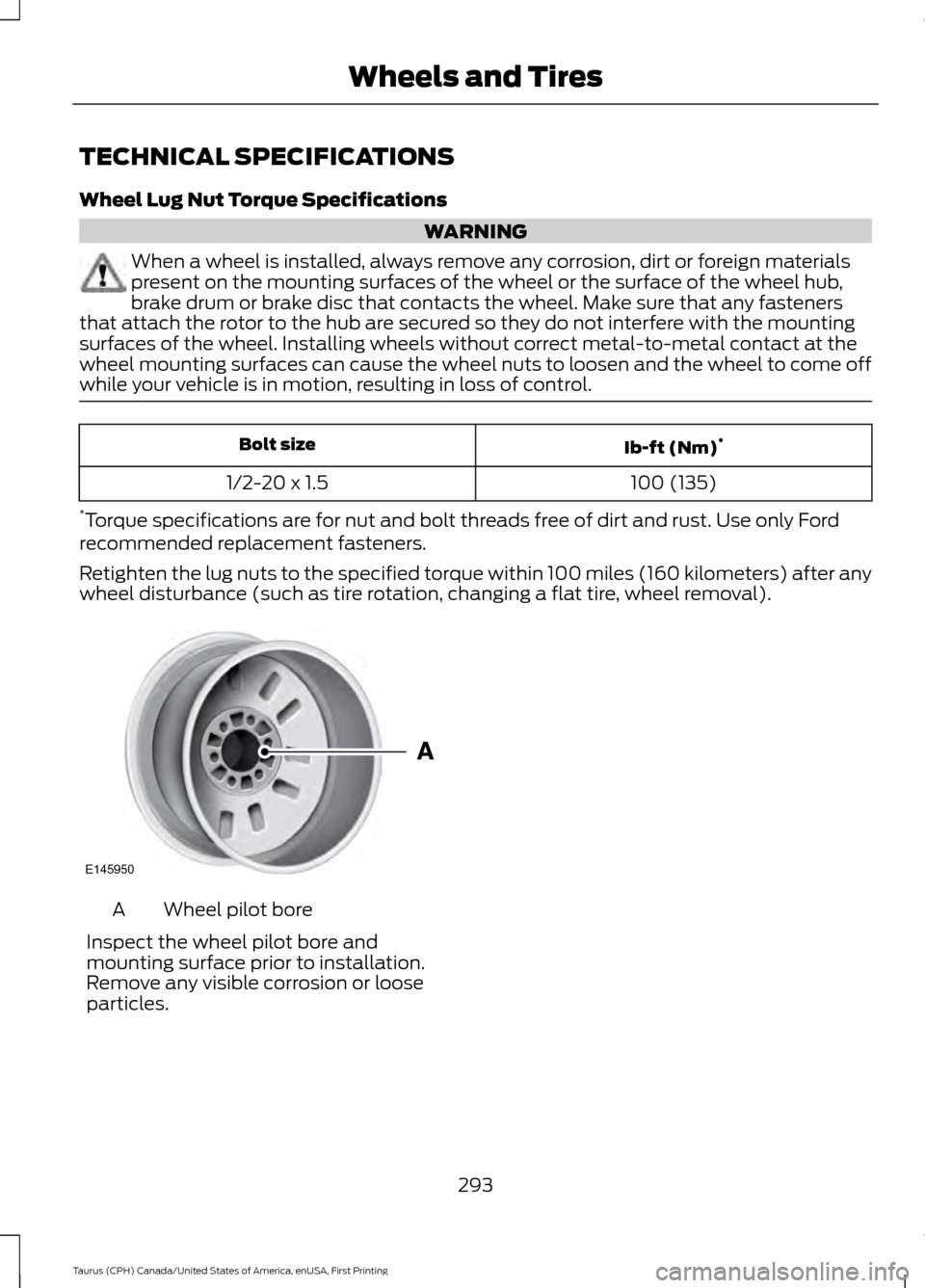

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materials

present on the mounting surfaces of the wheel or the surface of the wheel hub,

brake drum or brake disc that contacts the wheel. Make sure that any fasteners

that attach the rotor to the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off

while your vehicle is in motion, resulting in loss of control. Ib-ft (Nm)

*

Bolt size

100 (135)

1/2-20 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust. Use only Ford

recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kilometers) after any

wheel disturbance (such as tire rotation, changing a flat tire, wheel removal). Wheel pilot bore

A

Inspect the wheel pilot bore and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

293

Taurus (CPH) Canada/United States of America, enUSA, First Printing Wheels and TiresE145950