diagram GEELY MK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 3 of 416

Geely “MK” series sedans (JL7132U,JL7132HU,JL7152U,JL7152HU,JL7162U) are brand

new superior models developed by Geely Group who has fully proprietary intellectual property

rights. As a result of the three years of involvements and efforts of the experts from Geely Automo-

bile Research Institute, these sedans reach international leading level in model design, power,

sense of comfort, safety and manufacturing technology while featured in beautiful appearance,

economy, environment protection and safety. The meaning of MK implied that Geely Automobile

has a great development from caterpillar to butterfly. With respect to the power, Geely “MK” series

sedans are equipped with 1.3L, 1.5L, and 1.6L EFI engines developed and manufactured by Geely

itself, and has reached “Chinese III” (Euro III) emission standard.

This manual contains a detailed description of the structures and principles, servicing and adjustment,

removal, assembling technology and matching clearance of the parts of the Geely “MK” sedans

with torque information of the bolts and nuts as well as schematic diagram for special tool operation.

This manual also introduces the transmission control system of the automatic transmission models,

vehicle electric circuits and elaborates ABS system, SRS, BOSCH M7.9.7 electronic control fuel

injection and ignition system, rear parking radar, sound, air conditioning and onboard hands-free

phone system. You can refer to this manual for the information about the regular maintenance,

servicing, adjustment, troubleshooting, removal and installation procedure, specific operations of

the “MK” sedans.

This manual covers the matching relation among the engine assembly, transmission assembly and

the vehicle, but does not have the further description of the structures and principles of the engine

and transmission assemblies and their servicing process. You can refer to the service manuals

solely prepared for engine assembly and transmission assembly for these information.

All information in this manual is based on the latest products released at the time of publication of

this manual. However, the specifications and procedures may need to be modified, and the subse-

quent change will be revealed in later versions.

This manual is prepared by Geely Automobile Research Institute under the assistance of technical

staff from Zhejiang Geely Automobile Co., Ltd and Geely International Corporation. Readers

discovering during the use of this manual the errors and careless omissions due to limited skills of

the preparers and tight schedule are encouraged and pled to contact Geely International in time for

our timely correction of the mistakes.ForewordGeely International Corporation

Nov . 2007

Page 7 of 416

Table of Contents IV Section 7 Rear Brake Drum ............................................................................................ 4-99

Section 8 Parking Brake System.......................................................................................4-106Part V Electric System & AccessoryChapter 1 Starting and Charging System......................................................................... 5-1

Section 1 Starting System (MR479Q, MR479QA, MR481QA) ...................................... 5-1

Section 2 Charging System (MR479Q, MR479QA, MR481QA) .................................... 5-3

Chapter 2 Combination Instrument System..................................................................... 5-7

Section 1 Wiring diagram of Combination Instrument and Location of Multi-pin Plug-in Terminal5-7

Section 2 Malfunction Symptom Table and Troubleshooting ......................................... 5-10

Chapter 3 Wiper and Washer System............................................................................... 5-21

Section 1 Wiper and Washer System Inspection ........................................................... 5-21

Section 2 Replacement and Adjustment ........................................................................ 5-23

Chapter 4 Light System...................................................................................................... 5-26

Section 1 Light System Introduction ............................................................................... 5-26

Section 2 Light System Malfunction Inspection ............................................................. 5-28

Section 3 Headlamp Replacement ................................................................................. 5-34

Section 4 Front Fog Lamp Replacement ...................................................................... 5-35

Section 5 Rear Combination Lamp Replacement .......................................................... 5-36

Section 6 High-mounted Stop light Replacement .......................................................... 5-36

Section 7 Front Reading Lamp Replacement ................................................................ 5-37

Section 8 Rear Reading Lamp Replacement ................................................................. 5-37

Section 9 License Plate Lamp Replacement ................................................................. 5-37

Chapter 5 Audio System..................................................................................................... 5-38

Section 1 Audio System Description .............................................................................. 5-38

Section 2 Audio System Connector Terminal Layout ..................................................... 5-40

Section 3 Audio System Inspection ................................................................................ 5-41

Section 4 Audio System Replacement ........................................................................... 5-52

Chapter 6 SRS (Supplemental Restraint System)............................................................ 5-54

Page 189 of 416

Starting and Charging System-

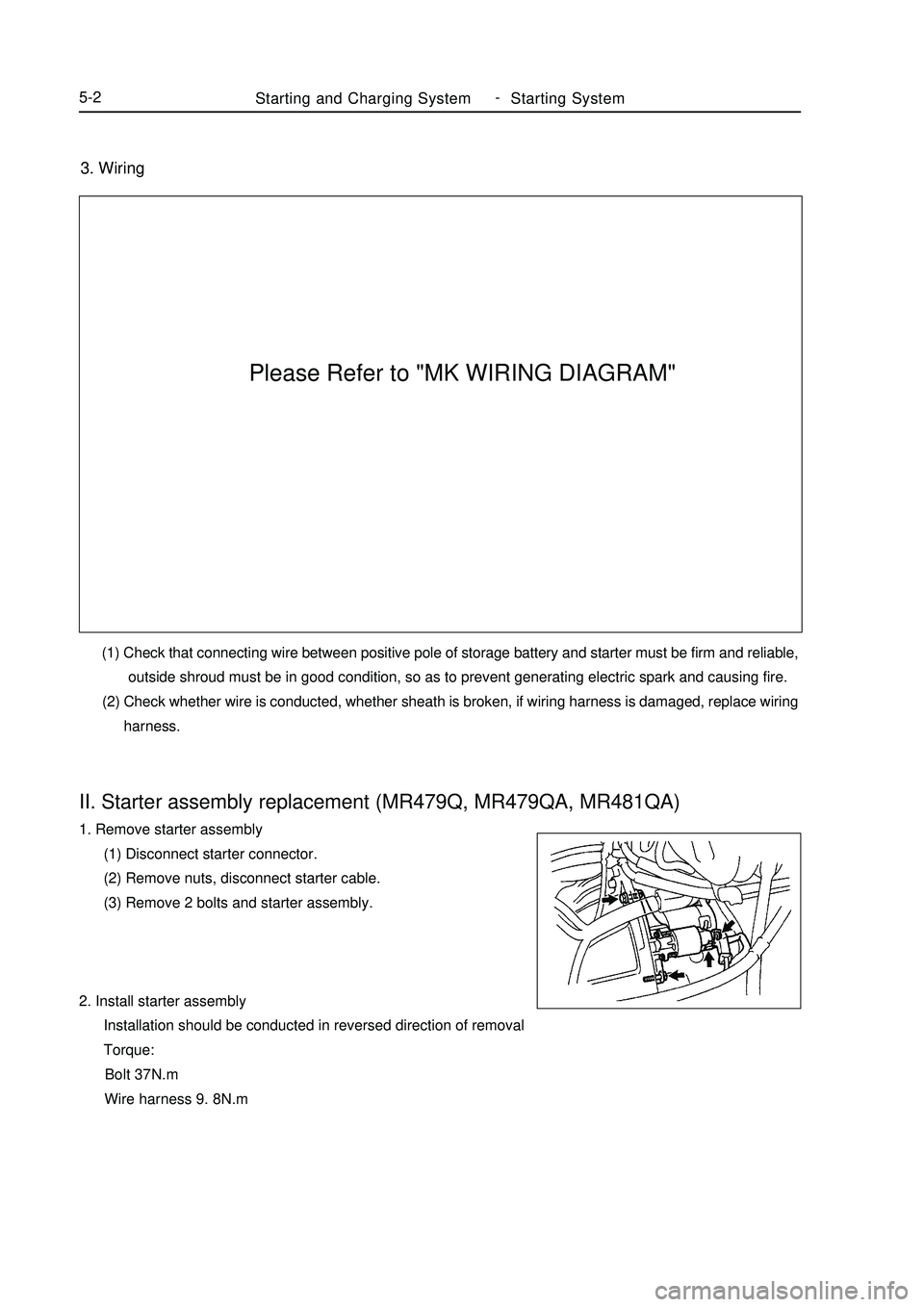

Starting System5-23. WiringII. Starter assembly replacement (MR479Q, MR479QA, MR481QA)1. Remove starter assembly

(1) Disconnect starter connector.

(2) Remove nuts, disconnect starter cable.

(3) Remove 2 bolts and starter assembly.

2. Install starter assembly

Installation should be conducted in reversed direction of removal

Torque:

Bolt 37N.m

Wire harness 9. 8N.m (1) Check that connecting wire between positive pole of storage battery and starter must be firm and reliable,

outside shroud must be in good condition, so as to prevent generating electric spark and causing fire.

(2) Check whether wire is conducted, whether sheath is broken, if wiring harness is damaged, replace wiring

harness.Please Refer to "MK WIRING DIAGRAM"

Page 194 of 416

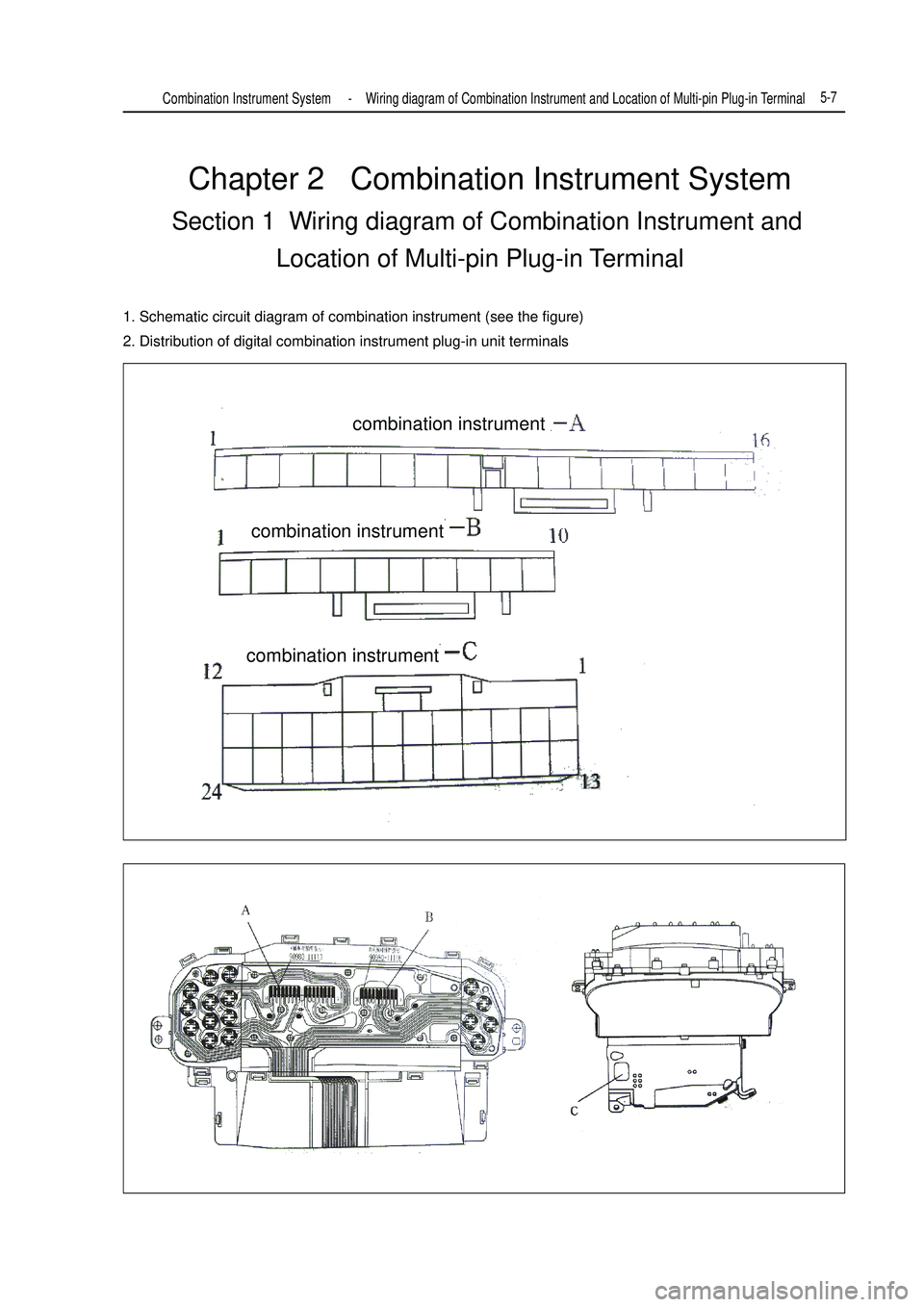

Chapter 2 Combination Instrument SystemSection 1 Wiring diagram of Combination Instrument and

Location of Multi-pin Plug-in Terminal1. Schematic circuit diagram of combination instrument (see the figure)

2. Distribution of digital combination instrument plug-in unit terminalsCombination Instrument System -Wiring diagram of Combination Instrument and Location of Multi-pin Plug-in Terminal5-7combination instrument

combination instrument

combination instrument

Page 195 of 416

Combination Instrument System -Wiring diagram of Combination Instrument and Location of Multi-pin Plug-in Terminal5-8Please Refer to "MK WIRING DIAGRAM"Wiring diagram of Combination Instrument

Page 196 of 416

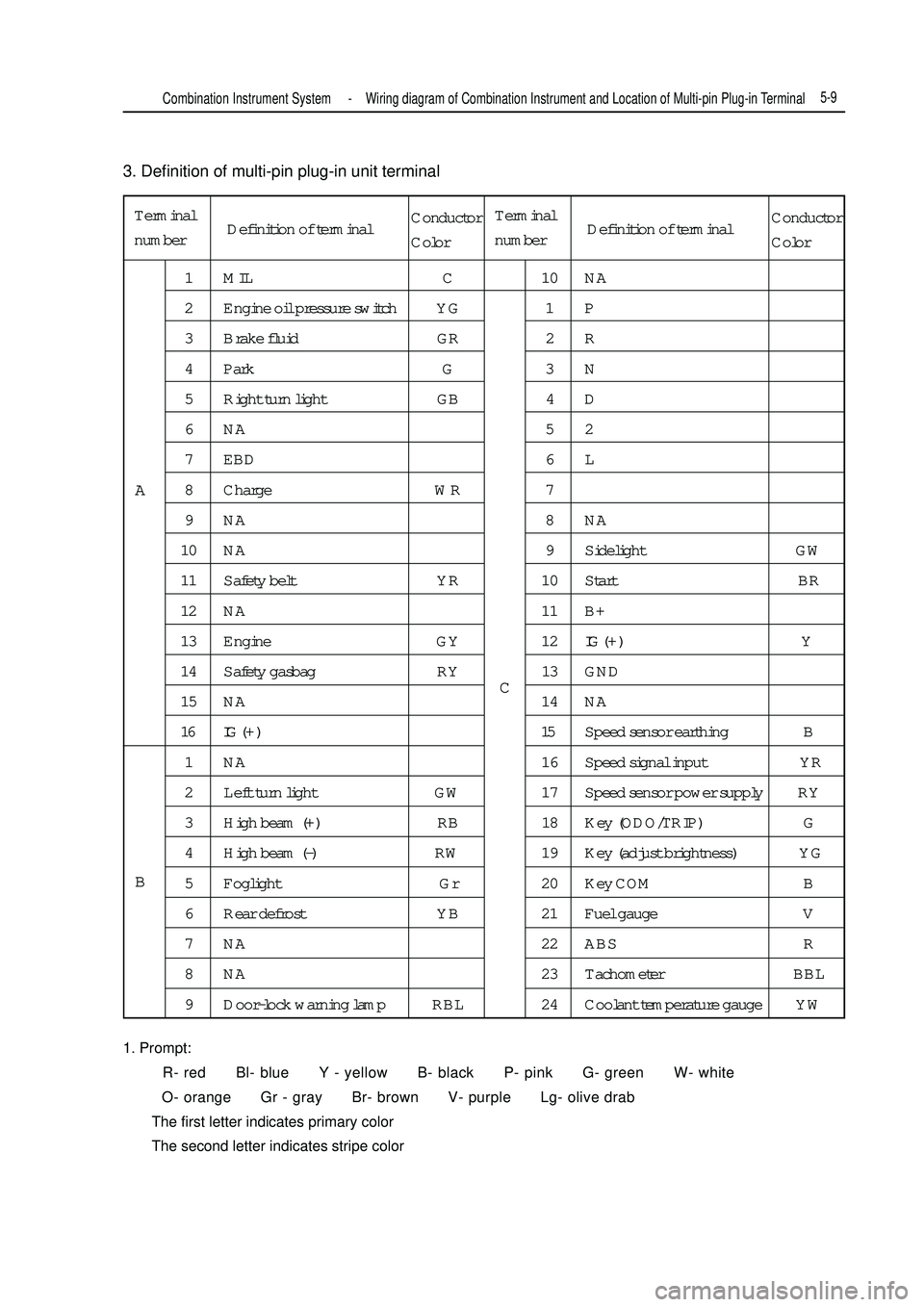

3. Definition of multi-pin plug-in unit terminal

1. Prompt:

R- red Bl- blue Y - yellow B- black P- pink G- green W- white

O- orange Gr - gray Br- brown V- purple Lg- olive drab

The first letter indicates primary color

The second letter indicates stripe colorTerminal

number1 MIL C 10 NA

2 Engine oil pressure switch YG 1 P

3 Brake fluid GR 2 R

4 Park G 3 N

5 Right turn light GB 4 D

6NA 52

7 EBD 6 L

8 Charge WR 7

9NA 8NA

10 NA 9 Sidelight GW

11 Safety belt YR 10 Start BR

12 NA 11 B+

13 Engine GY 12IG ( + ) Y

14 Safety gasbag RY 13 GND

15 NA 14 NA

16 IG ( + ) 15Speed sensor earthing B

1 NA 16 Speed signal input YR

2 Left turn light GW 17 Speed sensor power supply RY

3 High beam (+) RB 18 Key (ODO/TRIP) G

4 High beam (-) RW 19 Key (adjust brightness) YG

5 Foglight Gr 20 Key COM B

6 Rear defrost YB 21 Fuel gauge V

7 NA 22 ABS R

8 NA 23 Tachometer BBL

9 Door-lock warning lamp RBL 24 Coolant temperature gauge YWA

BCCombination Instrument System -Wiring diagram of Combination Instrument and Location of Multi-pin Plug-in Terminal5-9Definition of terminalConductor

ColorTerminal

numberDefinition of terminalConductor

Color

Page 197 of 416

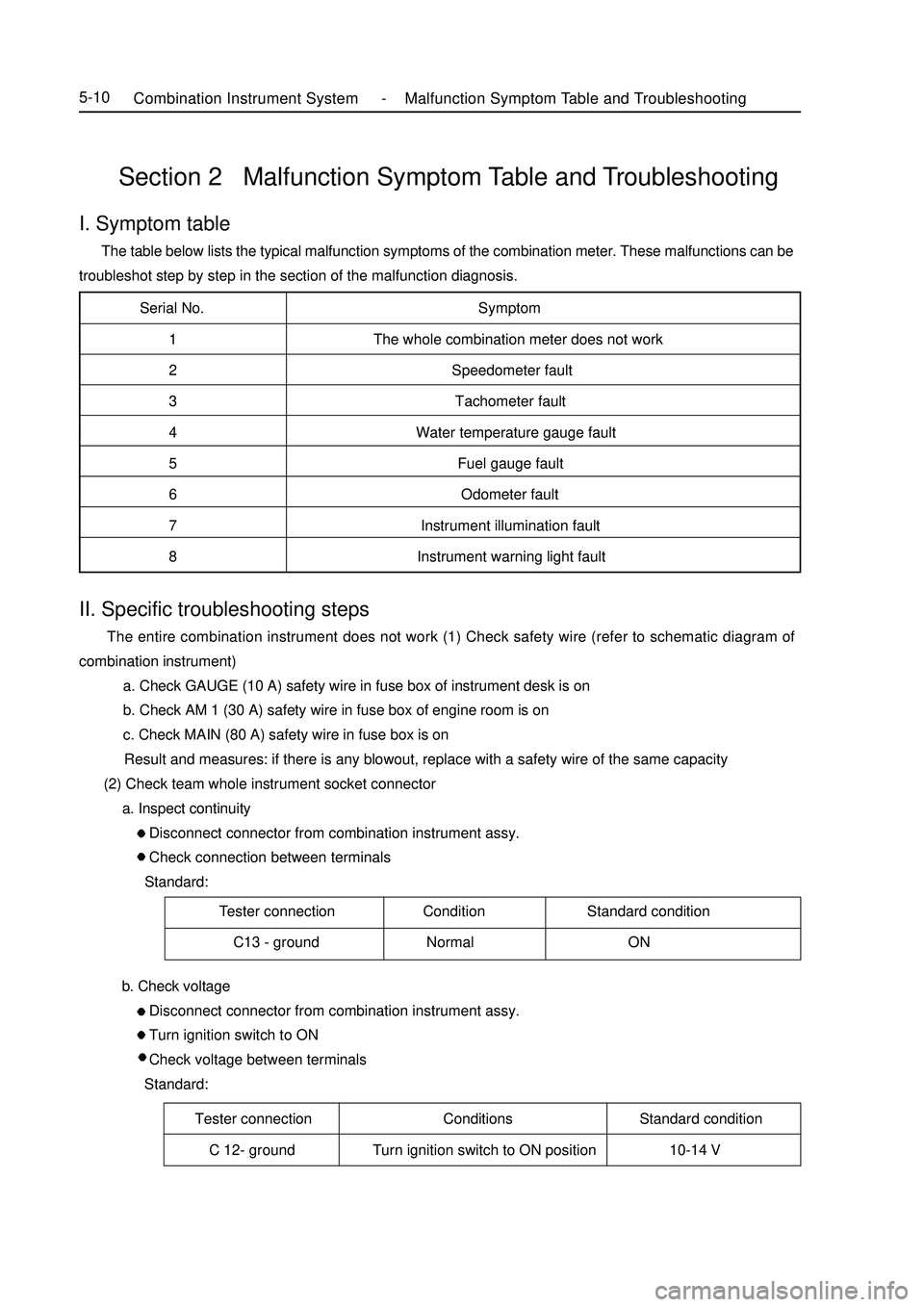

Serial No. Symptom

1 The whole combination meter does not work

2 Speedometer fault

3 Tachometer fault

4 Water temperature gauge fault

5 Fuel gauge fault

6 Odometer fault

7 Instrument illumination fault

8 Instrument warning light fault

Tester connection Condition Standard condition

C13 - ground Normal ONSection 2 Malfunction Symptom Table and TroubleshootingI. Symptom table The table below lists the typical malfunction symptoms of the combination meter. These malfunctions can be

troubleshot step by step in the section of the malfunction diagnosis.Tester connection Conditions Standard condition

C 12- ground Turn ignition switch to ON position 10-14 VCombination Instrument System -Malfunction Symptom Table and Troubleshooting5-10II. Specific troubleshooting steps The entire combination instrument does not work (1) Check safety wire (refer to schematic diagram of

combination instrument)

a. Check GAUGE (10 A) safety wire in fuse box of instrument desk is on

b. Check AM 1 (30 A) safety wire in fuse box of engine room is on

c. Check MAIN (80 A) safety wire in fuse box is on

Result and measures: if there is any blowout, replace with a safety wire of the same capacity

(2) Check team whole instrument socket connector

a. Inspect continuity

Disconnect connector from combination instrument assy.

Check connection between terminals

Standard:

b. Check voltage

Disconnect connector from combination instrument assy.

Turn ignition switch to ON

Check voltage between terminals

Standard:

Page 200 of 416

5-13 c. Check voltage between terminals

Standard:Tester connectionConditions Standard condition

C 12- ground Turn ignition switch to ON position 7. 5-9V

Result and measures:

Abnormal, repair or replace wiring harness or connector

Normal, replace combination instrument assy.

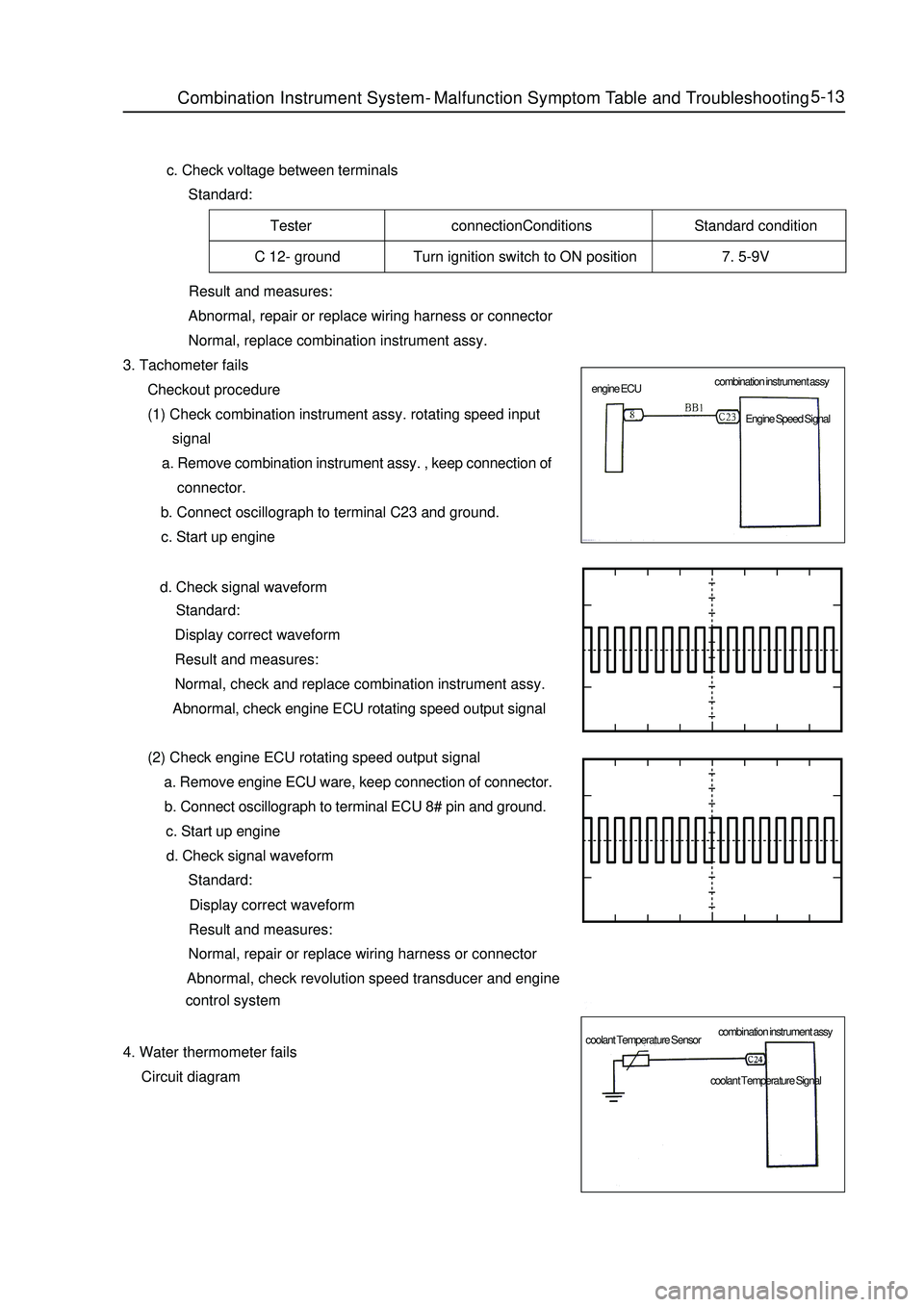

3. Tachometer fails

Checkout procedure

(1) Check combination instrument assy. rotating speed input

signal

a. Remove combination instrument assy. , keep connection of

connector.

b. Connect oscillograph to terminal C23 and ground.

c. Start up engine

d. Check signal waveform

Standard:

Display correct waveform

Result and measures:

Normal, check and replace combination instrument assy.

Abnormal, check engine ECU rotating speed output signal

(2) Check engine ECU rotating speed output signal

a. Remove engine ECU ware, keep connection of connector.

b. Connect oscillograph to terminal ECU 8# pin and ground.

c. Start up engine

d. Check signal waveform

Standard:

Display correct waveform

Result and measures:

Normal, repair or replace wiring harness or connector

Abnormal, check revolution speed transducer and engine

control system

4. Water thermometer fails

Circuit diagramCombination Instrument System -Malfunction Symptom Table and Troubleshooting combination instrument assy

combination instrument assy engine ECU

coolant Temperature SensorEngine Speed Signal

coolant Temperature Signal

Page 201 of 416

Tester connection Conditions Standard state

C(60°C)164.5±5 ohm

C 24- ground 1/2C(90°C)56±3 ohm

H(115°C)28.7±2 ohmConditions Standard state

C(60°C)164.5±5 ohm

1/2C(90°C)56±3 ohm

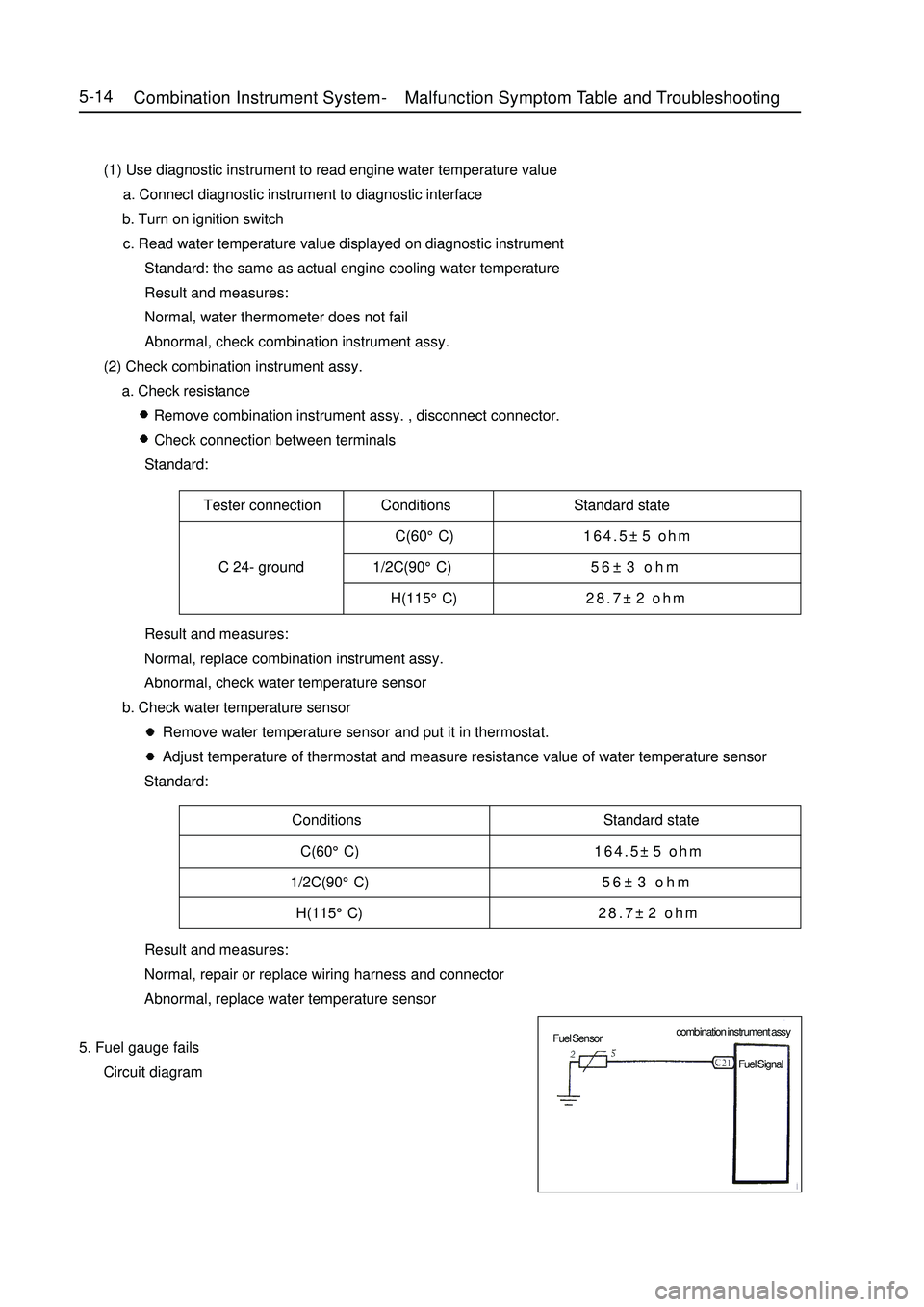

H(115°C)28.7±2 ohm5-14 (1) Use diagnostic instrument to read engine water temperature value

a. Connect diagnostic instrument to diagnostic interface

b. Turn on ignition switch

c. Read water temperature value displayed on diagnostic instrument

Standard: the same as actual engine cooling water temperature

Result and measures:

Normal, water thermometer does not fail

Abnormal, check combination instrument assy.

(2) Check combination instrument assy.

a. Check resistance

Remove combination instrument assy. , disconnect connector.

Check connection between terminals

Standard:

Result and measures:

Normal, replace combination instrument assy.

Abnormal, check water temperature sensor

b. Check water temperature sensor

Remove water temperature sensor and put it in thermostat.

Adjust temperature of thermostat and measure resistance value of water temperature sensor

Standard:

Result and measures:

Normal, repair or replace wiring harness and connector

Abnormal, replace water temperature sensor

5. Fuel gauge fails

Circuit diagramCombination Instrument System -Malfunction Symptom Table and Troubleshooting combination instrument assy

Fuel Sensor

Fuel Signal

Page 218 of 416

Headlight combination switch position drawingII. Lighting system troubleshooting1. Headlight combination switch assemblyHandle positionTerminal

FU TL TR

Turn

light

switchR

NL

LEL2 FF RF

Foglight

switchOFF

FF

RFE L T N S HEAD

Headlight,

small

light

switchOFF

P

HEL1 HL HU

Light

switchPASS

HL

HUPASSSwitch position Testing terminal Status

OFF EL-TNS OFF

Position light EL-TNS ON

Headlight EL-HEAD ON (1) Check whether headlight light control switch is ON

Check whether terminals are connected when switch is in each position according to the table. If it doest not meet stipulation, replace the switch.Light System -Light System Malfunction Inspection5-31Handle positionTerminalHandle positionTerminalHandle positionTerminalHeadlight combination switch shifting diagram