FORD WINDSTAR 1999 2.G Owners Manual

Manufacturer: FORD, Model Year: 1999, Model line: WINDSTAR, Model: FORD WINDSTAR 1999 2.GPages: 248, PDF Size: 2.28 MB

Page 221 of 248

Maintenance

²Keep tires properly inflated and use only recommended size.

²Operating a vehicle with the wheels out of alignment will reduce fuel

economy.

²Use recommended engine oil. Refer toLubricant Specifications.

²Perform all regularly scheduled maintenance items. Follow the

recommended maintenance schedule and owner maintenance checks

found in your vehicle Scheduled Maintenance Guide.

Conditions

²Heavily loading a vehicle or towing a trailer may reduce fuel economy

at any speed.

²Carrying unnecessary weight may reduce fuel economy (approximately

2 km/h [1 mpg] is lost for every 180 kg [400 lb] of weight carried).

²Adding certain accessories to your vehicle (for example bug

deflectors, rollover/light bars, running boards, ski/luggage racks) may

reduce fuel economy.

²Use of fuel blended with alcohol may lower fuel economy.

²Fuel economy may decrease with lower temperatures during the first

12±16 km (8±10 miles) of driving.

²Flat terrain driving improves fuel economy over hilly roads.

²Transmissions give their best fuel economy when operated in the top

cruise gear and with steady pressure on the gas pedal.

²Close windows for high speed driving.

EPA window sticker

Every new vehicle should have the EPA window sticker. Contact your

dealer if the window sticker is not supplied with your vehicle. The EPA

window sticker should be your guide for the fuel economy comparisons

with other vehicles.

It is important to note the box in the lower left corner of the window

sticker. These numbers represent the Range of Km/L (MPG) expected on

the vehicle, depending upon the driver's method of operation and

conditions.

Maintenance and care

221

Page 222 of 248

EMISSION CONTROL SYSTEM

Your vehicle is equipped with various emission control components and a

catalytic converter which will enable your vehicle to comply with

applicable exhaust emission standards. To make sure that the catalytic

converter and other emission control components continue to work

properly:

²Use only unleaded fuel.

²Avoid running out of fuel.

²Do not turn off the ignition while your vehicle is moving, especially at

high speeds.

²Have the items listed in your Scheduled Maintenance Guide performed

according to the specified schedule.

The scheduled maintenance items listed in the Scheduled Maintenance

Guide are essential to the life and performance of your vehicle and to its

emissions system.

If other than Ford, Motorcraft or Ford-authorized parts are used for

maintenance replacements or for service of components affecting

emission control, such non-Ford parts should be equivalent to genuine

Ford Motor Company parts in performance and durability.

Do not park, idle, or drive your vehicle in dry grass or other dry

ground cover. The emission system heats up the engine

compartment and exhaust system, which can start a fire.

Illumination of the charging system warning light,Check Engine

indicator light or the temperature warning light, fluid leaks, strange

odors, smoke or loss of oil pressure, could indicate that the emission

control system is not working properly.

Exhaust leaks may result in entry of harmful and potentially

lethal fumes into the passenger compartment.

Maintenance and care

222

Page 223 of 248

Do not make any unauthorized changes to your vehicle or engine. By

law, vehicle owners and anyone who manufactures, repairs, items, sells,

leases, trades vehicles, or supervises a fleet of vehicles are not permitted

to intentionally remove an emission control device or prevent it from

working. Information about your vehicle's emission system is on the

Vehicle Emission Control Information Decal located on or near the

engine. This decal identifies engine displacement and gives some tune up

specifications.

Please consult your ªWarranty Guideº for complete emission warranty

information.

Readiness for inspection/maintenance (I/M) testing

In some localities, it may be a legal requirement to pass an I/M test of

the on-board diagnostic (OBD-II) system. If your ªCheck Engine/Service

Engine Soonº light is on, refer to the description in theWarning Lights

and Chimessection of theInstrumentationchapter. Your vehicle may

not pass the I/M test with the ªCheck Engine/Service Engine Soonº light

on.

If the vehicle's powertrain system or its battery has just been serviced,

the OBD-II system is reset to a ªnot ready for I/M testº condition. To

ready the OBD-II system for I/M testing, a minimum of 30 minutes of city

and highway driving is necessary as described below:

²First, at least 10 minutes of driving on an expressway or highway.

²Next, at least 20 minutes driving in stop-and-go, city-type traffic with

at least four idle periods.

Allow the vehicle to sit for at least eight hours without starting the

engine. Then, start the engine and complete the above driving cycle. The

engine must warm up to its normal operating temperature. Once started,

do not turn off the engine until the above driving cycle is complete.

Maintenance and care

223

Page 224 of 248

EXTERIOR BULBS

Replacing exterior bulbs

It is a good idea to check the operation of the following lights frequently:

²Headlamps

²Turn signals

²Cornering lamps

²High-mount brakelamp

²Tail lamps

²Brakelamps

²Backup lamps

²License plate lamps

Do not remove lamp bulbs unless they will be replaced immediately. If a

bulb is removed for an extended period of time, contaminants may enter

the lamp housings and affect performance.

Handle a halogen bulb carefully and keep out of children's reach.

Grasp the bulb only by its plastic base and do not touch the

glass; the oil from your hand could cause the bulb to break the next

time that the headlamps are operated.

Replacing headlamp bulbs

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

To remove the headlamp bulb:

1. Make sure headlamp switch is in OFF position, then open the hood.

Maintenance and care

224

Page 225 of 248

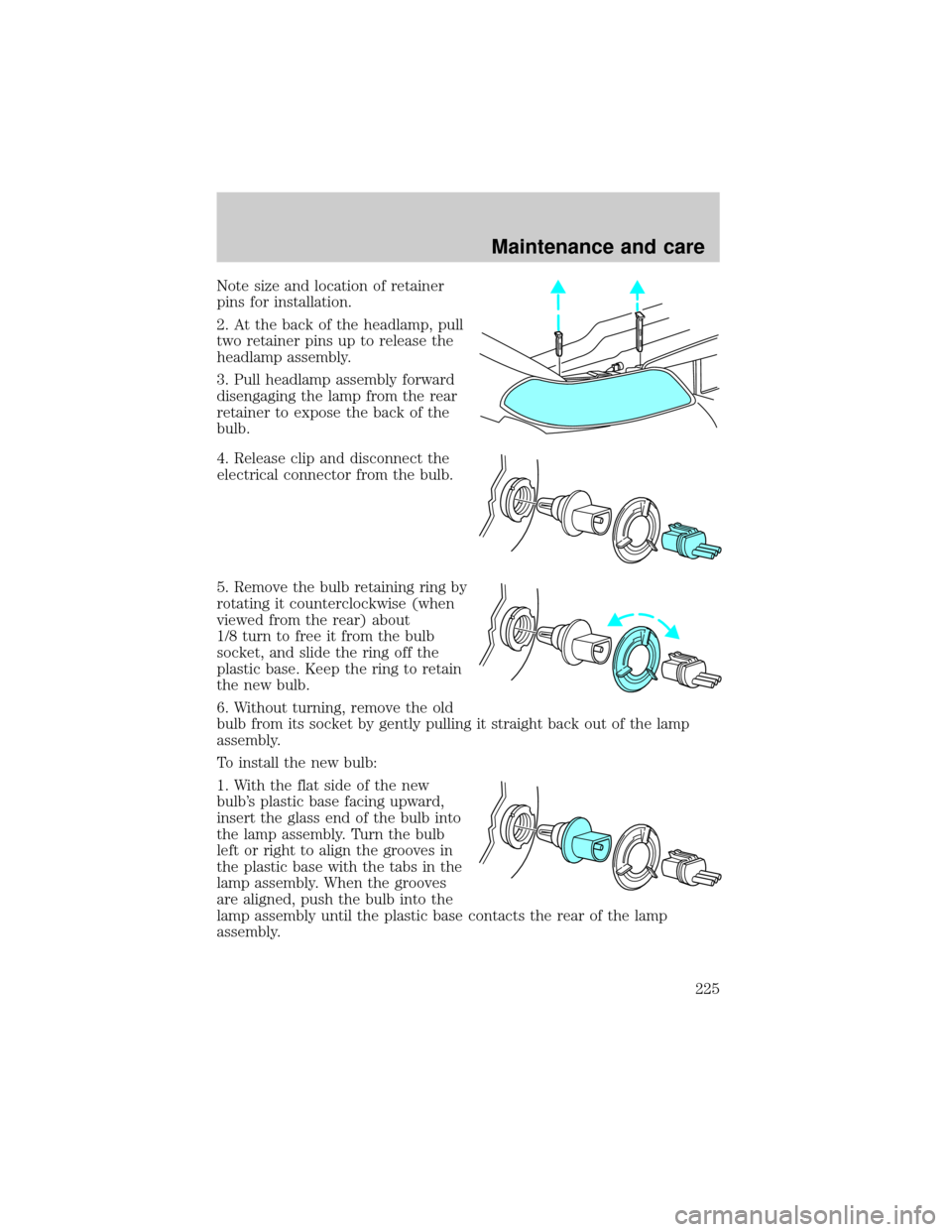

Note size and location of retainer

pins for installation.

2. At the back of the headlamp, pull

two retainer pins up to release the

headlamp assembly.

3. Pull headlamp assembly forward

disengaging the lamp from the rear

retainer to expose the back of the

bulb.

4. Release clip and disconnect the

electrical connector from the bulb.

5. Remove the bulb retaining ring by

rotating it counterclockwise (when

viewed from the rear) about

1/8 turn to free it from the bulb

socket, and slide the ring off the

plastic base. Keep the ring to retain

the new bulb.

6. Without turning, remove the old

bulb from its socket by gently pulling it straight back out of the lamp

assembly.

To install the new bulb:

1. With the flat side of the new

bulb's plastic base facing upward,

insert the glass end of the bulb into

the lamp assembly. Turn the bulb

left or right to align the grooves in

the plastic base with the tabs in the

lamp assembly. When the grooves

are aligned, push the bulb into the

lamp assembly until the plastic base contacts the rear of the lamp

assembly.

Maintenance and care

225

Page 226 of 248

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the socket by rotating clockwise until you feel a ªstop.º

3. Connect the electrical connector into the rear of the plastic base until

it snaps, locking it into position.

4. Install the headlamp on vehicle by aligning the lamp with the rear

retainer, push rearward and secure with two retainer pins.

5. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

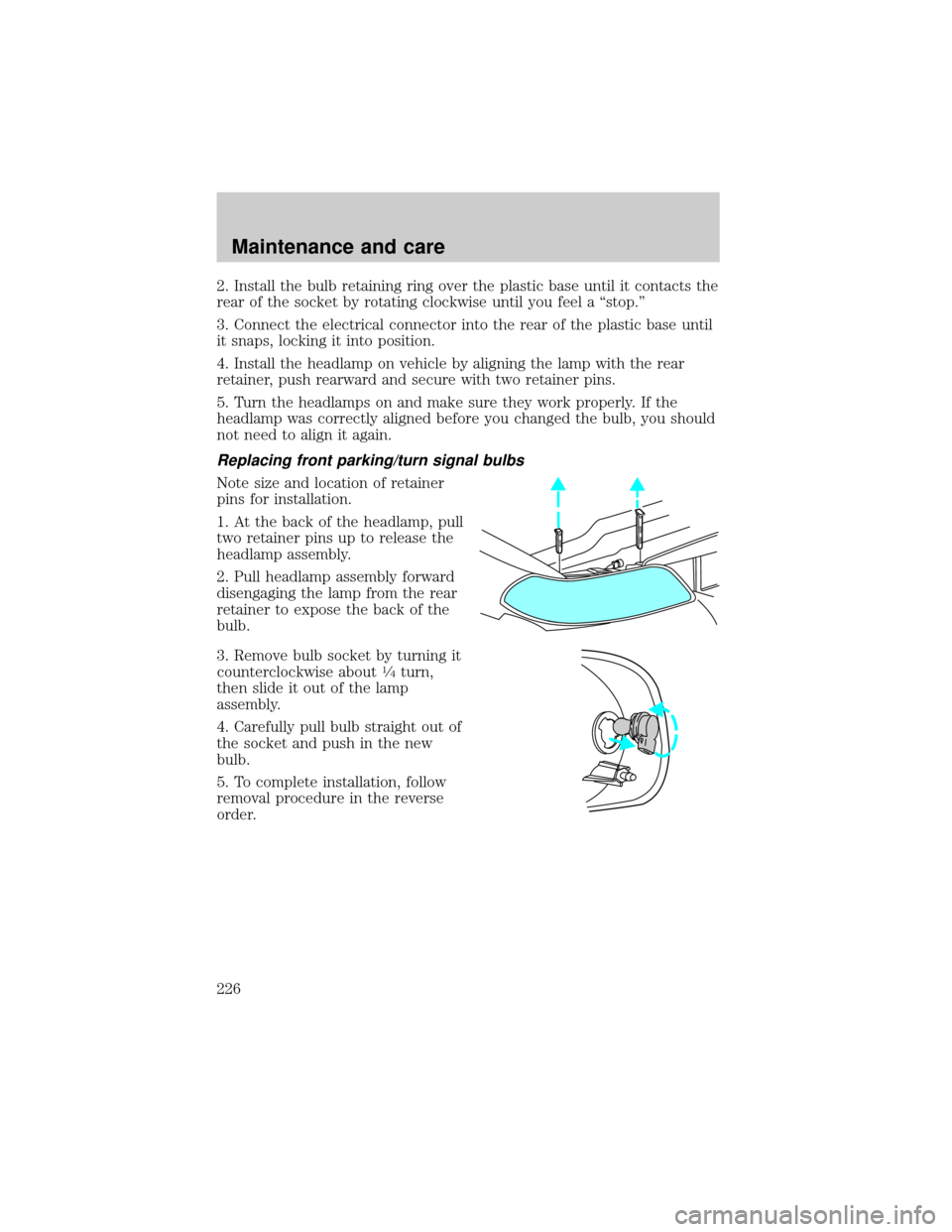

Replacing front parking/turn signal bulbs

Note size and location of retainer

pins for installation.

1. At the back of the headlamp, pull

two retainer pins up to release the

headlamp assembly.

2. Pull headlamp assembly forward

disengaging the lamp from the rear

retainer to expose the back of the

bulb.

3. Remove bulb socket by turning it

counterclockwise about

1¤4turn,

then slide it out of the lamp

assembly.

4. Carefully pull bulb straight out of

the socket and push in the new

bulb.

5. To complete installation, follow

removal procedure in the reverse

order.

Maintenance and care

226

Page 227 of 248

Replacing tail lamp/backup lamp bulbs

1. Open the liftgate to expose the

tail lamp assemblies.

2. Remove the two screws from the

lamp assembly.

3. Carefully remove the lamp

assembly by pulling it rearward

about 45 degrees.

4. Rotate bulb socket

counterclockwise

1¤4turn and

remove from lamp assembly.

5. Pull bulb straight out of socket and push in new bulb.

6. To complete installation, follow the removal procedure in the reverse

order.

Replacing license plate lamp bulbs

To change the license plate bulbs:

1. Remove two screws and the

license plate lamp assembly from

the liftgate.

2. Remove bulb socket by pulling it

straight out of the lamp assembly.

3. Carefully pull the bulb out from

the socket and push in the new

bulb.

4. Push bulb socket in to the lamp

assembly.

5. Install the lamp assembly on

liftgate with two screws.

High-mount brakelamp bulbs

For bulb replacement, see a dealer or qualified technician.

Cornering lamp bulbs

For bulb replacement, see a dealer or qualified technician.

Maintenance and care

227

Page 228 of 248

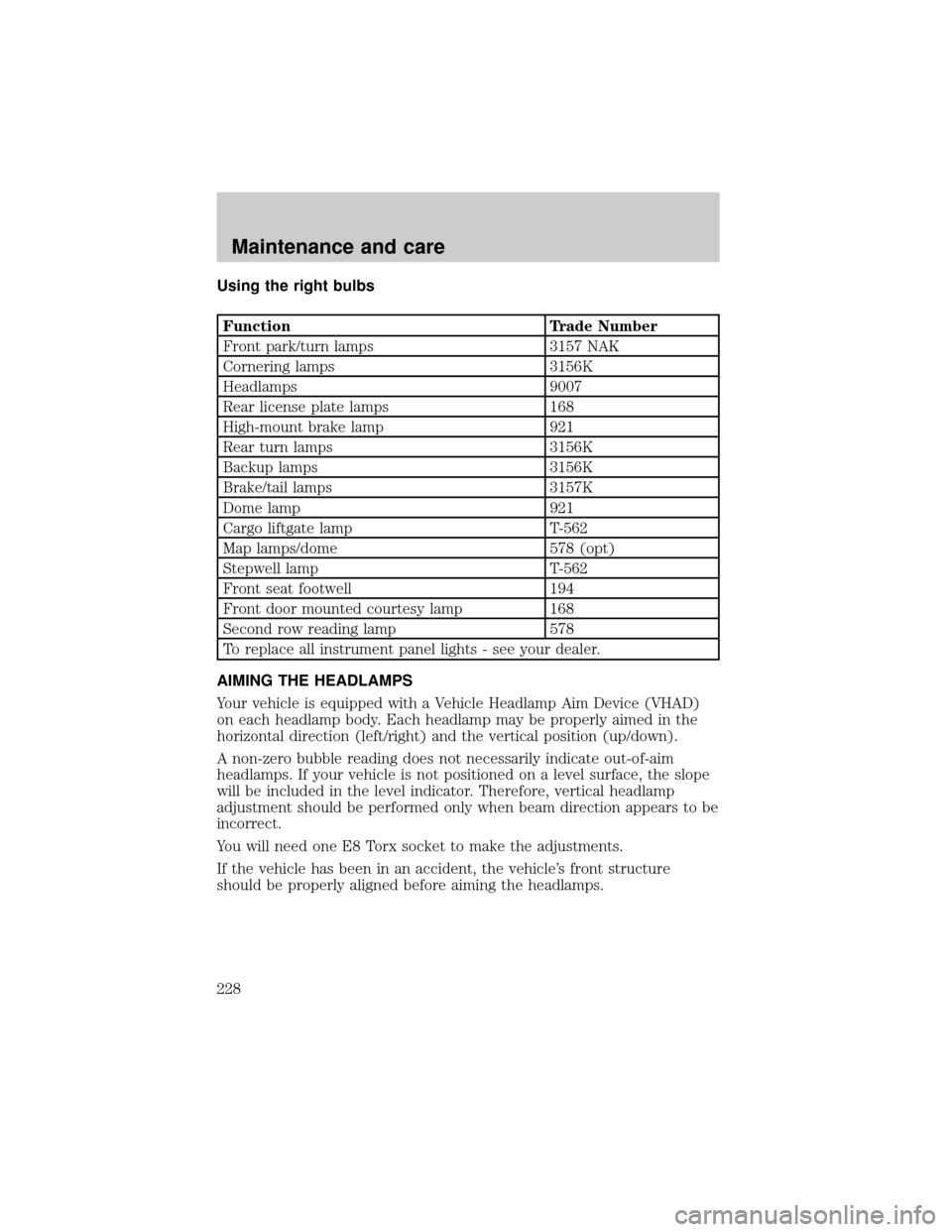

Using the right bulbs

Function Trade Number

Front park/turn lamps 3157 NAK

Cornering lamps 3156K

Headlamps 9007

Rear license plate lamps 168

High-mount brake lamp 921

Rear turn lamps 3156K

Backup lamps 3156K

Brake/tail lamps 3157K

Dome lamp 921

Cargo liftgate lamp T-562

Map lamps/dome 578 (opt)

Stepwell lamp T-562

Front seat footwell 194

Front door mounted courtesy lamp 168

Second row reading lamp 578

To replace all instrument panel lights - see your dealer.

AIMING THE HEADLAMPS

Your vehicle is equipped with a Vehicle Headlamp Aim Device (VHAD)

on each headlamp body. Each headlamp may be properly aimed in the

horizontal direction (left/right) and the vertical position (up/down).

A non-zero bubble reading does not necessarily indicate out-of-aim

headlamps. If your vehicle is not positioned on a level surface, the slope

will be included in the level indicator. Therefore, vertical headlamp

adjustment should be performed only when beam direction appears to be

incorrect.

You will need one E8 Torx socket to make the adjustments.

If the vehicle has been in an accident, the vehicle's front structure

should be properly aligned before aiming the headlamps.

Maintenance and care

228

Page 229 of 248

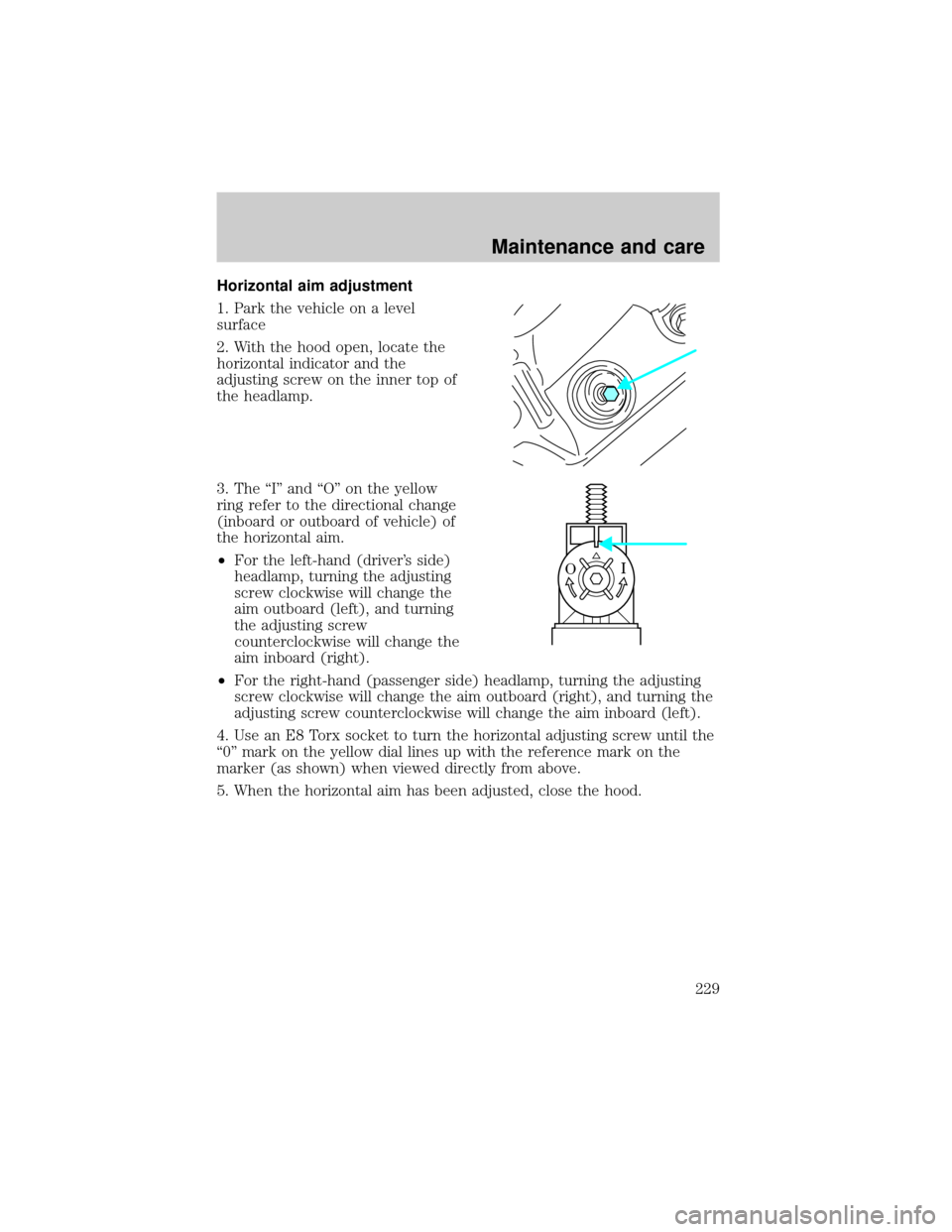

Horizontal aim adjustment

1. Park the vehicle on a level

surface

2. With the hood open, locate the

horizontal indicator and the

adjusting screw on the inner top of

the headlamp.

3. The ªIº and ªOº on the yellow

ring refer to the directional change

(inboard or outboard of vehicle) of

the horizontal aim.

²For the left-hand (driver's side)

headlamp, turning the adjusting

screw clockwise will change the

aim outboard (left), and turning

the adjusting screw

counterclockwise will change the

aim inboard (right).

²For the right-hand (passenger side) headlamp, turning the adjusting

screw clockwise will change the aim outboard (right), and turning the

adjusting screw counterclockwise will change the aim inboard (left).

4. Use an E8 Torx socket to turn the horizontal adjusting screw until the

ª0º mark on the yellow dial lines up with the reference mark on the

marker (as shown) when viewed directly from above.

5. When the horizontal aim has been adjusted, close the hood.

I O

Maintenance and care

229

Page 230 of 248

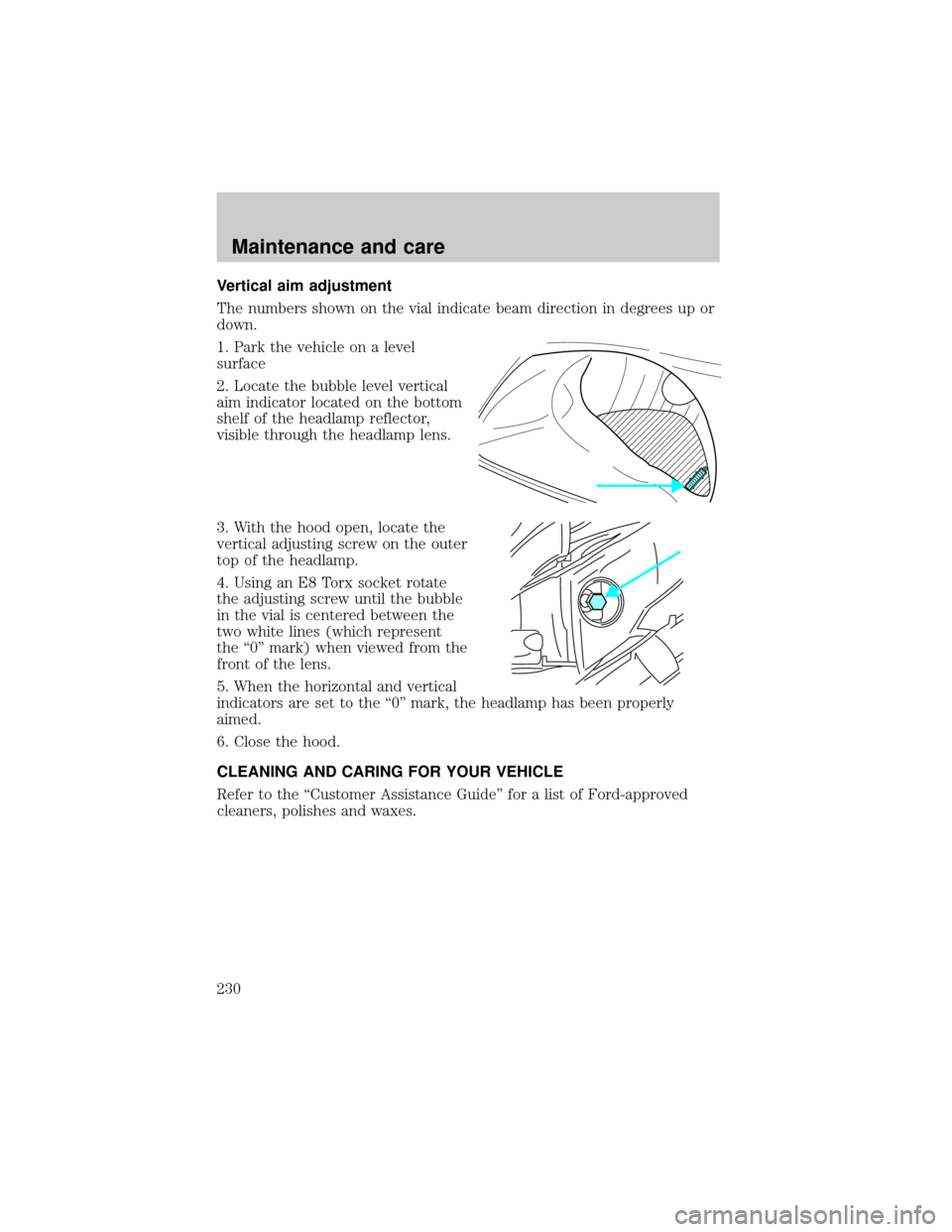

Vertical aim adjustment

The numbers shown on the vial indicate beam direction in degrees up or

down.

1. Park the vehicle on a level

surface

2. Locate the bubble level vertical

aim indicator located on the bottom

shelf of the headlamp reflector,

visible through the headlamp lens.

3. With the hood open, locate the

vertical adjusting screw on the outer

top of the headlamp.

4. Using an E8 Torx socket rotate

the adjusting screw until the bubble

in the vial is centered between the

two white lines (which represent

the ª0º mark) when viewed from the

front of the lens.

5. When the horizontal and vertical

indicators are set to the ª0º mark, the headlamp has been properly

aimed.

6. Close the hood.

CLEANING AND CARING FOR YOUR VEHICLE

Refer to the ªCustomer Assistance Guideº for a list of Ford-approved

cleaners, polishes and waxes.

DU

Maintenance and care

230