CAN GENESIS G90 2018 Owner's Manual

[x] Cancel search | Manufacturer: GENESIS, Model Year: 2018, Model line: G90, Model: GENESIS G90 2018Pages: 519, PDF Size: 19.52 MB

Page 460 of 519

7-58

Maintenance

Fuse/Relay Panel Description

Instrument panel fuse panel

Inside the fuse/relay box cover, you

can find the fuse/relay label describ-

ing fuse/relay name and capacity.

Information

Not all fuse panel descriptions in this

manual may be applicable to your

vehicle; the information is accurate at

the time of printing. When you inspect

the fuse box on your vehicle, refer to

the fuse box label.

i

OHI076032

OHI076033N

Page 464 of 519

7-62

Maintenance

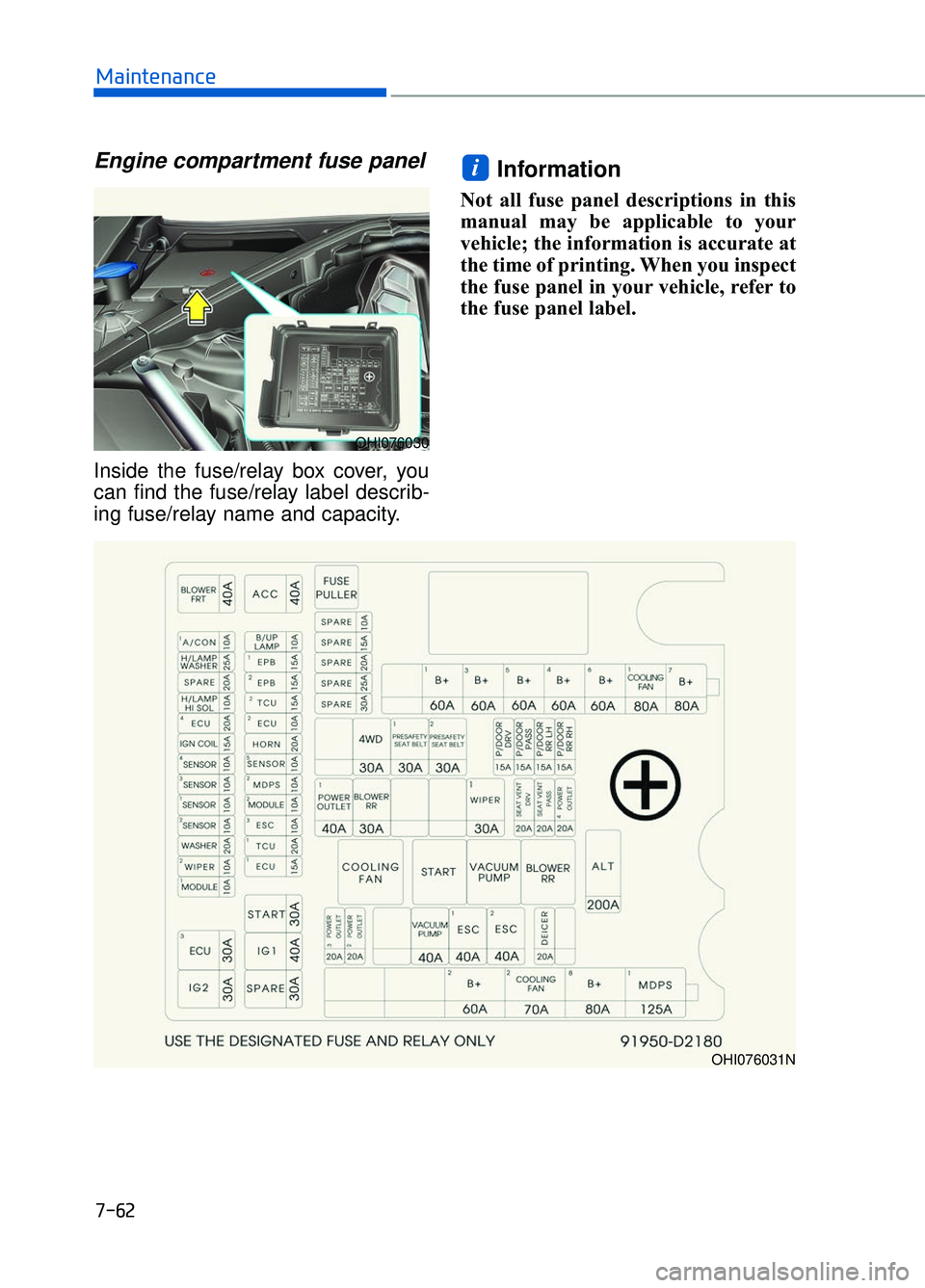

Engine compartment fuse panel

Inside the fuse/relay box cover, you

can find the fuse/relay label describ-

ing fuse/relay name and capacity.

Information

Not all fuse panel descriptions in this

manual may be applicable to your

vehicle; the information is accurate at

the time of printing. When you inspect

the fuse panel in your vehicle, refer to

the fuse panel label.

i

OHI076030

OHI076031N

Page 467 of 519

![GENESIS G90 2018 Owners Manual 7-65

07

Fuse name Fuse rating Circuit protected

SENSOR110A

[Lambda 3.3 T-GDI] Oil Controlvalve #1/#2/#3/#4(Intake/Exhaust), Purge Control

Solenoid Valve, Oil Pressure Solenoid

Valve, Canister Close Va GENESIS G90 2018 Owners Manual 7-65

07

Fuse name Fuse rating Circuit protected

SENSOR110A

[Lambda 3.3 T-GDI] Oil Controlvalve #1/#2/#3/#4(Intake/Exhaust), Purge Control

Solenoid Valve, Oil Pressure Solenoid

Valve, Canister Close Va](/img/46/35643/w960_35643-466.png)

7-65

07

Fuse name Fuse rating Circuit protected

SENSOR110A

[Lambda 3.3 T-GDI] Oil Controlvalve #1/#2/#3/#4(Intake/Exhaust), Purge Control

Solenoid Valve, Oil Pressure Solenoid

Valve, Canister Close Valve

[Tau 5.0 GDI] Oil Controlvalve #1/#2/#3/#4 (Intake/ Exhaust), Purge Control Solenoid Valve,

Canister Close Valve

SENSOR310A[Lambda 3.3 T-GDI] Electronic Thermostat, Rear Sub Junction Block (Fuel Pump Relay)

[Tau 5.0 GDI] Rear Sub Junction Block (Fuel Pump Relay)

SENSOR410A

[Lambda 3.3 T-GDI] E/R Junction Block (RLY. 1 - Cooling Fan Relay)

[Tau 5.0 GDI] E/R Junction Block (RLY. 1 - Cooling Fan Relay), Camshaft Position Sensor #1/#2/#3/#4

(Intake/ Exhaust)

IGN COIL15A[Lambda 3.3 T-GDI] Ignition Coil #1/#2/#3/#4/#5/#6

[Tau 5.0 GDI] Ignition Coil #1/#2/#3/#4/#5/#6/#7/#8

ECU420AECM

H/LAMPHI SOL10AHead Lamp (HI SOL) Relay

H/LAMP

WASHER25AHead Lamp Washer Relay

A/CON110AA/C Control Module

FRT

BLOWER40AFront Blower Relay

IGN140AIG1 Relay

START30AE/R Junction Block (RLY. 2 - Start Relay)

ECU115AECM

TCU120ATCM

ESC310AESC Control Module

Page 469 of 519

7-67

07

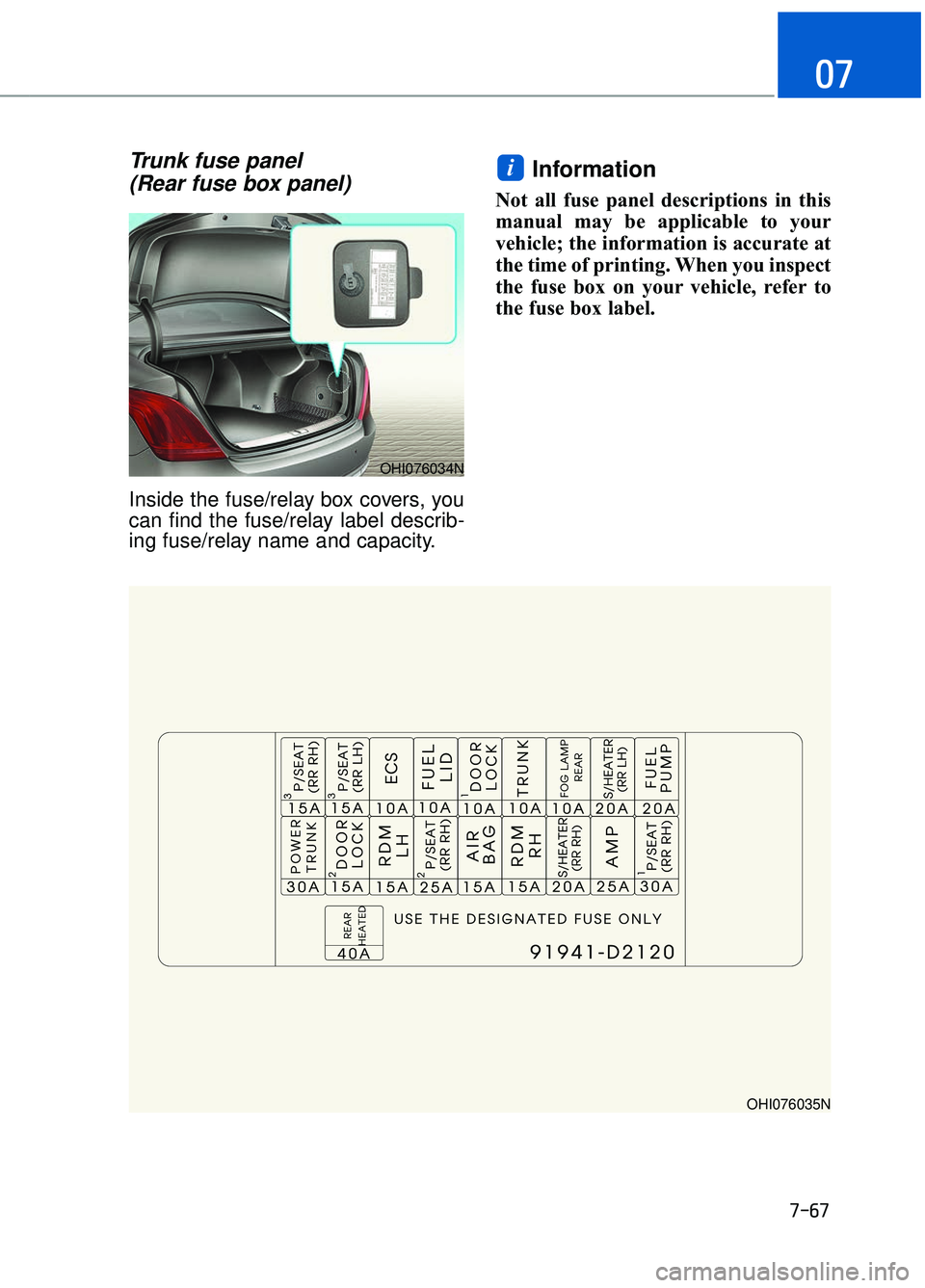

Trunk fuse panel (Rear fuse box panel)

Inside the fuse/relay box covers, you

can find the fuse/relay label describ-

ing fuse/relay name and capacity.

Information

Not all fuse panel descriptions in this

manual may be applicable to your

vehicle; the information is accurate at

the time of printing. When you inspect

the fuse box on your vehicle, refer to

the fuse box label.

i

OHI076034N

OHI076035N

Page 471 of 519

7-69

07

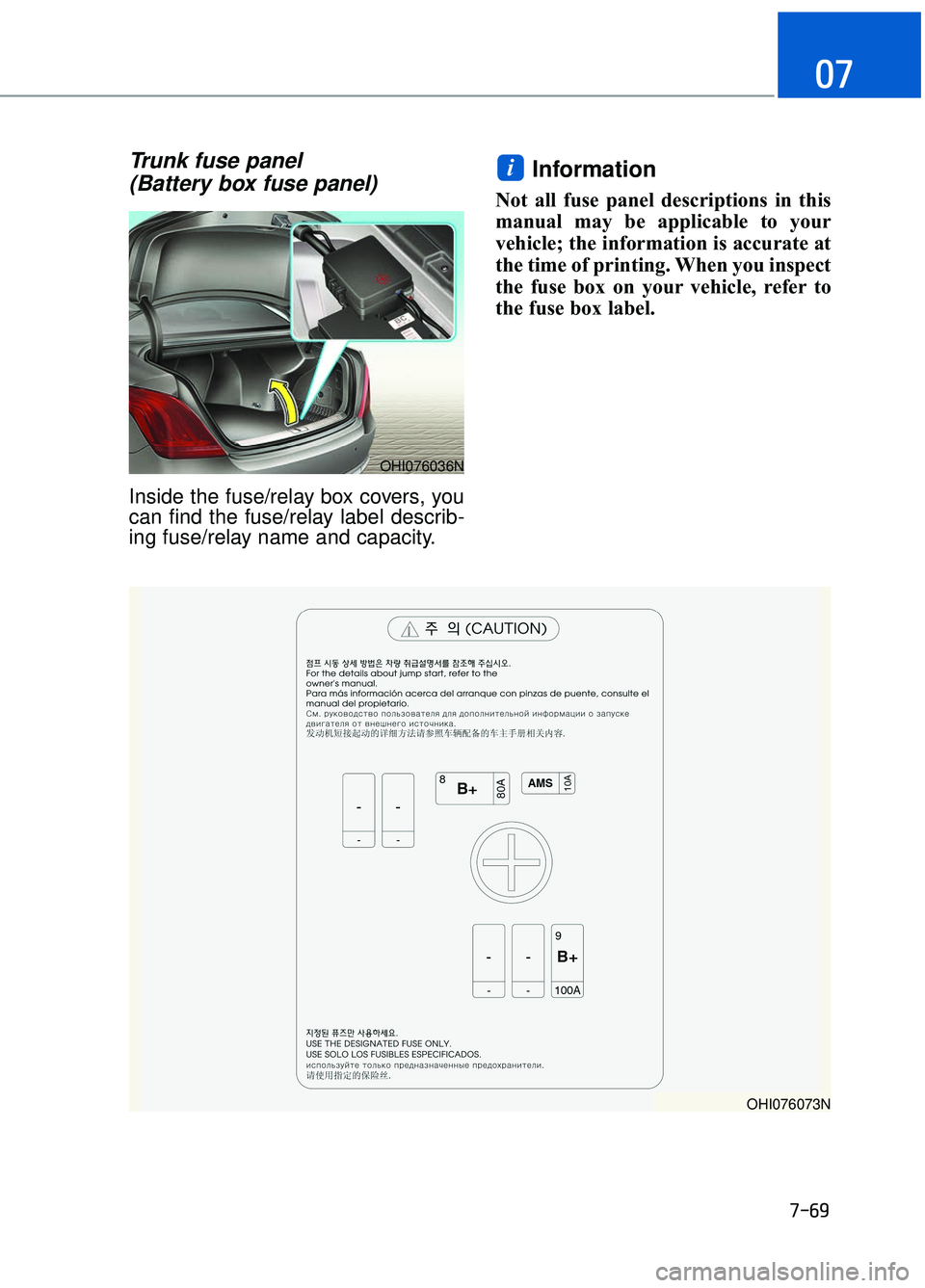

Trunk fuse panel (Battery box fuse panel)

Inside the fuse/relay box covers, you

can find the fuse/relay label describ-

ing fuse/relay name and capacity.

Information

Not all fuse panel descriptions in this

manual may be applicable to your

vehicle; the information is accurate at

the time of printing. When you inspect

the fuse box on your vehicle, refer to

the fuse box label.

i

OHI076036N

OHI076073N

Page 473 of 519

7-71

07

Consult an authorized HYUNDAI

dealer to replace most vehicle light

bulbs. It is difficult to replace vehicle

light bulbs because other parts of the

vehicle must be removed before you

can get to the bulb. This is especially

true for removing the headlamp

assembly to get to the bulb(s).

Removing/installing the headlamp

assembly can result in damage to

the vehicle.

Information

After heavy driving, rain or washing,

headlamp and trunk lenses could

appear frosty. This condition is caused

by the temperature difference between

the lamp inside and the outside tem-

perature. This is similar to the con-

densation on your windows inside

your vehicle during the rain and does-

n't indicate a problem with your vehi-

cle. If the water leaks into the lamp

bulb circuitry, have your vehicle

checked by an authorized retailer of

Genesis Branded products.

Headlamp, Parking Lamp, Turn

Signal Lamp, Daytime Running

Light and Side Marker

Replacement

Type A – HID headlamp

(1) Headlamp (Low/High)

(2) Parking lamp

(3) Turn signal lamp/ Daytime running light

(4) Side marker

Headlamp (Low, High)

If the light bulb does not operate,

have the vehicle checked by an

authorized retailer of Genesis

Branded products.

i

L L I

IG

G H

H T

T

B

B U

U L

LB

B S

S

Prior to replacing a lamp,

depress the foot brake, move

the shift lever into P (Park)

apply the parking brake, place

the Engine Start/Stop button

to the OFF position, and take

the key with you when leaving

the vehicle to avoid sudden

movement of the vehicle and

to prevent possible electric

shock.

Be aware the bulbs may be hot and may burn your fin-

gers.

WARNING

OHI076038N

Do not attempt to replace or

inspect the low/high beam

(XENON bulb) due to electric

shock danger. If the low/high

beam (XENON bulb) is not work-

ing, have your vehicle checked

by an authorized retailer of

Genesis Branded products.

WARNING

Page 474 of 519

7-72

Maintenance

Information

If your vehicle is equipped with High

Intensity Discharge (HID) headlamps,

these headlamps contain mercury. So

if you need to have your vehicle dis-

posed, you should remove the HID

headlamps before disposal. The

removed HID headlamps should be

recycled, re-used or disposed as haz-

ardous waste.

Information

HID lamps have superior perform-

ance vs. halogen bulbs.

HID lamps are estimated by the man-

ufacturer to last twice as long or

longer than halogen bulbs depending

on their frequency of use. They will

probably require replacement at some

point in the life of the vehicle. Cycling

the headlamps on and off more than

typical use will shorten HID lamps

life. HID lamps do not fail in the same

manner as halogen incandescent

lamps. If a headlamp goes out after a

period of operation but will immedi-

ately relight when the headlamp

switch is cycled it is likely the HID

lamp needs to be replaced. HID light-

ing components are more complex

than conventional halogen bulbs thus

have higher replacement cost.

Parking lamp/Daytime running

light/Side marker

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized retailer of

Genesis Branded products.

Type B – LED headlamp

(1) Headlamp (Low)

(2) Headlamp (High)

(3) Parking lamp

(4) Turn signal/Daytime running light

(5) Side marker

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized retailer of

Genesis Branded products.

i

i

OHI076039N

Page 477 of 519

7-75

07

Exterior Care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning

and caution statements that appear

on the label.

High-pressure washing

When using high-pressure wash-ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers)or

connectors as they may be dam-

aged if they come into contact with

high pressure water.

Do not use any high-pressure noz- zles, which induce either one-direct

water stream or water swirling.

Finish maintenance

Washing

To help protect your vehicle’s finish

from rust and deterioration, wash it

thoroughly and frequently at least

once a month with lukewarm or cold

water.

If you use your vehicle for off-road

driving, you should wash it after each

off-road trip. Pay special attention to

the removal of any accumulation of

salt, dirt, mud, and other foreign

materials. Make sure the drain holes

in the lower edges of the doors and

rocker panels are kept clear and

clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar

deposits can damage your vehicle’s

finish if not removed immediately.

Even prompt washing with plain

water may not completely remove all

these deposits. A mild soap, safe for

use on painted surfaces, should be

used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water.

Do not allow soap to dry on the finish.

A AP

PP

PE

EA

A R

RA

A N

N C

CE

E

C

C A

A R

RE

E

After washing the vehicle, test

the brakes while driving slowly

to see if they have been affected

by water before getting on the

road. If braking performance is

impaired, dry the brakes by

applying them lightly while

maintaining a slow forward

speed.

WARNING

Page 479 of 519

7-77

07

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or

replacement, be sure the body

shop applies anti-corrosion mate-

rials to the parts repaired or

replaced.

Bright-metal maintenance

To remove road tar and insects,use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may

collect on the underbody. If these

materials are not removed, acceler-

ated rusting can occur on underbody

parts such as the fuel lines, frame,

floor pan and exhaust system, even

though they have been treated with

rust protection.

Thoroughly flush the vehicle under-

body and wheel openings with luke-

warm or cold water once a month,

after off-road driving and at the end

of each winter. Pay special attention

to these areas because it is difficult

to see all the mud and dirt. It will do

more harm than good to wet down the

road grime without removing it. The

lower edges of doors, rocker panels,

and frame members have drain holes

that should not be allowed to clog with

dirt; trapped water in these areas can

cause rusting.

NOTICE

After washing the vehicle, test

the brakes while driving slowly

to see if they have been affected

by water. If braking performance

is impaired, dry the brakes by

applying them lightly while

maintaining a slow forward

speed.

WARNING

Page 480 of 519

7-78

Maintenance

Aluminum wheel maintenance

The aluminum wheels are coated

with a clear protective finish.

Do not use abrasive cleaner, pol-ishing compound, solvent, or

wire brushes on aluminum

wheels.

Clean the wheel when it has cooled.

Use only a mild soap or neutral detergent, and rinse thoroughly

with water. Also, clean the

wheels after driving on salted

roads.

Do not wash the wheels with high-speed car wash brushes.

Do not use cleaners containing acid or alkaline detergents.

Corrosion protection

Protecting your vehicle from corro-

sion

By using the most advanced design

and construction practices to combat

corrosion, Genesis Branded Vehicle

produces cars of the highest quality.

However, this is only part of the job.

To achieve the long-term corrosion

resistance your vehicle can deliver,

the owner’s cooperation and assis-

tance is also required.

Common causes of corrosion

The most common causes of corro-

sion on your vehicle are:

Road salt, dirt and moisture that isallowed to accumulate underneath

the vehicle.

Removal of paint or protective coatings by stones, gravel, abra-

sion or minor scrapes and dents

which leave unprotected metal

exposed to corrosion.

High-corrosion areas

If you live in an area where your vehi-

cle is regularly exposed to corrosive

materials, corrosion protection is

particularly important. Some of the

common causes of accelerated cor-

rosion are road salts, dust control

chemicals, ocean air and industrial

pollution.

NOTICE