headlamp FORD WINDSTAR 2000 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: WINDSTAR, Model: FORD WINDSTAR 2000 2.GPages: 280, PDF Size: 2.49 MB

Page 138 of 280

One time disable

Anytime the safety belt is buckled and then unbuckled during an ignition

ON cycle, Belt Minder will be disabled for that ignition cycle only.

Deactivating/activating the belt minder feature

Read steps1-9thoroughly before proceeding with the

deactivation/activation programming procedure.

The Belt Minder feature can be deactivated/activated by performing the

following procedure:

Before following the procedure, make sure that:

²the parking brake is set

²the gearshift is in P (Park) (automatic transmission).

²the ignition switch is in the OFF position

²all vehicle doors are closed

²the driver's safety belt is unbuckled

²the parklamps/headlamps are in OFF position (If vehicle is equipped

with Autolamps, this will not affect the procedure.)

To reduce the risk of injury, do not deactivate/activate the Belt

Minder feature while driving the vehicle.

1. Turn the ignition switch to the RUN (or ON) position. (DO NOT

START THE ENGINE)

2. Wait until the safety belt warning light turns off. (Approximately 1

minute)

²Steps 3±5 must be completed within 60 seconds or the procedure will

have to be repeated.

3. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled. This can be done before or during Belt Minder

warning activation.

4. Turn on the parklamps/headlamps, turn off the parklamps/headlamps.

5. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled.

²After step 5 the safety belt warning light will be turned on for three

seconds.

Seating and safety restraints

138

Page 161 of 280

PREPARING TO START YOUR VEHICLE

Engine starting is controlled by the powertrain control system. This system

meets all Canadian Interference-Causing Equipment standard requirements

regulating the impulse electrical field strength of radio noise.

When starting a fuel-injected engine, avoid pressing the accelerator

before or during starting. Only use the accelerator when you have

difficulty starting the engine. For more information on starting the

vehicle, refer toStarting the enginein this chapter.

Extended idling at high engine speeds can produce very high

temperatures in the engine and exhaust system, creating the risk

of fire or other damage.

Do not park, idle, or drive your vehicle in dry grass or other dry

ground cover. The emission system heats up the engine

compartment and exhaust system, which can start a fire.

Do not start your vehicle in a closed garage or in other enclosed

areas. Exhaust fumes can be toxic. Always open the garage door

before you start the engine. SeeGuarding against exhaust fumesin

this chapter for more instructions.

If you smell exhaust fumes inside your vehicle, have your dealer

inspect your vehicle immediately. Do not drive if you smell

exhaust fumes.

Important safety precautions

A computer system controls the engine's idle revolutions per minute

(RPM). When the engine starts, the idle RPM runs faster to warm the

engine. If the engine idle speed does not slow down automatically, have

the vehicle checked. Do not allow the vehicle to idle for more than 10

minutes at the higher engine RPM.

Before starting the vehicle:

1. Make sure all vehicle occupants have buckled their safety belts. For

more information on safety belts and their proper usage, refer to the

Seating and safety restraintschapter.

2. Make sure the headlamps and vehicle accessories are off.

Starting

161

Page 188 of 280

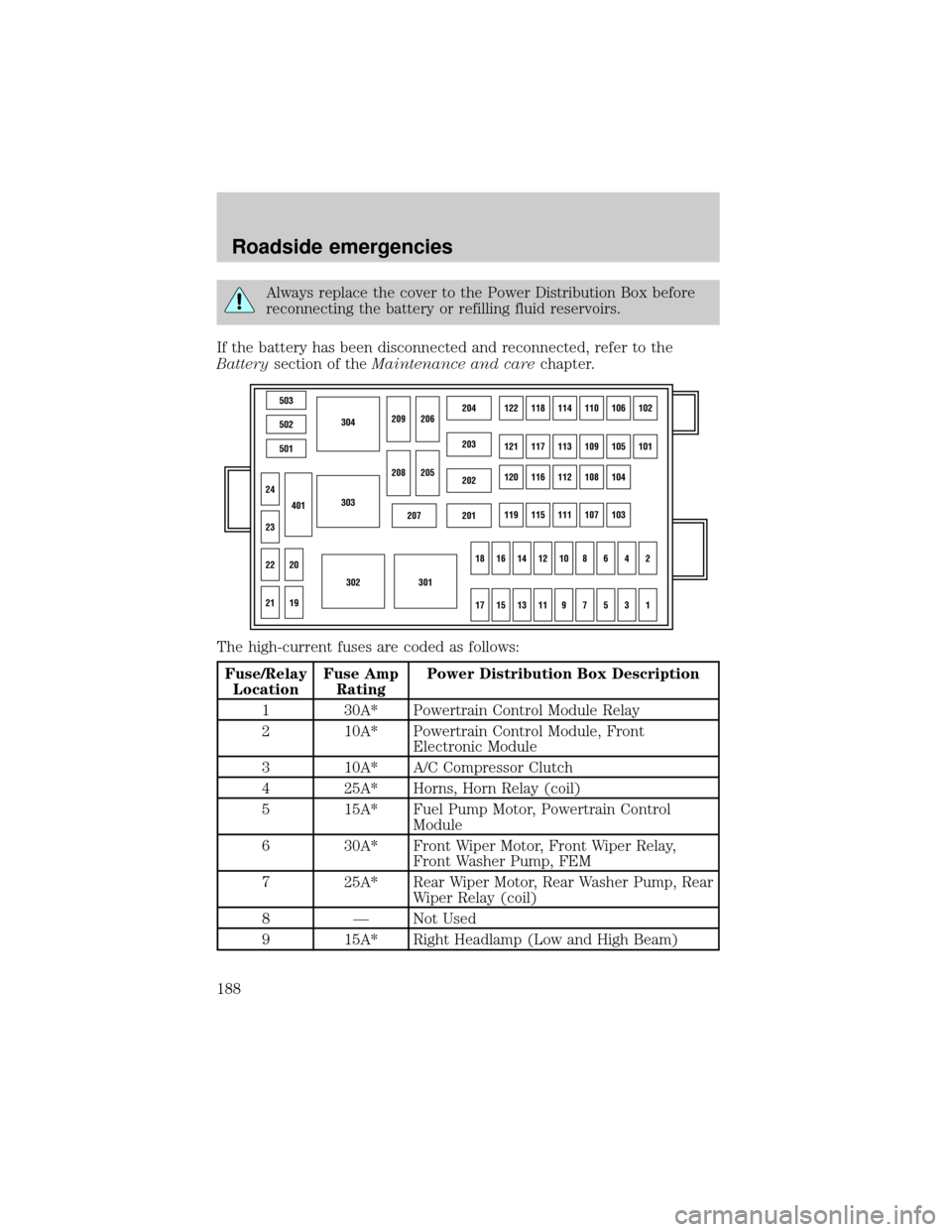

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and carechapter.

The high-current fuses are coded as follows:

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

1 30A* Powertrain Control Module Relay

2 10A* Powertrain Control Module, Front

Electronic Module

3 10A* A/C Compressor Clutch

4 25A* Horns, Horn Relay (coil)

5 15A* Fuel Pump Motor, Powertrain Control

Module

6 30A* Front Wiper Motor, Front Wiper Relay,

Front Washer Pump, FEM

7 25A* Rear Wiper Motor, Rear Washer Pump, Rear

Wiper Relay (coil)

8 Ð Not Used

9 15A* Right Headlamp (Low and High Beam)

503

304

303

302301

502

501

207201

202

203

204122118114110106102

121117113109105101

120116112108104

119115111107103

24

209206

208

18161412108642

1715131197531

205

23

22

21

401

20

19

Roadside emergencies

188

Page 189 of 280

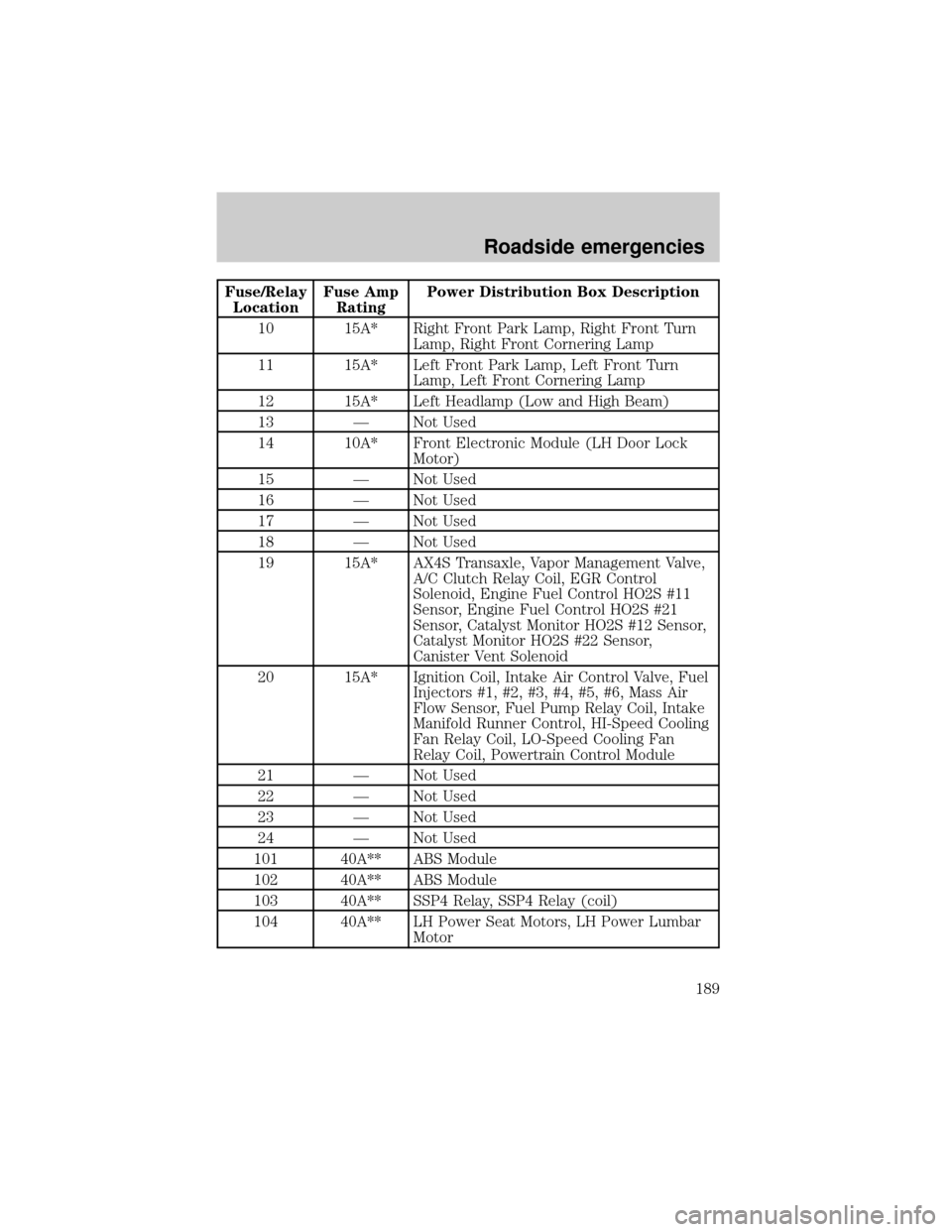

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

10 15A* Right Front Park Lamp, Right Front Turn

Lamp, Right Front Cornering Lamp

11 15A* Left Front Park Lamp, Left Front Turn

Lamp, Left Front Cornering Lamp

12 15A* Left Headlamp (Low and High Beam)

13 Ð Not Used

14 10A* Front Electronic Module (LH Door Lock

Motor)

15 Ð Not Used

16 Ð Not Used

17 Ð Not Used

18 Ð Not Used

19 15A* AX4S Transaxle, Vapor Management Valve,

A/C Clutch Relay Coil, EGR Control

Solenoid, Engine Fuel Control HO2S #11

Sensor, Engine Fuel Control HO2S #21

Sensor, Catalyst Monitor HO2S #12 Sensor,

Catalyst Monitor HO2S #22 Sensor,

Canister Vent Solenoid

20 15A* Ignition Coil, Intake Air Control Valve, Fuel

Injectors #1, #2, #3, #4, #5, #6, Mass Air

Flow Sensor, Fuel Pump Relay Coil, Intake

Manifold Runner Control, HI-Speed Cooling

Fan Relay Coil, LO-Speed Cooling Fan

Relay Coil, Powertrain Control Module

21 Ð Not Used

22 Ð Not Used

23 Ð Not Used

24 Ð Not Used

101 40A** ABS Module

102 40A** ABS Module

103 40A** SSP4 Relay, SSP4 Relay (coil)

104 40A** LH Power Seat Motors, LH Power Lumbar

Motor

Roadside emergencies

189

Page 240 of 280

engine. This decal identifies engine displacement and gives some tune up

specifications.

Please consult your ªWarranty Guideº for complete emission warranty

information.

Readiness for Inspection/Maintenance (I/M) testing

In some localities, it may be a legal requirement to pass an I/M test of

the on-board diagnostics system. If your ªCheck Engine/Service Engine

Soonº light is on, refer to the description in theWarning Lights and

Chimessection of theInstrumentationchapter. Your vehicle may not

pass the I/M test with the ªCheck Engine/Service Engine Soonº light on.

If the vehicle's powertrain system or its battery has just been serviced,

the on-board diagnostics system is reset to a ªnot ready for I/M testº

condition. To ready the on-board diagnostics system for I/M testing, a

minimum of 30 minutes of city and highway driving is necessary as

described below:

²First, at least 10 minutes of driving on an expressway or highway.

²Next, at least 20 minutes driving in stop-and-go, city-type traffic with

at least four idle periods.

Allow the vehicle to sit for at least eight hours without starting the

engine. Then, start the engine and complete the above driving cycle. The

engine must warm up to its normal operating temperature. Once started,

do not turn off the engine until the above driving cycle is complete.

BULBS

Replacing exterior bulbs

It is a good idea to check the operation of the following lights frequently:

²Headlamps

²Turn signals

²Cornering lamps

²High-mount brakelamp

²Tail lamps

²Brakelamps

²Backup lamps

²License plate lamps

Maintenance and care

240

Page 241 of 280

Do not remove lamp bulbs unless they will be replaced immediately. If a

bulb is removed for an extended period of time, contaminants may enter

the lamp housings and affect performance.

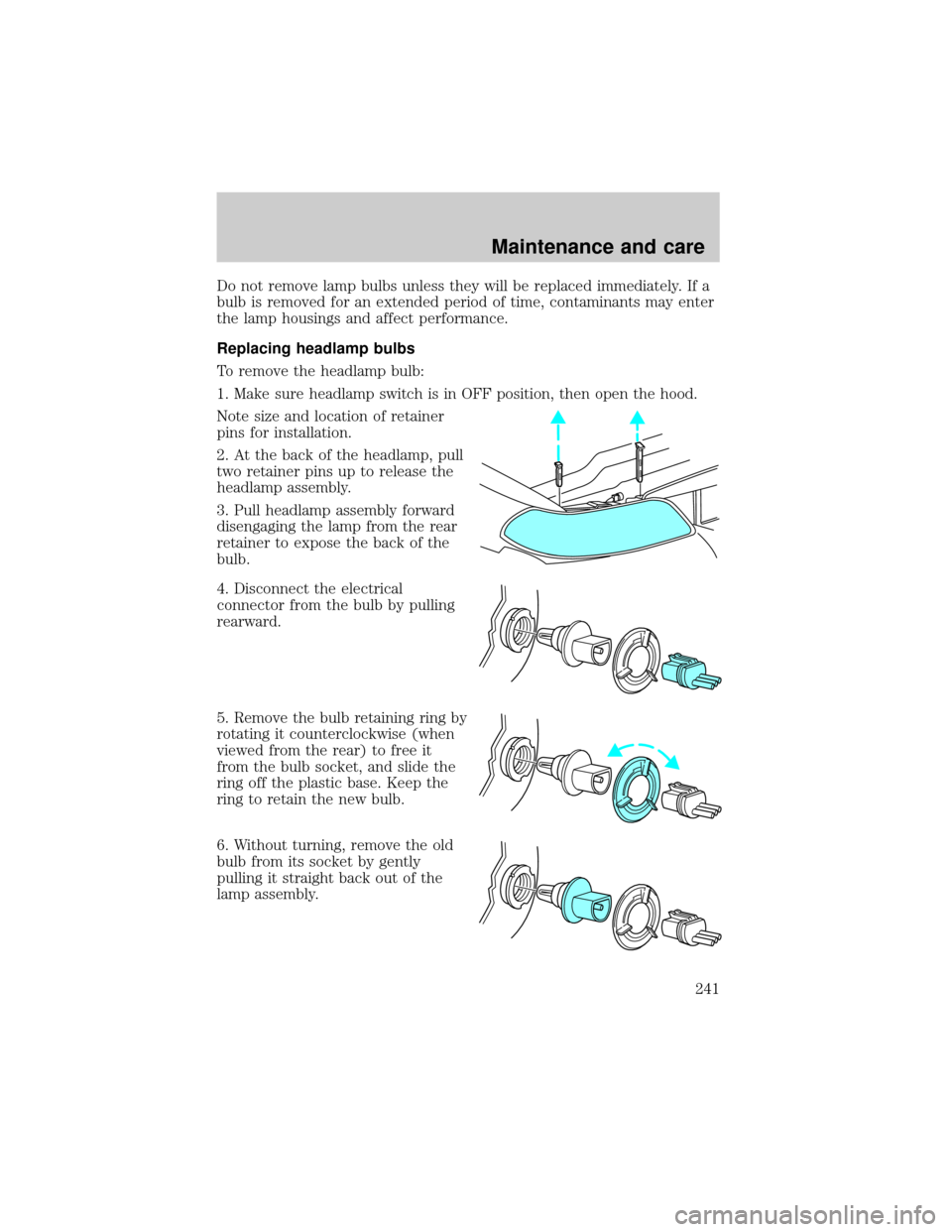

Replacing headlamp bulbs

To remove the headlamp bulb:

1. Make sure headlamp switch is in OFF position, then open the hood.

Note size and location of retainer

pins for installation.

2. At the back of the headlamp, pull

two retainer pins up to release the

headlamp assembly.

3. Pull headlamp assembly forward

disengaging the lamp from the rear

retainer to expose the back of the

bulb.

4. Disconnect the electrical

connector from the bulb by pulling

rearward.

5. Remove the bulb retaining ring by

rotating it counterclockwise (when

viewed from the rear) to free it

from the bulb socket, and slide the

ring off the plastic base. Keep the

ring to retain the new bulb.

6. Without turning, remove the old

bulb from its socket by gently

pulling it straight back out of the

lamp assembly.

Maintenance and care

241

Page 242 of 280

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

1. With the flat side of the new bulb's plastic base facing upward, insert

the glass end of the bulb into the lamp assembly. Turn the bulb left or

right to align the grooves in the plastic base with the tabs in the lamp

assembly. When the grooves are aligned, push the bulb into the lamp

assembly until the plastic base contacts the rear of the lamp assembly.

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the socket by rotating clockwise until you feel a ªstop.º

3. Connect the electrical connector into the rear of the plastic base until

it snaps, locking it into position.

4. Install the headlamp on vehicle by aligning the lamp with the rear

retainer, push rearward and secure with two retainer pins.

5. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Maintenance and care

242

Page 243 of 280

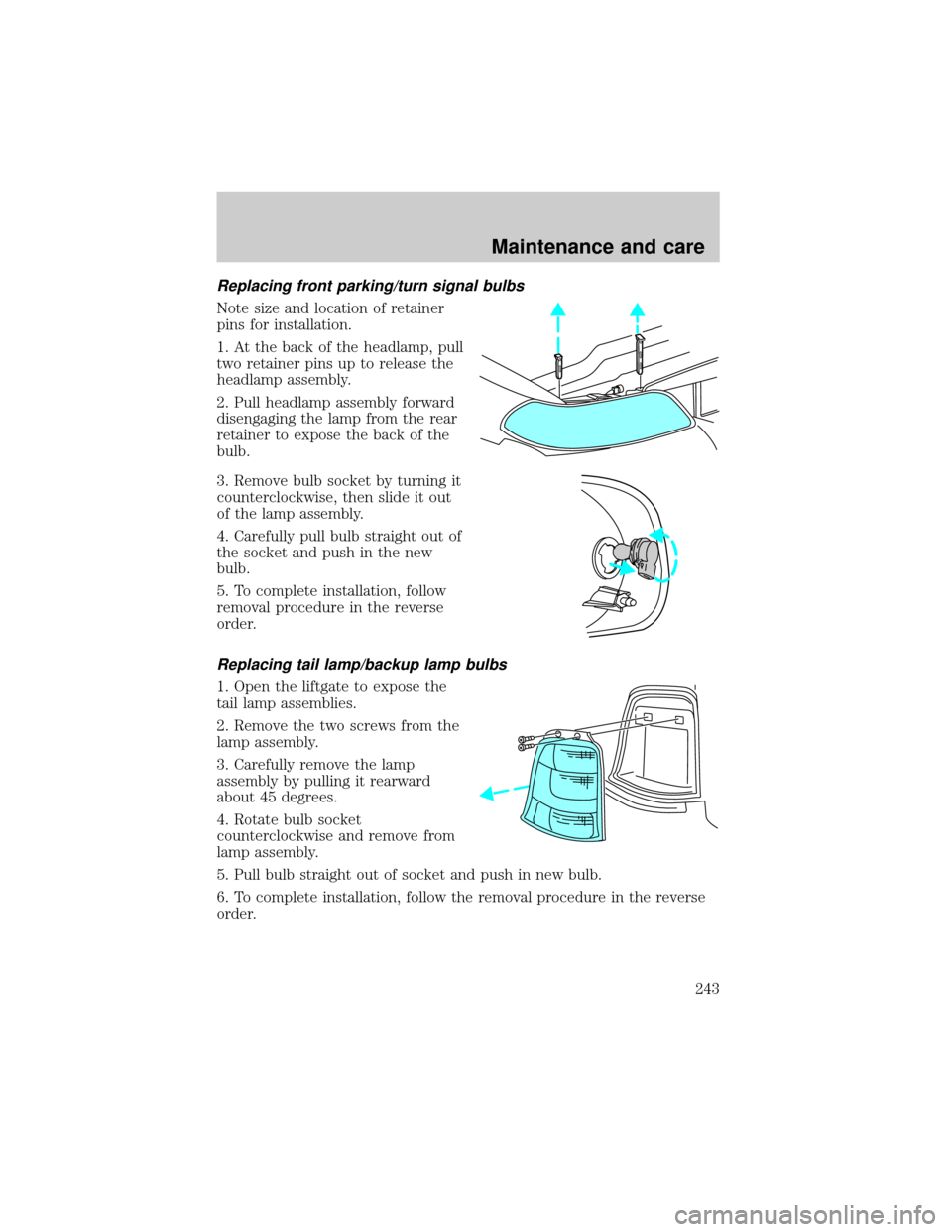

Replacing front parking/turn signal bulbs

Note size and location of retainer

pins for installation.

1. At the back of the headlamp, pull

two retainer pins up to release the

headlamp assembly.

2. Pull headlamp assembly forward

disengaging the lamp from the rear

retainer to expose the back of the

bulb.

3. Remove bulb socket by turning it

counterclockwise, then slide it out

of the lamp assembly.

4. Carefully pull bulb straight out of

the socket and push in the new

bulb.

5. To complete installation, follow

removal procedure in the reverse

order.

Replacing tail lamp/backup lamp bulbs

1. Open the liftgate to expose the

tail lamp assemblies.

2. Remove the two screws from the

lamp assembly.

3. Carefully remove the lamp

assembly by pulling it rearward

about 45 degrees.

4. Rotate bulb socket

counterclockwise and remove from

lamp assembly.

5. Pull bulb straight out of socket and push in new bulb.

6. To complete installation, follow the removal procedure in the reverse

order.

Maintenance and care

243

Page 245 of 280

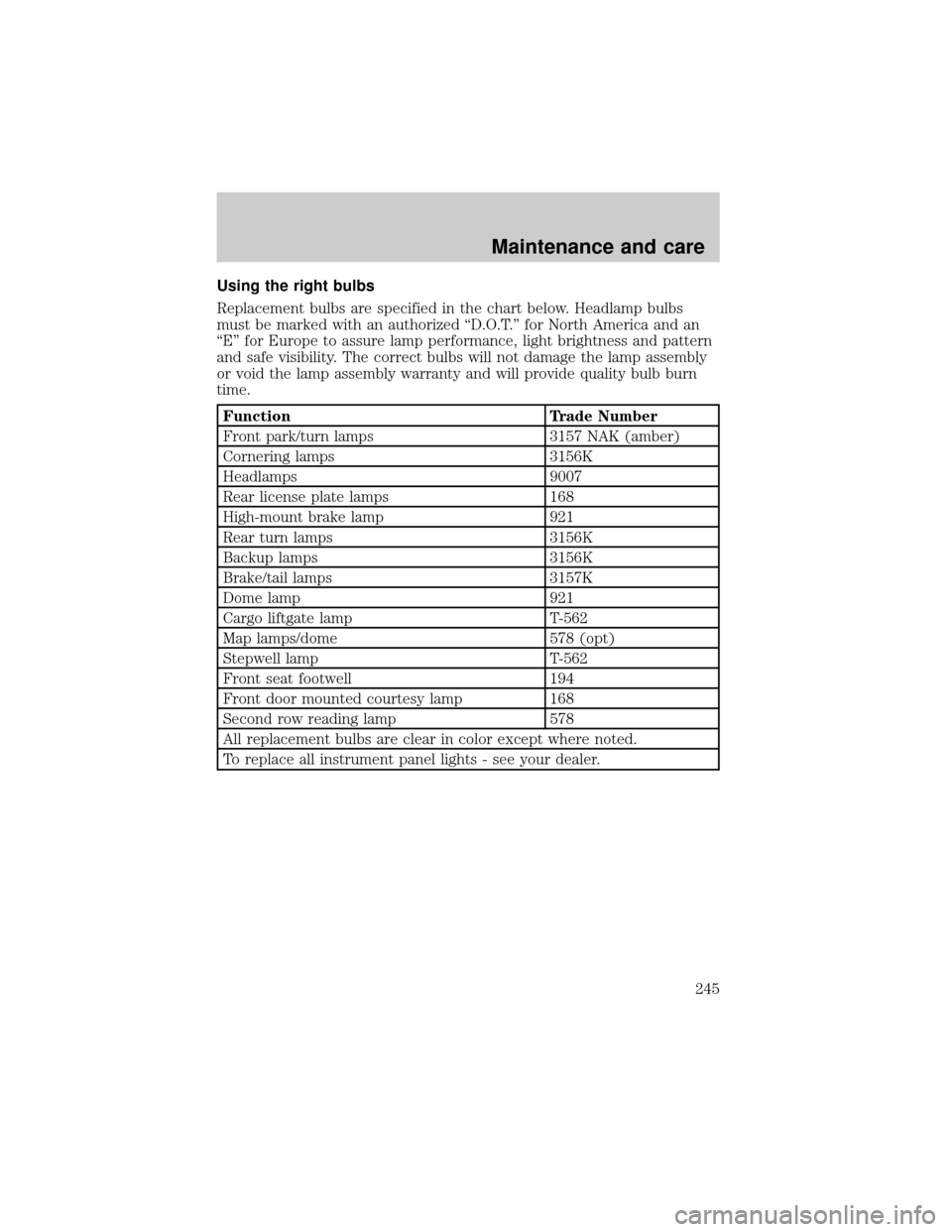

Using the right bulbs

Replacement bulbs are specified in the chart below. Headlamp bulbs

must be marked with an authorized ªD.O.T.º for North America and an

ªEº for Europe to assure lamp performance, light brightness and pattern

and safe visibility. The correct bulbs will not damage the lamp assembly

or void the lamp assembly warranty and will provide quality bulb burn

time.

Function Trade Number

Front park/turn lamps 3157 NAK (amber)

Cornering lamps 3156K

Headlamps 9007

Rear license plate lamps 168

High-mount brake lamp 921

Rear turn lamps 3156K

Backup lamps 3156K

Brake/tail lamps 3157K

Dome lamp 921

Cargo liftgate lamp T-562

Map lamps/dome 578 (opt)

Stepwell lamp T-562

Front seat footwell 194

Front door mounted courtesy lamp 168

Second row reading lamp 578

All replacement bulbs are clear in color except where noted.

To replace all instrument panel lights - see your dealer.

Maintenance and care

245

Page 246 of 280

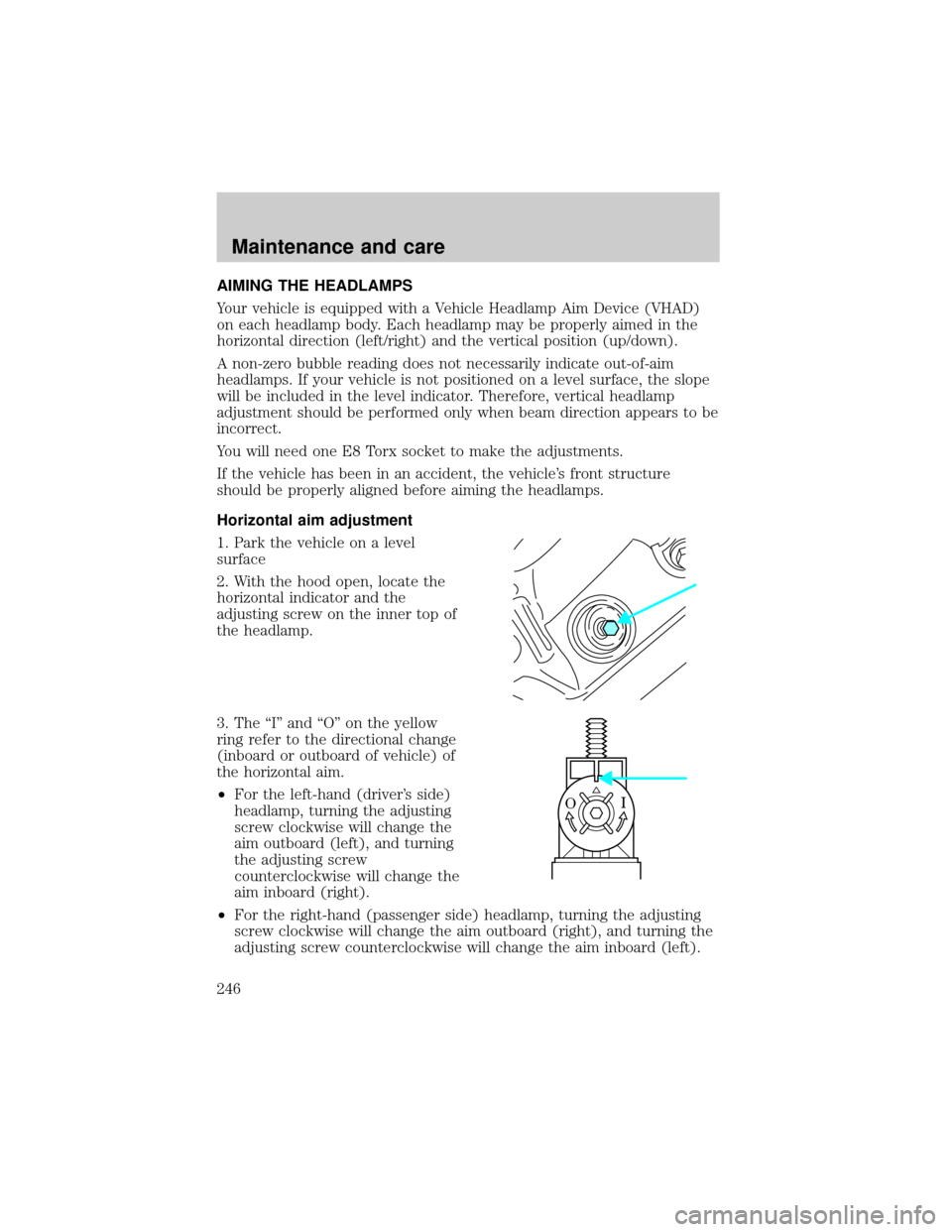

AIMING THE HEADLAMPS

Your vehicle is equipped with a Vehicle Headlamp Aim Device (VHAD)

on each headlamp body. Each headlamp may be properly aimed in the

horizontal direction (left/right) and the vertical position (up/down).

A non-zero bubble reading does not necessarily indicate out-of-aim

headlamps. If your vehicle is not positioned on a level surface, the slope

will be included in the level indicator. Therefore, vertical headlamp

adjustment should be performed only when beam direction appears to be

incorrect.

You will need one E8 Torx socket to make the adjustments.

If the vehicle has been in an accident, the vehicle's front structure

should be properly aligned before aiming the headlamps.

Horizontal aim adjustment

1. Park the vehicle on a level

surface

2. With the hood open, locate the

horizontal indicator and the

adjusting screw on the inner top of

the headlamp.

3. The ªIº and ªOº on the yellow

ring refer to the directional change

(inboard or outboard of vehicle) of

the horizontal aim.

²For the left-hand (driver's side)

headlamp, turning the adjusting

screw clockwise will change the

aim outboard (left), and turning

the adjusting screw

counterclockwise will change the

aim inboard (right).

²For the right-hand (passenger side) headlamp, turning the adjusting

screw clockwise will change the aim outboard (right), and turning the

adjusting screw counterclockwise will change the aim inboard (left).

I O

Maintenance and care

246