fuse GEELY MK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 229 of 416

Suspected Area

1. Wire between CD box and main unit

2. CD box

3. CD bag

4. CD PLAYER main unit

1. Wire between CD box and main unit

2. CD box

1. CD box

2. CD box installation Symptom

CD can not be taken out

Sound quality poor only when playing CD

(Volume faint)

CD sound jumpTester connection Condition Standard state

GND and vehicle earth Normal status ON

Tester connection Condition Standard state

+B and GND Normal status 10-14V

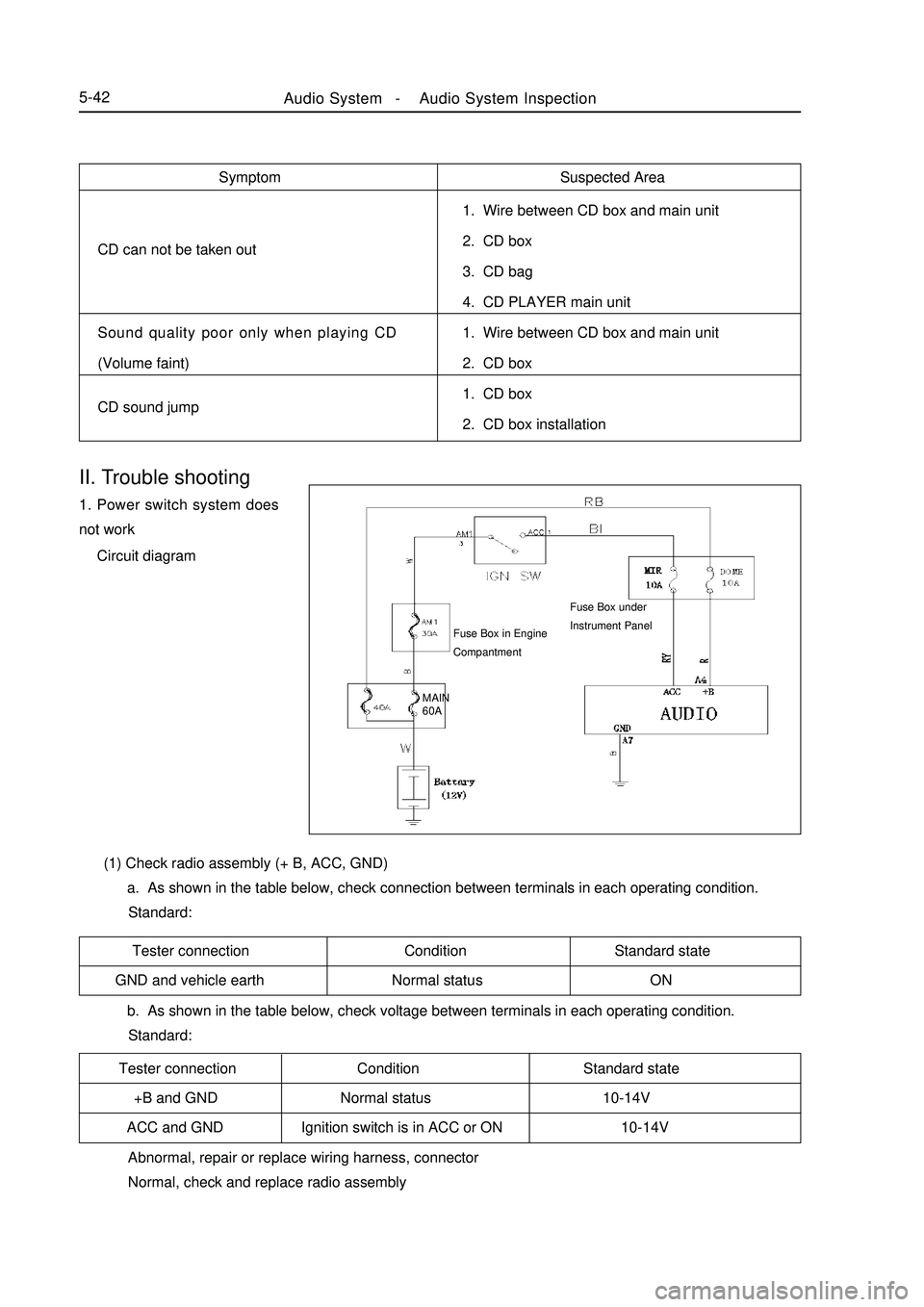

ACC and GND Ignition switch is in ACC or ON 10-14VII. Trouble shooting1. Power switch system does

not work

Circuit diagram

Abnormal, repair or replace wiring harness, connector

Normal, check and replace radio assembly (1) Check radio assembly (+ B, ACC, GND)

a. As shown in the table below, check connection between terminals in each operating condition.

Standard:

b. As shown in the table below, check voltage between terminals in each operating condition.

Standard:Fuse Box in Engine

CompantmentAudio System -Audio System Inspection5-42MAIN

60AFuse Box under

Instrument Panel

Page 260 of 416

5-73Precautions:1. Don't operate refrigerant in confined space or near open fire.

2. Always wear eyeglass.

3. Be careful don't let liquid refrigerant contact your eyes and skin,

if liquid refrigerant contacts your eye or skin.

(a) Please wash with fresh water.

Warning:

Don't knead your eyes or scrub your skin

(b) Apply soft petroleum ointment on your skin.

(c) See doctor or go to hospital immediately for specialized

treatment.

4. Don't heat container or put it near open fire.

5. Be careful not to fall off, object should not touch container.

6. If there is no sufficient refrigerant in refrigerating system, don't

operate the compressor.

If there is no sufficient refrigerant in the system, insufficient oil

lubrication might cause burning out of compressor. Be careful to

avoid occurrence of such things.

7. When compressor runs, don't turn on pressure gauge high-pressure

valve.

If high-pressure valve is turned on, refrigerant will flow in reverse

direction, and cause bursting of refrigerant tank, so only low

pressure valve may be turned on or off.

8. Be careful to avoid excess refrigerant

Excess refrigerant will result in poor refrigerating capacity, worse

fuel economical efficiency, engine overheat etc problems.Symptom

Blower does not workSymptom table Use the following table to find out the cause of fault, number indicates probable priority of problem, check each

part according to priority, replace components if required.

Suspected Area

1.Blower fuse

2.Centralized controller fuse

3. Blower relay

4. Integrated control panel assembly (blower switch)

5. Blower adjustment resistor

6. Blower

7. Wiring harness.Air Conditioning System -General Information

Page 261 of 416

Air Conditioning System -General Information5-74Symptom

No air temperature control

Compressor does not work

Insufficient refrigeration

No engine idle speed when air conditioning

switch is ON (switch on)

No air input control

No mode control

Condenser fan does not workSuspected Area

1. Engine coolant quantity

2. Air conditioning control mechanism assembly.

1. Refrigerant quantity

2. Compressor fuse

3. Centralized controller fuse

4. Magnetic clutch relay

5. Pressure switch

6. Magnetic clutch assembly

7. Air conditioning compressor assembly

8. Integrated control panel assembly (air conditioner switch)

9. Air conditioner thermistor

10. Engine ECU

11. Wiring harness

1. Refrigerant quantity

2. Refrigerant pressure

3. Driving belt

4. Air conditioner thermistor

5. Integrated control panel assembly (air conditioner switch)

6. Magnetic clutch assembly

7. Air conditioning compressor assembly

8. Condenser

9. Accumulator-drier

10. Expansion valve

11. Evaporator

12. Refrigerant line

13. Pressure switch

14. Air conditioner control mechanism assembly

15. Wiring harness

1. Idle speed control system

2. Wiring harness

3. ECM

1.Air conditioner control mechanism assembly

1.Air conditioner control mechanism assembly

1. MAIN fuse

2. Condenser fan fuse

3. Condenser fan relay

4. Condenser fan motor

5. Wiring harness

Page 294 of 416

![GEELY MK 2008 User Guide MK-60 ABS system -ABS System Check5-107Fault code is 01044 5

[Description]When ECU software code is inconsistent with hardware

bouncing pin connection, this fault code will appea GEELY MK 2008 User Guide MK-60 ABS system -ABS System Check5-107Fault code is 01044 5

[Description]When ECU software code is inconsistent with hardware

bouncing pin connection, this fault code will appea](/img/58/57162/w960_57162-293.png)

MK-60 ABS system -ABS System Check5-107Fault code is 01044 5

[Description]When ECU software code is inconsistent with hardware

bouncing pin connection, this fault code will appearPossible cause

Bouncing pin connection

error in ABS wiring harness

Abs ecu coding error

Fault code is 00668 6

[Description]When supply terminal 30 does not supply voltage or

voltage is too high, this fault code will appear.Possible cause

Abs system fuse is blown out

Storage battery voltage is too

low or too high

ABS wiring harness socket

connector is damaged

ABS ECU is damaged

Check ABS system 30 A safety wireReplace fuse

NormalAbnormal

Disconnect connection of ABS wiring harness and ECU,

turn ignition switch to ON position, measure voltage value

between the following terminals of ABS wiring harness

Terminal 1 and 47 9.5 _ 16.5V

Terminal 32 and 16 9.5 - 16.5V

Terminal 4 and 16 9.5 _16.5VReplace fuse Normal

Check ABS wiring harness socket connectorReplace fuse Abnormal

Retry. Abnormity reoccursYes

Check storage battery voltageNormal Abnormal

NoRefer to repair of

occasional fault

Key pointsUse fault diagnosis instrument to check whether ABS ECU software

code is correct

Correct value: 040907Recode

YesNoCheck whether ABS wiring harness bouncing pin joint is connected

Bouncing pin joint : ABS ECU Pin 38and Pin 14Repair wiring harness Abnormal

Page 296 of 416

Check ABS warning lamp

safety wire in fuse boxCheck

ABS warning lamp safety wire

in fuse boxReplace AbnormalRemove ECU joint, when igni-

tion switch is in ON, does warn-

ing lamp illuminate ?NoNormalCheck whether ABS warn-

ing lamp is burnt outYes

ReplaceCheck whether warning

lamp power supply circuit

and ground loop in wiring

harness is disconnectedAbnormalRepair wiring

harnessCheck warning lamp power

supply circuit and ground

loop socket connector in

wiring harnessAbnormalRepair socket

connectorDoes fault reoccurNoRepair wiring harnessYe s NormalNormal NoRefer to key point

for repair of occa-

sional faultII. Check list of fault without malfunction codeMK-60 ABS system -ABS System Check5-109When ignition switch is in ON position (engine stall), ABS warning

lamp does not illuminate 1

[Description ] ABS warning lamp does not illuminate, warning lamp power

supply circuit might be disconnected, bulb is burnt out or

warning lamp driving module is damaged.Possible cause

Safety wire is burnt out

ABS warning lamp bulb

is burnt out

Power circuit is discon-

nected

ABS warning lamp driv-

ing module is damaged

YesCheck whether the wire in ABS

wiring harness connecting ABS

warning lamp driving module

and ECU is shorted to ground

Page 300 of 416

Whether fault diagnosis instrument

may communicate with MK -60 ABS

ECU on other vehicleNoYesABS fault diagnosis instrument fails,

check again after repairCheck ABS power fuseAbnormalNormalReplaceWhether there is display on the screen

of fault diagnosis instrumentNoNormalCheck power cord, earth wire

and diagnosis wire in fault

diagnosis interface and their

connectionRepair fault di-

agnosis inter-

face or wiring

harnessNoRemove ABS ECU connector, check

whether ECU binding post 2 in ABS

wiring harness is connected with pin

7 in diagnostic interfaceNoYesCheck diagnosis interface or wire harnessReplace ABS ECUMK-60 ABS system -ABS System Check5-113No diagnostic code output (cannot communicate with fault diagnosis

instrument) 6

[Description] When it cannot communicate with fault diagnosis instrument,

ABS ECU power supply circuit or diagnosis wire circuit might

be disconnectedPossible cause

Safety wire is burnt out

Diagnosis wire is broken

or joint gets loose

ABS ECU is damaged

Fault diagnosis instru-

ment has problem

Page 334 of 416

Chapter 3 Front Seat BeltSeat Belt Reminder SystemI. Component View

II. Fault diagnosis

Possible causes

1. GAUGE fuse;

2. Instrument cluster;

3. Left front buckle assembly

4. Wiring harnessSymptom

Driver's seat belt lamp is not onIII. Alarm system inspection

1. To inspect the left front buckle assembly

Check the conductivity of left front buckle assemblyTerminal Number Seat Belt Required

1<=>2Insert OFF

1<=>2Release ON If you find that the result of the inspection is not the same as

required, you can replace the left front buckle assembly.DriverÕs seat belt reminder lamp

Left front buckleInterior & Exterior Trim and Accessory

-Front Seat Belt6-5

Page 369 of 416

Chapter 17 Moonroof Assembly (Optional)Component ViewII. Inspection of sunroof Troubleshooting formSunshade sub-assy Sunroof motorBracket sub-assy.Sunroof frameSunroof glass bracketSunroof glass sealSunroof glassInterior & Exterior Trim and Accessory -Moonroof Assembly (Optional)6-40Possible causes

1. Power relay

2. Instrument fuse

3. Sunroof switch

4. Sunroof lock switch

5. Sunroof motor

6. Sunroof guide rail

7. Wire harness

1. Sunroof lock switch

2. Sunroof motor

3. Sunroof guide rail

4. Wire harnessSymptom

Sliding sunroof system doesn't work.

Sling sunroof system gets stuck (e.g.

foreign matter like gravel caught in motor)