Chapter 9 GEELY MK 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 94 of 416

Chapter 4 Propeller Shaft/DriveshaftSection 1 Propeller Shaft, Driveshaft and TransaxleI. Symptom Table The table below can help find the causes of the problem. The numbers indicate the priority of the causes of the

problem. Replace the parts if necessary.

Inspection Area

1. Wheel

2. Front wheel alignment

3. Rear wheel alignment

4. Front wheel hub bearing (worn)

5. Rear wheel hub bearing (worn)

6. Front shock absorber with coil spring

7. Steering linkage (loose or damaged)

8. Stabilizer bar

1. Wheel balance

2. Wheel hub bearing (worn)

3. Front shock absorber with coil spring

1. Outer joint (worn)

2. Inner joint (worn) Symptom

Deviation

Front wheel vibration

Noise (drive shaft)ReferenceII. On-board Inspection1. Check front wheel hub bearing

(1) Remove front wheel.

(2) Remove front brake caliper assembly.

(3) Remove front brake disc.

(4) Check the bearing backlash.

Set a dial indicator near the front wheel hub center to check

the backlash.

Maximum: 0.05mm

If the backlash exceeds the maximum value, replace the front

wheel hub bearing.

(5) Check the front wheel hub deviation

Using a dial indicator, check the deviation of the surface of the

wheel hub outside the hub bolt.

Maximum: 0.07mm

If the backlash exceeds the maximum value, replace the front

wheel hub subassembly.Propeller Shaft/DriveshaftPropeller Shaft, Driveshaft and Transaxle4-17 -

Page 115 of 416

Chapter 5 Front Suspension SystemSection 1 Front Suspension SystemDescription on front suspension structureThis model uses strut swing arm independent suspension with stabilizer bar.

The shock absorber upper end is flexibly connected to the body through the shock absorber mounting seat, the

lower end is rigidly connected to the steering knuckle. The coil spring encloses the shock absorber (coil spring

geometrical axial line does not coincide with that of the shock absorber piston rod), and is supported between the

upper and lower spring seats.

Both ends of the stabilizer bar are connected to the shock absorber through the strut bar ball pin and the intermediate

part is supported on the lower front body by the rubber bushing and support frame.

The front cushion sleeves the shock absorber piston rod head to restrict the wheel jump limit position and plays

the role of buffer.

The thrust ball bearing, installed between the spring upper seat and the shock absorber mount, is used for the

relative rotation upon steering of the shock absorber rigidly connected to the steering knuckle to the shock absorber

mount flexibly connected to the body.

"L" type lower swing arm is secured to the lower engine compartment with the press plate through elastic rubber

bushing and hinge, and its outer end is connected to the steering knuckle through the ball stud pin which is attached

to the lower swing arm by 3 high intension bolts. The ball stud pin can be removed and replaced when it is worn.

The ball seat material is saturated polyester containing oil, featured in comparatively high intensity and wearability

and good self-lubrication performance. Proper amount of grease has been added during the assembly and there is

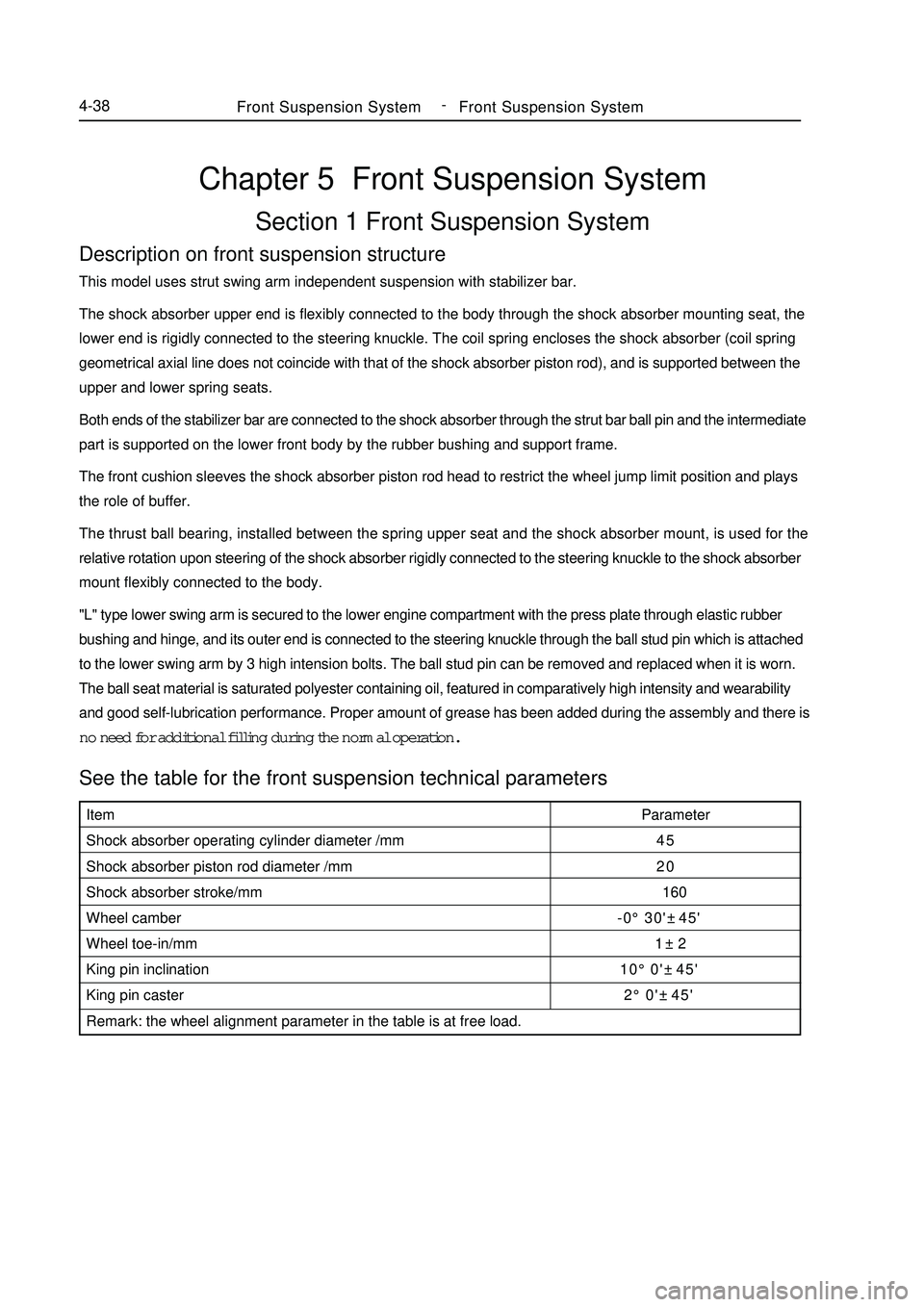

no need for additional filling during the normal operation.See the table for the front suspension technical parametersFront Suspension SystemFront Suspension System4-38Item

Shock absorber operating cylinder diameter /mm

Shock absorber piston rod diameter /mm

Shock absorber stroke/mm

Wheel camber

Wheel toe-in/mm

King pin inclination

King pin caster

Remark: the wheel alignment parameter in the table is at free load.Parameter

45

20

160

-0°30'±45'

1±2

10°0'±45'

2°0'±45' -

Page 131 of 416

Component ViewUpper washer

Left rear

helical spring

Lower washer Rear shock absorber assembly Right rear helical spring

Left rear helical spring

Lower washer829.09849Chapter 6 Rear Suspension SystemSection 1 Rear Suspension SystemLoad-sensing valve

bracketRear supension crossmemberRear Suspension System-Rear Suspension System4-54specified torqueN.

m :With ABS

Side slip control sensor wire

Washer

Clip Brake hose

Brake hoseNon-reusable parts

Page 144 of 416

Chapter 8 Power Steering SystemSection 1 Power Steering System3. Precaution: (1) Precaution for steering system

Make sure of the correct replacement of parts, incorrect replacement might affect the performance of the

steering system and lead to driving accidents.

(2) Precaution for SRS System

This vehicle is equipped with SRS (Supplemental Restraint System), driver side air bag and front passenger

side air bag.

Failure to carry out service operations in the correct sequence could cause the unexpected deployment of

the air bag during servicing, possibly leading to a serious accident.1. Power Steering System Description Power Steering System consists of the steering wheel, steering transmit device, power steering fixed device

and steering pipelines. The steering gear is rack and pinion type.2. Major parameters for steering system:Power Steering System-Power Steering System4-67Item

Steering Wheel total revolutions

Maximum Front

Wheel Turn Angle

Minimum Turning DiameterParameter

3.58±0.1

37.2°±2°/ 32°±2°

37.2°±2°/ 32°±2°

10.4

mInner

OuterSuspected Area

1. Tire (improperly inflated)

2. Power steering fluid (insufficient)

3. Front wheel alignment (incorrect)

4. Steering knuckle (worn)

5. Swing arm ball stud pin joint (worn)

6. Steering column (bent or binding)

7. Power steering pump assembly

8. Power steering gear assembly

1. Tire (improperly inflated)

2. Front wheel alignment (incorrect)

3. Steering column (bent or binding)

4. Power steering gear assemblySymptom

Heavy steering

Poor return4. Symptom Table The table below is helpful to find the cause of the problem. The numbers indicate the priority of the likely cause

of the problem. Check each part in order. Repair or replace these parts or assemblies if necessary.

Page 156 of 416

Brake System -Brake System4-79Chapter 9 Brake SystemSection 1 Brake SystemI. Precaution 1. It's very important to keep the parts and area clean when repairing the brake system.

2. Care must be taken to replace each part properly as it could affect the performance of the brake system and

result in a driving hazard.

3. Do not let brake fluid remain on a painted surface when repairing any parts. Wash it off immediately.

4. If any work is done on the brake system or air in the brake pipelines is suspected, bleed the system of air.

5. Check the brake system for leakage after repairing the brake system.

6. Use specified brake fluid. Do not mix with other brand of brake fluid.II. Symptom table Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, replace these parts.Symptom

Low brake pedal or recoil

Brake StagnationSuspected Area

1 Brake system (fluid leaks)

2 Brake system (air in)

3 Piston Cup in Sub-pump (worn or damaged)

4 Rear brake shoe clearance (out of adjustment)

5 Master cylinder (faulty)

6 Booster push rod (out of adjustment)

7 Brake shoe or lining (oily)

8 Disc/Drum scratched

1. Brake pedal free stroke is too small

2. Parking brake lever stroke (out of adjustment)

3. Parking brake cable (sticking)

4. Rear brake shoe clearance (out of adjustment)

5. Brake pad or lining (cracked or distorted)

6. Wheel cylinder piston (stuck or frozen)

7. Return spring (faulty)

8. Vacuum booster (faulty)

9. Brake master cylinder (faulty)

Page 188 of 416

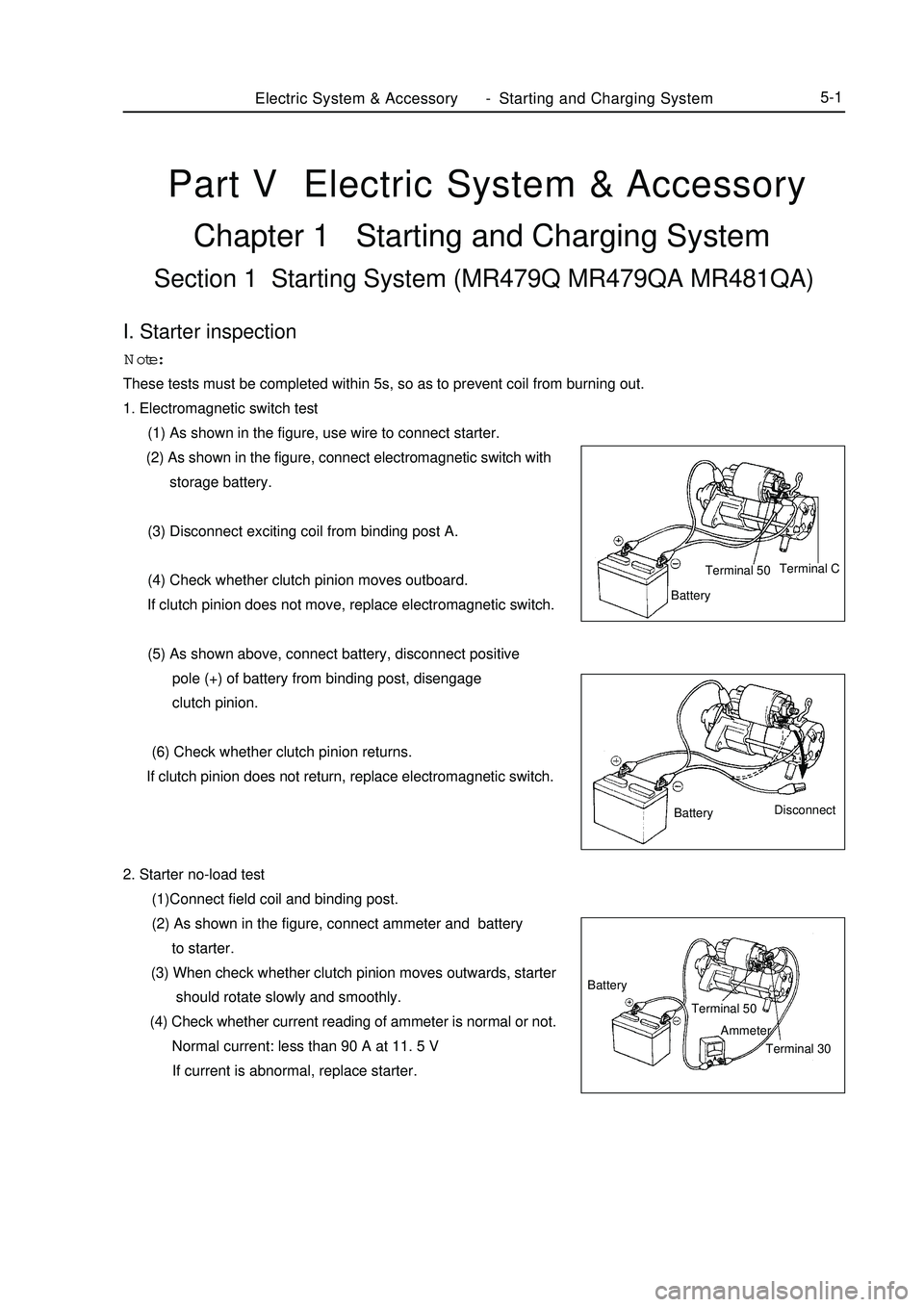

Part V Electric System & AccessoryChapter 1 Starting and Charging SystemSection 1 Starting System (MR479Q MR479QA MR481QA)I. Starter inspectionNote:

These tests must be completed within 5s, so as to prevent coil from burning out.

1. Electromagnetic switch testElectric System & Accessory-Starting and Charging System5-1 (1) As shown in the figure, use wire to connect starter.

(2) As shown in the figure, connect electromagnetic switch with

storage battery.

(3) Disconnect exciting coil from binding post A.

(4) Check whether clutch pinion moves outboard.

If clutch pinion does not move, replace electromagnetic switch.

(5) As shown above, connect battery, disconnect positive

pole (+) of battery from binding post, disengage

clutch pinion.

(6) Check whether clutch pinion returns.

If clutch pinion does not return, replace electromagnetic switch.

2. Starter no-load test

(1)Connect field coil and binding post.

(2) As shown in the figure, connect ammeter and battery

to starter.

(3) When check whether clutch pinion moves outwards, starter

should rotate slowly and smoothly.

(4) Check whether current reading of ammeter is normal or not.

Normal current: less than 90 A at 11. 5 V

If current is abnormal, replace starter.Ammeter Battery

Terminal 50

Terminal 30Disconnect

BatteryBatteryTerminal C

Terminal 50

Page 194 of 416

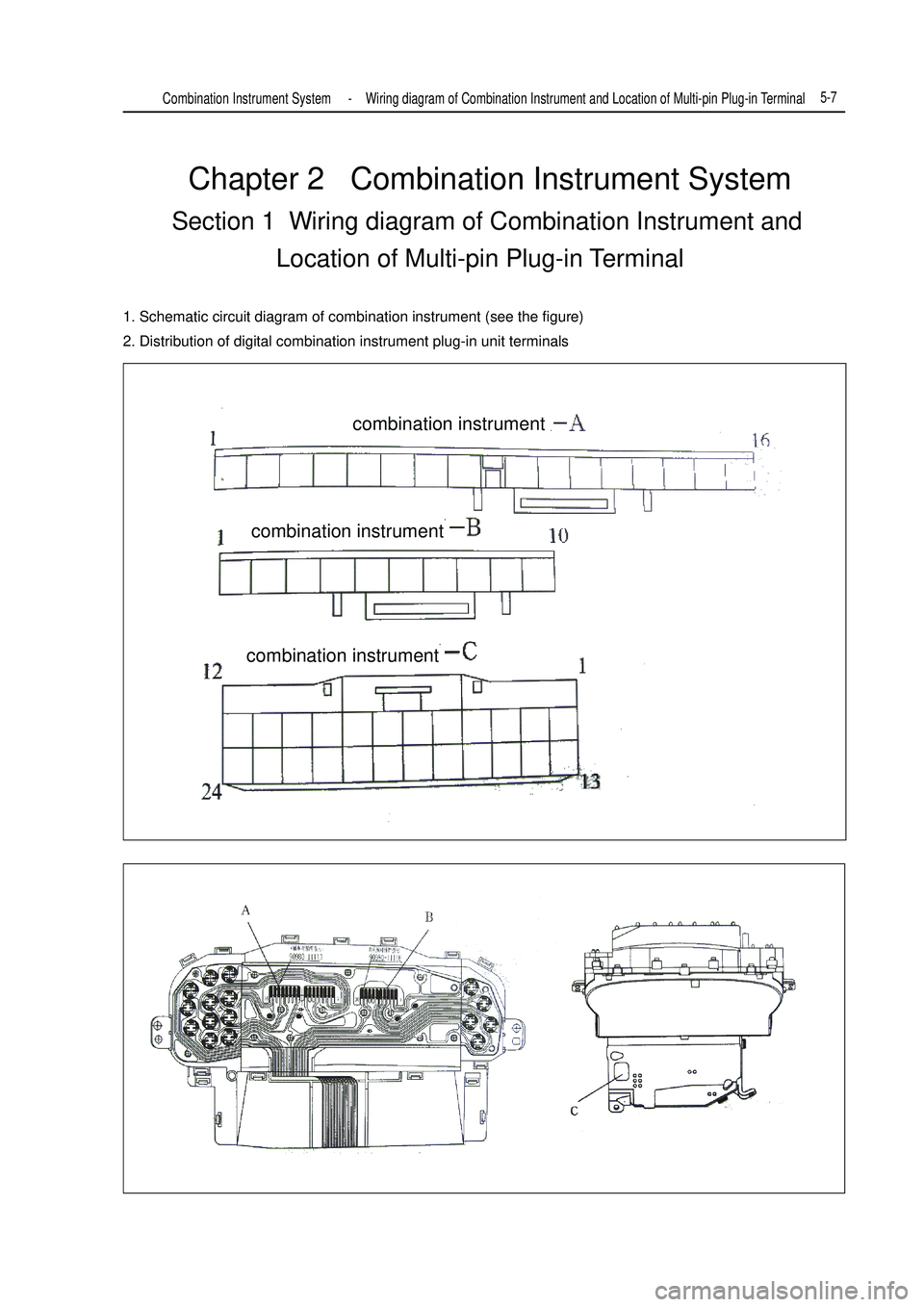

Chapter 2 Combination Instrument SystemSection 1 Wiring diagram of Combination Instrument and

Location of Multi-pin Plug-in Terminal1. Schematic circuit diagram of combination instrument (see the figure)

2. Distribution of digital combination instrument plug-in unit terminalsCombination Instrument System -Wiring diagram of Combination Instrument and Location of Multi-pin Plug-in Terminal5-7combination instrument

combination instrument

combination instrument

Page 208 of 416

Chapter 3 Wiper and Washer SystemSection 1 Wiper and Washer System Inspection5-21Remark:

The table below can help you find the causes of malfunction. These figures show the most possible

malfunctions in order of priority. Inspect each part in the order given. If necessary, repair or replace these parts.

Symptom

Front wiper does not work.

Front wiper in intermittent shift does not work.

Front washer motor does not work

When the washer switch is placed ON, front

wiper does not work

Washer fluid dose not jet out

1. When the washer switch places on OFF, wiper

blade can not return, or stay in a wrong place.

2. The wiper blade scratches the bodySuspected Area

1. Wiper fuse

2. Wiper switch assembly

3. Harness

1. Wiper switch assembly

2. Wiper motor assembly

3. Harness

4. Central controller

1. Wiper fuse

2. Wiper switch assembly

3. Wiper motor assembly

4. Harness

1. Wiper switch assembly

2. Wiper motor assembly

3. Harness

4. Central controller

1. Washer hose and nozzle

1.Wiper motor assembly (The position of wiper arm)II. Trouble shooting1. Check work of washer pump

(1) Install washer pump on tank system, pour cleaning fluid into

the tank.

(2) Disconnect connector of washer pump.

(3) As shown in the figure below, connect No. 1 terminal of

washer pump with positive pole (+) of storage battery; con

nect No. 2 terminal with negative pole (-) of storage battery.

Check whether cleaning fluid flows from tank.

(4) If there is no outflow, replace washer pump.Wiper and Washer System -Wiper and Washer System Inspection

Page 213 of 416

Chapter 4 Light SystemSection 1 Light System IntroductionI. Composition Light system comprises external illumination and signal system and internal illumination system.

The function of the external illumination and signal system is to illuminate the road ahead and send signals

to other vehicles.

The internal illumination system provides internal illumination for driver and passengers.II. Precaution for service1. Precaution when repairing electrical equipments

Disconnect the battery ground cable.

2. Precaution when replacing a headlamp bulb

(1) Before replacing a halogen bulb, turn the headlamp OFF to make it cool.

(2) When installing a new halogen bulb, do not touch the glass part of the bulb with bare hands.

(3) If there is oil stain on the surface of halogen bulb (headlamp and front fog lamp) when the lamps are

turned ON, its service life will be shortened.

(4) Halogen bulbs (headlamp and front fog lamp) have pressurized gas inside and require special handling.

They can explode if dropped to ground. The glass fragments will splash up.

(5) When replacing, make sure to use the bulbs with the same power, same model.

(6) After the bulb is installed, make the lamp holder tight.III. Bulb specificationsRemark: All bulbs are made by Philips Corp..Light System-

Light System Introduction5-26Name Specifications

Headlamp (High beam and Low beam) H1 12V 55W

Turn signal lamp PY21W 12V 21W

Position lamp W5W 12V 5W

Front fog lamp H3 12V 55W

Rear combination lamp (Turn signal lamp) PY21W 12V 21W

Rear combination lamp (Brake / Position lamp) P21/5W 12V 21/5W

Rear combination lamp (Rear fog lamp) P21W 12V 21W

Rear combination lamp (Back-up lamp) P21W 12V 21W

Interior lamp (dome lamp) R5W 12V 5W

Rear row reading lamp C5W 12V 5W

Side turn signal lamp W5W 12V 5W

High mounted stop lamp (incl. rear trunk lamp) W5W 12V 5W

License plate lamp W5W 12V 5W

Door courtesy lamp W5W 12V 5W

Page 225 of 416

Wave band LF MF HF VHF

Radio wave AM FM

Modulation Amplitude modulation Frequency modulationFrequency 30KHZ 300KHZ 3MHZ 30MHZ 300MHZ

2. Area coverage

Scope of AM and FM broadcasting coverage area differs greatly.

Sometimes although AM broadcast may be received clearly, FM

binaural broadcasting cannot be received. Not only listening zone of

FM binaural broadcasting is small, but also static noise or other

cacophony (noise) tends to occur.

3. Receiving problem

Notes:

Besides static noise problem, there is also interference, multiplex

and attenuation. These problems are not caused by electric cacophony,

but the problem of radio wave itself.

(1) Interference

Besides static noise problem, AM broadcast tends to receive

other types of noise, especially at night. This is because ionosphere

reflects AM radio wave at night, these interference electric waves

interfere with signals from the same signal source while entering into

vehicle antenna directly, this kind of noise is called "interference".

(2) Multiplex

Noise caused by radio wave reflected from barrier is called

"multiplex". When radio signal emitted by broadcast antenna is

reflected by high buildings or high mountains, and disturbs directly

received other signals, multiplex phenomenon occurs.

(3) Attenuation

Since its frequency is higher than AM, FM wave is more easily

reflected by high buildings or high mountains. Therefore, FM signal

often disappears gradually, or when vehicle is blocked by barrier, it

cannot receive any signal, such phenomenon is called "attenuation".Audio System -Audio System Description5-38Chapter 5 Audio SystemSection 1 Audio System DescriptionDescription:

1. Radio wave band

Wave bands used in radiobroadcast are as follows:

LF: low frequency MF: medium frequency HF: high frequency VHF: very high frequencyFM (stereo)

FM (non-stereo)

AMInterference

IonosphereMultiplexAttenuation