warning light FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 4 of 234

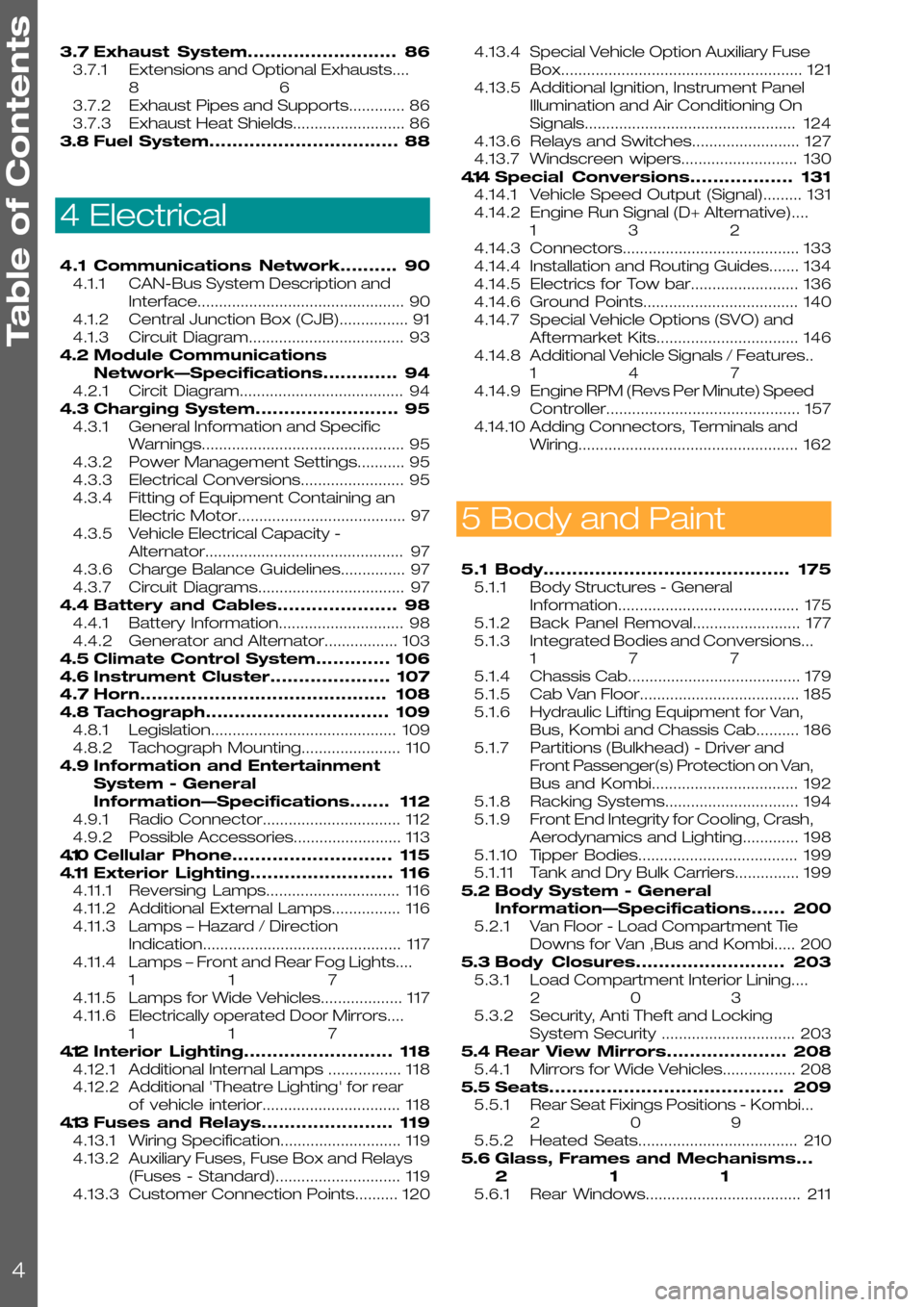

3.7Exhaust System..........................86

3.7.1Extensions and Optional Exhausts....

86

3.7.2Exhaust Pipes and Supports.............86

3.7.3Exhaust Heat Shields..........................86

3.8Fuel System.................................88

4 Electrical

4.1Communications Network..........90

4.1.1CAN-Bus System Description and

Interface................................................90

4.1.2Central Junction Box (CJB)................91

4.1.3Circuit Diagram....................................93

4.2Module Communications

Network—Specifications.............94

4.2.1Circit Diagram......................................94

4.3Charging System.........................95

4.3.1General Information and Specific

Warnings...............................................95

4.3.2Power Management Settings...........95

4.3.3Electrical Conversions........................95

4.3.4Fitting of Equipment Containing an

Electric Motor.......................................97

4.3.5Vehicle Electrical Capacity -

Alternator..............................................97

4.3.6Charge Balance Guidelines...............97

4.3.7Circuit Diagrams..................................97

4.4Battery and Cables.....................98

4.4.1Battery Information.............................98

4.4.2Generator and Alternator.................103

4.5Climate Control System.............106

4.6Instrument Cluster.....................107

4.7Horn...........................................108

4.8Tachograph................................109

4.8.1Legislation...........................................109

4.8.2Tachograph Mounting.......................110

4.9Information and Entertainment

System - General

Information—Specifications.......112

4.9.1Radio Connector................................112

4.9.2Possible Accessories.........................113

4.10Cellular Phone............................115

4.11Exterior Lighting.........................116

4.11.1Reversing Lamps...............................116

4.11.2Additional External Lamps................116

4.11.3Lamps – Hazard / Direction

Indication..............................................117

4.11.4Lamps – Front and Rear Fog Lights....

117

4.11.5Lamps for Wide Vehicles...................117

4.11.6Electrically operated Door Mirrors....

117

4.12Interior Lighting..........................118

4.12.1Additional Internal Lamps .................118

4.12.2Additional 'Theatre Lighting' for rear

of vehicle interior................................118

4.13Fuses and Relays.......................119

4.13.1Wiring Specification............................119

4.13.2Auxiliary Fuses, Fuse Box and Relays

(Fuses - Standard).............................119

4.13.3Customer Connection Points..........120

4.13.4Special Vehicle Option Auxiliary Fuse

Box........................................................121

4.13.5Additional Ignition, Instrument Panel

Illumination and Air Conditioning On

Signals.................................................124

4.13.6Relays and Switches.........................127

4.13.7Windscreen wipers...........................130

4.14Special Conversions..................131

4.14.1Vehicle Speed Output (Signal).........131

4.14.2Engine Run Signal (D+ Alternative)....

132

4.14.3Connectors.........................................133

4.14.4Installation and Routing Guides.......134

4.14.5Electrics for Tow bar.........................136

4.14.6Ground Points....................................140

4.14.7Special Vehicle Options (SVO) and

Aftermarket Kits.................................146

4.14.8Additional Vehicle Signals / Features..

147

4.14.9Engine RPM (Revs Per Minute) Speed

Controller.............................................157

4.14.10Adding Connectors, Terminals and

Wiring...................................................162

5 Body and Paint

5.1Body...........................................175

5.1.1Body Structures - General

Information..........................................175

5.1.2Back Panel Removal.........................177

5.1.3Integrated Bodies and Conversions...

177

5.1.4Chassis Cab........................................179

5.1.5Cab Van Floor.....................................185

5.1.6Hydraulic Lifting Equipment for Van,

Bus, Kombi and Chassis Cab..........186

5.1.7Partitions (Bulkhead) - Driver and

Front Passenger(s) Protection on Van,

Bus and Kombi..................................192

5.1.8Racking Systems...............................194

5.1.9Front End Integrity for Cooling, Crash,

Aerodynamics and Lighting.............198

5.1.10Tipper Bodies.....................................199

5.1.11Tank and Dry Bulk Carriers...............199

5.2Body System - General

Information—Specifications......200

5.2.1Van Floor - Load Compartment Tie

Downs for Van ,Bus and Kombi.....200

5.3Body Closures..........................203

5.3.1Load Compartment Interior Lining....

203

5.3.2Security, Anti Theft and Locking

System Security ...............................203

5.4Rear View Mirrors.....................208

5.4.1Mirrors for Wide Vehicles.................208

5.5Seats.........................................209

5.5.1Rear Seat Fixings Positions - Kombi...

209

5.5.2Heated Seats.....................................210

5.6Glass, Frames and Mechanisms...

211

5.6.1Rear Windows....................................211

Table of Contents

4

Page 7 of 234

1.2 Commercial and Legal Aspects

1.2.1 Terminology

NOTE: Any modifications to the vehicle must

be noted in the owner's handbook or new

descriptive literature included with the owner's

documentation.

Vehicle Converter refers to any re-seller altering

the vehicle by converting the body and adding

or modifying any equipment not originally

specified and or supplied by Ford.

Unique component or similar wording refers to

non-Ford specified or after sale fitment not

covered by Ford warranty.

1.2.2 Warranty on Ford Vehicles

Please contact The National Sales Company in

the country where the vehicle will be registered

for details of the terms of any applicable Ford

warranty.

The Vehicle Converter should warrant its design,

materials and construction for a period at least

equal to any applicable Ford warranty

The Vehicle Converter must ensure that any

alteration made to a Ford vehicle or component

does not reduce the safety, function, or durability

of the vehicle or any component.

The Vehicle Converter shall be solely responsible

for any damage resulting from any alteration

made by the Vehicle Converter or any of its

agents to a Ford Vehicle Component.

The Vehicle Converter releases Ford from all

claims by any third party for any cost or loss

(including any consequential damages) arising

from work performed by a Vehicle Converter

unless Ford has given its prior written consent

to such liability.

1.2.3 Legal and Vehicle Type

Approval

•All components embodied on Ford vehicles

are approved to the applicable legal

requirements.

•Ford vehicles have Type Approval for the

intended marketing territories.

WARNING: Exception - Incomplete

vehicles require further approval

when completed by the Body

Builder.

•The Transit range has Type Approval for many

territories, although the full range of vehicles

shown in this manual are not necessarily

released in all territories. Check with your local

ford National Sales Company representative.

•Significant changes to the vehicle may affect

its legal compliance. Strict adherence to the

original design intent for brakes, weight

distribution, lighting, occupant safety and

hazardous materials compliance in particular

is mandatory.

1.2.4 Alternative Type Approval

If significant changes are made the Body Builder

must negotiate with the relevant authority. Any

changes to the vehicle operating conditions must

be advised to the customer.

1.2.5 Legal Obligations and

Liabilities

The Vehicle Converter should consult with its

legal advisor on any questions concerning its

legal obligations and liabilities.

1.2.6 General Product Safety

Requirement

The Vehicle Converter shall ensure that any

vehicle it places on the market complies with the

European General Product safety Directive

2001/95/EC (as amended periodically). The

Vehicle Converter shall also ensure that any

alteration it makes to a Ford vehicle or

component does not reduce its compliance with

the European General Product Safety Directive.

The Vehicle Converter shall release Ford from all

liability for damages resulting from:

•Failure to comply with these Body Equipment

Mounting directives, in particular warnings.

•Faulty design, production, installation,

assembly or alteration not originally specified

by Ford.

•Failure to comply with the basic fit for purpose

principles inherent in the original product.

WARNINGS:

Do not exceed the gross vehicle

mass, gross train mass, axle plates

and trailer plate

Do not change the tire size or load

rating

Do not modify the steering system.

Excessive heat can build up from

the exhaust system, in particular

from the catalytic converter. Ensure

adequate heat shields are

maintained. Maintain sufficient

clearance to hot parts

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

7

Page 33 of 234

1.13 Package and Ergonomics

1.13.1 General Component

Package Guidelines

WARNING: Do not modify, drill, cut

or weld any suspension

components, specifically the

steering gear system, subframe or

anti-roll bars, springs or shock

absorbers including mounting

brackets.

The Vehicle Converter has to ensure that

sufficient clearance is maintained under all drive

conditions to moving components such as axles,

fans, steering, brake system etc.

The Vehicle Converter is responsible for all

installed components during the conversion. The

durability has to be confirmed by appropriate test

procedures.

1.13.2 Driver Reach Zones

Controls and/or equipment required to be used

while driving should be located within easy reach

of the driver so as not to impair driver control

1.13.3 Driver Field of View

WARNING: Make sure that the

modified vehicle complies with all

relevant legal requirements.

1.13.4 Conversion Affects on

Parking Aids

WARNING: Ensure that monitors

mounted in the cabin meet the

interior package and safety

requirements

On conversions requiring a rear camera, the

reverse signal may be taken as described in the

electrical section, described in reversing lamps.

Refer to: 4.11 Exterior Lighting (page 116).

1.13.5 Aids for Vehicle Entry and

Exit

Steps

WARNINGS:

Make sure that the modified vehicle

complies with all relevant legal

requirements.

If this modification alters the

homologated dimensions, a new

approval may be necessary.

CAUTION: Make sure that

reinforcements are installed to

maintain the integrity of the original

body structure.

Steps can be ordered as an option on the base

vehicle. Please check for availability.

Where additional steps are installed the required

ground clearance line is to be maintained.

The Vehicle Converter must make sure that a

movable step is set in the stored position when

the vehicle is running. The step surface must be

non-slip.

Grab Handles

WARNING: Make sure that the

location of the no-drill zones are

checked before drilling.

CAUTION: Make sure that

reinforcements are installed to

maintain the integrity of the original

body structure.

Grab handles can be ordered as an option on

the base vehicle. Please check for availability.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

33

Page 91 of 234

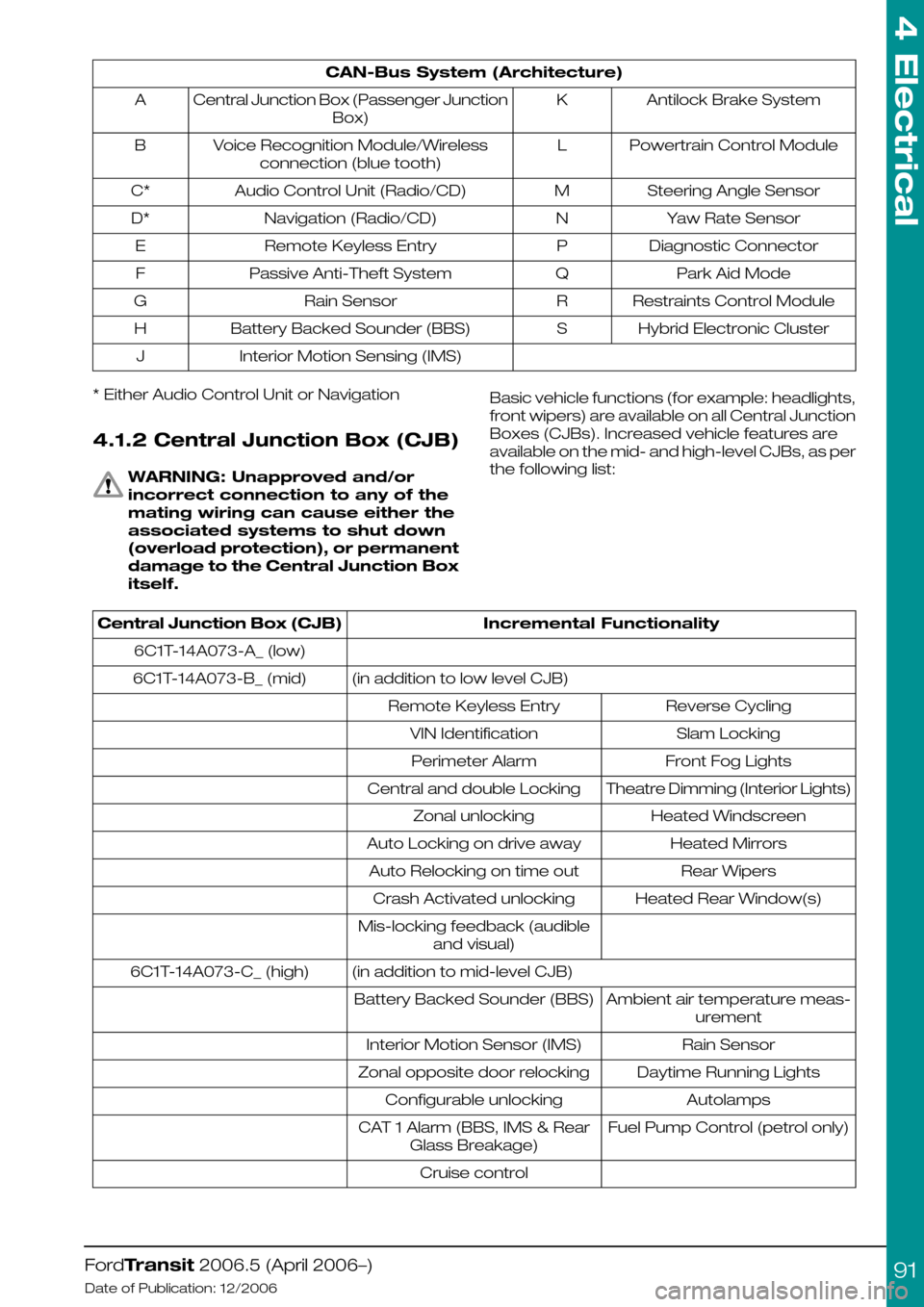

CAN-Bus System (Architecture)

Antilock Brake SystemKCentral Junction Box (Passenger Junction

Box)

A

Powertrain Control ModuleLVoice Recognition Module/Wireless

connection (blue tooth)

B

Steering Angle SensorMAudio Control Unit (Radio/CD)C*

Yaw Rate SensorNNavigation (Radio/CD)D*

Diagnostic ConnectorPRemote Keyless EntryE

Park Aid ModeQPassive Anti-Theft SystemF

Restraints Control ModuleRRain SensorG

Hybrid Electronic ClusterSBattery Backed Sounder (BBS)H

Interior Motion Sensing (IMS)J

* Either Audio Control Unit or Navigation

4.1.2 Central Junction Box (CJB)

WARNING: Unapproved and/or

incorrect connection to any of the

mating wiring can cause either the

associated systems to shut down

(overload protection), or permanent

damage to the Central Junction Box

itself.

Basic vehicle functions (for example: headlights,

front wipers) are available on all Central Junction

Boxes (CJBs). Increased vehicle features are

available on the mid- and high-level CJBs, as per

the following list:

Incremental FunctionalityCentral Junction Box (CJB)

6C1T-14A073-A_ (low)

(in addition to low level CJB)6C1T-14A073-B_ (mid)

Reverse CyclingRemote Keyless Entry

Slam LockingVIN Identification

Front Fog LightsPerimeter Alarm

Theatre Dimming (Interior Lights)Central and double Locking

Heated WindscreenZonal unlocking

Heated MirrorsAuto Locking on drive away

Rear WipersAuto Relocking on time out

Heated Rear Window(s)Crash Activated unlocking

Mis-locking feedback (audible

and visual)

(in addition to mid-level CJB)6C1T-14A073-C_ (high)

Ambient air temperature meas-

urement

Battery Backed Sounder (BBS)

Rain SensorInterior Motion Sensor (IMS)

Daytime Running LightsZonal opposite door relocking

AutolampsConfigurable unlocking

Fuel Pump Control (petrol only)CAT 1 Alarm (BBS, IMS & Rear

Glass Breakage)

Cruise control

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

91

Page 95 of 234

4.3 Charging System

4.3.1 General Information and

Specific Warnings

The Transit electrical system is a 12-Volt supply

with a negative earth return. The alternator and

battery equipment used as standard are

designed for normal operations with the type of

engine fitted. Higher capacity batteries are

available as standard production options and

special vehicle options. Before installing additional

electrical equipment check that the battery

capacity, harness load capability, and alternator

output are suitable for the extra load.

The battery capacity and charge available from

the alternator must be adequate to ensure

engine cranking in unfavorable climatic conditions

but excessive battery capacity could damage

the starter motor.

The Transit utilizes multiplexed vehicle electronics

- it is recommended that the appropriate Ford

proprietary accessory systems are used.

Inappropriate or incorrect connection of

additional equipment could cause mis-operation,

or damage to the vehicle, and so invalidate any

warranty.

Additional connection points are provided

specifically for customer use (except M1 and M2

Bus), and are located on the outside of the

driver's seat base.

Do not jump-start the vehicle directly from the

battery. Use designated jump-start points. Refer

to the owners literature.

4.3.2 Power Management

Settings

There are four Power Management Settings

available:

•Factory

•Transport

•Normal

•Crash

Factory and Transport modes are only active

with ignition off; with ignition on, the vehicle

operates with full functionality. When in Transport

mode, the interior lights, clocks, and power

locking and alarms (where fitted) do not work.

It is possible to switch from Transport Mode to

Normal Mode without the use of any ancillary

equipment, but not vice versa. To change mode,

the brake pedal must be depressed five times,

and the hazard warning switch operated twice

(in any combination) within 10 seconds.

WARNING: It is not possible to return

the transport setting without using

the vehicle's diagnostics.

At the end of production, the vehicle is

configured to the transport setting to minimize

power consumption. As part of the Pre Delivery

Inspection process at the Ford dealership, the

vehicle is reconfigured to normal operation.

4.3.3 Electrical Conversions

Operator requirements for additional and

specialised electrical equipment varies. The

vehicle converter/modifier must, therefore,

consider the following points when designing the

installation:

•Legality and regulatory conformity of the base

vehicle.

•Drive-ability and serviceability of the base

vehicle.

•The effect of regulations governing the

proposed conversion including National

Legislation in the country of sale.

•The method of integrating the circuit into the

base vehicle.

•No additional circuits are to be run alongside

the electrical circuits (shown in blue in the

figure below) associated with the

Management System (shown in green in the

figure below), due to the possible Electro

Motive Force (EMF) effect on the circuits.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

95

Page 116 of 234

4.11 Exterior Lighting

Where the following text makes reference to the

addition of wires

Refer to: 4.14 Special Conversions (page 131).

(Adding Connectors, Terminals and Wiring)

WARNING: Make sure that the

modified vehicle complies with all

relevant legal requirements.

4.11.1 Reversing Lamps

These are hard-wired, activated by the reversing

switch on the transmission and passing through

the Central Junction Box where the signal is

sensed. A marginal increase in current (via a relay

or buffered electrical input) is permissible to

trigger a rear-view camera system, or audible

device.

4.11.2 Additional External Lamps

All power for additional exterior lamps must be

taken through the Auxiliary Fuse Box with a

suitable switch and / or relay as required.

Refer to: 4.13 Fuses and Relays (page 119).

• If CAT 6 directional indicators are to be fitted,

the Central Junction Box will need to be

configured for this.

• The load on the reversing lamps should not

exceed a total of 3A (42W).

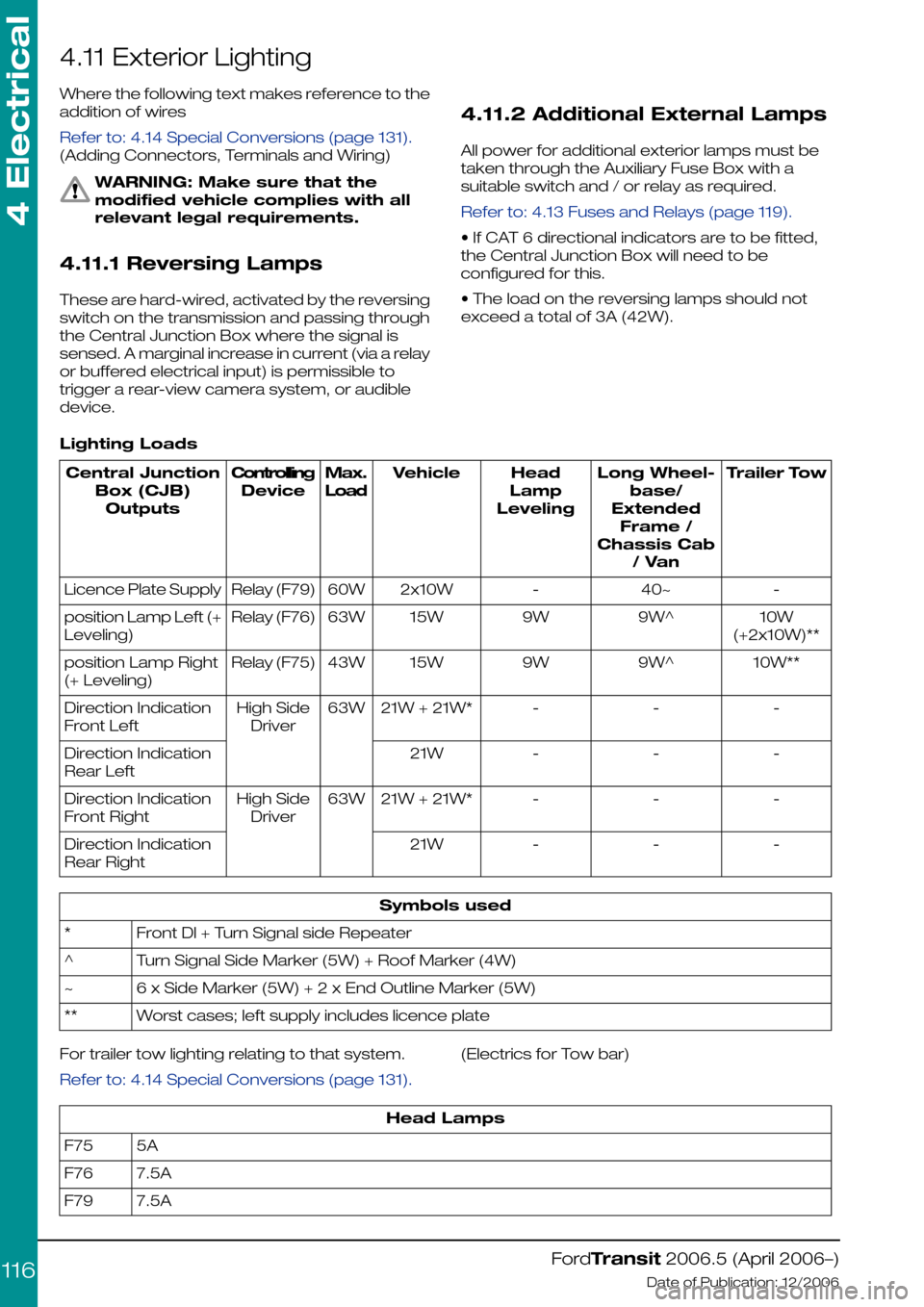

Lighting Loads

Trailer TowLong Wheel-

base/

Extended

Frame /

Chassis Cab

/ Van

Head

Lamp

Leveling

VehicleMax.

Load

Controlling

Device

Central Junction

Box (CJB)

Outputs

-40~-2x10W60WRelay (F79)Licence Plate Supply

10W

(+2x10W)**

9W^9W15W63WRelay (F76)position Lamp Left (+

Leveling)

10W**9W^9W15W43WRelay (F75)position Lamp Right

(+ Leveling)

---21W + 21W*63WHigh Side

Driver

Direction Indication

Front Left

---21WDirection Indication

Rear Left

---21W + 21W*63WHigh Side

Driver

Direction Indication

Front Right

---21WDirection Indication

Rear Right

Symbols used

Front Dl + Turn Signal side Repeater*

Turn Signal Side Marker (5W) + Roof Marker (4W)^

6 x Side Marker (5W) + 2 x End Outline Marker (5W)~

Worst cases; left supply includes licence plate**

For trailer tow lighting relating to that system.

Refer to: 4.14 Special Conversions (page 131).

(Electrics for Tow bar)

Head Lamps

5AF75

7.5AF76

7.5AF79

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

116

Page 117 of 234

4.11.3 Lamps – Hazard / Direction

Indication

The maximum permissible load with the standard

system is:

•3 x 21W – front and rear indicators + side

repeaters (Left Hand Side)

•3 x 21W – front and rear indicators + side

repeaters (Right Hand Side)

That is:- 63W per side maximum.

4.11.4 Lamps – Front and Rear

Fog Lights

National Regulations regarding inter-connection

with other front and rear fog lights must be

checked before designing the wiring circuit.

For trailer tow for rear fog lighting relating to that

system.

Refer to: 4.14 Special Conversions (page 131).

(Electrics for Tow bar)

4.11.5 Lamps for Wide Vehicles

Lamps – End outline and side marker

lamps

All Chassis Cab vehicles are fitted with front

marker lamps on the cab roof as standard, less

roof marker lamps they are optional. Where

additional side marker lamps and rear outline

marker lamps are required to comply with local

regulations, access to the appropriate signals

may be obtained from the licence plate lamps.

A special jumper link is available for this purpose

from the local Ford dealer.

The maximum permissible load with the standard

system is:

NOTE: For various vehicles Cat 6 repeater

lamps must be fitted. See legislation for full

details.

•6 x 5W – side marker

•2 x 5W – end outline marker

•2 x 5W – Cat 6

•2 x 4W – roof marker

4.11.6 Electrically operated Door

Mirrors

WARNING: Do not tamper with the

base system (controlled by Central

Junction Box and multiplex

architecture) and any feeds taken

from the associated wiring or

controller.

NOTE: These options are not suitable for

aftermarket or Body Builder fit.

Refer to: 1.14 (page 34).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

117

Page 134 of 234

Where wires are required to be extended, break

in points should only be at existing connector

points and only Ford approved connectors should

be used.

Ford approved link harnesses should be used.

Unused Connectors

The harnesses may have a number of unused

connectors – these are dedicated to other

features and options, e.g. heated seats, but are

not always present depending on level of

harness fitted. Ford do not recommend the use

of these connectors for any other purpose than

that intended by design.

Power Outlet / Cigar Lighter

Both features adopt a 20A fusing strategy. With

a single battery system, continued loading of

these features will lead to battery drain, and risk

vehicle starting. If continuous power is required,

a second battery option should be installed and

the customer connection points, where fitted,

utilized.

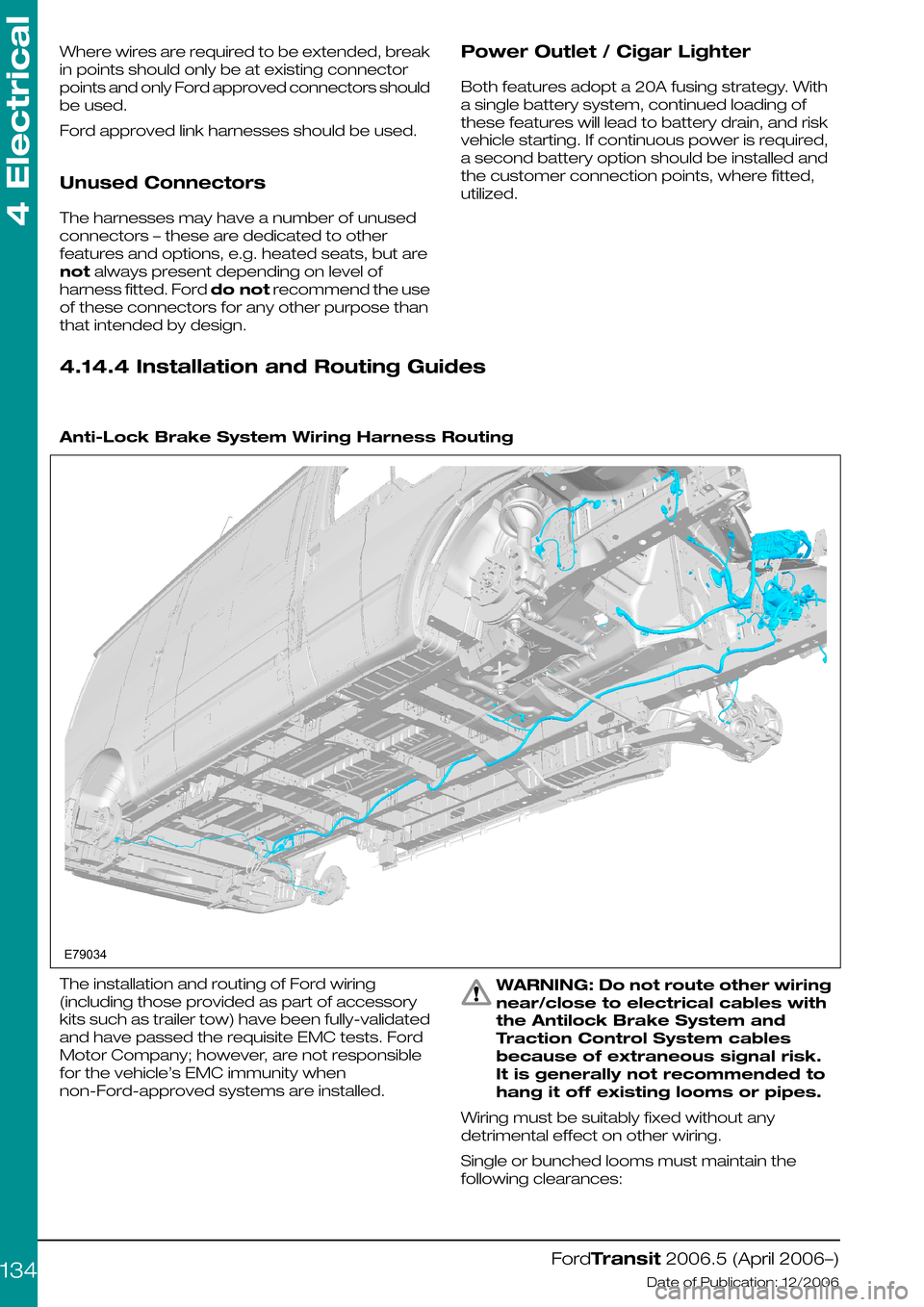

4.14.4 Installation and Routing Guides

Anti-Lock Brake System Wiring Harness Routing

The installation and routing of Ford wiring

(including those provided as part of accessory

kits such as trailer tow) have been fully-validated

and have passed the requisite EMC tests. Ford

Motor Company; however, are not responsible

for the vehicle’s EMC immunity when

non-Ford-approved systems are installed.

WARNING: Do not route other wiring

near/close to electrical cables with

the Antilock Brake System and

Traction Control System cables

because of extraneous signal risk.

It is generally not recommended to

hang it off existing looms or pipes.

Wiring must be suitably fixed without any

detrimental effect on other wiring.

Single or bunched looms must maintain the

following clearances:

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

134E79034

Page 137 of 234

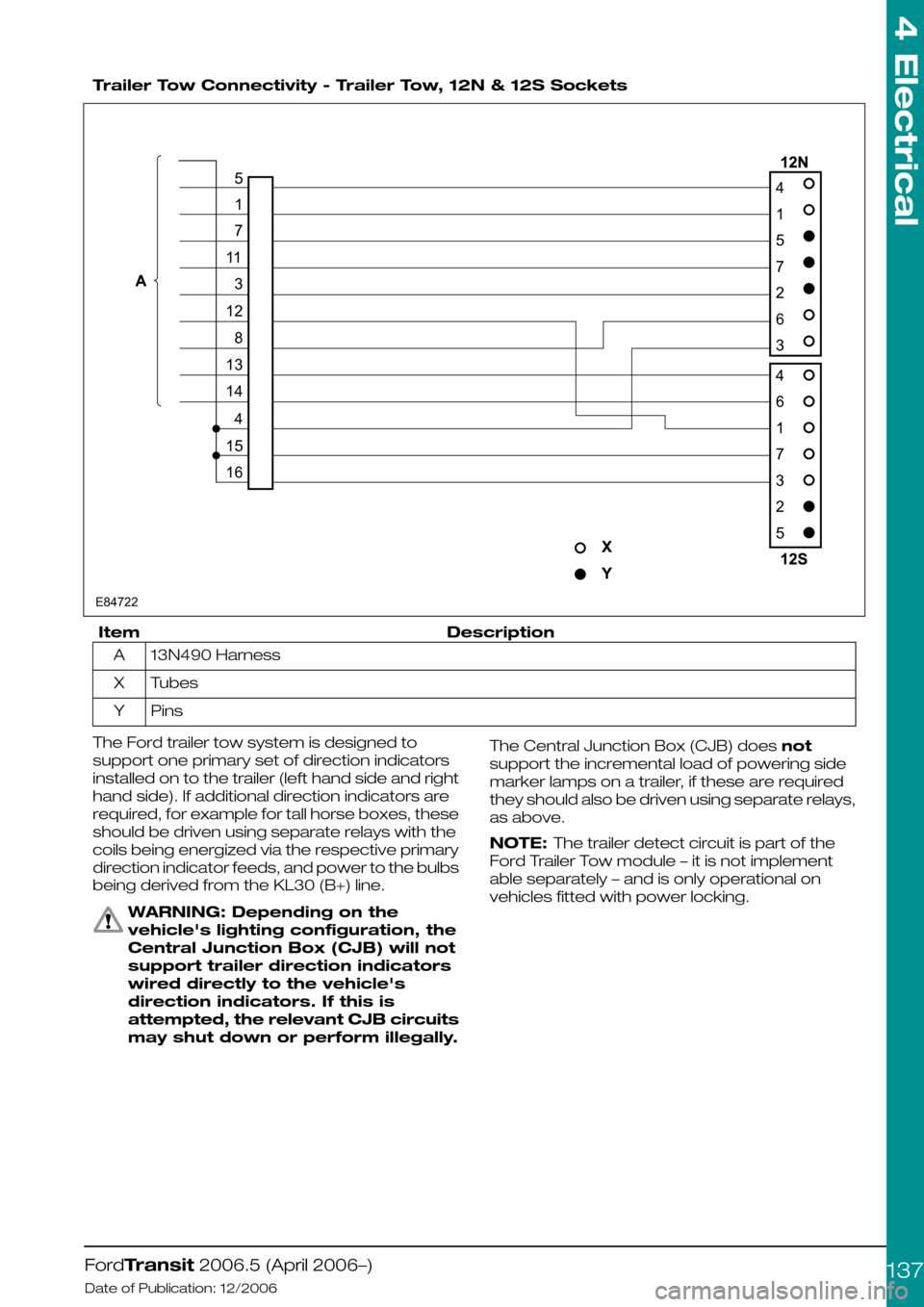

Trailer Tow Connectivity - Trailer Tow, 12N & 12S Sockets

DescriptionItem

13N490 HarnessA

TubesX

PinsY

The Ford trailer tow system is designed to

support one primary set of direction indicators

installed on to the trailer (left hand side and right

hand side). If additional direction indicators are

required, for example for tall horse boxes, these

should be driven using separate relays with the

coils being energized via the respective primary

direction indicator feeds, and power to the bulbs

being derived from the KL30 (B+) line.

WARNING: Depending on the

vehicle's lighting configuration, the

Central Junction Box (CJB) will not

support trailer direction indicators

wired directly to the vehicle's

direction indicators. If this is

attempted, the relevant CJB circuits

may shut down or perform illegally.

The Central Junction Box (CJB) does not

support the incremental load of powering side

marker lamps on a trailer, if these are required

they should also be driven using separate relays,

as above.

NOTE: The trailer detect circuit is part of the

Ford Trailer Tow module – it is not implement

able separately – and is only operational on

vehicles fitted with power locking.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

137E8472241572634617325517113128131441516

Page 154 of 234

harness that provides roof-mounted rear turn

indicators, powered via relays. This should be

used in conjunction with SVO fusebox.

3.Chassis cab LED rear lamp cluster

replacement recommendations, especially

turn indicator relay implications – see lighting

load table. Generally the use of LED equivalent

lighting systems reduces the electrical load on

the vehicle; however, special care needs to

be taken with respect to any change to or

addition of turn indicator lights. Depending on

the current requirements of the LED(s)

compared to the bulb it is replacing, a ballast

resistor may be required, if not already

integrated into the LED lamp assembly.

Without this, bulb outage detection for turn

indicators will be affected, which is a legal

requirement.

Additional turn indicators must be powered

through relays (max 300mA), driven by existing

turn lights. The maximum load that the Central

Junction Box can drive is 3 x 21W per side (front,

rear and CAT 6 turn indicators); but even if the

vehicle is not fitted with the CAT 6 lights, the feeds

for these should not be used as the Central

Junction Box would need reconfiguring, which

could have safety as well as functional

implications.

4.Special Vehicle Option beacon switch: wiring

locations, circuit diagrams and max amperage

– see Special Vehicle Option fuse box

schematic (max current is 15A); there is

provision for the Special Vehicle Option beacon

switch in an empty switch location on the

instrument panel.

5.Rear loom connector detail location and supply

details for retro-fit loom extension for

example:- when extending a medium wheel

base, long wheel base or extended frame

overhang, what connectors do they use to

make a plug and play loom extension? – for

chassis cab vehicles, there is an Special

Vehicle Option extension loom for rear lamps

(part number 6C1V-14408-A*). There is not, at

present, a similar loom for Van, Bus and

Kombi's, although the appropriate mating

connector is now tooled, so this would be

possible.

Miscellaneous Systems

Handbrake on - Cluster Warning Light -

Unless the vehicle is specified with options that

drive the handbrake warning light (for example

ESP, Australia market), the components making

up this system are not fitted. We do not

recommend installation of this feature as an

aftermarket addition. There are several reasons

for this:

1.Not all circuits carry the requisite wire as a give

away:

•The wires might be part of the main vehicle

harness (14401) even if not used – for example

camper vehicles are normally ordered with

power mirrors, and the wires will be present

as a give-away.

•The seat pedestal harness (14K076), however,

is vehicle specific – if the handbrake is not part

of the specification, it will not be present or

give-away. This harness would need to be

changed to the compatible part that also

includes the handbrake warning light circuit.

2.The handbrake switch (part number

2F2T-15852-A*) together with its short jumper

harness (6C1T-15K857-A*) would need to be

obtained and fitted.

3.The handbrake warning light is in all clusters,

but unless the vehicle config. parameter

“parking brake switch” is set, the Central

Junction Box will not read this input, and hence

NO CAN message sent to the cluster.

Reconfiguration can only be done at a Ford

Dealer.

NOTE: If a vehicle already has a handbrake

warning light in the cluster, or one is installed as

per the Ford design, it is not possible to utilize the

wire from the handbrake switch as part of an

interlock circuit (this is a pull up resistor input that

provides a wetting current of 20mA – anything in

excess of this, for example through additional

circuitry, will almost certainly damage the Central

Junction Box). If there is no handbrake switch

installed, it would be possible to add one and

utilize this as part of a separate circuit, up to a

maximum current of 500mA through the switch.

Reverse Sensors (Rear Park Aid

Module)- The factory-fit option is a CAN-based

system, but for Van, Bus, and Kombi vehicles

only. Stand-alone systems can be installed (for

example for chassis cab conversions), but would

need to utilize the PTA line of the radio if muting

is required.

Fuel Fired Heater (FFH)- Add FFH: wiring is

only present (give-away) in certain harnesses.

There was an aftermarket kit available for this

system on current Transit, which could probably

be “updated” to suit V347/8.

Fuel Fired Heater (FFH) - Programmable

FFH: this utilizes a timer/control module mounted

to the Instrument Panel, which necessitates

having the correct Instrument Panel harness

fitted. Retrofit of this would be a difficult.

For both systems, the appropriate 6C1T-14K132

harness would be required (suffix -A* for

Programmable FFH, and suffix –B* for Add FFH).

Central Locking

Locking is controlled by the Central Junction Box

module. There is current sensing on certain

locking circuit pins as part of the security system

– if these are tampered with, locking cannot be

guaranteed.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

154