dimensions FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 49 of 234

Minimum Kerb + Driver

Running Order (Dimensions

mm)

Laden Gross Vehicle Mass (GVM)

with all passengers (Dimensions

mm)

Roof

Height

Model

8508001568136595723131750High300L

Diesel

8508001549136595724431818Medium330L

Diesel

8508001566136595724431818High330L

Diesel

8508001544136595724181762Medium350L

Diesel

8508001562136595724181762High350L

Diesel

All 430 Series have Anti-lock Brake System (ABS) so are not shown on these charts

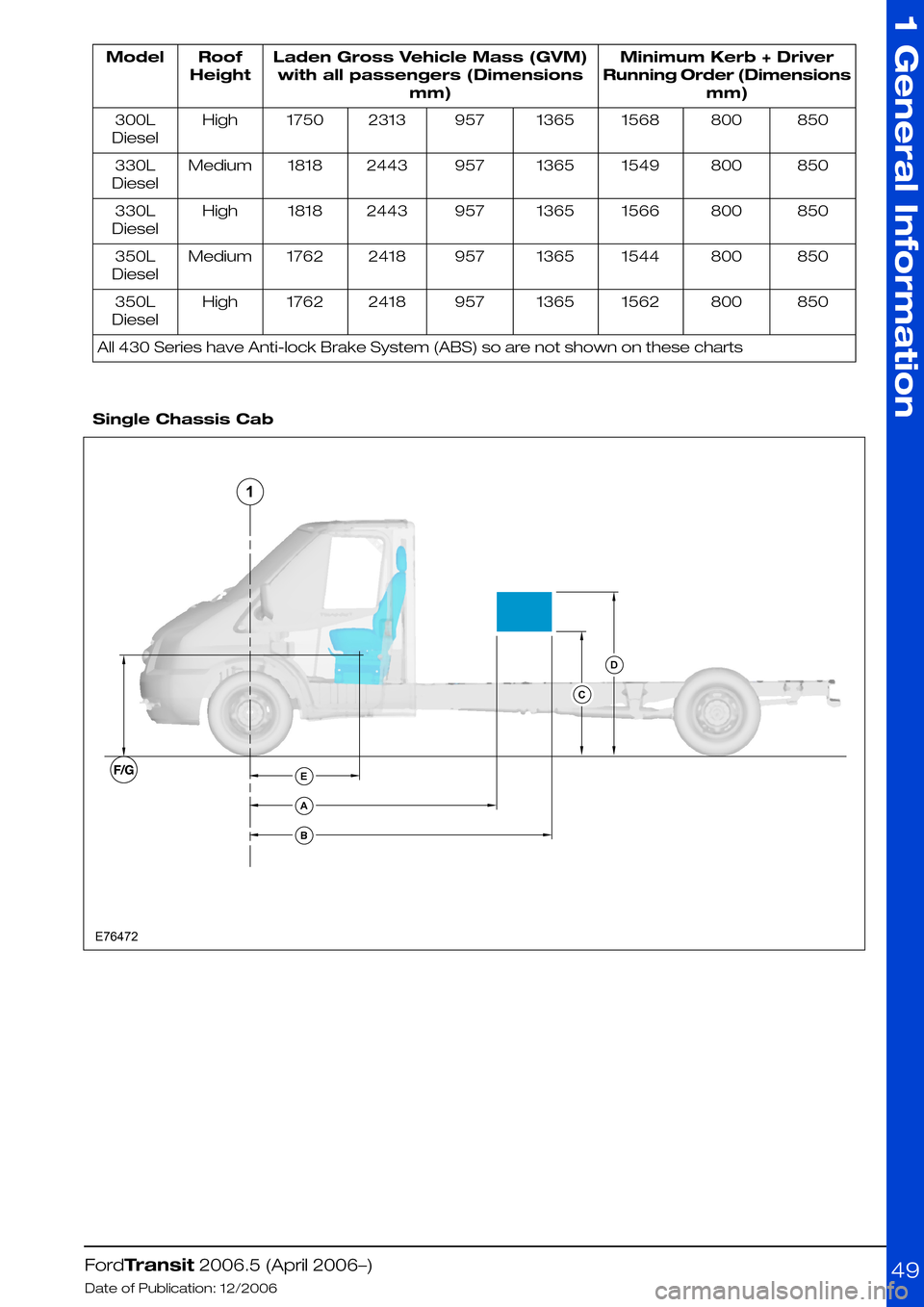

Single Chassis Cab

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

49EABCD1E76472

Page 50 of 234

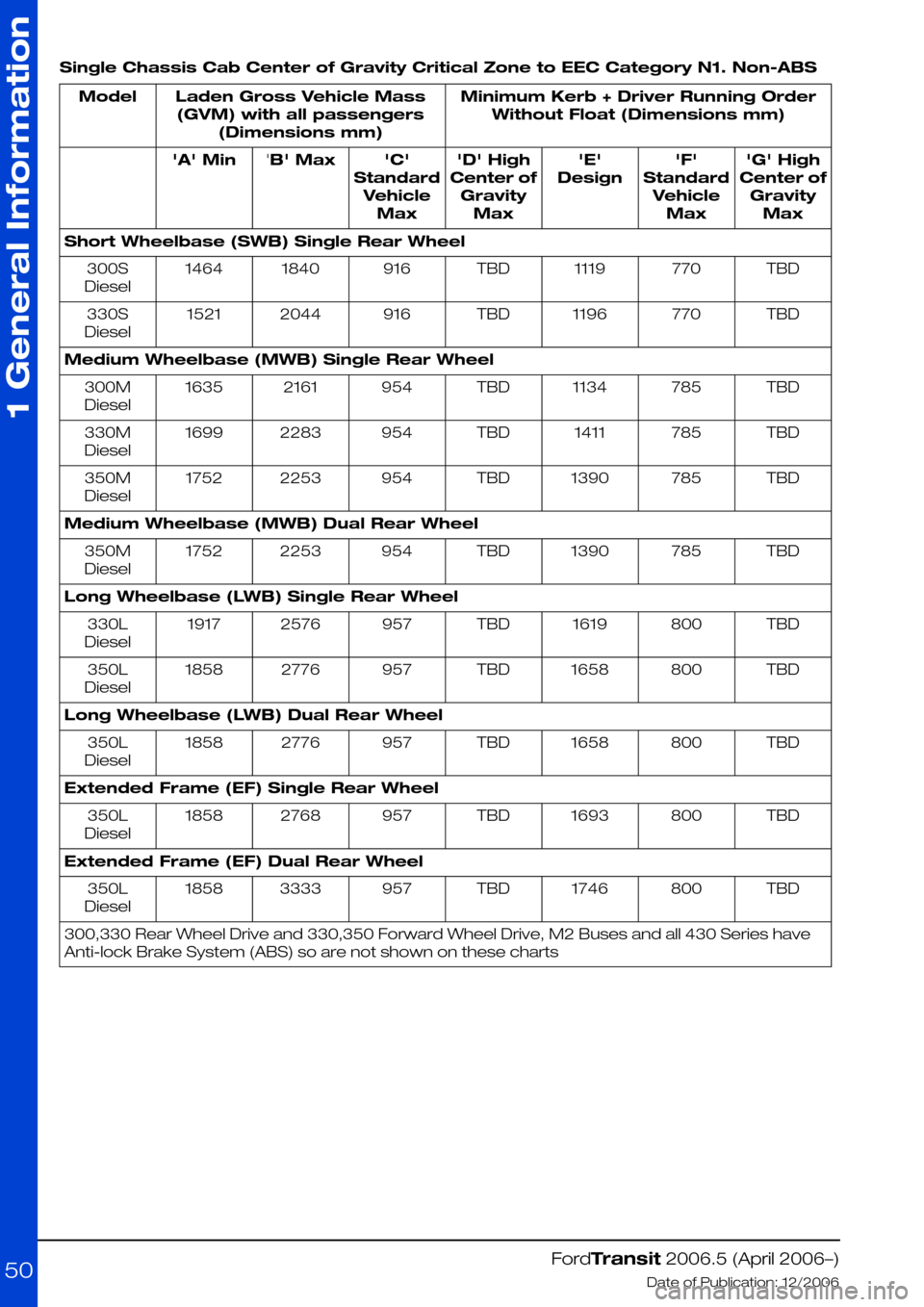

Single Chassis Cab Center of Gravity Critical Zone to EEC Category N1. Non-ABS

Minimum Kerb + Driver Running Order

Without Float (Dimensions mm)

Laden Gross Vehicle Mass

(GVM) with all passengers

(Dimensions mm)

Model

'G' High

Center of

Gravity

Max

'F'

Standard

Vehicle

Max

'E'

Design

'D' High

Center of

Gravity

Max

'C'

Standard

Vehicle

Max

'B' Max'A' Min

Short Wheelbase (SWB) Single Rear Wheel

TBD7701119TBD91618401464300S

Diesel

TBD7701196TBD91620441521330S

Diesel

Medium Wheelbase (MWB) Single Rear Wheel

TBD7851134TBD95421611635300M

Diesel

TBD7851411TBD95422831699330M

Diesel

TBD7851390TBD95422531752350M

Diesel

Medium Wheelbase (MWB) Dual Rear Wheel

TBD7851390TBD95422531752350M

Diesel

Long Wheelbase (LWB) Single Rear Wheel

TBD8001619TBD95725761917330L

Diesel

TBD8001658TBD95727761858350L

Diesel

Long Wheelbase (LWB) Dual Rear Wheel

TBD8001658TBD95727761858350L

Diesel

Extended Frame (EF) Single Rear Wheel

TBD8001693TBD95727681858350L

Diesel

Extended Frame (EF) Dual Rear Wheel

TBD8001746TBD95733331858350L

Diesel

300,330 Rear Wheel Drive and 330,350 Forward Wheel Drive, M2 Buses and all 430 Series have

Anti-lock Brake System (ABS) so are not shown on these charts

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

50

Page 52 of 234

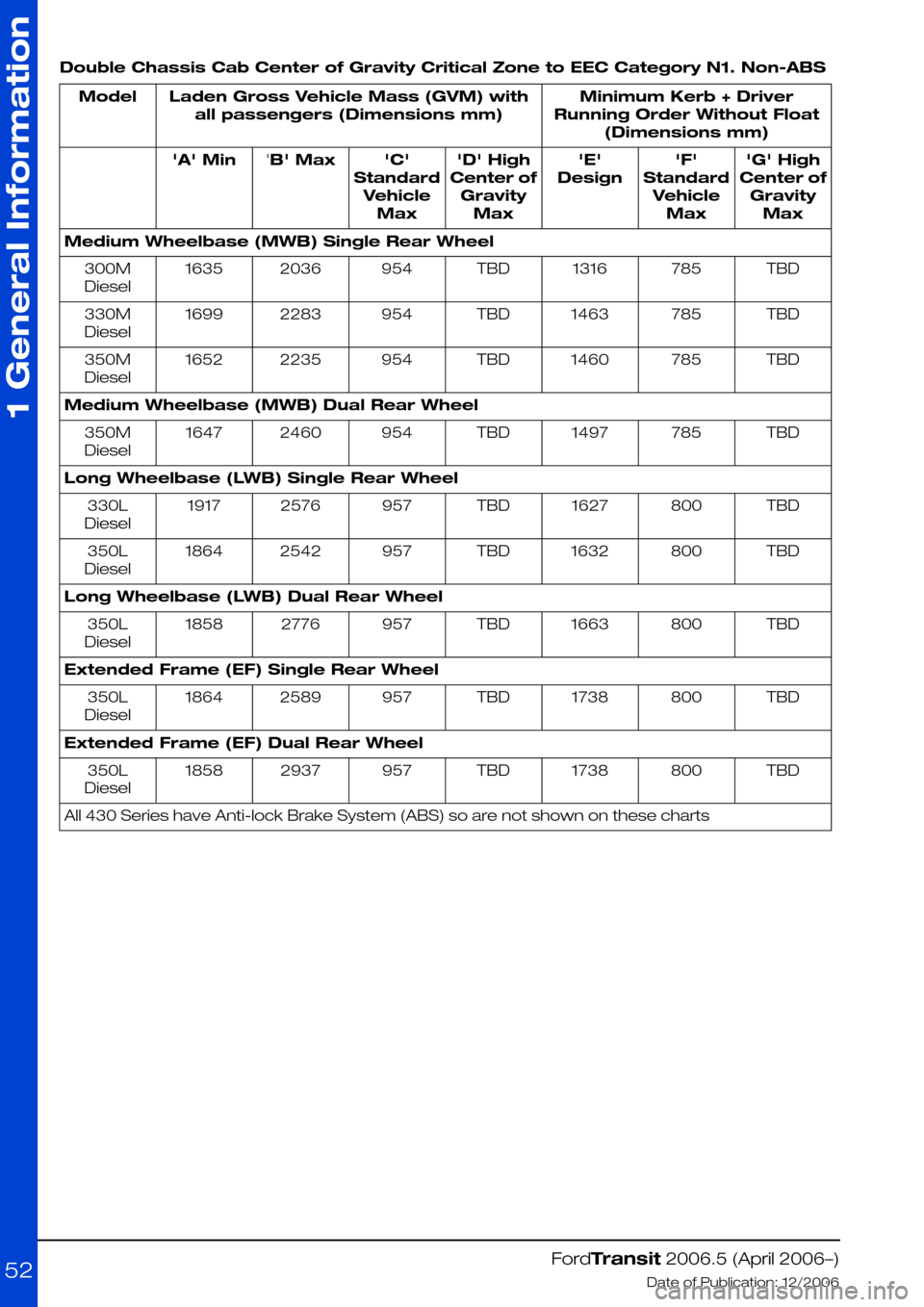

Double Chassis Cab Center of Gravity Critical Zone to EEC Category N1. Non-ABS

Minimum Kerb + Driver

Running Order Without Float

(Dimensions mm)

Laden Gross Vehicle Mass (GVM) with

all passengers (Dimensions mm)

Model

'G' High

Center of

Gravity

Max

'F'

Standard

Vehicle

Max

'E'

Design

'D' High

Center of

Gravity

Max

'C'

Standard

Vehicle

Max

'B' Max'A' Min

Medium Wheelbase (MWB) Single Rear Wheel

TBD7851316TBD95420361635300M

Diesel

TBD7851463TBD95422831699330M

Diesel

TBD7851460TBD95422351652350M

Diesel

Medium Wheelbase (MWB) Dual Rear Wheel

TBD7851497TBD95424601647350M

Diesel

Long Wheelbase (LWB) Single Rear Wheel

TBD8001627TBD95725761917330L

Diesel

TBD8001632TBD95725421864350L

Diesel

Long Wheelbase (LWB) Dual Rear Wheel

TBD8001663TBD95727761858350L

Diesel

Extended Frame (EF) Single Rear Wheel

TBD8001738TBD95725891864350L

Diesel

Extended Frame (EF) Dual Rear Wheel

TBD8001738TBD95729371858350L

Diesel

All 430 Series have Anti-lock Brake System (ABS) so are not shown on these charts

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

52

Page 53 of 234

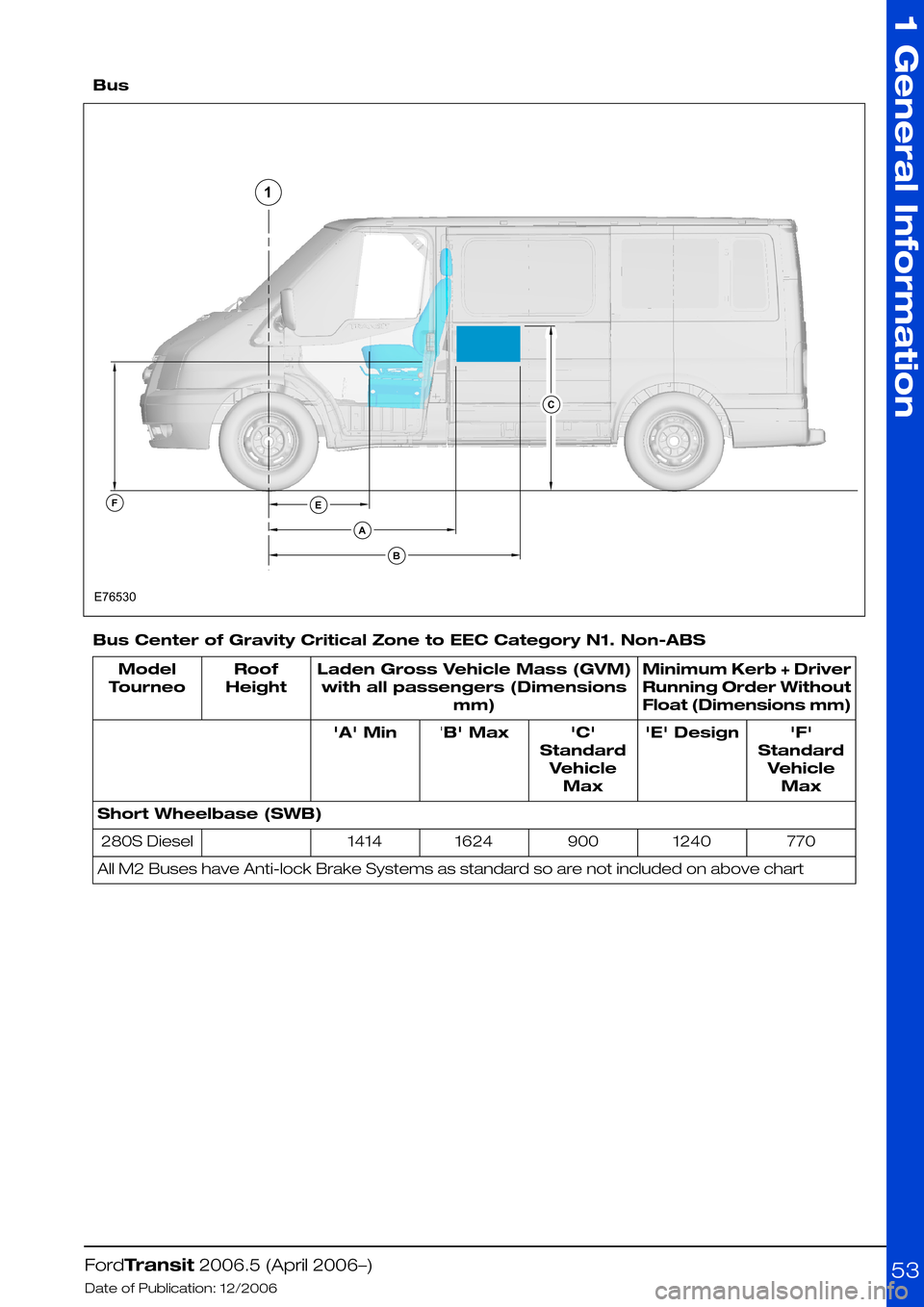

Bus

Bus Center of Gravity Critical Zone to EEC Category N1. Non-ABS

Minimum Kerb + Driver

Running Order Without

Float (Dimensions mm)

Laden Gross Vehicle Mass (GVM)

with all passengers (Dimensions

mm)

Roof

Height

Model

Tourneo

'F'

Standard

Vehicle

Max

'E' Design'C'

Standard

Vehicle

Max

'B' Max'A' Min

Short Wheelbase (SWB)

770124090016241414280S Diesel

All M2 Buses have Anti-lock Brake Systems as standard so are not included on above chart

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

53EABFCE765301

Page 60 of 234

2.4 Wheels and Tires

2.4.1 Wheel Clearance

The distance from the tire to the mudguard or

wheel arch must be sufficient, even if snow or

anti-skid chains are fitted and the suspension is

fully compressed allowing for axle twist as well.

Please consult the Vehicle Converter Advisory

Service [email protected] for clearance

requirements and data.

NOTE: Make sure that only approved wheels

and /or permissible tire sizes are fitted

For standard wheelhouse dimensions.

Refer to: 5.1 Body (page 175).

(Integral Bodies and Conversions)

2.4.2 Tire Manufacturers

Replacement tires should be of the same make,

size, tread pattern and load rating as the Original

Equipment Manufacturer. Under these conditions

the original tire label should be satisfactory,

however if the specified tires and/or inflation

pressures are changed then a new label should

be affixed over the original label.

2.4.3 Spare wheel

When converting or relocating the spare wheel,

access must be ensured.

2.4.4 Painting Road Wheels

CAUTION: Do not paint wheel clamp

surfaces in contact with other

wheels, brake drum or disc, hub and

holes, or surfaces under wheel nuts.

Any further treatment in these areas

may affect the wheel clamp

performance and the vehicle safety.

•Mask the wheel when changing the color or

repairing paint.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

2 Chassis

60

Page 176 of 234

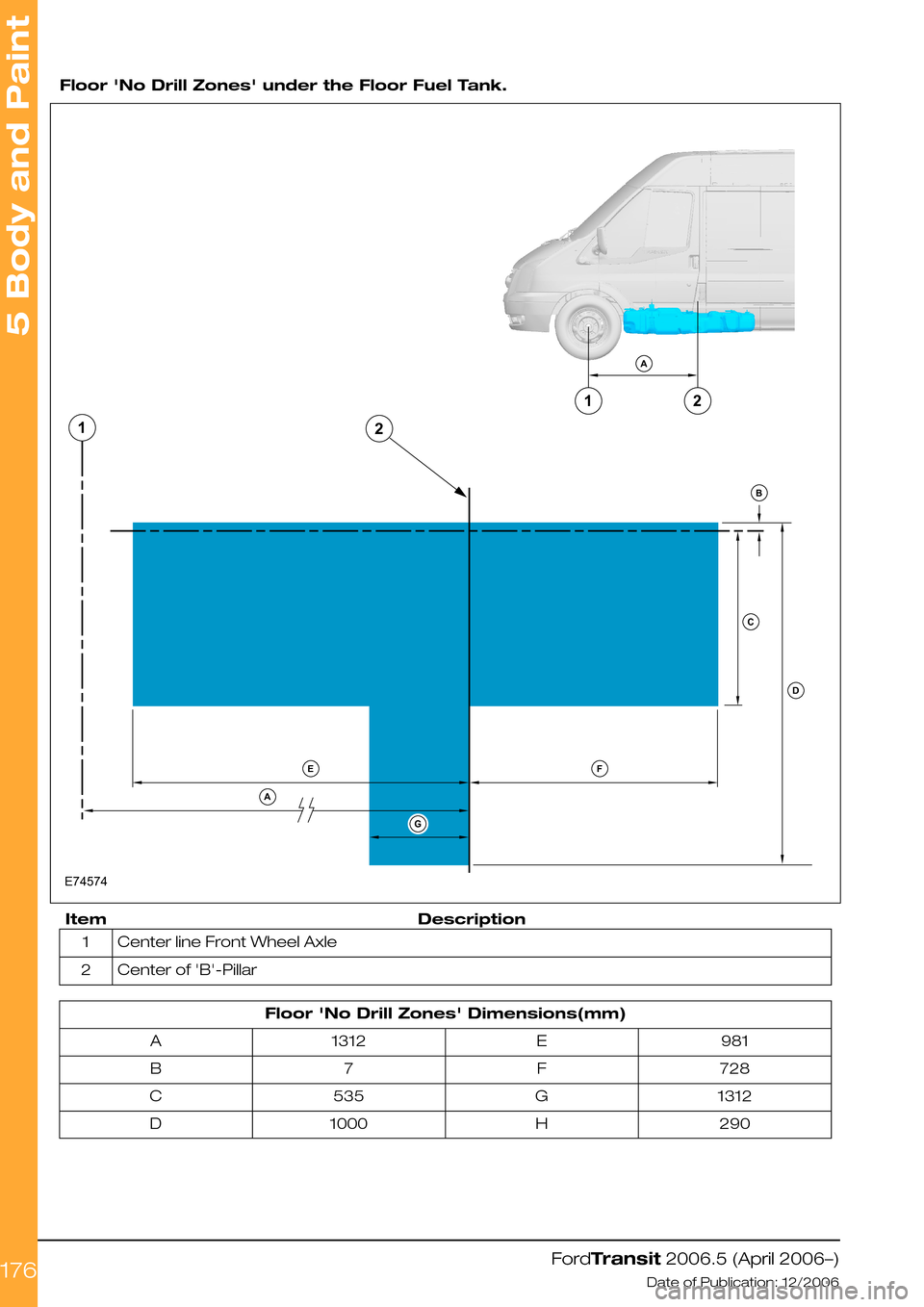

Floor 'No Drill Zones' under the Floor Fuel Tank.

DescriptionItem

Center line Front Wheel Axle1

Center of 'B'-Pillar2

Floor 'No Drill Zones' Dimensions(mm)

981E1312A

728F7B

1312G535C

290H1000D

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

176E745742211ABCDEAFG

Page 177 of 234

5.1.2 Back Panel Removal

When planning and specifying the base vehicle

and the conversion, select the Special Vehicle

Option, which has a detachable cab back panel.

Please consult your local National Sales

Representative for availability.

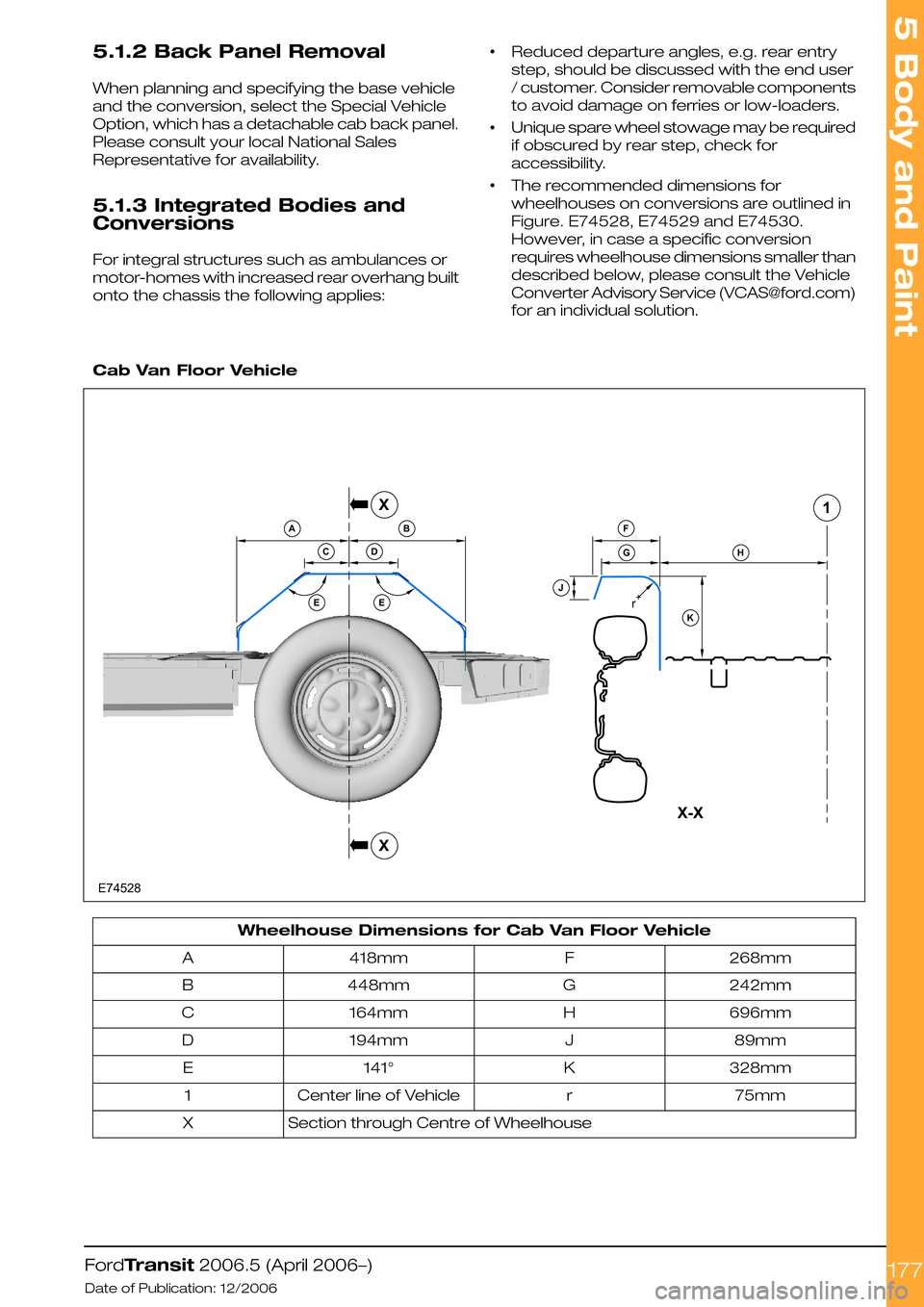

5.1.3 Integrated Bodies and

Conversions

For integral structures such as ambulances or

motor-homes with increased rear overhang built

onto the chassis the following applies:

•Reduced departure angles, e.g. rear entry

step, should be discussed with the end user

/ customer. Consider removable components

to avoid damage on ferries or low-loaders.

•Unique spare wheel stowage may be required

if obscured by rear step, check for

accessibility.

•The recommended dimensions for

wheelhouses on conversions are outlined in

Figure. E74528, E74529 and E74530.

However, in case a specific conversion

requires wheelhouse dimensions smaller than

described below, please consult the Vehicle

Converter Advisory Service ([email protected])

for an individual solution.

Cab Van Floor Vehicle

Wheelhouse Dimensions for Cab Van Floor Vehicle

268mmF418mmA

242mmG448mmB

696mmH164mmC

89mmJ194mmD

328mmK141°E

75mmrCenter line of Vehicle1

Section through Centre of WheelhouseX

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

177E74528rBFGHJKACDEEX1XX-X

Page 178 of 234

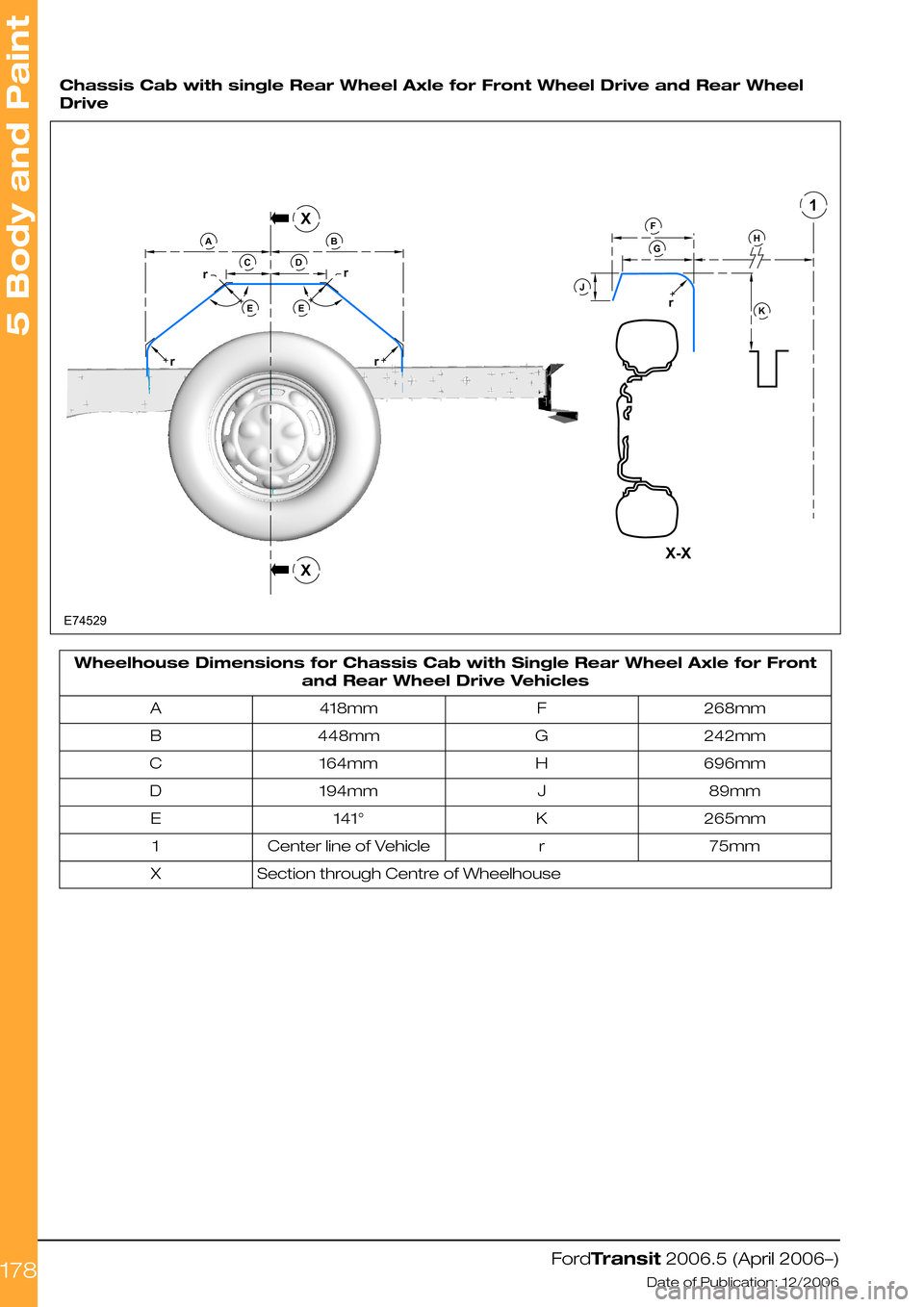

Chassis Cab with single Rear Wheel Axle for Front Wheel Drive and Rear Wheel

Drive

Wheelhouse Dimensions for Chassis Cab with Single Rear Wheel Axle for Front

and Rear Wheel Drive Vehicles

268mmF418mmA

242mmG448mmB

696mmH164mmC

89mmJ194mmD

265mmK141°E

75mmrCenter line of Vehicle1

Section through Centre of WheelhouseX

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

178E74529rrrrrACDBEEFKJHGX1XX-X

Page 179 of 234

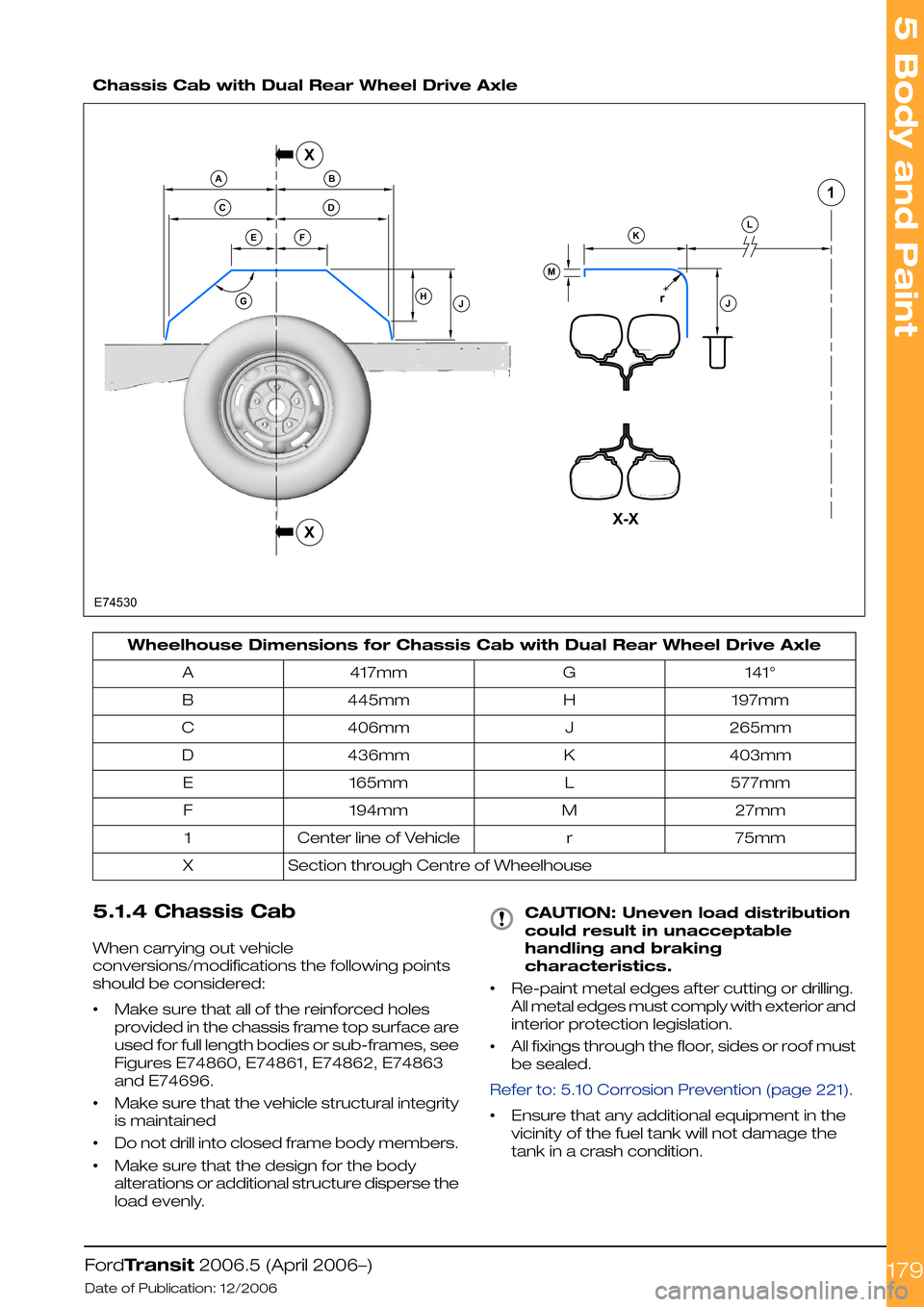

Chassis Cab with Dual Rear Wheel Drive Axle

Wheelhouse Dimensions for Chassis Cab with Dual Rear Wheel Drive Axle

141°G417mmA

197mmH445mmB

265mmJ406mmC

403mmK436mmD

577mmL165mmE

27mmM194mmF

75mmrCenter line of Vehicle1

Section through Centre of WheelhouseX

5.1.4 Chassis Cab

When carrying out vehicle

conversions/modifications the following points

should be considered:

•Make sure that all of the reinforced holes

provided in the chassis frame top surface are

used for full length bodies or sub-frames, see

Figures E74860, E74861, E74862, E74863

and E74696.

•Make sure that the vehicle structural integrity

is maintained

•Do not drill into closed frame body members.

•Make sure that the design for the body

alterations or additional structure disperse the

load evenly.

CAUTION: Uneven load distribution

could result in unacceptable

handling and braking

characteristics.

•Re-paint metal edges after cutting or drilling.

All metal edges must comply with exterior and

interior protection legislation.

•All fixings through the floor, sides or roof must

be sealed.

Refer to: 5.10 Corrosion Prevention (page 221).

•Ensure that any additional equipment in the

vicinity of the fuel tank will not damage the

tank in a crash condition.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

179rE74530GABDCEFHJMKLJX1XX-X

Page 180 of 234

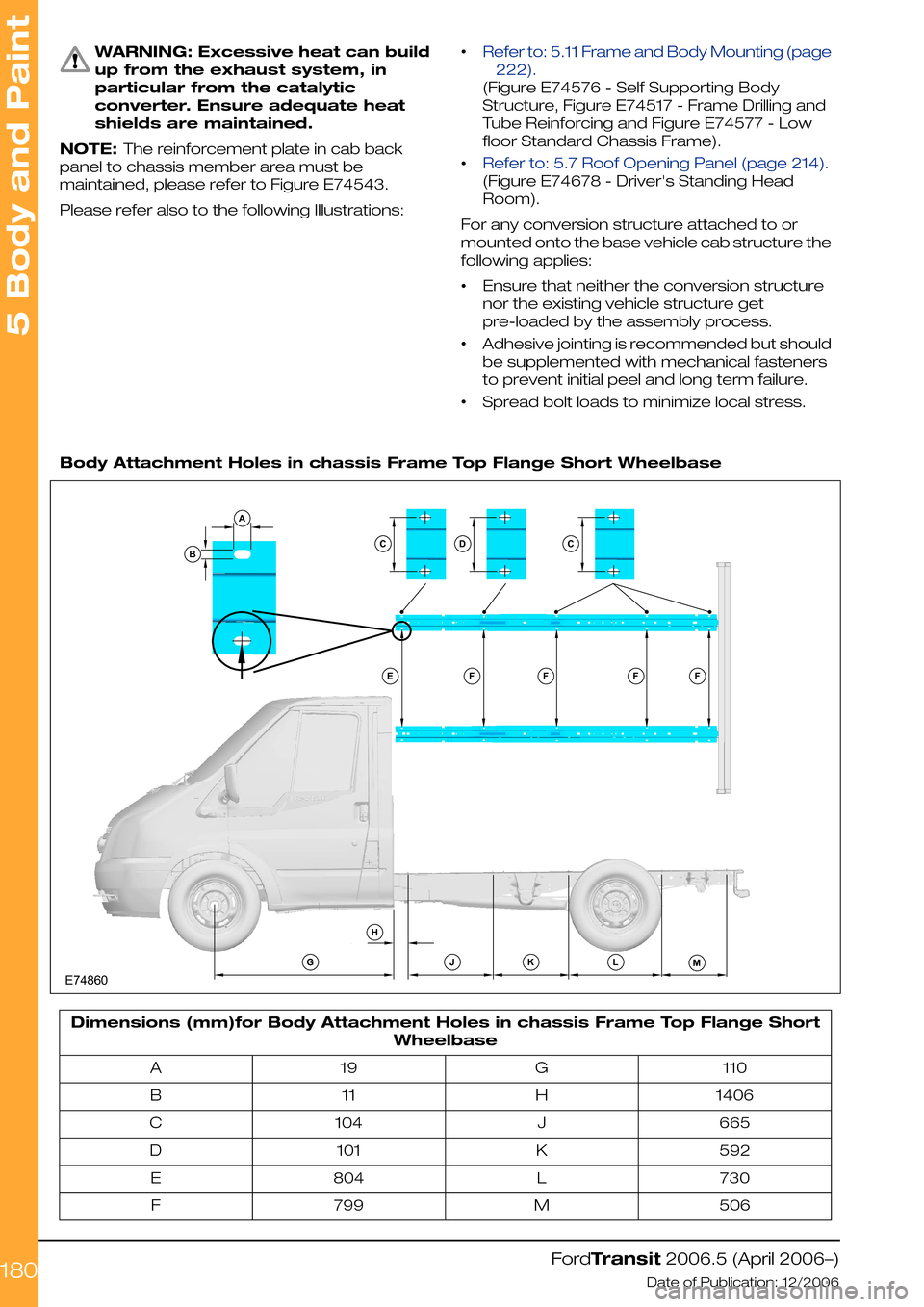

WARNING: Excessive heat can build

up from the exhaust system, in

particular from the catalytic

converter. Ensure adequate heat

shields are maintained.

NOTE: The reinforcement plate in cab back

panel to chassis member area must be

maintained, please refer to Figure E74543.

Please refer also to the following Illustrations:

•Refer to: 5.11 Frame and Body Mounting (page

222).

(Figure E74576 - Self Supporting Body

Structure, Figure E74517 - Frame Drilling and

Tube Reinforcing and Figure E74577 - Low

floor Standard Chassis Frame).

•Refer to: 5.7 Roof Opening Panel (page 214).

(Figure E74678 - Driver's Standing Head

Room).

For any conversion structure attached to or

mounted onto the base vehicle cab structure the

following applies:

•Ensure that neither the conversion structure

nor the existing vehicle structure get

pre-loaded by the assembly process.

•Adhesive jointing is recommended but should

be supplemented with mechanical fasteners

to prevent initial peel and long term failure.

•Spread bolt loads to minimize local stress.

Body Attachment Holes in chassis Frame Top Flange Short Wheelbase

Dimensions (mm)for Body Attachment Holes in chassis Frame Top Flange Short

Wheelbase

110G19A

1406H11B

665J104C

592K101D

730L804E

506M799F

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

180ADBE74860CEFFHGJKLMFFC