clock FORD WINDSTAR 2002 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2002, Model line: WINDSTAR, Model: FORD WINDSTAR 2002 2.GPages: 296, PDF Size: 2.45 MB

Page 76 of 296

4. Install the headlamp on vehicle by aligning the lamp with the rear

retainer, push rearward and secure with two retainer pins.

5. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

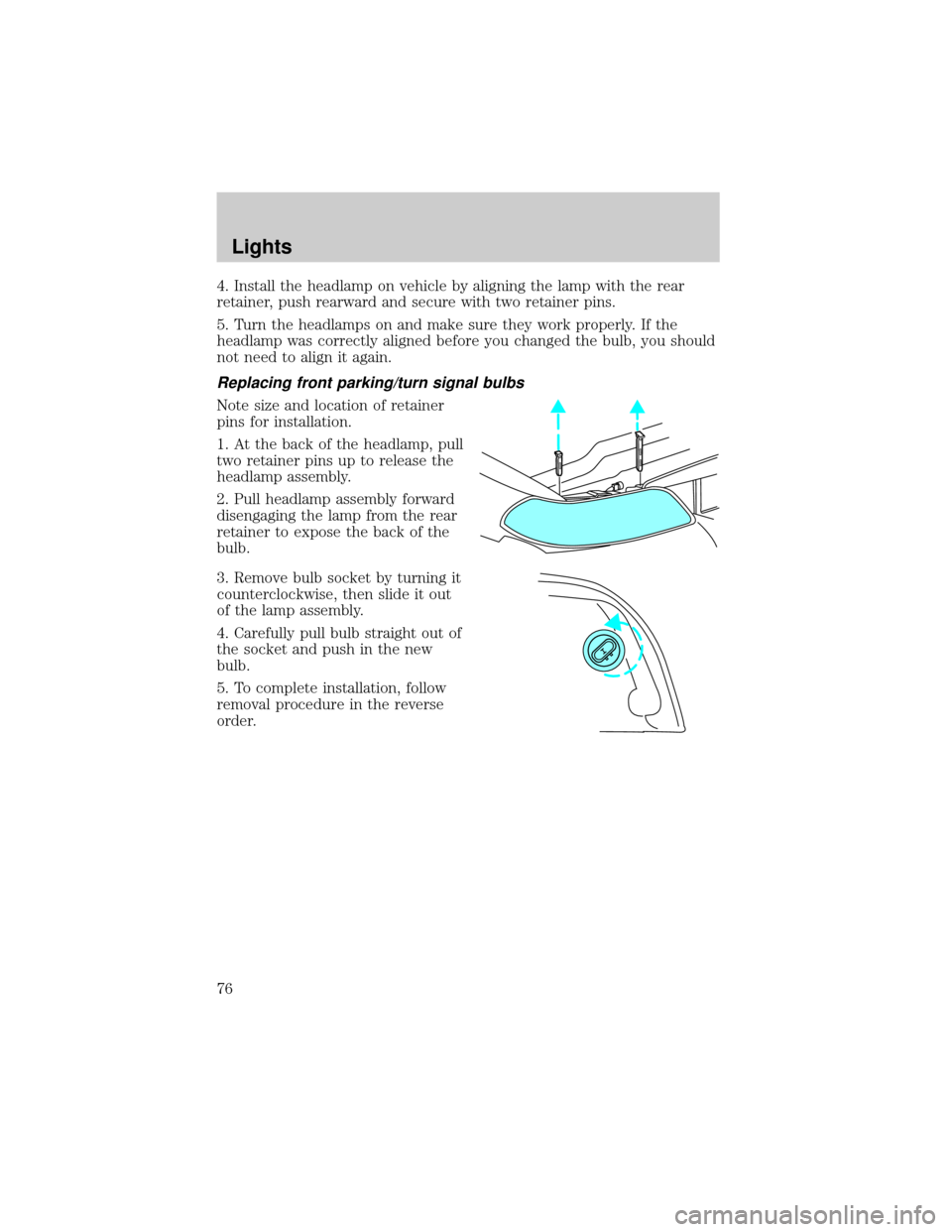

Replacing front parking/turn signal bulbs

Note size and location of retainer

pins for installation.

1. At the back of the headlamp, pull

two retainer pins up to release the

headlamp assembly.

2. Pull headlamp assembly forward

disengaging the lamp from the rear

retainer to expose the back of the

bulb.

3. Remove bulb socket by turning it

counterclockwise, then slide it out

of the lamp assembly.

4. Carefully pull bulb straight out of

the socket and push in the new

bulb.

5. To complete installation, follow

removal procedure in the reverse

order.

Lights

76

Page 77 of 296

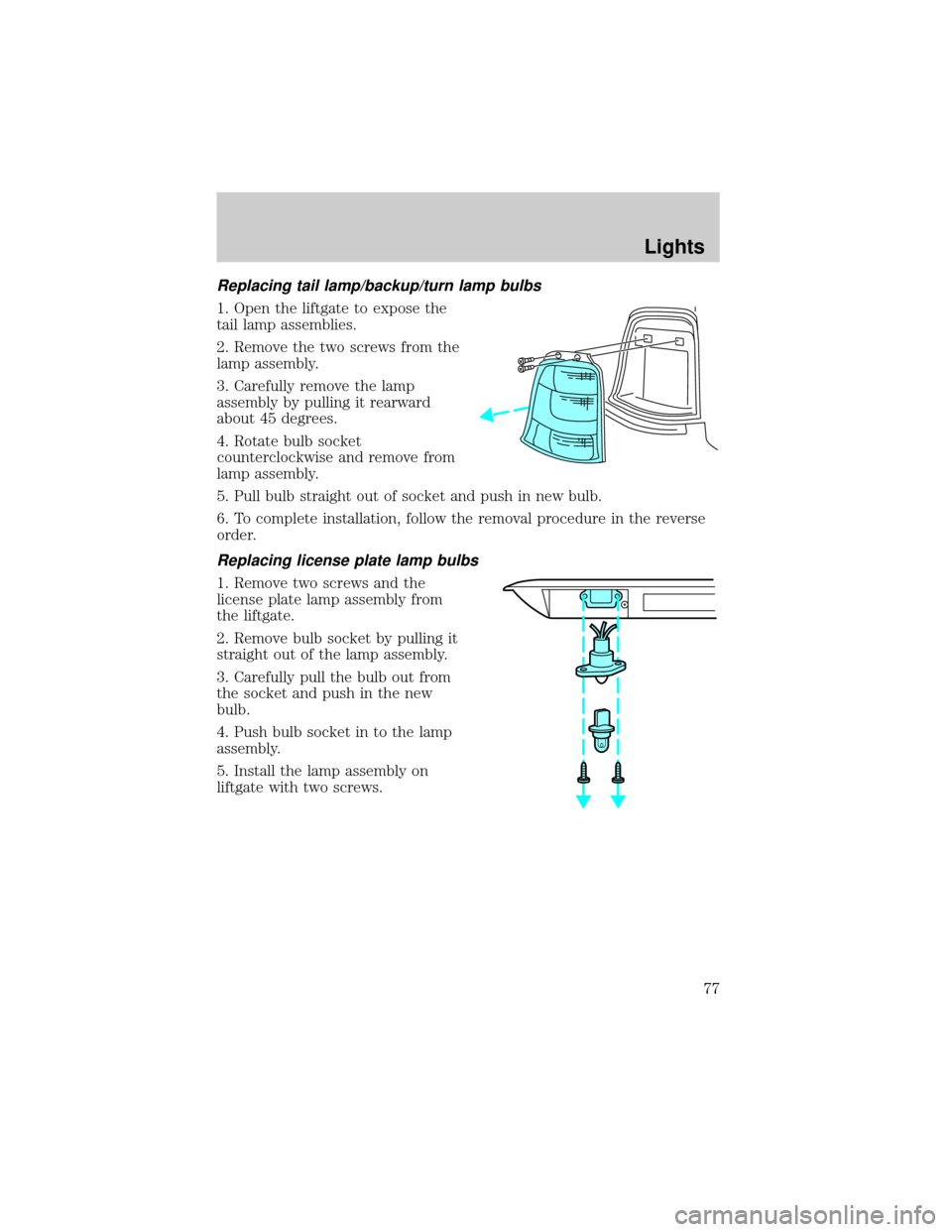

Replacing tail lamp/backup/turn lamp bulbs

1. Open the liftgate to expose the

tail lamp assemblies.

2. Remove the two screws from the

lamp assembly.

3. Carefully remove the lamp

assembly by pulling it rearward

about 45 degrees.

4. Rotate bulb socket

counterclockwise and remove from

lamp assembly.

5. Pull bulb straight out of socket and push in new bulb.

6. To complete installation, follow the removal procedure in the reverse

order.

Replacing license plate lamp bulbs

1. Remove two screws and the

license plate lamp assembly from

the liftgate.

2. Remove bulb socket by pulling it

straight out of the lamp assembly.

3. Carefully pull the bulb out from

the socket and push in the new

bulb.

4. Push bulb socket in to the lamp

assembly.

5. Install the lamp assembly on

liftgate with two screws.

Lights

77

Page 78 of 296

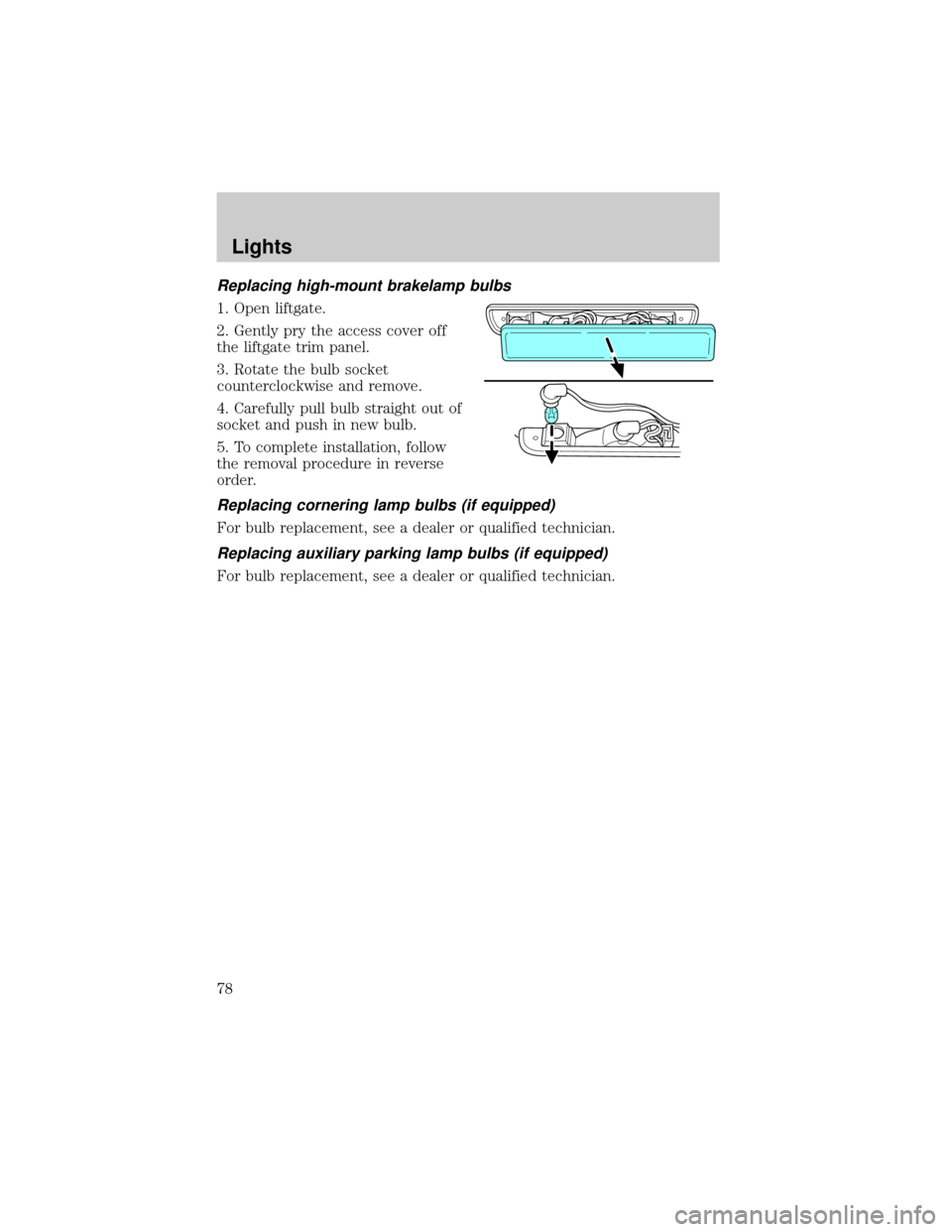

Replacing high-mount brakelamp bulbs

1. Open liftgate.

2. Gently pry the access cover off

the liftgate trim panel.

3. Rotate the bulb socket

counterclockwise and remove.

4. Carefully pull bulb straight out of

socket and push in new bulb.

5. To complete installation, follow

the removal procedure in reverse

order.

Replacing cornering lamp bulbs (if equipped)

For bulb replacement, see a dealer or qualified technician.

Replacing auxiliary parking lamp bulbs (if equipped)

For bulb replacement, see a dealer or qualified technician.

Lights

78

Page 110 of 296

TRIP ELAPSED DRIVE TIME

Select this function from the INFO menu to display your trip elapsed

drive time and will display and accumulate when the key is in the RUN

position.

1. Press the INFO control until the message center display shows the

TRIP ELAPSED TIME XXXX.

2. Hold the RESET control down for two seconds to clear display.

DISPLAY ON/OFF

Select this function from the INFO menu to turn your message center

display OFF or ON.

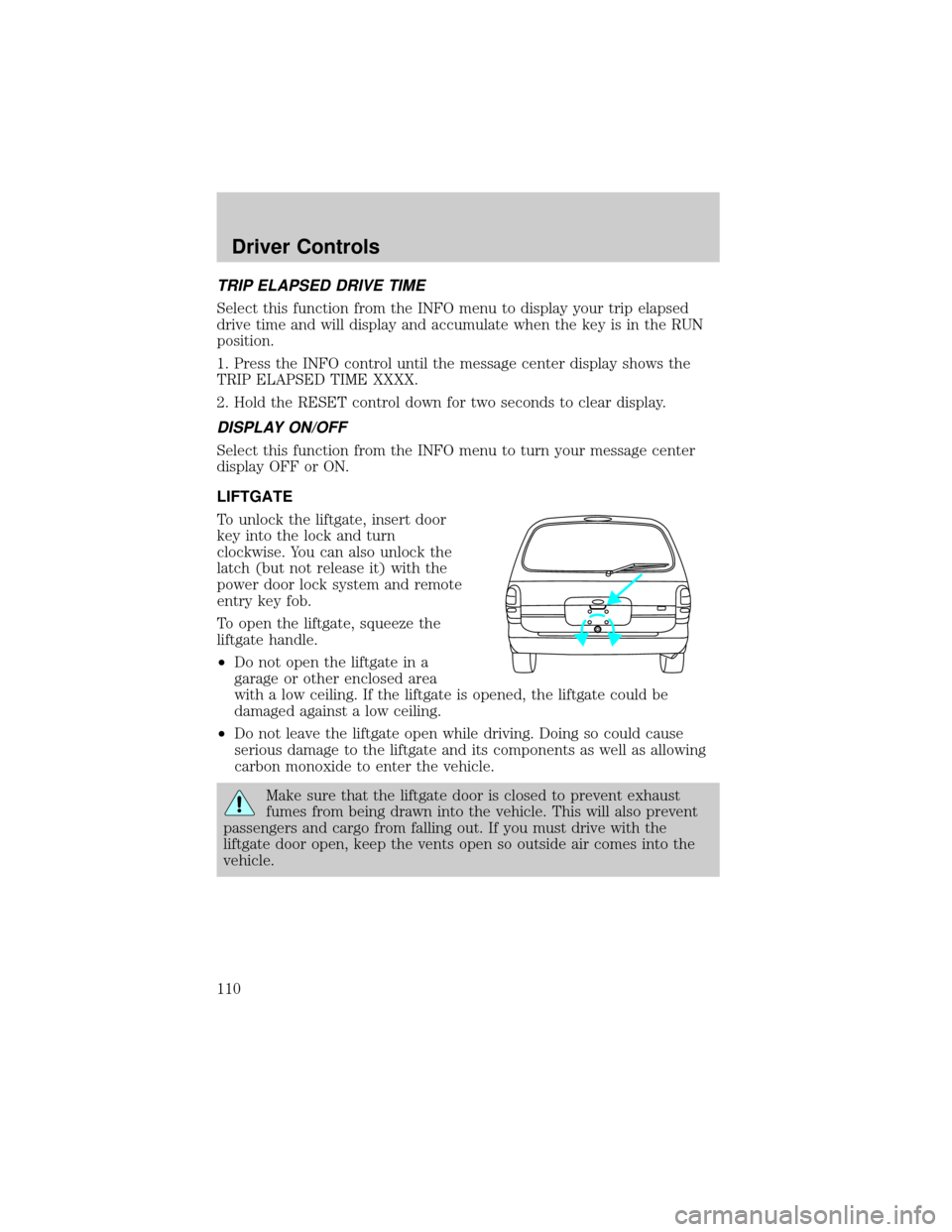

LIFTGATE

To unlock the liftgate, insert door

key into the lock and turn

clockwise. You can also unlock the

latch (but not release it) with the

power door lock system and remote

entry key fob.

To open the liftgate, squeeze the

liftgate handle.

²Do not open the liftgate in a

garage or other enclosed area

with a low ceiling. If the liftgate is opened, the liftgate could be

damaged against a low ceiling.

²Do not leave the liftgate open while driving. Doing so could cause

serious damage to the liftgate and its components as well as allowing

carbon monoxide to enter the vehicle.

Make sure that the liftgate door is closed to prevent exhaust

fumes from being drawn into the vehicle. This will also prevent

passengers and cargo from falling out. If you must drive with the

liftgate door open, keep the vents open so outside air comes into the

vehicle.

Driver Controls

110

Page 214 of 296

Removing the jack and tools

1. Locate the access panel on the interior trim. Rotate the two panel

retaining clips and remove the panel.

2. Remove the jack and lug nut wrench by turning the thumbscrew

counterclockwise to remove clamp and relieve tension against the

stowage bracket.

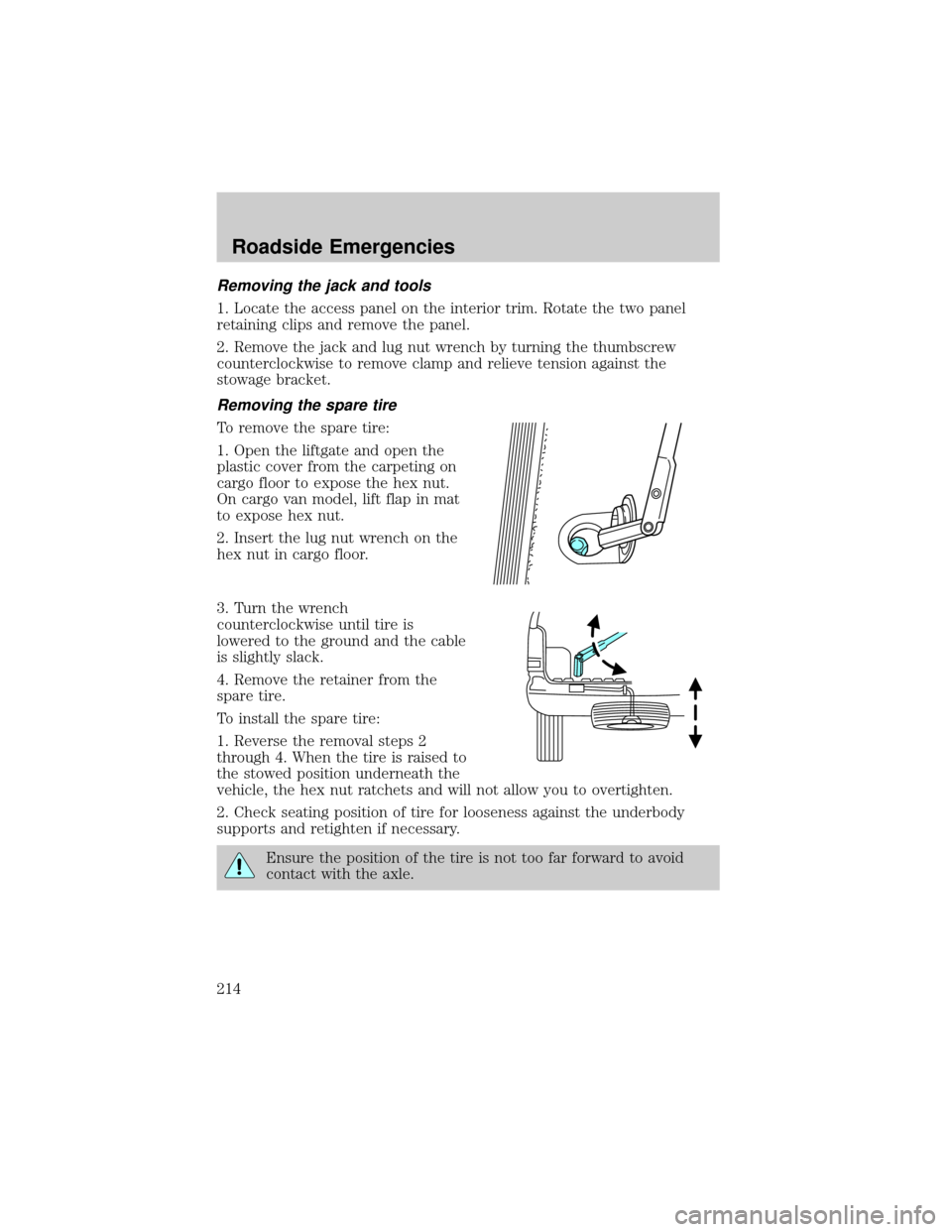

Removing the spare tire

To remove the spare tire:

1. Open the liftgate and open the

plastic cover from the carpeting on

cargo floor to expose the hex nut.

On cargo van model, lift flap in mat

to expose hex nut.

2. Insert the lug nut wrench on the

hex nut in cargo floor.

3. Turn the wrench

counterclockwise until tire is

lowered to the ground and the cable

is slightly slack.

4. Remove the retainer from the

spare tire.

To install the spare tire:

1. Reverse the removal steps 2

through 4. When the tire is raised to

the stowed position underneath the

vehicle, the hex nut ratchets and will not allow you to overtighten.

2. Check seating position of tire for looseness against the underbody

supports and retighten if necessary.

Ensure the position of the tire is not too far forward to avoid

contact with the axle.

Roadside Emergencies

214

Page 216 of 296

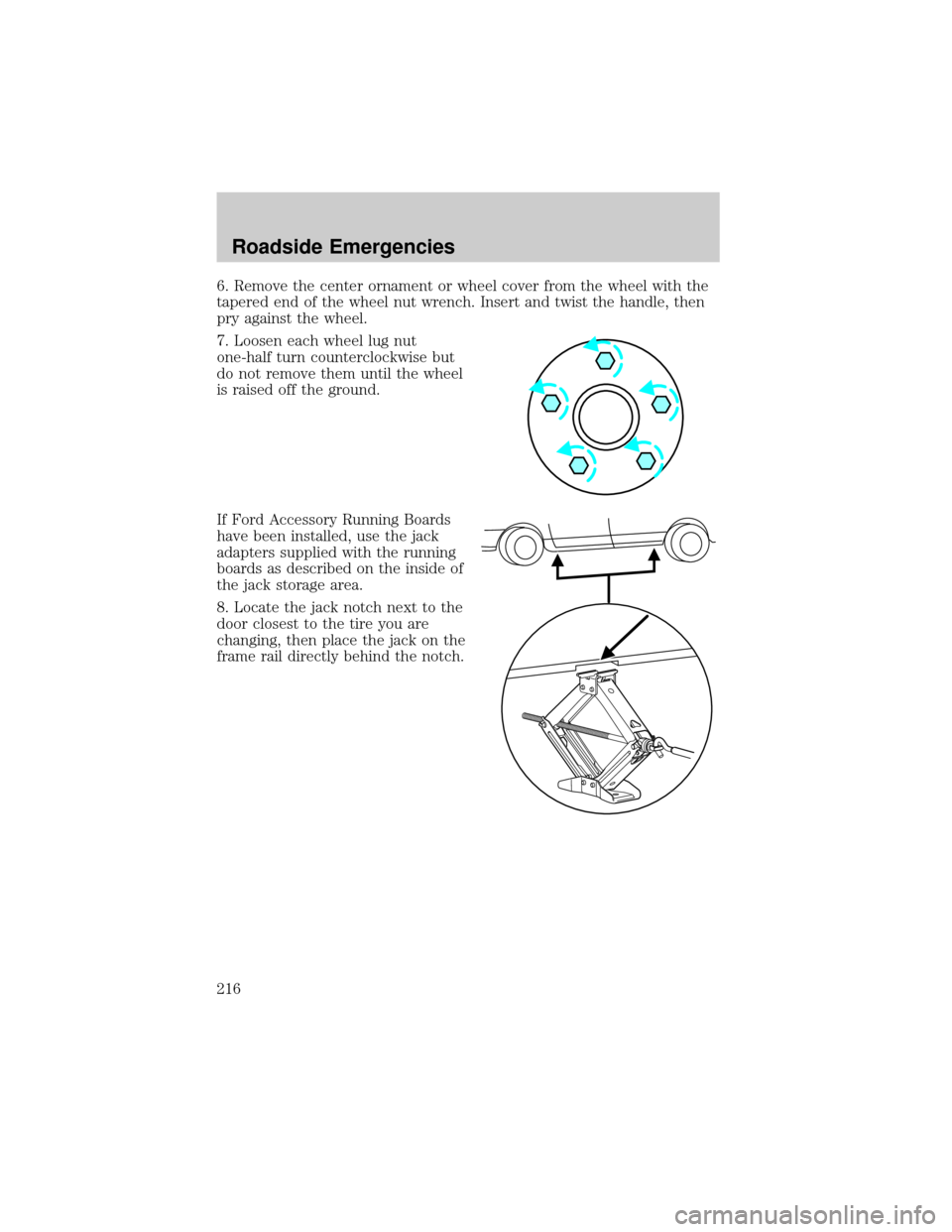

6. Remove the center ornament or wheel cover from the wheel with the

tapered end of the wheel nut wrench. Insert and twist the handle, then

pry against the wheel.

7. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

If Ford Accessory Running Boards

have been installed, use the jack

adapters supplied with the running

boards as described on the inside of

the jack storage area.

8. Locate the jack notch next to the

door closest to the tire you are

changing, then place the jack on the

frame rail directly behind the notch.

Roadside Emergencies

216

Page 217 of 296

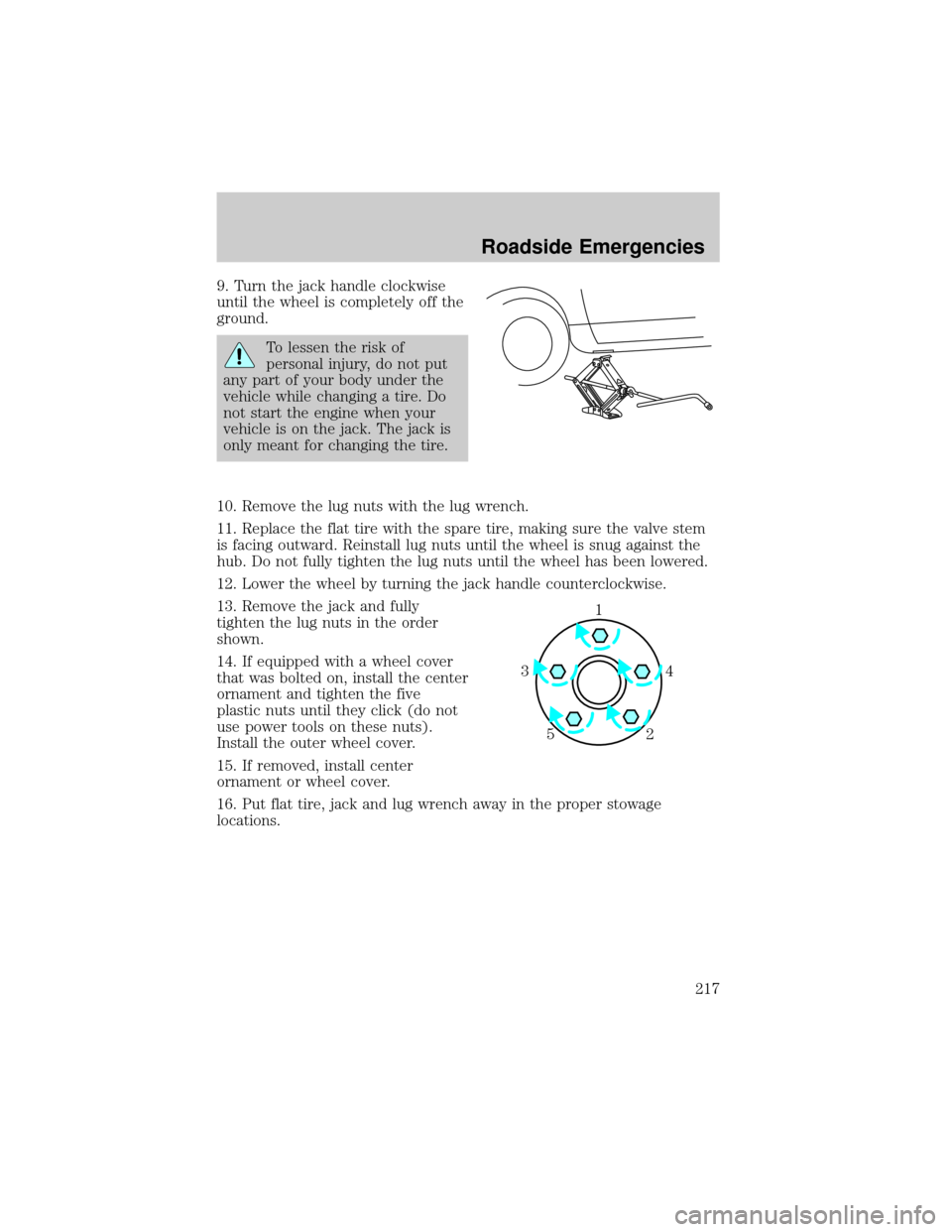

9. Turn the jack handle clockwise

until the wheel is completely off the

ground.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

10. Remove the lug nuts with the lug wrench.

11. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward. Reinstall lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

12. Lower the wheel by turning the jack handle counterclockwise.

13. Remove the jack and fully

tighten the lug nuts in the order

shown.

14. If equipped with a wheel cover

that was bolted on, install the center

ornament and tighten the five

plastic nuts until they click (do not

use power tools on these nuts).

Install the outer wheel cover.

15. If removed, install center

ornament or wheel cover.

16. Put flat tire, jack and lug wrench away in the proper stowage

locations.

1

4 3

2 5

Roadside Emergencies

217

Page 247 of 296

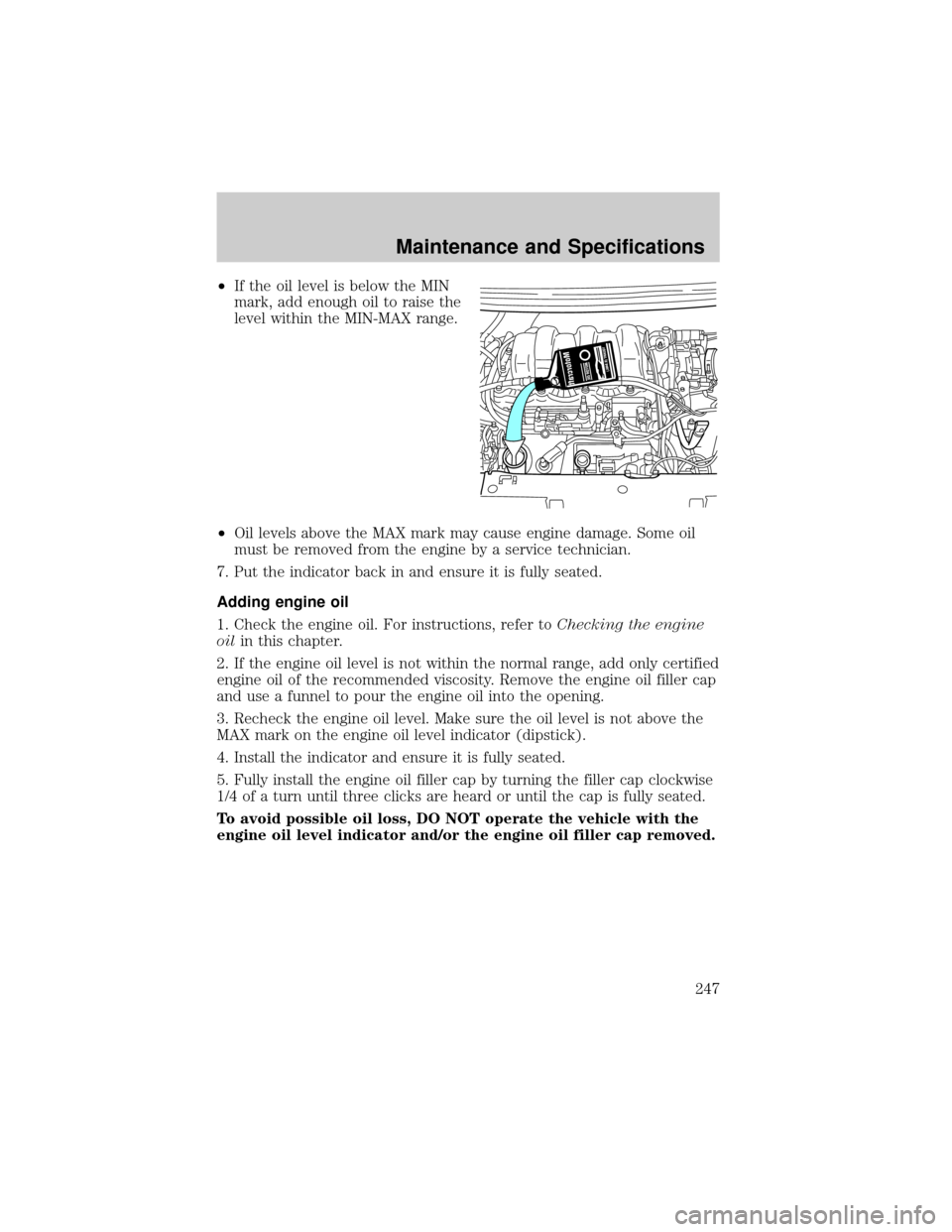

²If the oil level is below the MIN

mark, add enough oil to raise the

level within the MIN-MAX range.

²Oil levels above the MAX mark may cause engine damage. Some oil

must be removed from the engine by a service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until three clicks are heard or until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and Specifications

247

Page 251 of 296

Because your vehicle's engine is electronically controlled by a computer,

some control conditions are maintained by power from the battery. When

the battery is disconnected or a new battery is installed, the engine must

relearn its idle and fuel trim strategy for optimum driveability and

performance. To begin this process:

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P (Park), turn off all accessories and start the

engine.

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. With your foot on the brake pedal and with the A/C on, put the

vehicle in D (Drive) and allow the engine to idle for at least one minute.

7. Drive the vehicle to complete the relearning process.

²The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

²If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

If the battery has been discharged, disconnected or a new battery has

been installed, the power sliding door may need to be reset. Refer to

Power Sliding Door-Resetting the PSDin theControls and Features

chapter.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

LEAD

RETURN

RECYCLE

Maintenance and Specifications

251

Page 255 of 296

²Do not mix with recycled coolant unless from a Ford-approved

recycling process (seeUse of Recycled Engine Coolantsection).

For vehicles with overflow coolant systems with a non-pressurized cap

on the coolant recovery system, add coolant to the coolant recovery

reservoir when the engine is cool. Add the proper mixture of coolant and

water to the ªcold fullº level. For all other vehicles, which have a coolant

degas system with a pressurized cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator of a vehicle with an overflow

system, follow these steps to add engine coolant.

To avoid personal injury, make sure the engine is cool before

unscrewing the coolant pressure relief cap. The cooling system is

under pressure; steam and hot liquid can come out forcefully when the

cap is loosened slightly.

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (an opaque plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture (see

above), to within the ªcold fill rangeº or the ªcold fullº level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. (Cap must be tightly

installed to prevent coolant loss.)

After any coolant has been added, check the coolant concentration see

Checking Engine Coolant section). If the concentration is not 50/50

(protection to ±34É F/±36É C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Whenever coolant has been added, the coolant level in the coolant

reservoir should be checked the next few times you drive the vehicle. If

necessary, add enough 50/50 concentration of engine coolant and

distilled water to bring the liquid level to the proper level.

Maintenance and Specifications

255