boot GEELY MK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 36 of 416

2-15

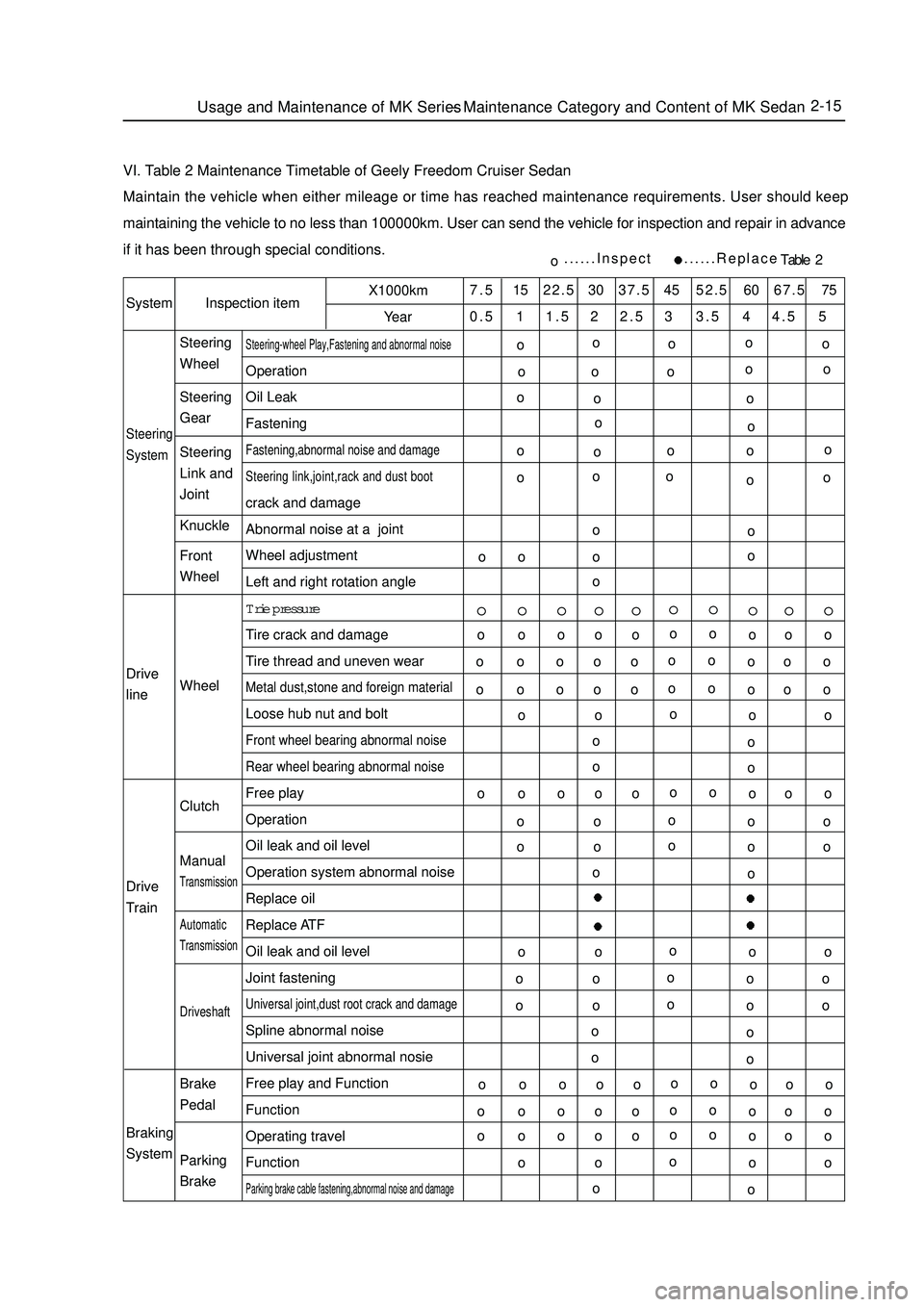

VI. Table 2 Maintenance Timetable of Geely Freedom Cruiser SedanMaintain the vehicle when either mileage or time has reached maintenance requirements. User should keep

maintaining the vehicle to no less than 100000km. User can send the vehicle for inspection and repair in advance

if it has been through special conditions.SystemInspection itemX1000km

Year7.5 15 22.5 30 37.5 45 52.5 60 67.5 75

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5Steering

SystemSteering-wheel Play,Fastening and abnormal noiseOperation

Oil Leak

FasteningFastening,abnormal noise and damage

Steering link,joint,rack and dust bootcrack and damage

Abnormal noise at a joint

Wheel adjustment

Left and right rotation angle

Trie pressure

Tire crack and damage

Tire thread and uneven wearMetal dust,stone and foreign materialLoose hub nut and boltFront wheel bearing abnormal noise

Rear wheel bearing abnormal noiseFree play

Operation

Oil leak and oil level

Operation system abnormal noise

Replace oil

Replace ATF

Oil leak and oil level

Joint fasteningUniversal joint,dust root crack and damageSpline abnormal noise

Universal joint abnormal nosie

Free play and Function

Function

Operating travel

FunctionParking brake cable fastening,abnormal noise and damageo......Inspect ......ReplaceTable 2 Drive

line

Drive

Train

Braking

SystemSteering

Wheel

Steering

Gear

Steering

Link and

Joint

Knuckle

Front

Wheel

Wheel

Clutch

ManualTransmissionAutomaticTransmissionDriveshaftBrake

Pedal

Parking

BrakeUsage and Maintenance of MK Series - Maintenance Category and Content of MK Sedano

o

oo

o o oo o

o o

oo

o o

oo

ooo

o

o oo

o ooo

o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

oo o o

o

o

o o o

o

o

o o o

o

o

o o o

o

o

o o o

o

o

o o o

o

oo o

o o

o o

o o

o o

o oo o o

o

o

Page 97 of 416

tripod jointPropeller Shaft/DriveshaftFront Driveshaft4-20outboard rzeppa joint

outboard joint big clamp

outboard joint boot

outboard joint small clamp

drive shaft damper clamp

right front drive

shaft damper

inboard joint small clamp

inboard joint boot

inboard joint big clamp

tripod

retainerComponent ViewRH:

Non-reusable parts -

Page 99 of 416

10. Separate left lower swing arm assembly

(1) Remove cotter pin and nut

(2) On steering knuckle, remove the left lower swing arm

assembly with ball joint puller.

11. Separate steering gear with tie rod assembly

(1) Remove cotter pin and nut

(2) On steering knuckle, remove the steering gear with tie rod

assembly with ball joint puller.Propeller Shaft/DriveshaftFront Driveshaft4-2212. Separate LF steering knuckle assembly

Using a plastic hamper, separate left front drive shaft assembly from left front steering knuckle assembly

Notice:

Do not damage the boot.

With ABS:

Be careful not to damage the vehicle speed sensor rotor.

13. Remove left constant velocity drive shaft assembly

Using a differential side gear shaft remover, remove the left

constant velocity drive shaft assembly.

Notice:

Do not damage the boot and oil seal.

Be careful not to drop the drive shaft assembly.

14. Remove right constant velocity drive shaft assembly

Using a brass bar and a hammer, remove the right constant

velocity drive shaft assembly.

Notice:

Do not damage the boot and oil seal.

Be careful not to drop the drive shaft assembly. -

Page 100 of 416

15. Install LF steering knuckle assembly

Notice:

The hub bearing could be damaged if it is subjected to the vehicle

weight, such as when moving the vehicle with the drive shaft

bearing removed.

Therefore if it is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with the special service tool for

front hub bearing.

16. Check left constant velocity drive shaft assembly

(1) Check the outboard joint for apparent looseness.

(2) Check that the inboard joint slide smoothly.

(3) Check the inboard joint for radial looseness.

(4) Check the boot for damage.

Notice:

Place the drive shaft assembly on level surface during the

inspection.

17. Remove inboard joint big clamp

Using a screw driver, loosen the inboard joint big clamp.

18. Remove inboard joint small clamp

Using a screw driver, loosen the inboard joint small clamp.

19. Separate inboard joint boot

Separate the outboard joint boot from the outboard Rzeppa joint

assembly.

20. Remove left tripod joint assembly

(1) Wipe off the old grease from the tripod joint assembly.

(2) Place the matchmarks between the tripod joint assembly and

the outboard Rzeppa joint.

Notice:

Do not punch the matchmarks.Propeller Shaft/DriveshaftFront Driveshaft4-23Mark -

Page 101 of 416

Propeller Shaft/DriveshaftFront Driveshaft4-24 (3) Remove the tripod joint assembly from the Rzeppa joint

assembly.

(4) Using a snap ring plier, remove the left drive shaft inner snap

ring.

(5) Place matchmarks on the tripod joint assembly and outboard

Rzeppa joint assembly.

Notice:

Do not punch the matchmarks.

(6) Using a brass bar and a hammer, remove the tripod joint from

the outboard Rzeppa joint assembly.

Notice:

Do not tap the roller.

(7) Remove the inboard joint boot clamp, boot, inner boot and left

boot small clamp.

21. Remove drive shaft damper clamp

Hint:

Perform the following operations only when disassembling the

right drive shaft.

Using a screwdriver, loosen the damper clamp.

22. Remove right drive shaft damper

Hint:

Perform the following operations only when disassembling the right drive shaft.

Remove the right driver shaft damper clamp.

23. Remove left constant velocity outboard joint boot big clamp

Using a screwdriver, loosen the left constant velocity drive shaft

outboard joint boot big clamp.Markbrass bar -

Page 102 of 416

Propeller Shaft/DriveshaftFront Driveshaft4-2524. Remove outboard joint boot small clamp

Using a screw driver, loosen the outboard joint boot small clamp.

25. Remove outboard joint boot

(1) Remove the outboard joint boot from the outboard Rzeppa joint assembly.

(2) Wipe off the old grease from the Rzeppa joint assembly.

26. Remove left front drive shaft tripod retainer

Using a screw driver, loosen the left front drive shaft tripod

retainer.

27. Install left front tripod retainer

Install the new tripod retainer.

28. Install outboard joint boot

(1) Wrap vinyl tape around the spline of the Rzeppa joint to prevent damaging the boots.

(2) Install the new parts on the tripod joint in the following sequence.

a. Outboard joint boot big clamp

b. Outboard joint boot

c. Outboard joint boot small clamp

(3) Coat the left Rzeppa joint assembly with grease.

Grease amount: 69-79g

(4) Install the outboard joint boot on the Rzeppa joint assembly.

29. Install outboard joint boot small clamp

As shown in the illustration, use a screwdriver to install the

outboard joint boot clamp. -

Page 103 of 416

Distance (A) 470 ± 4.0mmPropeller Shaft/DriveshaftFront Driveshaft4-2630. Install outboard joint boot big clamp

As shown in the illustration, use a screwdriver to install the

outboard joint boot big clamp.

31. Install right front drive shaft damper

Hint:

Perform the following operations only when disassembling the

right drive shaft.

Set the following distance:

32. Install drive shaft damper clamp

Hint:

Perform the following operations only when disassembling the

right drive shaft.

(1) Slide the damper clamp on the shaft.

Notice:

Make sure the clamp is correctly installed.

(2) As shown in the illustration, use a screwdriver to install the

damper clamp.

33. Install tripod joint assembly

Before installing the boot, wrap vinyl tape around the spline of the Rzeppa joint to prevent damaging the boots.

(1) Install the new parts on the tripod joint in the following sequence.

a. Inboard joint boot small clamp

b. Inboard joint boot

c. Inboard joint boot big clamp

(2) Align the matchmarks, install the tripod assembly on the

tripod joint outer shaft assembly.

(3) Using a brass bar and a hammer, install the tripod assembly.

Notice:

Do not tap the roller.

Make sure the tripod is correctly installed.Mark -

Page 104 of 416

Propeller Shaft/DriveshaftFront Driveshaft4-27 (4) Using a snap ring plier, install the new retainer.

(5) Coat the tripod joint assembly with grease.

Grease amount: 99-109g

(6) Align the matchmarks, install the left intermediate shaft

assembly on the tripod joint assembly.

34. Install inboard joint boot

Install the inboard joint boot on the intermediate shaft and

35. Install inboard joint boot small clamp

As shown in the illustration, use a screwdriver to install the

inboard joint boot small clamp.

36. Install inboard joint big clamp

As shown in the illustration, use a screwdriver to install the

inboard joint big clamp.

37. Check front drive shaft

(1) Check the outboard joint for apparent looseness.

(2) Check that the inboard joint slide smoothly.

(3) Check the inboard joint for radial looseness.

(4) Check the boot for damage.

Notice:

Place the drive shaft assembly on level surface during the

inspection.Mark - tripod joint outer shaft.

Page 105 of 416

Propeller Shaft/DriveshaftFront Driveshaft4-28 Hint:

Please refer to the following table for dimension (A).LH mm

528.3±5.0

527.0±5.0RH mm

859.3±5.0

860.0±5.0 M/T manual transmission

A/T automatic transmission38. Install left constant velocity drive shaft assembly

(1) M/T

Coat the spline of the tripod joint assembly with gear oil.

(2) A/T

Coat the spline of the tripod joint assembly with ATF

(Automatic Transmission Fluid).

(3) Align the spline, use a brass bar and hammer to install the left

drive shaft assembly.

Notice:

Face the retainer open end downward.

Be careful not to damage the boot and oil seal.

Hint:

You can find out whether the tripod joint shaft contact the pinion shaft by rotating the shaft assembly, listening

to the sound and feeling.

39. Install right constant velocity drive shaft assembly

Hint:

The installation of the right side is the same as that of the left side.

Notice:

Install the retainer with its open end facing downward.

Be careful not to damage the boot and oil seal.

40. Install left steering knuckle assembly

Install the left constant velocity drive shaft assembly on the left steering knuckle assembly.

Notice:

Be careful not to damage the outboard joint boot.

With ABS:

Be careful not to damage the vehicle speed sensor rotor.

41. Install left steering gear with tie rod assembly

(1) Install the steering gear with tie rod assembly on the steering knuckle assembly with nuts.

Torque: 33N.m

(2) Install the new cotter pins.

Notice:

If the pin holes are not aligned, further tighten the nut by 60°.

42. Install left lower swing arm assembly

(1) Install the left lower swing arm assembly on the steering knuckle assembly with nuts.

Torque: 98N.m -

Page 109 of 416

(2) Using sst, remove inner race of the left axle hub bearing from

the left axle hub sub assembly.

13. Remove front left brake disc boot

Remove 3 bolts and front left boot.

14. Remove left front axle hub bearing

(1) Place the left axle hub bearing inner race into the left axle hub

bearing outer race.

(2) Remove the left axle hub bearing from the steering knuckle

with press and sst

15. Install left front axle hub bearing

Install the new left axle hub bearing on the steering knuckle with

press and sst

16. Install front left brake disc boot

Install the front left boot with 3 bolts.

Torque: 8.3N.m

17. Install left front axle hub subassembly

Install left axle hub assembly with press and sst.

18. Install left front axle hub snap ring

Install the new left snap ring with snap ring plier.Propeller Shaft/DriveshaftFront Wheel Hub4-32 -