jack points FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 27 of 234

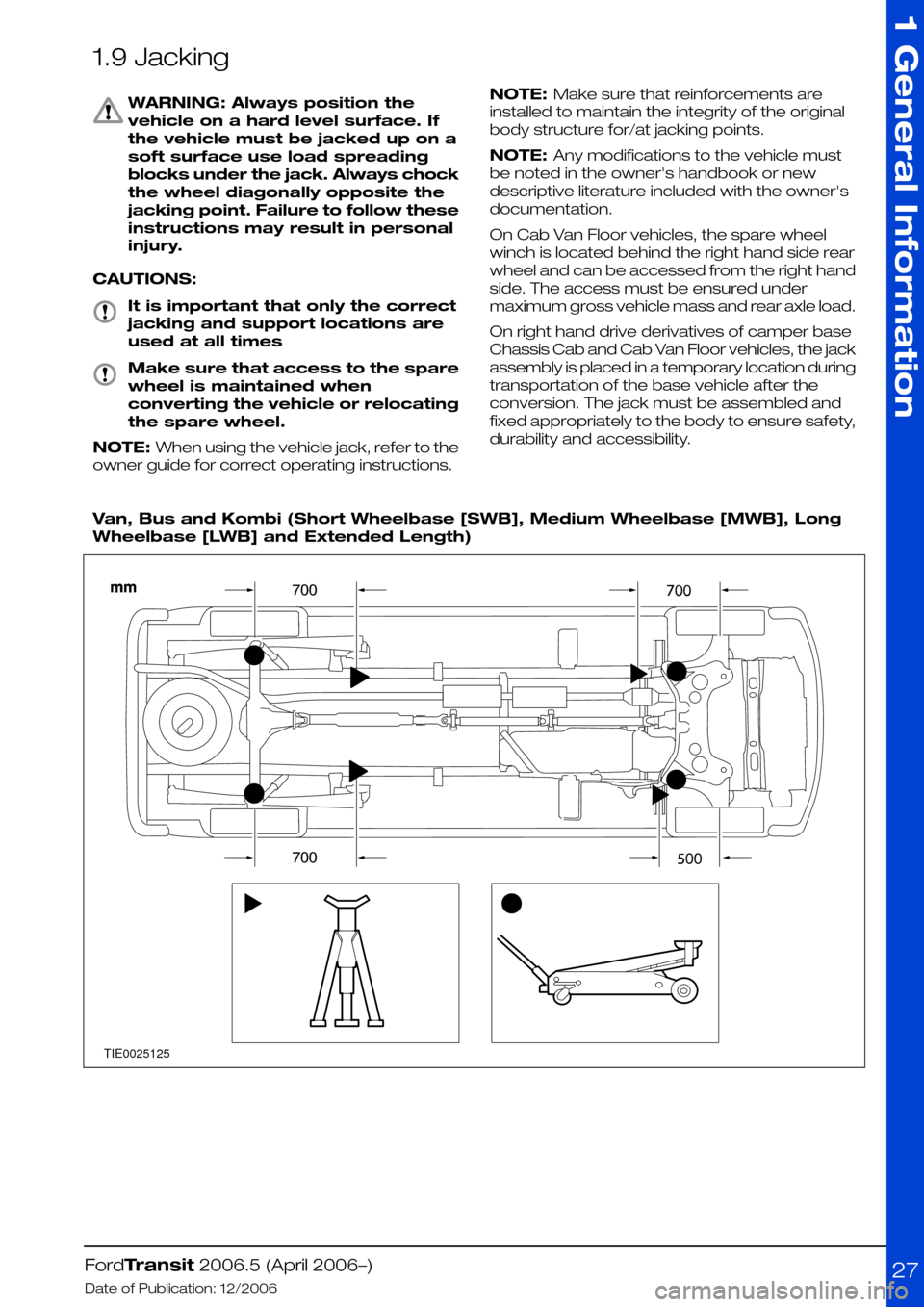

1.9 Jacking

WARNING: Always position the

vehicle on a hard level surface. If

the vehicle must be jacked up on a

soft surface use load spreading

blocks under the jack. Always chock

the wheel diagonally opposite the

jacking point. Failure to follow these

instructions may result in personal

injury.

CAUTIONS:

It is important that only the correct

jacking and support locations are

used at all times

Make sure that access to the spare

wheel is maintained when

converting the vehicle or relocating

the spare wheel.

NOTE: When using the vehicle jack, refer to the

owner guide for correct operating instructions.

NOTE: Make sure that reinforcements are

installed to maintain the integrity of the original

body structure for/at jacking points.

NOTE: Any modifications to the vehicle must

be noted in the owner's handbook or new

descriptive literature included with the owner's

documentation.

On Cab Van Floor vehicles, the spare wheel

winch is located behind the right hand side rear

wheel and can be accessed from the right hand

side. The access must be ensured under

maximum gross vehicle mass and rear axle load.

On right hand drive derivatives of camper base

Chassis Cab and Cab Van Floor vehicles, the jack

assembly is placed in a temporary location during

transportation of the base vehicle after the

conversion. The jack must be assembled and

fixed appropriately to the body to ensure safety,

durability and accessibility.

Van, Bus and Kombi (Short Wheelbase [SWB], Medium Wheelbase [MWB], Long

Wheelbase [LWB] and Extended Length)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

27TIE0025125

Page 192 of 234

For Chassis Cab with tail lift design as described

above it is recommended to use unique body

sub-frame for fixing to Chassis Cab structure. For

connection between sub-frame Chassis Cab

body structure please refer to Figure E74696.

For Chassis Cab with under-slung tail lift load

capacity is up to 1000kg at 1000mm from rear

end of chassis frame to center of load if mounted

and functioning on centre line of vehicle. If

mounted and functioning off center line or at the

side of the vehicle load capacity is reduced to

500kg at 1000mm from side/rear end to center

of load.

Greater off-sets and/or loads require additional

stabilizing equipment such as outriggers or

ground jacks. It is recommended not to increase

vehicle body stress over limit as given by load

factors above. If uncertain please consult your

local national sales representative or the Vehicle

Converter Advisory Service [email protected].

It is the Vehicle converters responsibility to fit a

decal to the converted vehicle stating that the

equipment must not be used without

outriggers/ground jacks in operating position. It

is also the vehicle converters responsibility to

guarantee safe functioning of the equipment.

For hydraulic tail lifts as used for general loading

or more specialized for wheel-chair lifts please

refer to Figure E75874.

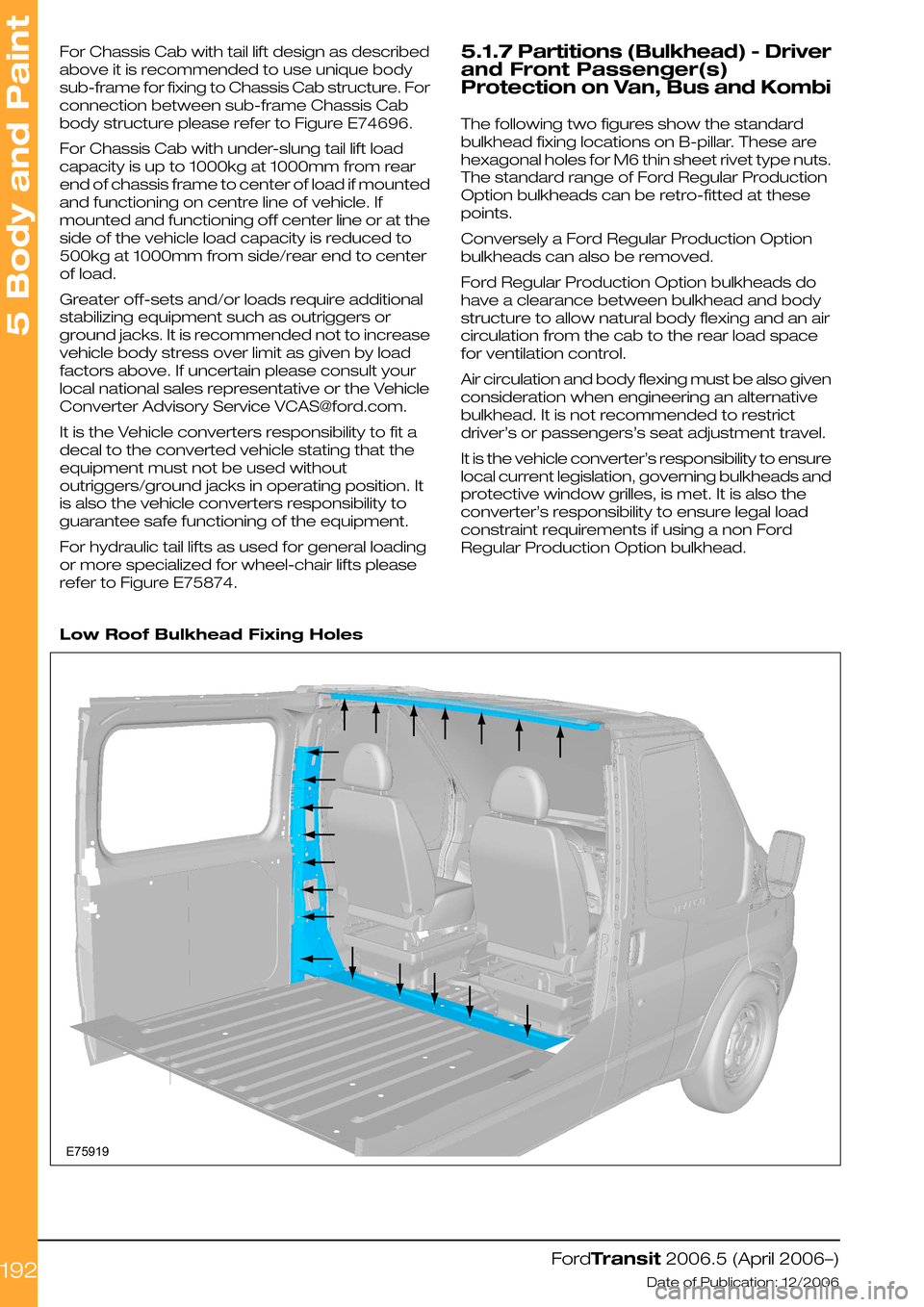

5.1.7 Partitions (Bulkhead) - Driver

and Front Passenger(s)

Protection on Van, Bus and Kombi

The following two figures show the standard

bulkhead fixing locations on B-pillar. These are

hexagonal holes for M6 thin sheet rivet type nuts.

The standard range of Ford Regular Production

Option bulkheads can be retro-fitted at these

points.

Conversely a Ford Regular Production Option

bulkheads can also be removed.

Ford Regular Production Option bulkheads do

have a clearance between bulkhead and body

structure to allow natural body flexing and an air

circulation from the cab to the rear load space

for ventilation control.

Air circulation and body flexing must be also given

consideration when engineering an alternative

bulkhead. It is not recommended to restrict

driver’s or passengers’s seat adjustment travel.

It is the vehicle converter’s responsibility to ensure

local current legislation, governing bulkheads and

protective window grilles, is met. It is also the

converter’s responsibility to ensure legal load

constraint requirements if using a non Ford

Regular Production Option bulkhead.

Low Roof Bulkhead Fixing Holes

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

192E75919

Page 231 of 234

Generator and Alternator...............................103

Glass, Frames and Mechanisms...................211

Ground Points..................................................140

H

Hardware—Specifications...............................43

Heated Seats...................................................210

Heated Windshield and Heated Rear Window.

213

Horn...................................................................108

How to Use This Manual....................................6

Hydraulic Brake Actuation...............................64

Hydraulic Lifting Equipment for Van, Bus, Kombi

and Chassis Cab...........................................186

I

Important Safety Instructions............................6

Information and Entertainment System -

General Information—Specifications...........112

Installation and Routing Guides.....................134

Instrument Cluster...........................................107

Integrated Bodies and Conversions.............177

Interior Lighting.................................................118

Introduction..........................................................6

J

Jacking................................................................27

K

Kerb Mass Data.................................................62

L

Lamps for Wide Vehicles.................................117

Lamps – Front and Rear Fog Lights..............117

Lamps – Hazard / Direction Indication..........117

Legal and Vehicle Type Approval......................7

Legal Obligations and Liabilities.........................7

Legislation.........................................................109

Lifting...................................................................29

Load Apportioning Valves................................64

Load Compartment Interior Lining...............203

Load Distribution—Specifications...................44

Load Distribution Calculations - Driver and

Passenger Weight Distribution.....................44

M

Manual Transmission........................................83

Minimum Requirements for Brake system and

Load Apportioning Valves ...............................8

Mirrors for Wide Vehicles...............................208

Module Communications

Network—Specifications................................94

Mounting Points and Tubing.........................222

N

Noise, Vibration and Harshness (NVH)...........31

Non Standard Rear Chassis Frame Extension.

226

P

Package and Ergonomics—Specifications....

34

Package and Ergonomics...............................33

Painting Road Wheels..............................60, 221

Parking Brake....................................................63

Partitions (Bulkhead) - Driver and Front

Passenger(s) Protection on Van, Bus and

Kombi..............................................................192

Possible Accessories.......................................113

Power Management Settings.........................95

Power Take Off...................................................61

Product Liability....................................................8

R

Racking Systems.............................................194

Radio Connector..............................................112

Rear Anti-Roll Bar..............................................59

Rear Seat Fixings Positions - Kombi............209

Rear Suspension...............................................59

Rear View Mirrors...........................................208

Rear Windows..................................................211

Recommended Main Dimensions.................34

Recommended Main Load Area Dimensions

for Bulkhead with Depression Driver Side....

39

Recommended Main Load Area Dimensions

for Bulkhead with Full Depression................40

Recommended Main Load Area Dimensions

for Double Cab In Van Bulkhead...................41

Recommended Nominal Body Lengths for

Chassis Cab models......................................36

Relays and Switches.......................................127

Relocated Parking Brake Lever......................63

Repairing Damaged Paint..............................221

Restraints System...............................................8

Reversing Lamps.............................................116

Road Safety..........................................................8

Roof Opening Panel........................................214

Roof Racks.......................................................216

Roof Ventilation................................................215

S

Safety Belt System.........................................220

Seats.................................................................209

Security, Anti Theft and Locking System

Security ..........................................................203

Self-Supporting Body Structure...................224

Spare Tire Access and Mounting.................229

Spare wheel.......................................................60

Special Conversions........................................131

Special Vehicle Option Auxiliary Fuse Box....

121

Index

231