lock FORD WINDSTAR 2003 2.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2003, Model line: WINDSTAR, Model: FORD WINDSTAR 2003 2.GPages: 240, PDF Size: 3.09 MB

Page 156 of 240

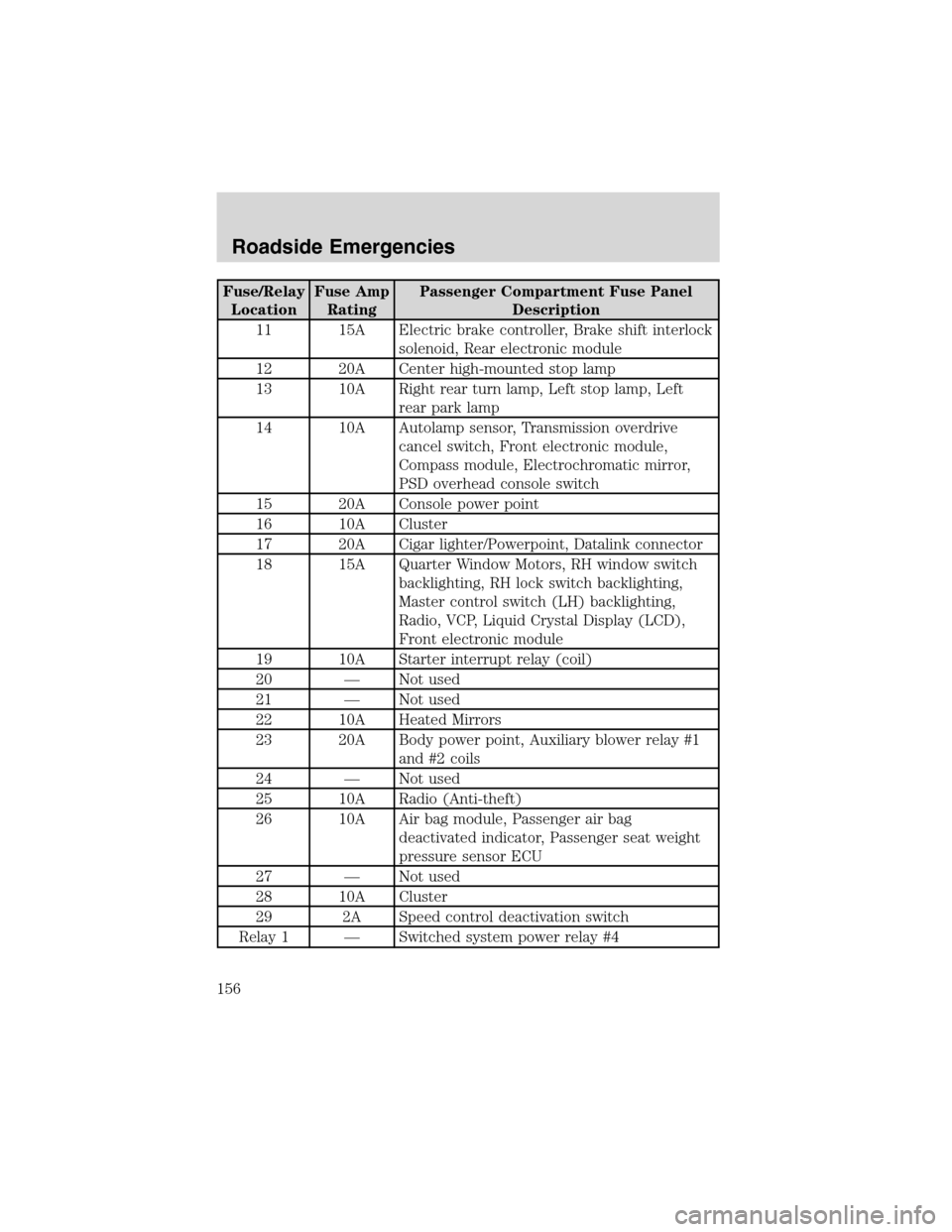

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

11 15A Electric brake controller, Brake shift interlock

solenoid, Rear electronic module

12 20A Center high-mounted stop lamp

13 10A Right rear turn lamp, Left stop lamp, Left

rear park lamp

14 10A Autolamp sensor, Transmission overdrive

cancel switch, Front electronic module,

Compass module, Electrochromatic mirror,

PSD overhead console switch

15 20A Console power point

16 10A Cluster

17 20A Cigar lighter/Powerpoint, Datalink connector

18 15A Quarter Window Motors, RH window switch

backlighting, RH lock switch backlighting,

Master control switch (LH) backlighting,

Radio, VCP, Liquid Crystal Display (LCD),

Front electronic module

19 10A Starter interrupt relay (coil)

20—Not used

21—Not used

22 10A Heated Mirrors

23 20A Body power point, Auxiliary blower relay #1

and #2 coils

24—Not used

25 10A Radio (Anti-theft)

26 10A Air bag module, Passenger air bag

deactivated indicator, Passenger seat weight

pressure sensor ECU

27—Not used

28 10A Cluster

29 2A Speed control deactivation switch

Relay 1—Switched system power relay #4

Roadside Emergencies

156

Page 158 of 240

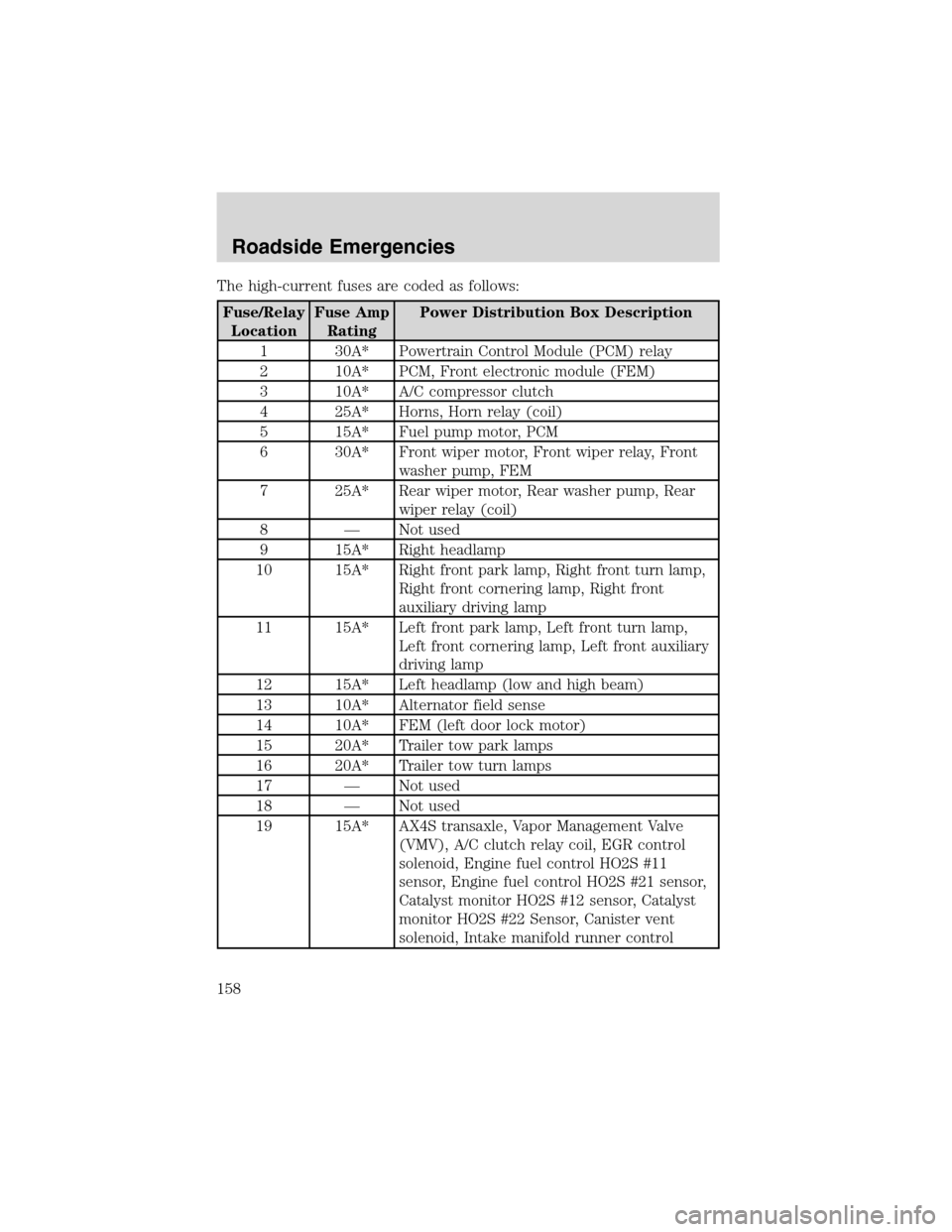

The high-current fuses are coded as follows:

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

1 30A* Powertrain Control Module (PCM) relay

2 10A* PCM, Front electronic module (FEM)

3 10A* A/C compressor clutch

4 25A* Horns, Horn relay (coil)

5 15A* Fuel pump motor, PCM

6 30A* Front wiper motor, Front wiper relay, Front

washer pump, FEM

7 25A* Rear wiper motor, Rear washer pump, Rear

wiper relay (coil)

8—Not used

9 15A* Right headlamp

10 15A* Right front park lamp, Right front turn lamp,

Right front cornering lamp, Right front

auxiliary driving lamp

11 15A* Left front park lamp, Left front turn lamp,

Left front cornering lamp, Left front auxiliary

driving lamp

12 15A* Left headlamp (low and high beam)

13 10A* Alternator field sense

14 10A* FEM (left door lock motor)

15 20A* Trailer tow park lamps

16 20A* Trailer tow turn lamps

17—Not used

18—Not used

19 15A* AX4S transaxle, Vapor Management Valve

(VMV), A/C clutch relay coil, EGR control

solenoid, Engine fuel control HO2S #11

sensor, Engine fuel control HO2S #21 sensor,

Catalyst monitor HO2S #12 sensor, Catalyst

monitor HO2S #22 Sensor, Canister vent

solenoid, Intake manifold runner control

Roadside Emergencies

158

Page 159 of 240

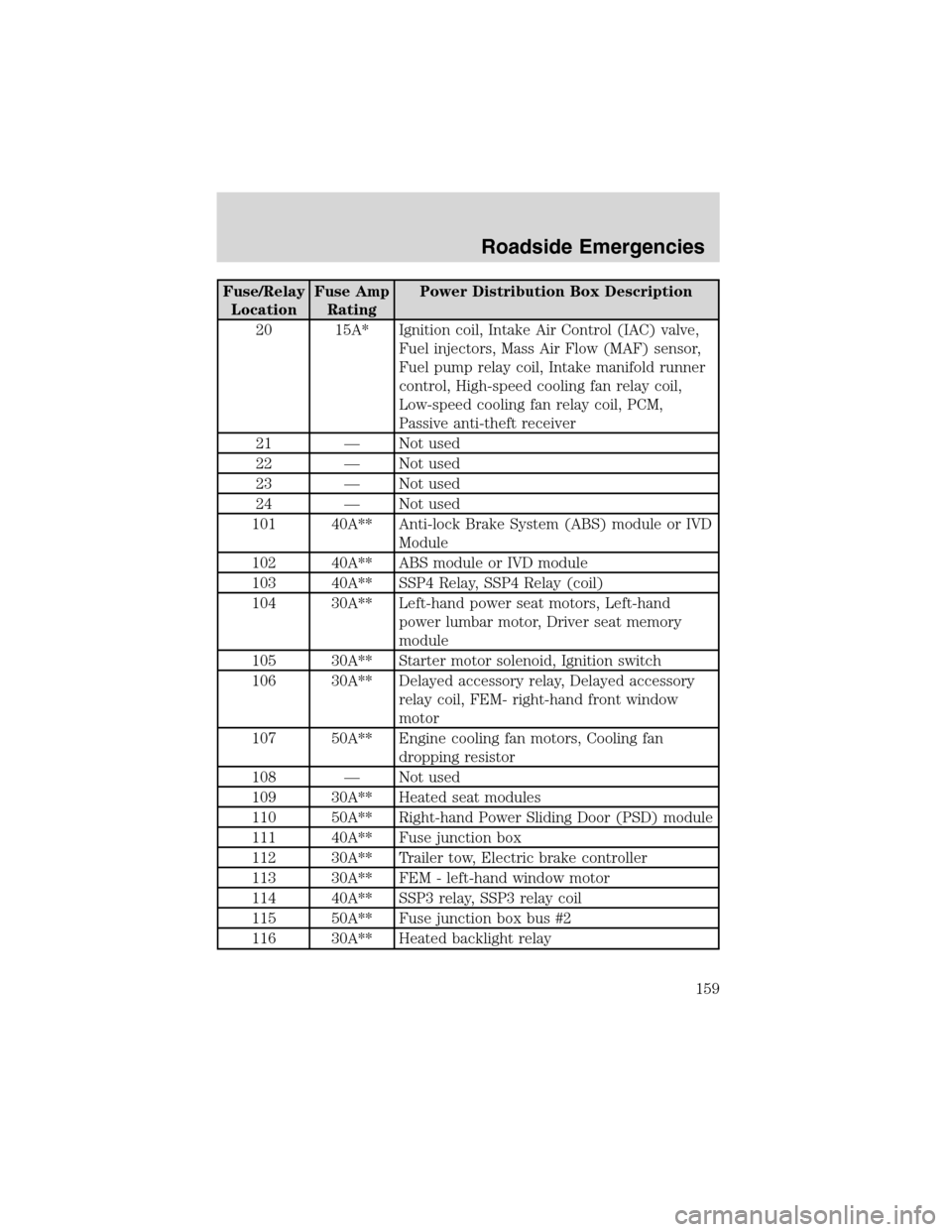

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

20 15A* Ignition coil, Intake Air Control (IAC) valve,

Fuel injectors, Mass Air Flow (MAF) sensor,

Fuel pump relay coil, Intake manifold runner

control, High-speed cooling fan relay coil,

Low-speed cooling fan relay coil, PCM,

Passive anti-theft receiver

21—Not used

22—Not used

23—Not used

24—Not used

101 40A** Anti-lock Brake System (ABS) module or IVD

Module

102 40A** ABS module or IVD module

103 40A** SSP4 Relay, SSP4 Relay (coil)

104 30A** Left-hand power seat motors, Left-hand

power lumbar motor, Driver seat memory

module

105 30A** Starter motor solenoid, Ignition switch

106 30A** Delayed accessory relay, Delayed accessory

relay coil, FEM- right-hand front window

motor

107 50A** Engine cooling fan motors, Cooling fan

dropping resistor

108—Not used

109 30A** Heated seat modules

110 50A** Right-hand Power Sliding Door (PSD) module

111 40A** Fuse junction box

112 30A** Trailer tow, Electric brake controller

113 30A** FEM - left-hand window motor

114 40A** SSP3 relay, SSP3 relay coil

115 50A** Fuse junction box bus #2

116 30A** Heated backlight relay

Roadside Emergencies

159

Page 162 of 240

Use of a temporary spare tire at any one wheel location can lead to

impairment of the following:

•handling, stability and braking performance

•comfort and noise

•ground clearance and parking at curbs

•Winter driving capability

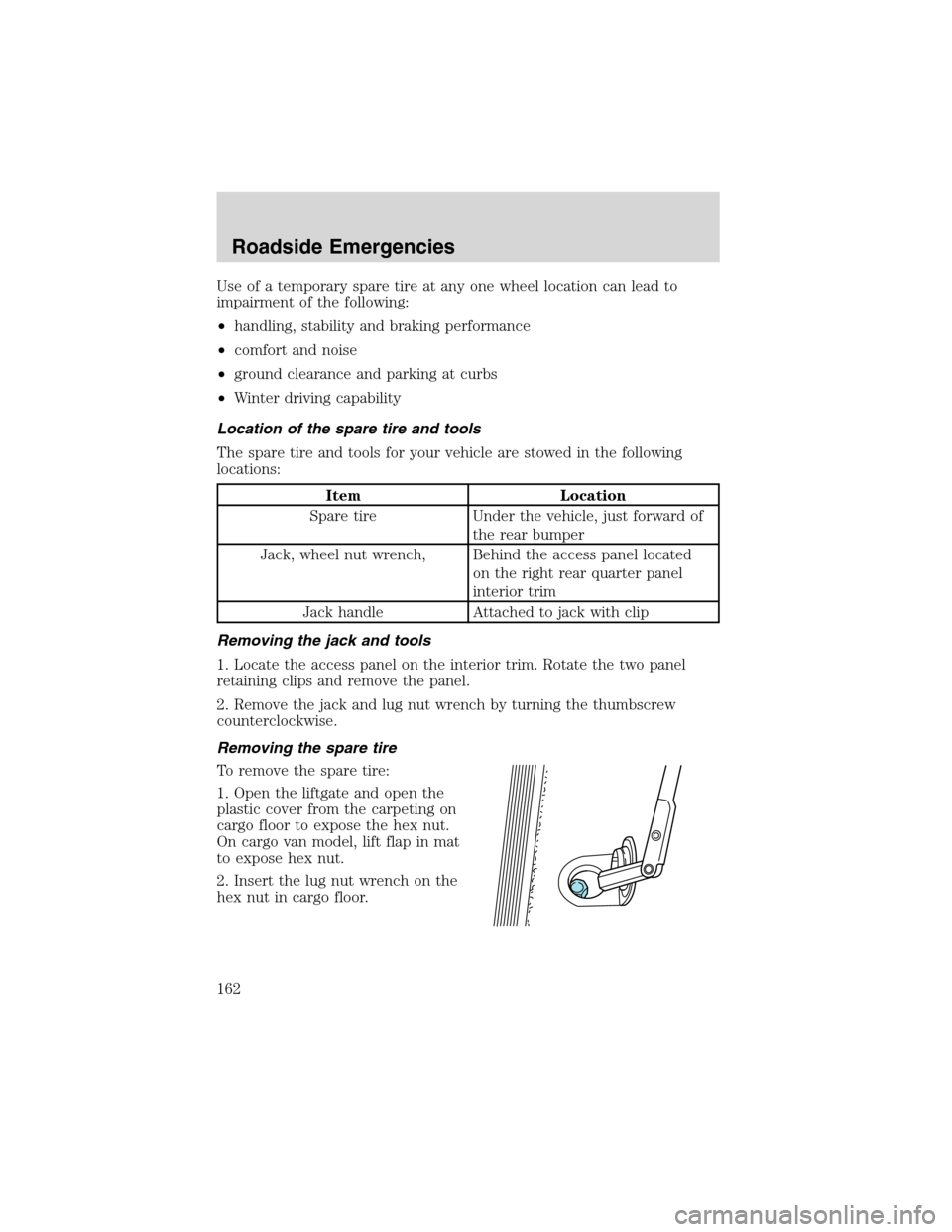

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Item Location

Spare tire Under the vehicle, just forward of

the rear bumper

Jack, wheel nut wrench, Behind the access panel located

on the right rear quarter panel

interior trim

Jack handle Attached to jack with clip

Removing the jack and tools

1. Locate the access panel on the interior trim. Rotate the two panel

retaining clips and remove the panel.

2. Remove the jack and lug nut wrench by turning the thumbscrew

counterclockwise.

Removing the spare tire

To remove the spare tire:

1. Open the liftgate and open the

plastic cover from the carpeting on

cargo floor to expose the hex nut.

On cargo van model, lift flap in mat

to expose hex nut.

2. Insert the lug nut wrench on the

hex nut in cargo floor.

Roadside Emergencies

162

Page 163 of 240

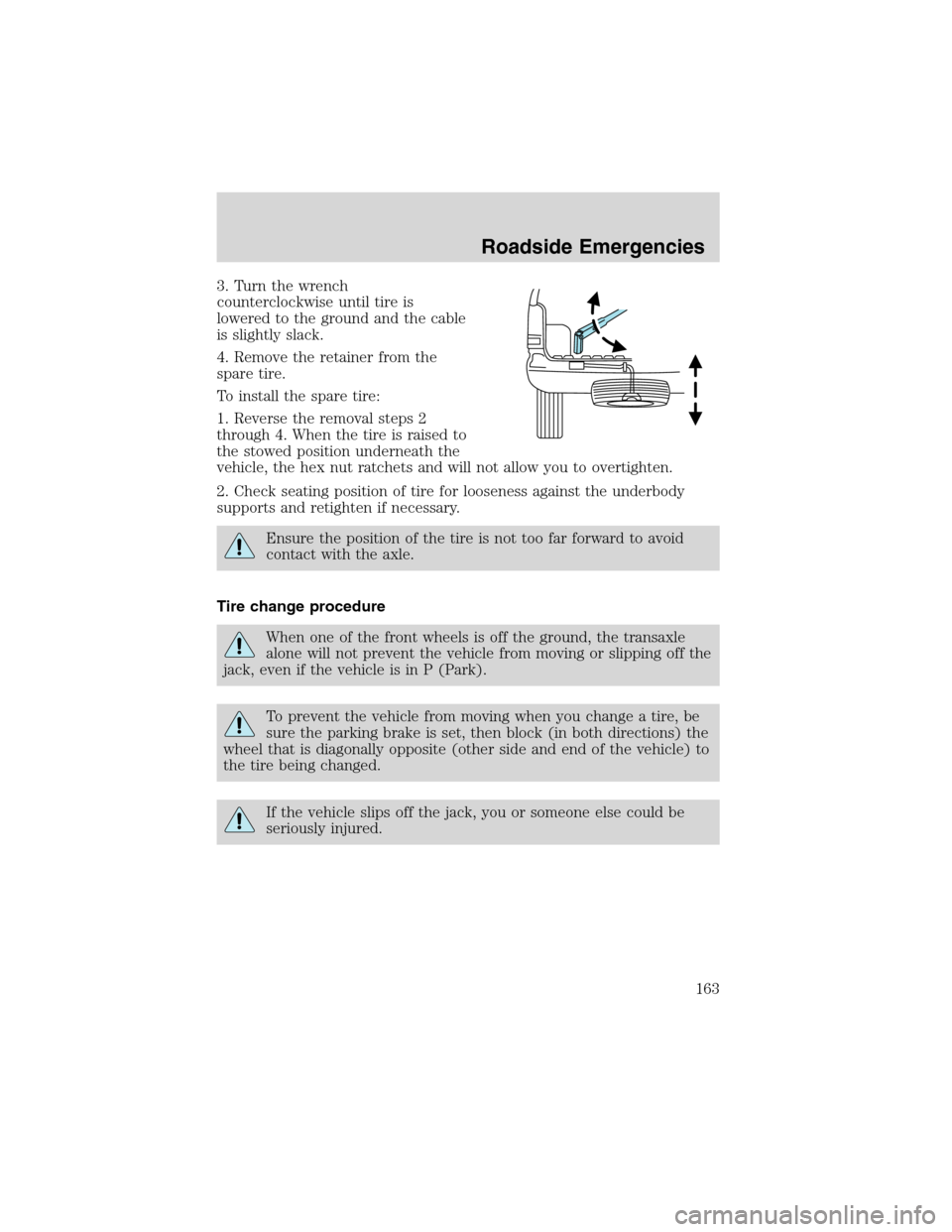

3. Turn the wrench

counterclockwise until tire is

lowered to the ground and the cable

is slightly slack.

4. Remove the retainer from the

spare tire.

To install the spare tire:

1. Reverse the removal steps 2

through 4. When the tire is raised to

the stowed position underneath the

vehicle, the hex nut ratchets and will not allow you to overtighten.

2. Check seating position of tire for looseness against the underbody

supports and retighten if necessary.

Ensure the position of the tire is not too far forward to avoid

contact with the axle.

Tire change procedure

When one of the front wheels is off the ground, the transaxle

alone will not prevent the vehicle from moving or slipping off the

jack, even if the vehicle is in P (Park).

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

Roadside Emergencies

163

Page 164 of 240

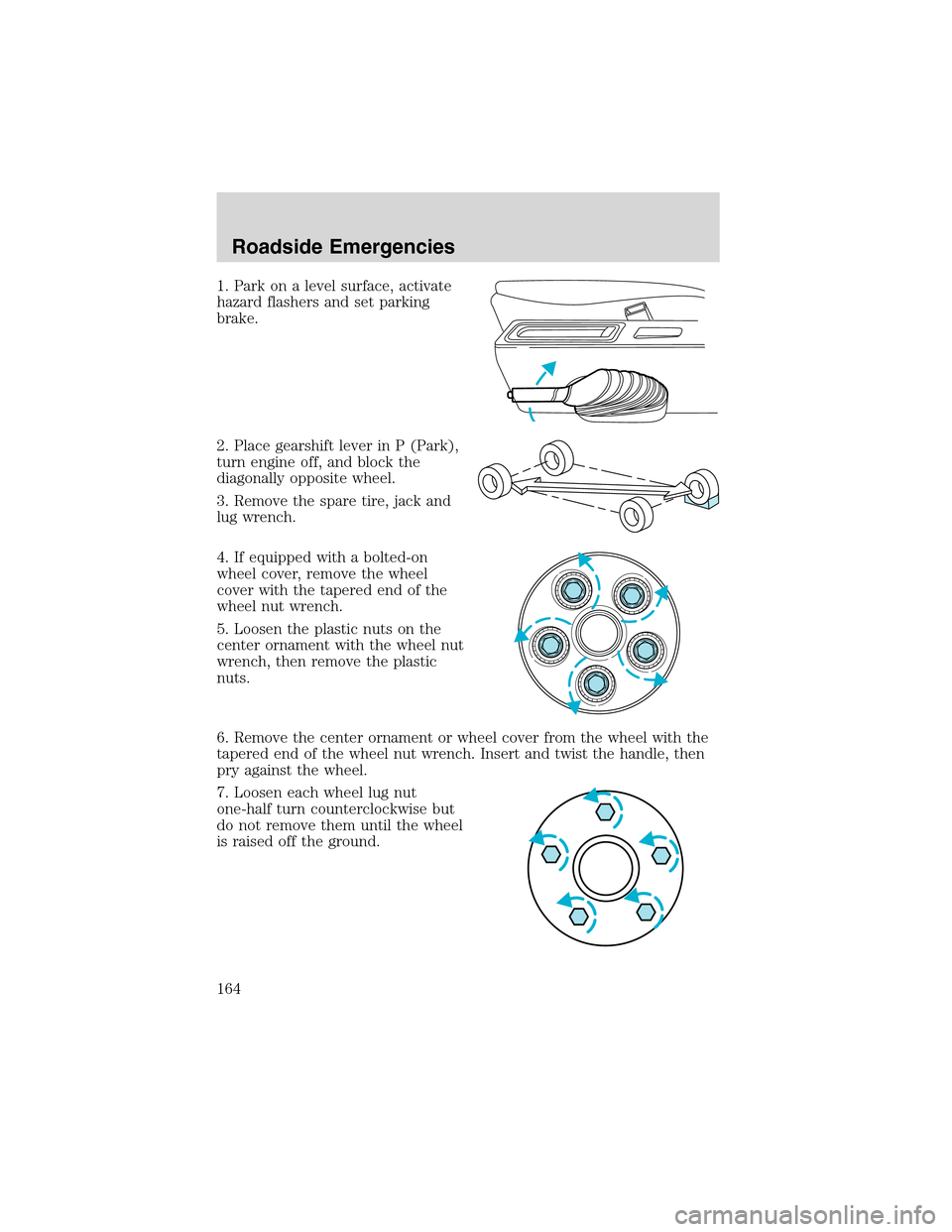

1. Park on a level surface, activate

hazard flashers and set parking

brake.

2. Place gearshift lever in P (Park),

turn engine off, and block the

diagonally opposite wheel.

3. Remove the spare tire, jack and

lug wrench.

4. If equipped with a bolted-on

wheel cover, remove the wheel

cover with the tapered end of the

wheel nut wrench.

5. Loosen the plastic nuts on the

center ornament with the wheel nut

wrench, then remove the plastic

nuts.

6. Remove the center ornament or wheel cover from the wheel with the

tapered end of the wheel nut wrench. Insert and twist the handle, then

pry against the wheel.

7. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

Roadside Emergencies

164

Page 165 of 240

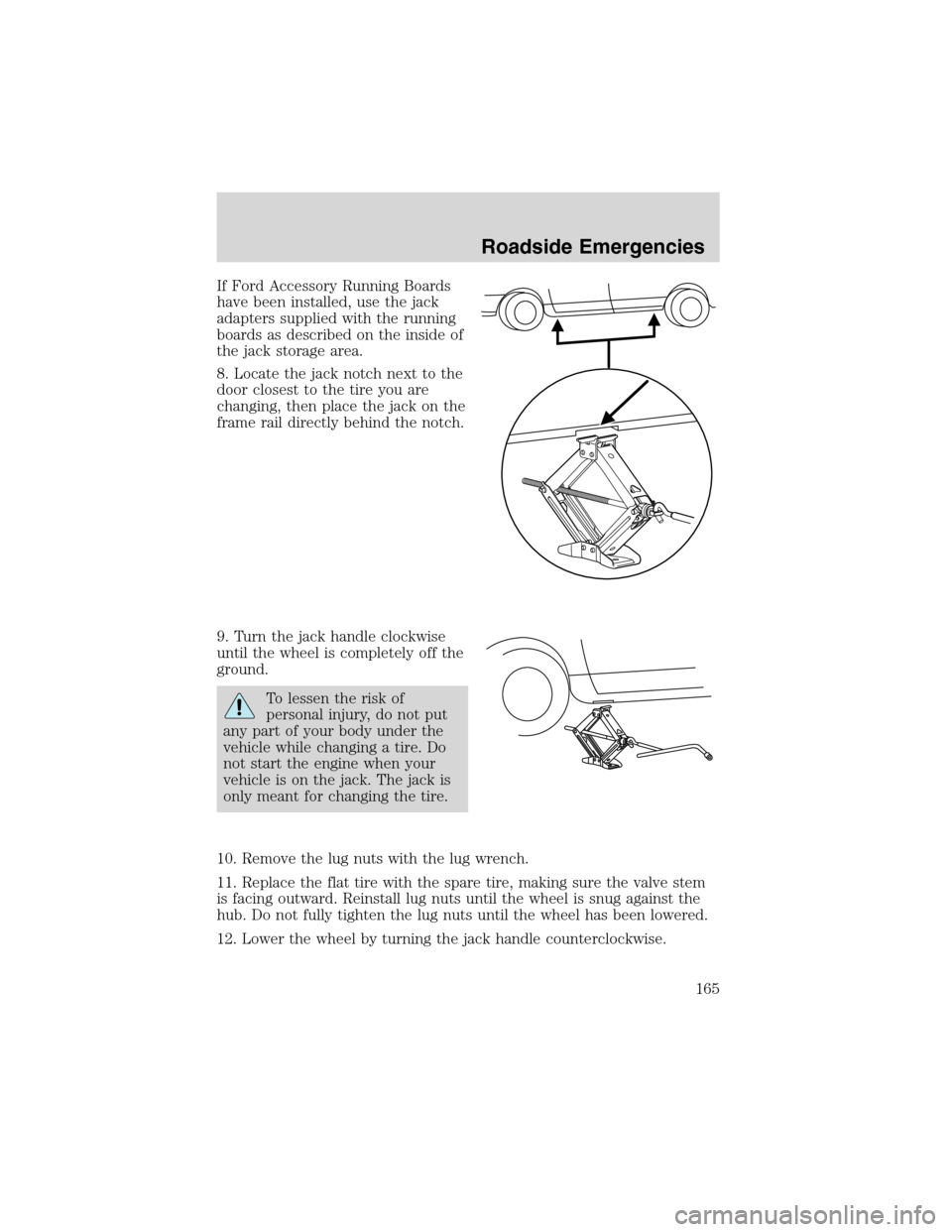

If Ford Accessory Running Boards

have been installed, use the jack

adapters supplied with the running

boards as described on the inside of

the jack storage area.

8. Locate the jack notch next to the

door closest to the tire you are

changing, then place the jack on the

frame rail directly behind the notch.

9. Turn the jack handle clockwise

until the wheel is completely off the

ground.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

10. Remove the lug nuts with the lug wrench.

11. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward. Reinstall lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

12. Lower the wheel by turning the jack handle counterclockwise.

Roadside Emergencies

165

Page 166 of 240

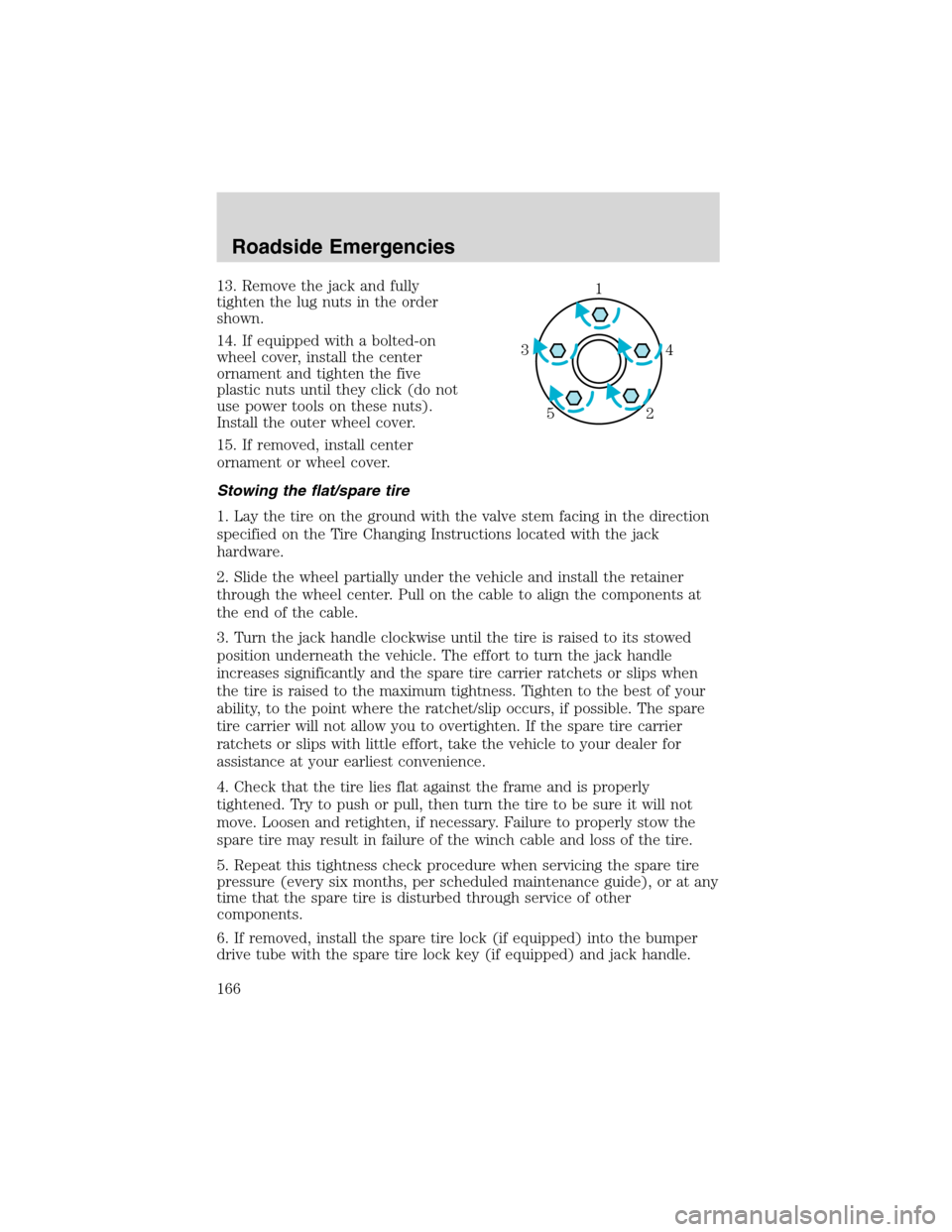

13. Remove the jack and fully

tighten the lug nuts in the order

shown.

14. If equipped with a bolted-on

wheel cover, install the center

ornament and tighten the five

plastic nuts until they click (do not

use power tools on these nuts).

Install the outer wheel cover.

15. If removed, install center

ornament or wheel cover.

Stowing the flat/spare tire

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your dealer for

assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance guide), or at any

time that the spare tire is disturbed through service of other

components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.1

4 3

2 5

Roadside Emergencies

166

Page 183 of 240

•Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

•Always read the instructions before using the products.

ALUMINUM WHEELS AND COVERS

Aluminum wheel rims or covers are coated with a clearcoat paint finish.

In order to maintain their shine:

•Clean weekly with Motorcraft Wheel and Tire Cleaner (ZC-37–A),

which is available from your dealer. Agitate the area with a sponge and

rinse thoroughly with a strong stream of water.

•Never apply any cleaning chemical to hot or warm wheel rims or

covers.

•Some automatic car washes may cause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear away the clearcoat finish over time.

•Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

•To remove tar and grease, use Ford Extra Strength Tar and Road Oil

Removal (B7A-19520–AA), available from your dealer.

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

Cleaning

183

Page 188 of 240

SERVICE RECOMMENDATIONS

To help you service your vehicle:

•We highlight do-it-yourself items in the engine compartment for easy

location.

•We provide a scheduled maintenance guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

the necessary parts and service. Check yourWarranty Guide/Owner

Information Guideto find out which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

•Do not work on a hot engine.

•Make sure that nothing gets caught in moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all open flames and other lit material away from the battery and

all fuel related parts.

Working with the engine off

1. Set the parking brake and shift to P (Park).

2. Turn off the engine and remove the key.

3. Block the wheels.

Working with the engine on

1. Set the parking brake and shift to P (Park).

2. Block the wheels.

Note:Do not start your engine with the air cleaner removed and do not

remove it while the engine is running.

Maintenance and Specifications

188