bulb FORD WINDSTAR 1999 2.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1999, Model line: WINDSTAR, Model: FORD WINDSTAR 1999 2.GPages: 248, PDF Size: 2.28 MB

Page 7 of 248

Traction ControlYoff light (if equipped)

This light momentarily illuminates

when the ignition is turned to ON

position and illuminates when the

Traction Controlysystem has been

disabled (by the driver or as a result

of a system failure). For more

information, refer to theDrivingchapter.

Safety belt

Momentarily illuminates when the

ignition is turned to the ON position

to remind you to fasten your safety

belts. For more information, refer to

theSeating and safety restraints

chapter.

Anti-theft system

Refer toSecuriLockypassive

anti-theft systemin theControls

and featureschapter.

Turn signal

Illuminates when the left or right

turn signal or the hazard lights are

turned on. If one or both of the

indicators stay on continuously or

flash faster, check for a burned-out

turn signal bulb. Refer toExterior bulbsin theMaintenance and care

chapter.

TRAC

OFF

THEFT

Instrumentation

7

Page 9 of 248

Brake system warning

Momentarily illuminates when the

ignition is turned to the ON

position, the engine is off and the

parking brake is engaged. If the

brake warning lamp does not

illuminate at this time, seek service immediately. Illumination after

releasing the parking brake indicates low brake fluid level and the brake

system should be inspected immediately.

O/D off

Illuminates when the ignition is

turned to the ON position and

transmission control switch has

been pushed. When the light is on,

the transmission does not shift into

overdrive. If the light does not come on when the transmission control

switch is depressed or if the light flashes when you are driving, have

your vehicle serviced.

Check engine

Your vehicle is equipped with a

computer that monitors the engine's

emission control system. This

system is commonly known as the

On Board Diagnostics System (OBD II). This OBD II system protects the

environment by ensuring that your vehicle continues to meet

government emission standards. The OBD II system also assists the

service technician in properly servicing your vehicle.

TheCheck Engineindicator light illuminates when the ignition is first

turned to the ON position to check the bulb. If it comes on after the

engine is started, one of the engine's emission control systems may be

malfunctioning. The light may illuminate without a driveability concern

being noted. The vehicle will usually be drivable and will not require

towing.

!

BRAKE

O/D

OFF

Instrumentation

9

Page 11 of 248

Bulb Warning

Illuminates when the ignition is in

the ON position and one of the

exterior bulbs has burned out.

Low washer fluid

Illuminates when the ignition is

turned to ON and when the

windshield washer fluid is low.

Safety belt warning chime

Chimes to remind you to fasten your safety belts.

For information on the safety belt warning chime, refer to theSeating

and safety restraintschapter.

Supplemental restraint system (SRS) warning chime

For information on the SRS warning chime, refer to theSeating and

safety restraintschapter.

Key-in-ignition warning chime

Sounds when the key is left in the ignition in the OFF/LOCK or ACC

position and the driver's door is opened.

Headlamps on warning chime (if equipped)

Sounds when the headlamps or parking lamps are on, the ignition is off

(and the key is not in the ignition) and the driver's door is opened.

Turn signal chime (if equipped)

Sounds when the turn signal lever has been activated to signal a turn

and not turned off after the vehicle is driven more than 0.8 km

(1/2 mile).

Instrumentation

11

Page 18 of 248

DRIVER'S DOOR AJAR.Displayed when the driver's door is not

completely closed.

PASSENGER DOOR AJAR.Displayed when the passenger side door is

not completely closed.

DRIVER'S REAR DOOR AJAR.Displayed when the driver's rear door

is not completely closed.

PASSENGER REAR DOOR AJAR.Displayed when the passenger side

rear door is not completely closed.

LIFTGATE AJAR.Displayed when the liftgate is not completely closed.

CHECK CHARGING SYSTEM.Displayed when the electrical system is

not maintaining proper voltage. If you are operating electrical accessories

when the engine is idling at a low speed, turn off as many of the

electrical loads as soon as possible. If the warning stays on or comes on

when the engine is operating at normal speeds, have the electrical

system checked as soon as possible.

LOW FUEL LEVEL.Displayed when you have approximately 1/16th of

a tank indicated on the fuel gauge.

CHECK TRANSMISSION.Indicates the transmission is not operating

properly. If this warning stays on, contact your dealer as soon as

possible.

TRANSMISSION OVERHEATED.Indicates the transmission is

overheating. This warning may appear when towing heavy loads or when

driving in a low gear at a high speed for an extended period of time.

Stop the vehicle as soon as safely possible, turn off the engine and let it

cool. Check the transmission fluid and level. Refer toTransmission

fluidin theMaintenance and carechapter. If the warning stays on or

continues to come on, contact your dealer for transmission service as

soon as possible.

CHECK BRAKE LAMPS.Displayed when the brake lamps are

activated and at least one is burned out. Check the lamps as soon as

safely possible and have the burned out lamp replaced. The center

high-mount brakelamp is not monitored.

CHECK HEADLAMPS.Displayed when the headlamps are activated

and at least one is burned out. Check the lamps as soon as safely

possible and have the burned out lamp replaced. Refer toReplacing

headlamp bulbsin theMaintenance and carechapter.

Instrumentation

18

Page 164 of 248

Safety chains

Always connect the trailer's safety chains to the vehicle. To connect the

trailer's safety chains, cross the chains under the trailer tongue and allow

slack for turning corners.

If you use a rental trailer, follow the instructions that the rental agency

gives to you.

Do not attach safety chains to the bumper.

Trailer brakes

Electric brakes and manual, automatic or surge-type brakes are safe if

installed properly and adjusted to the manufacturer's specifications. The

trailer brakes must meet local and Federal regulations.

Do not connect a trailer's hydraulic brake system directly to your

vehicle's brake system. Your vehicle may not have enough

braking power and your chances of having a collision greatly increase.

The braking system of the tow vehicle is rated for operation at the

GVWR not GCWR.

Trailer lamps

Trailer lamps are required on most towed vehicles. Ensure that your

trailer lamps conform to local and Federal Regulations.

Do not splice or modify the vehicle electrical wiring or lamps for

trailer towing.

Your vehicle uses an advanced electronic module with ground side

switching to control and monitor your vehicle lamps. Splicing into the

wiring or attaching wiring to the vehicle bulbs will DISABLE the rear

vehicle lamps from functioning. Your lamp outage feature will also be

disabled or provide incorrect information.

Your vehicle is ready to install a Trailer Tow module that will provide the

proper communication with the vehicle electrical system so your trailer

lamps will function properly. See your dealer or trailer rental agency for

proper instructions and equipment for hooking up trailer lamps.

Driving

164

Page 224 of 248

EXTERIOR BULBS

Replacing exterior bulbs

It is a good idea to check the operation of the following lights frequently:

²Headlamps

²Turn signals

²Cornering lamps

²High-mount brakelamp

²Tail lamps

²Brakelamps

²Backup lamps

²License plate lamps

Do not remove lamp bulbs unless they will be replaced immediately. If a

bulb is removed for an extended period of time, contaminants may enter

the lamp housings and affect performance.

Handle a halogen bulb carefully and keep out of children's reach.

Grasp the bulb only by its plastic base and do not touch the

glass; the oil from your hand could cause the bulb to break the next

time that the headlamps are operated.

Replacing headlamp bulbs

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

To remove the headlamp bulb:

1. Make sure headlamp switch is in OFF position, then open the hood.

Maintenance and care

224

Page 225 of 248

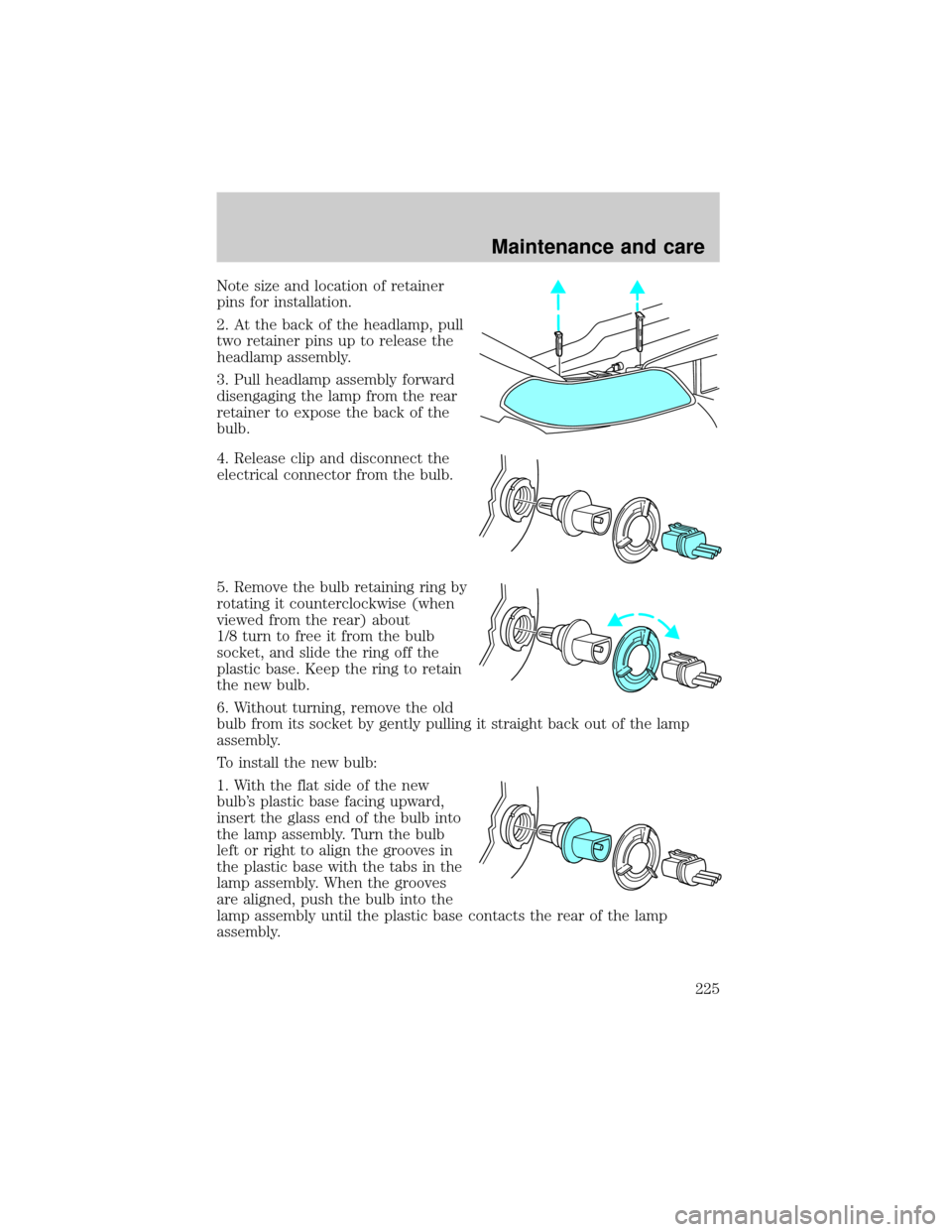

Note size and location of retainer

pins for installation.

2. At the back of the headlamp, pull

two retainer pins up to release the

headlamp assembly.

3. Pull headlamp assembly forward

disengaging the lamp from the rear

retainer to expose the back of the

bulb.

4. Release clip and disconnect the

electrical connector from the bulb.

5. Remove the bulb retaining ring by

rotating it counterclockwise (when

viewed from the rear) about

1/8 turn to free it from the bulb

socket, and slide the ring off the

plastic base. Keep the ring to retain

the new bulb.

6. Without turning, remove the old

bulb from its socket by gently pulling it straight back out of the lamp

assembly.

To install the new bulb:

1. With the flat side of the new

bulb's plastic base facing upward,

insert the glass end of the bulb into

the lamp assembly. Turn the bulb

left or right to align the grooves in

the plastic base with the tabs in the

lamp assembly. When the grooves

are aligned, push the bulb into the

lamp assembly until the plastic base contacts the rear of the lamp

assembly.

Maintenance and care

225

Page 226 of 248

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the socket by rotating clockwise until you feel a ªstop.º

3. Connect the electrical connector into the rear of the plastic base until

it snaps, locking it into position.

4. Install the headlamp on vehicle by aligning the lamp with the rear

retainer, push rearward and secure with two retainer pins.

5. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Replacing front parking/turn signal bulbs

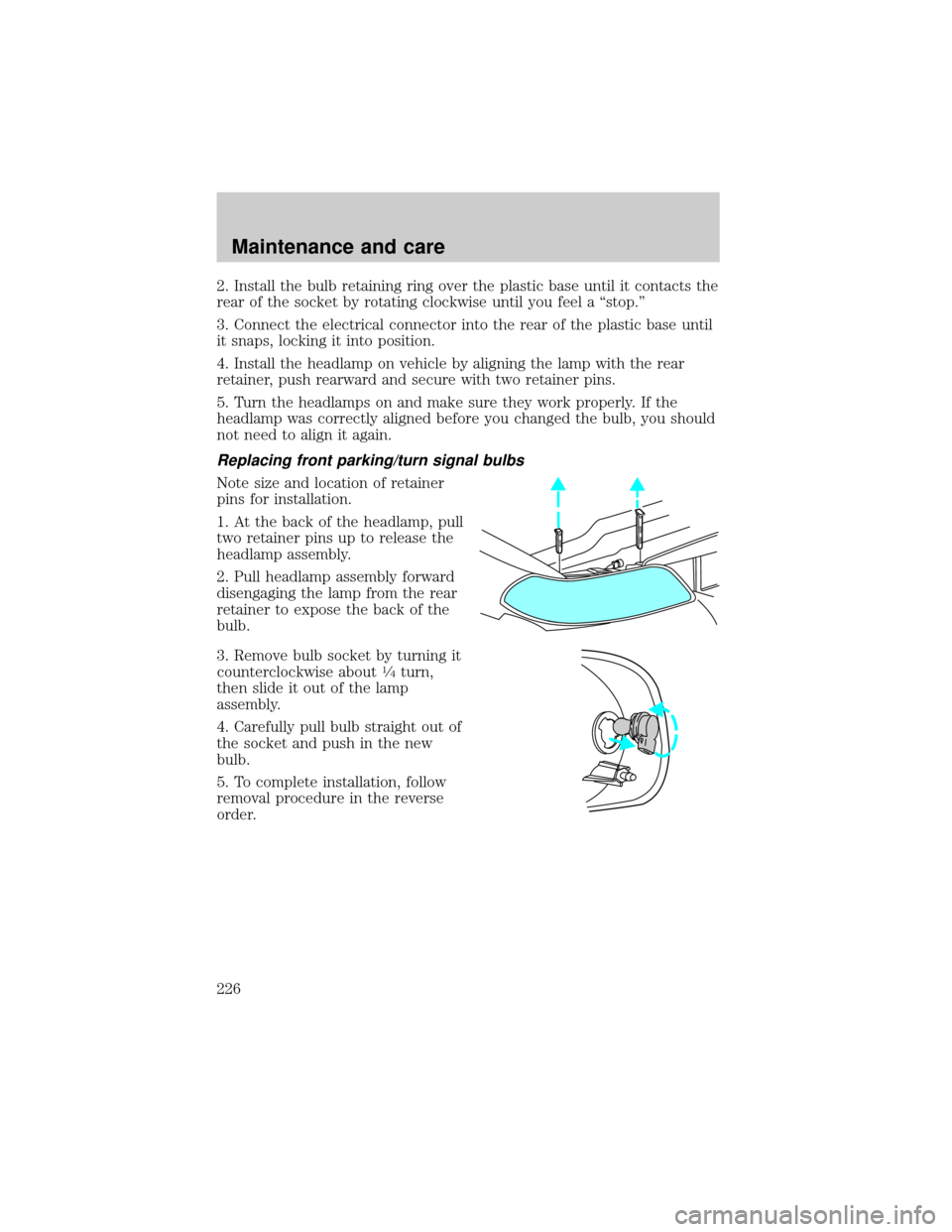

Note size and location of retainer

pins for installation.

1. At the back of the headlamp, pull

two retainer pins up to release the

headlamp assembly.

2. Pull headlamp assembly forward

disengaging the lamp from the rear

retainer to expose the back of the

bulb.

3. Remove bulb socket by turning it

counterclockwise about

1¤4turn,

then slide it out of the lamp

assembly.

4. Carefully pull bulb straight out of

the socket and push in the new

bulb.

5. To complete installation, follow

removal procedure in the reverse

order.

Maintenance and care

226

Page 227 of 248

Replacing tail lamp/backup lamp bulbs

1. Open the liftgate to expose the

tail lamp assemblies.

2. Remove the two screws from the

lamp assembly.

3. Carefully remove the lamp

assembly by pulling it rearward

about 45 degrees.

4. Rotate bulb socket

counterclockwise

1¤4turn and

remove from lamp assembly.

5. Pull bulb straight out of socket and push in new bulb.

6. To complete installation, follow the removal procedure in the reverse

order.

Replacing license plate lamp bulbs

To change the license plate bulbs:

1. Remove two screws and the

license plate lamp assembly from

the liftgate.

2. Remove bulb socket by pulling it

straight out of the lamp assembly.

3. Carefully pull the bulb out from

the socket and push in the new

bulb.

4. Push bulb socket in to the lamp

assembly.

5. Install the lamp assembly on

liftgate with two screws.

High-mount brakelamp bulbs

For bulb replacement, see a dealer or qualified technician.

Cornering lamp bulbs

For bulb replacement, see a dealer or qualified technician.

Maintenance and care

227

Page 228 of 248

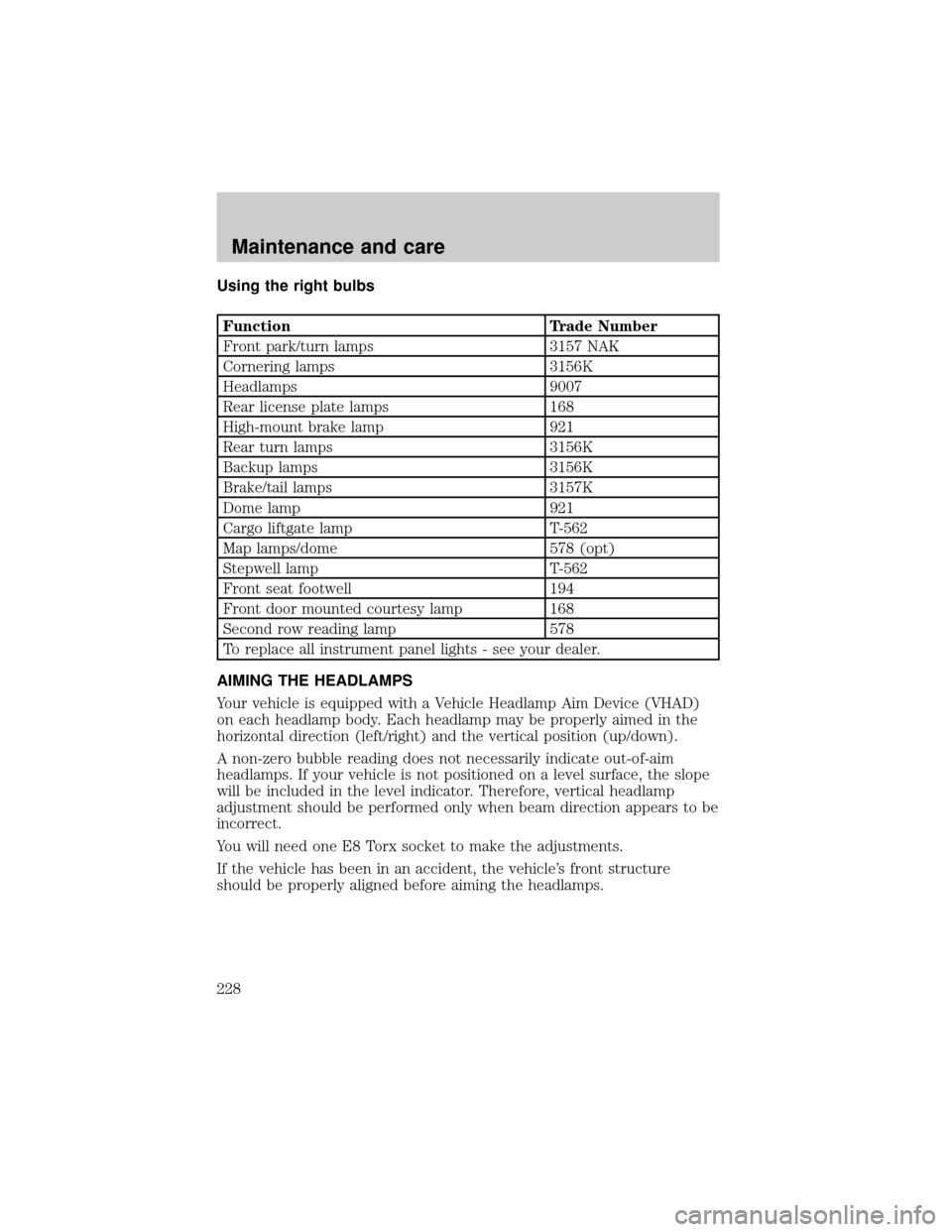

Using the right bulbs

Function Trade Number

Front park/turn lamps 3157 NAK

Cornering lamps 3156K

Headlamps 9007

Rear license plate lamps 168

High-mount brake lamp 921

Rear turn lamps 3156K

Backup lamps 3156K

Brake/tail lamps 3157K

Dome lamp 921

Cargo liftgate lamp T-562

Map lamps/dome 578 (opt)

Stepwell lamp T-562

Front seat footwell 194

Front door mounted courtesy lamp 168

Second row reading lamp 578

To replace all instrument panel lights - see your dealer.

AIMING THE HEADLAMPS

Your vehicle is equipped with a Vehicle Headlamp Aim Device (VHAD)

on each headlamp body. Each headlamp may be properly aimed in the

horizontal direction (left/right) and the vertical position (up/down).

A non-zero bubble reading does not necessarily indicate out-of-aim

headlamps. If your vehicle is not positioned on a level surface, the slope

will be included in the level indicator. Therefore, vertical headlamp

adjustment should be performed only when beam direction appears to be

incorrect.

You will need one E8 Torx socket to make the adjustments.

If the vehicle has been in an accident, the vehicle's front structure

should be properly aligned before aiming the headlamps.

Maintenance and care

228