battery FORD WINDSTAR 2000 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: WINDSTAR, Model: FORD WINDSTAR 2000 2.GPages: 280, PDF Size: 2.49 MB

Page 187 of 280

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment

Fuse Panel Description

18 10A LH Quarter Window Motor, RH Quarter

Window Motor, RH Window Switch

Backlighting, RH Lock Switch Backlighting,

Master Control Switch (LH) Backlighting,

Radio

19 10A Starter Interrupt Relay (coil)

20 Ð Not Used

21 Ð Not Used

22 10A LH Heated Mirror, RH Heated Mirror

23 20A Body Powerpoint, Auxiliary Blower Relay

#1 and #2

24 Ð Not Used

25 10A Radio

26 10A Airbag Module

27 15A Power Adjustable Foot Pedals

28 10A Cluster

29 Ð Not Used

Relay 1 Ð Switched System Power Relay #4

Relay 2 Ð Accessory Delay Relay

Relay 3 Ð Front Blower Motor Relay

Relay 4 Ð Switched System Power Relay #3

Relay 5 Ð Rear Defrost Relay

Relay 6 Ð Auxiliary Blower Motor Relay

Power distribution box

The power distribution box is located in the engine compartment. The

power distribution box contains high-current fuses that protect your

vehicle's main electrical systems from overloads.

Always disconnect the battery before servicing high current

fuses.

Roadside emergencies

187

Page 188 of 280

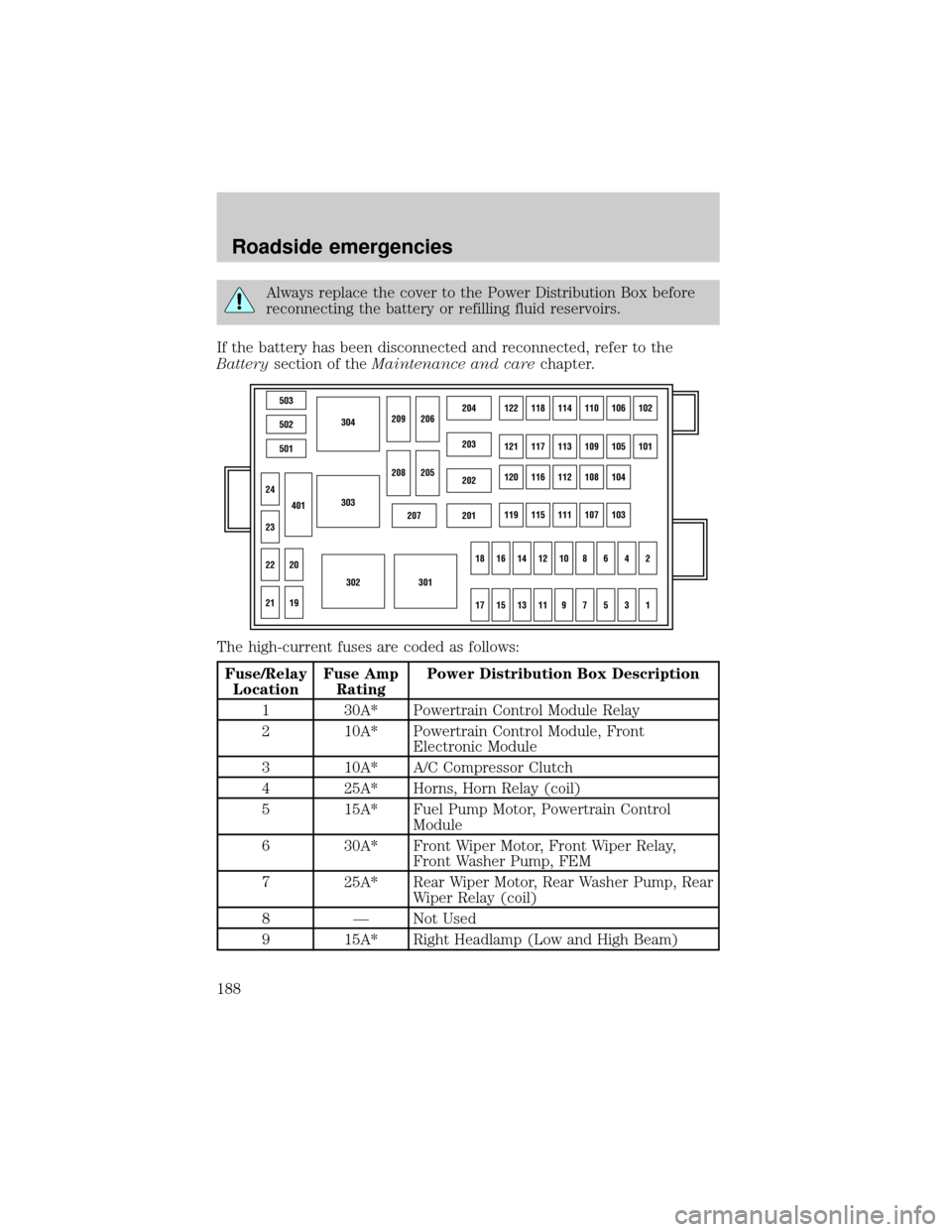

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and carechapter.

The high-current fuses are coded as follows:

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

1 30A* Powertrain Control Module Relay

2 10A* Powertrain Control Module, Front

Electronic Module

3 10A* A/C Compressor Clutch

4 25A* Horns, Horn Relay (coil)

5 15A* Fuel Pump Motor, Powertrain Control

Module

6 30A* Front Wiper Motor, Front Wiper Relay,

Front Washer Pump, FEM

7 25A* Rear Wiper Motor, Rear Washer Pump, Rear

Wiper Relay (coil)

8 Ð Not Used

9 15A* Right Headlamp (Low and High Beam)

503

304

303

302301

502

501

207201

202

203

204122118114110106102

121117113109105101

120116112108104

119115111107103

24

209206

208

18161412108642

1715131197531

205

23

22

21

401

20

19

Roadside emergencies

188

Page 197 of 280

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Do not push start your vehicle. You could damage the catalytic

converter.

Batteries contain sulfuric acid which can burn skin, eyes, and

clothing, if contacted.

Do not attempt to push start your vehicle. Automatic

transmissions do not have push-start capability.

Preparing your vehicle

1.Use only a 12±volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle's electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Roadside emergencies

197

Page 198 of 280

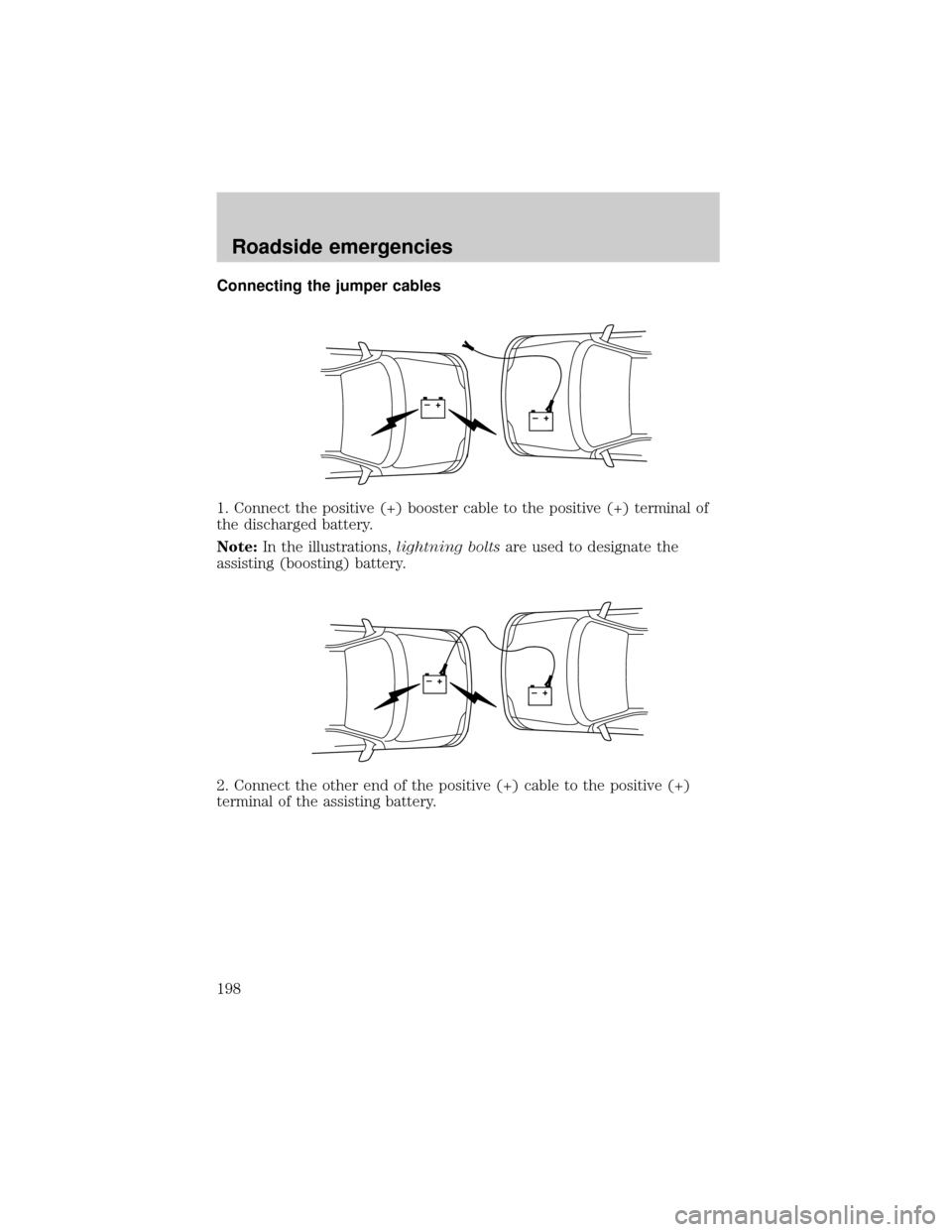

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

+–+–

+–+–

Roadside emergencies

198

Page 199 of 280

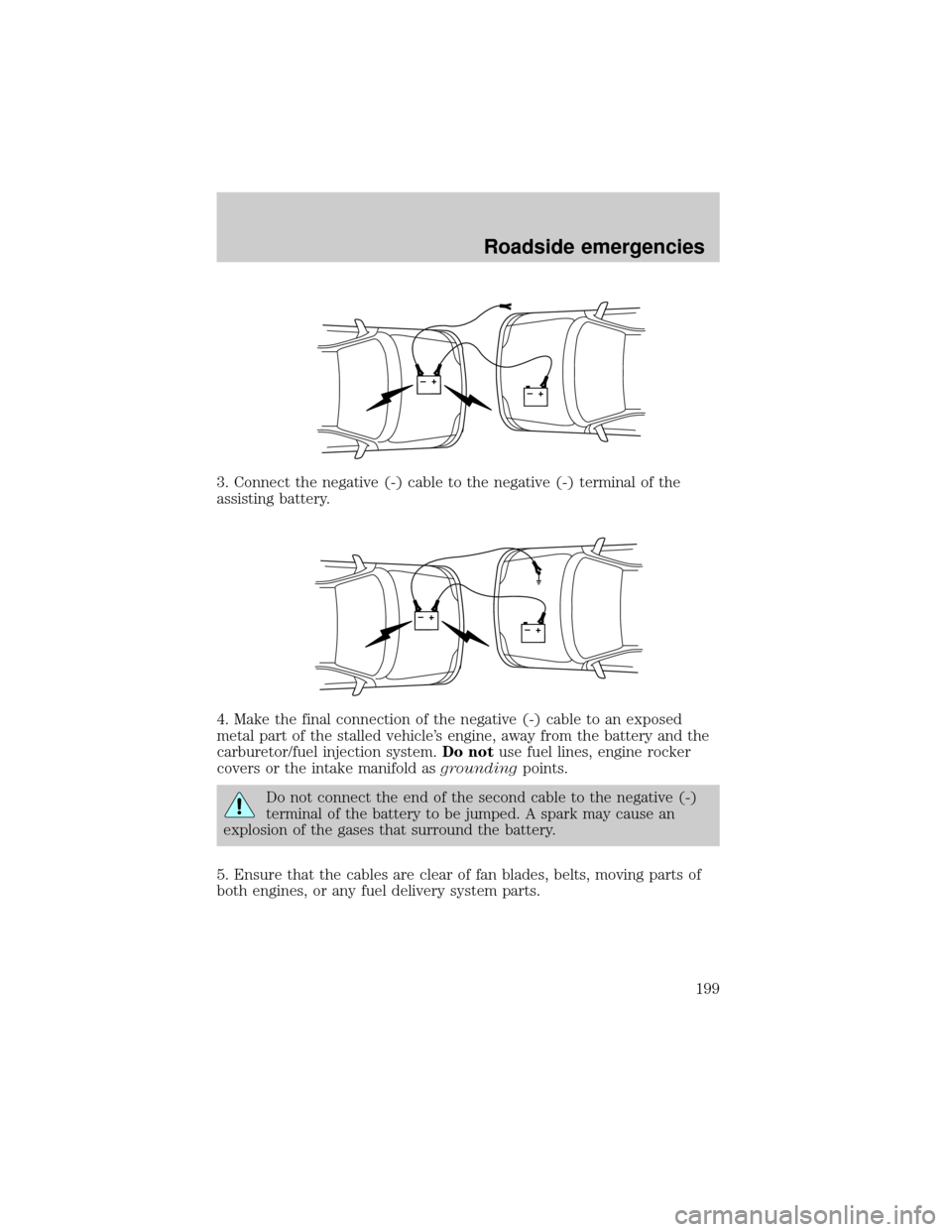

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle's engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

+–+–

+–+–

Roadside emergencies

199

Page 200 of 280

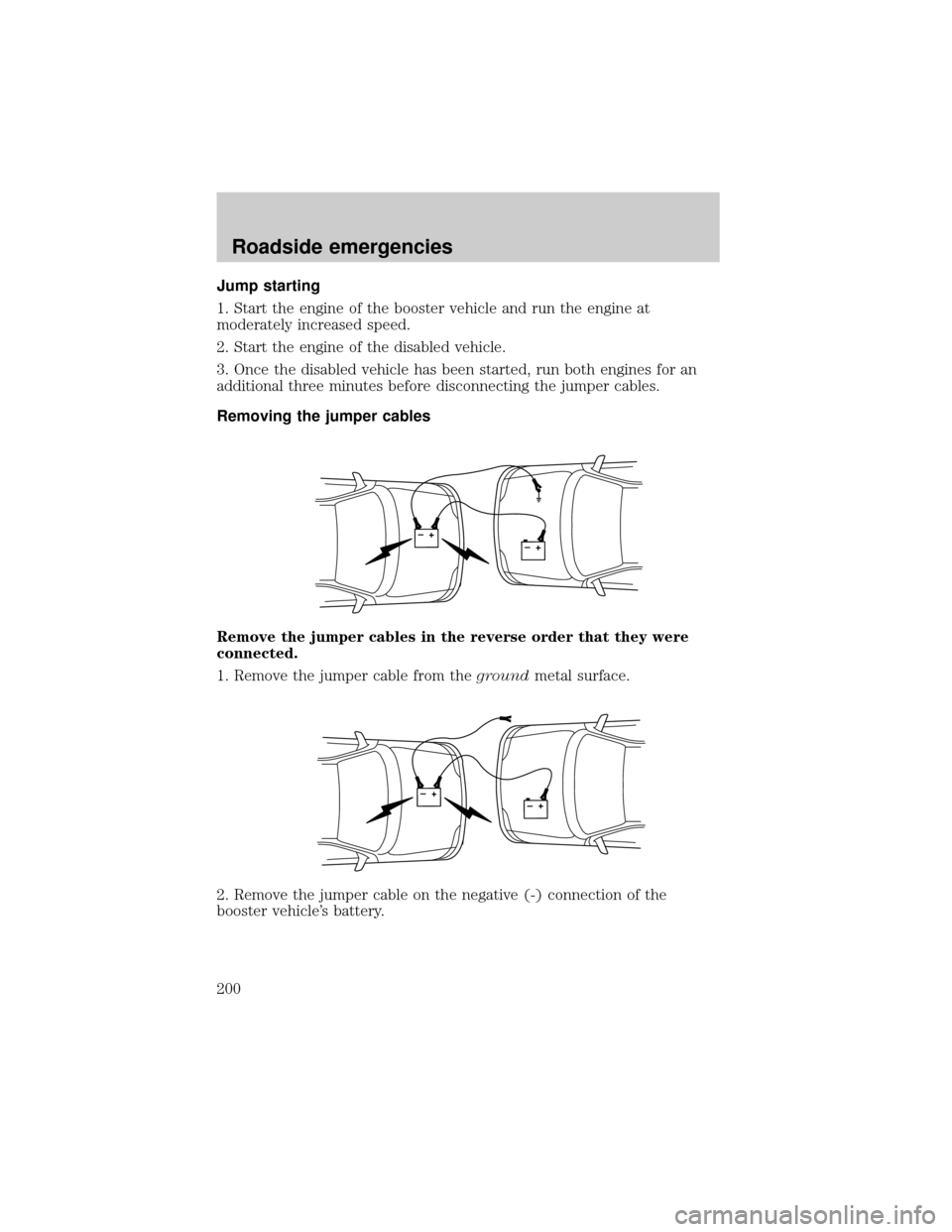

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle's battery.

+–+–

+–+–

Roadside emergencies

200

Page 201 of 280

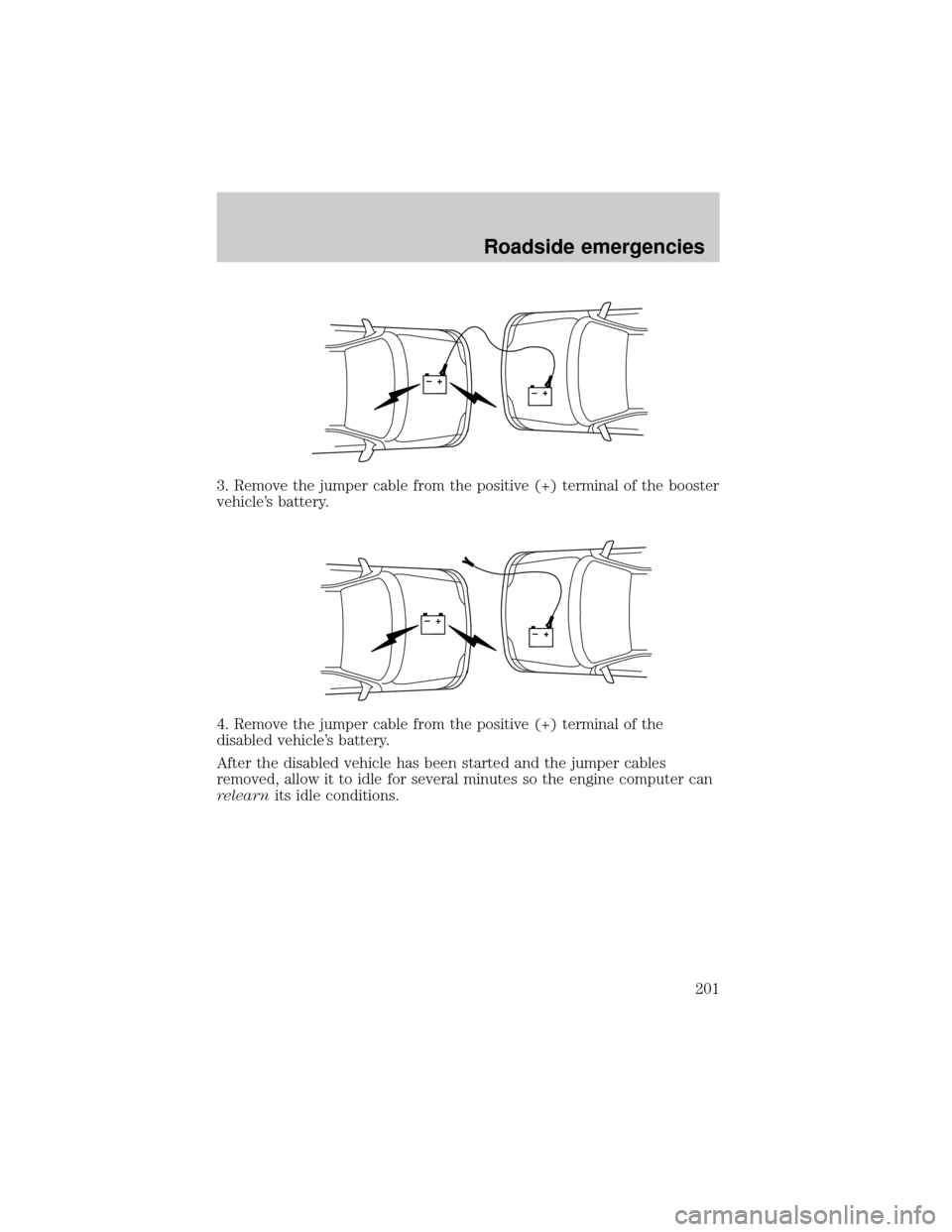

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle's battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle's battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

Roadside emergencies

201

Page 203 of 280

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a Scheduled Maintenance Guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, make sure that loose clothing, jewelry or

long hair does not get caught up in moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained inBattery

in this chapter.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

203

Page 205 of 280

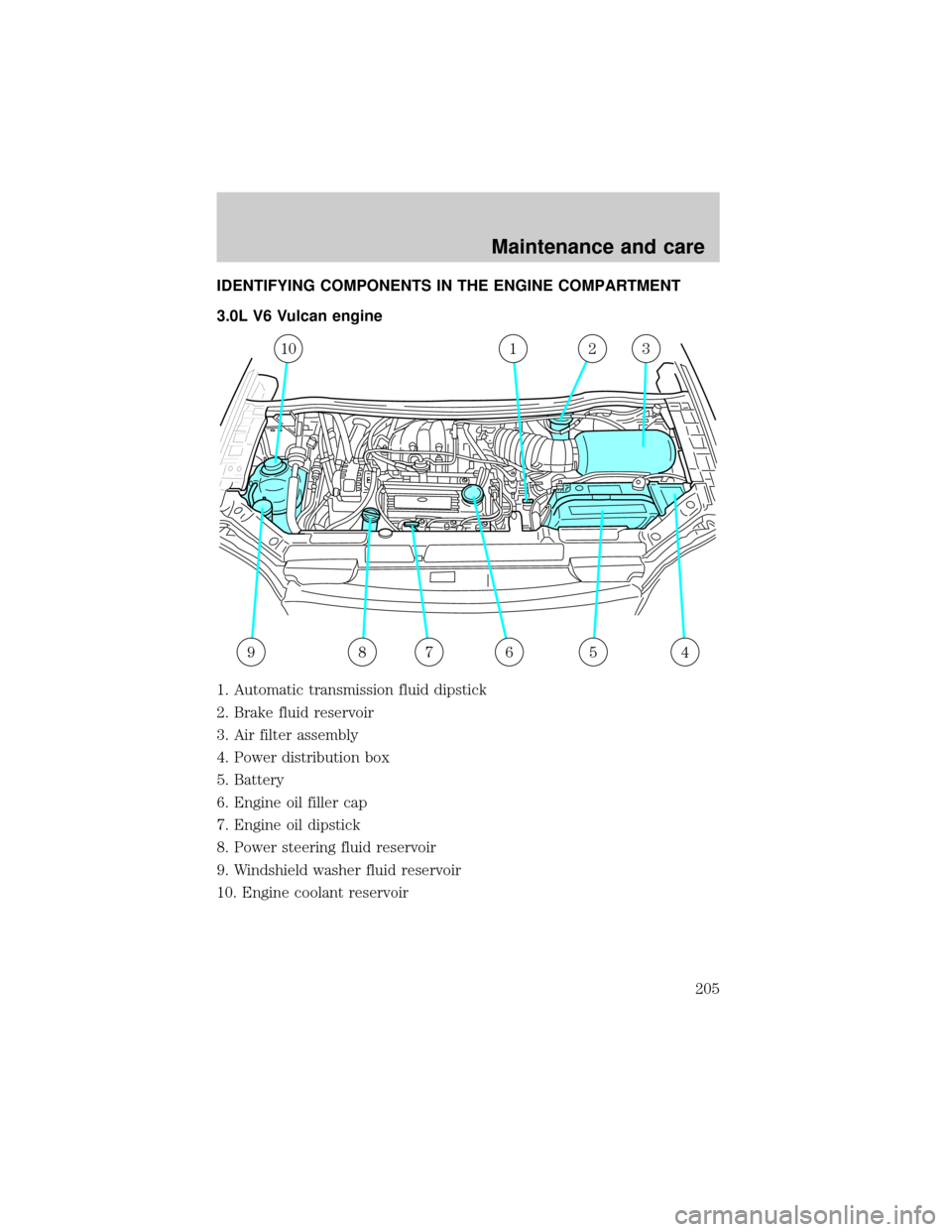

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

3.0L V6 Vulcan engine

1. Automatic transmission fluid dipstick

2. Brake fluid reservoir

3. Air filter assembly

4. Power distribution box

5. Battery

6. Engine oil filler cap

7. Engine oil dipstick

8. Power steering fluid reservoir

9. Windshield washer fluid reservoir

10. Engine coolant reservoir

987654

10123

Maintenance and care

205

Page 206 of 280

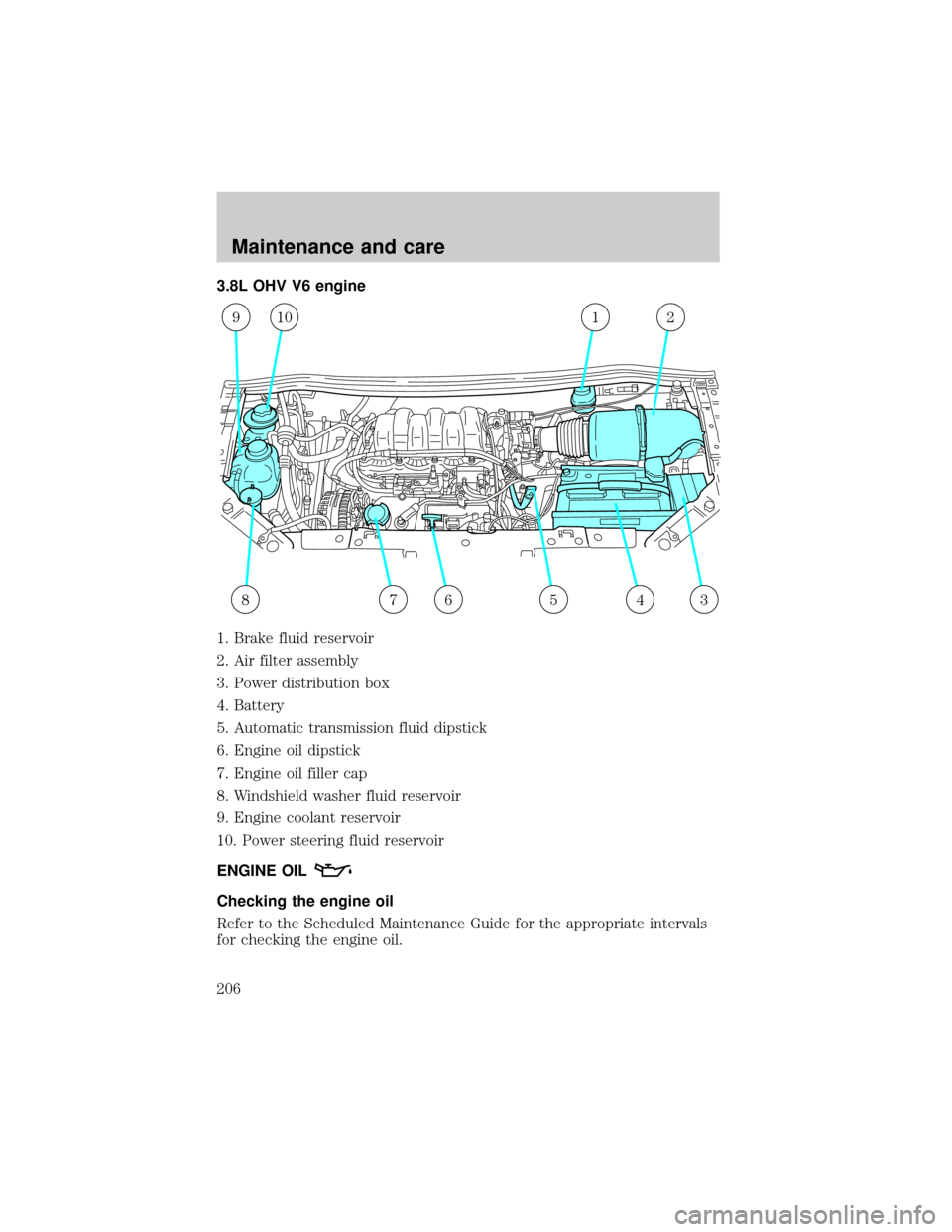

3.8L OHV V6 engine

1. Brake fluid reservoir

2. Air filter assembly

3. Power distribution box

4. Battery

5. Automatic transmission fluid dipstick

6. Engine oil dipstick

7. Engine oil filler cap

8. Windshield washer fluid reservoir

9. Engine coolant reservoir

10. Power steering fluid reservoir

ENGINE OIL

Checking the engine oil

Refer to the Scheduled Maintenance Guide for the appropriate intervals

for checking the engine oil.

345678

91012

Maintenance and care

206