lock GMC CANYON 2010 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: CANYON, Model: GMC CANYON 2010Pages: 448, PDF Size: 2.62 MB

Page 370 of 448

3. Loosen the cable by turning the wheel wrench

counterclockwise three or four turns.

4. Repeat this procedure at least two times. If the

spare tire lowers to the ground, continue with

Step 5 underRemoving the Spare Tire and Tools

on page 6-81.

5. Turn the wrench counterclockwise until

approximately 6 inches (15 cm) of cable is

exposed.

6. Stand the wheel blocks on their shortest ends,

with the backs facing each other.

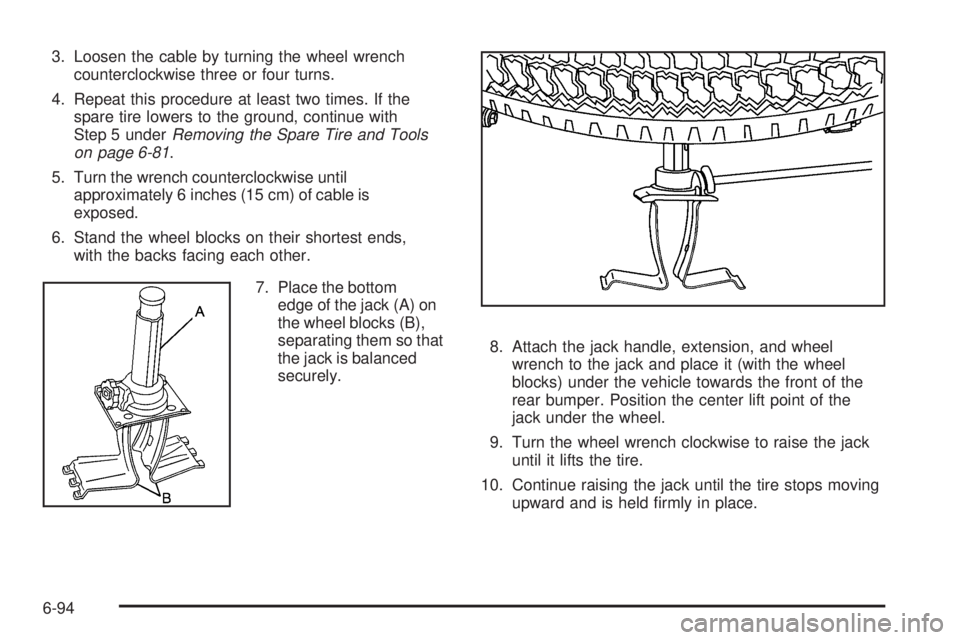

7. Place the bottom

edge of the jack (A) on

the wheel blocks (B),

separating them so that

the jack is balanced

securely.8. Attach the jack handle, extension, and wheel

wrench to the jack and place it (with the wheel

blocks) under the vehicle towards the front of the

rear bumper. Position the center lift point of the

jack under the wheel.

9. Turn the wheel wrench clockwise to raise the jack

until it lifts the tire.

10. Continue raising the jack until the tire stops moving

upward and is held firmly in place.

6-94

Page 371 of 448

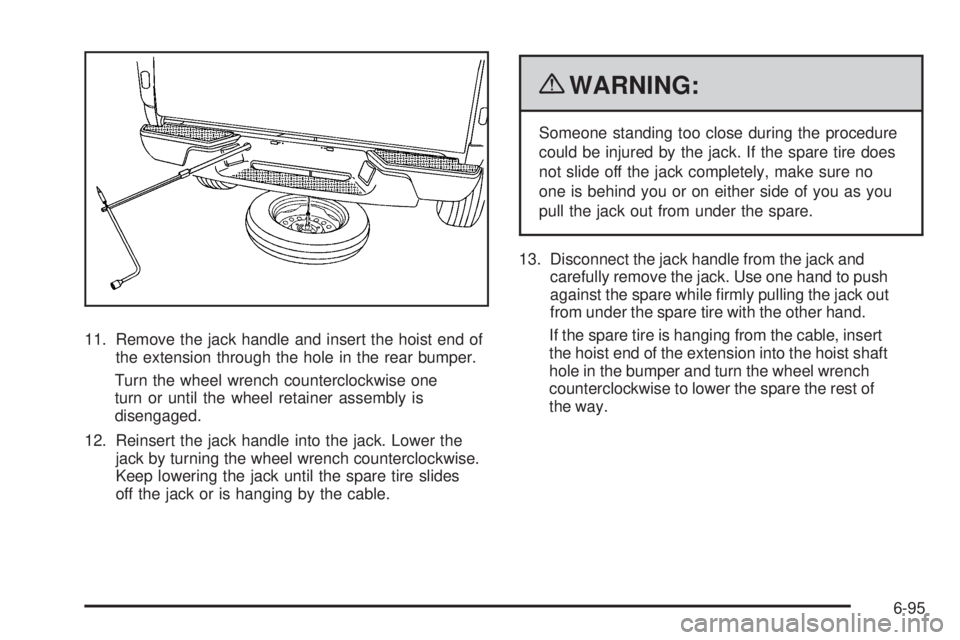

11. Remove the jack handle and insert the hoist end of

the extension through the hole in the rear bumper.

Turn the wheel wrench counterclockwise one

turn or until the wheel retainer assembly is

disengaged.

12. Reinsert the jack handle into the jack. Lower the

jack by turning the wheel wrench counterclockwise.

Keep lowering the jack until the spare tire slides

off the jack or is hanging by the cable.

{WARNING:

Someone standing too close during the procedure

could be injured by the jack. If the spare tire does

not slide off the jack completely, make sure no

one is behind you or on either side of you as you

pull the jack out from under the spare.

13. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push

against the spare while firmly pulling the jack out

from under the spare tire with the other hand.

If the spare tire is hanging from the cable, insert

the hoist end of the extension into the hoist shaft

hole in the bumper and turn the wheel wrench

counterclockwise to lower the spare the rest of

the way.

6-95

Page 372 of 448

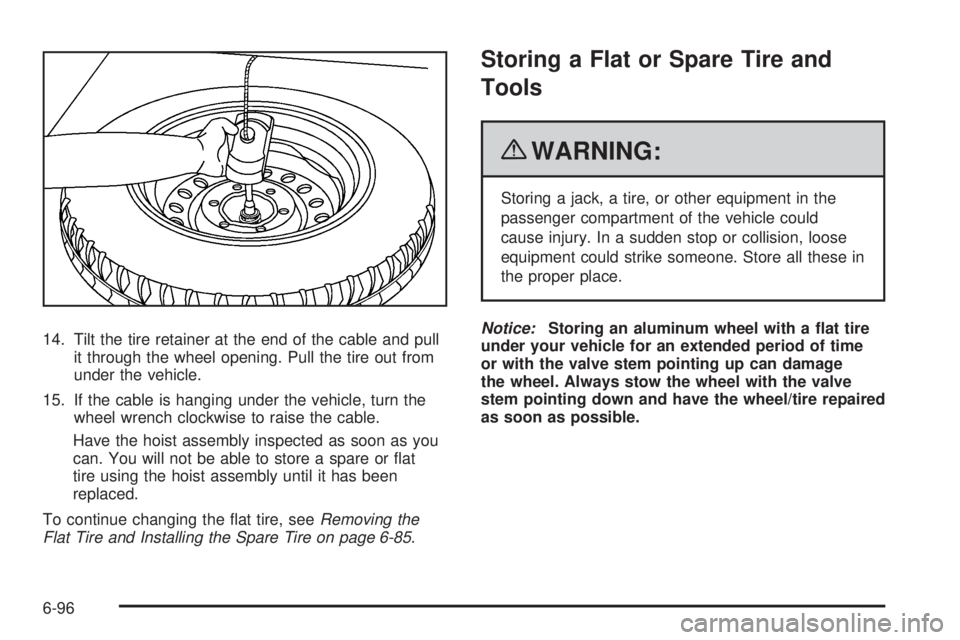

14. Tilt the tire retainer at the end of the cable and pull

it through the wheel opening. Pull the tire out from

under the vehicle.

15. If the cable is hanging under the vehicle, turn the

wheel wrench clockwise to raise the cable.

Have the hoist assembly inspected as soon as you

can. You will not be able to store a spare or flat

tire using the hoist assembly until it has been

replaced.

To continue changing the flat tire, seeRemoving the

Flat Tire and Installing the Spare Tire on page 6-85.

Storing a Flat or Spare Tire and

Tools

{WARNING:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision, loose

equipment could strike someone. Store all these in

the proper place.

Notice:Storing an aluminum wheel with a �at tire

under your vehicle for an extended period of time

or with the valve stem pointing up can damage

the wheel. Always stow the wheel with the valve

stem pointing down and have the wheel/tire repaired

as soon as possible.

6-96

Page 374 of 448

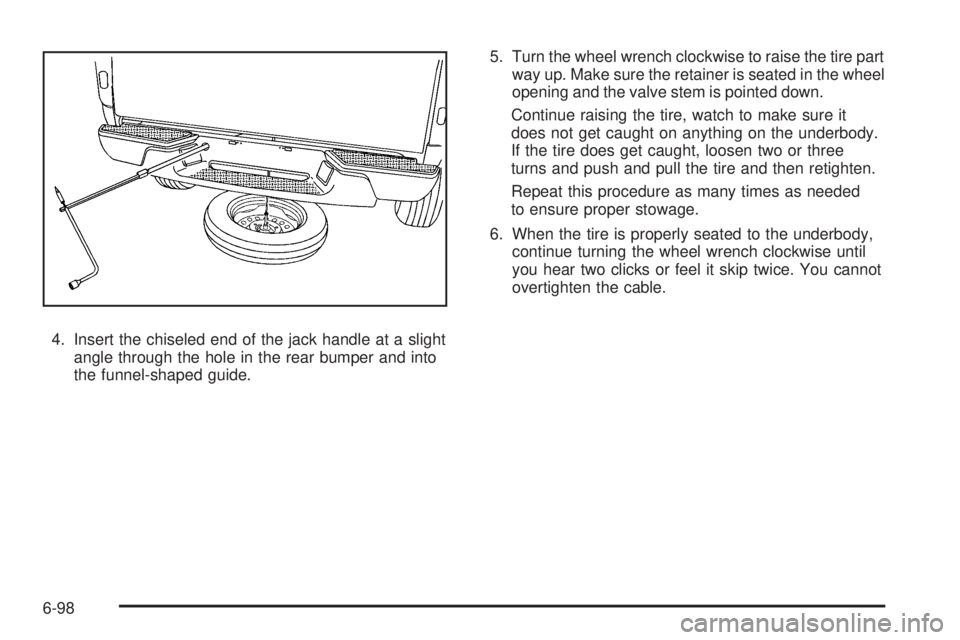

4. Insert the chiseled end of the jack handle at a slight

angle through the hole in the rear bumper and into

the funnel-shaped guide.5. Turn the wheel wrench clockwise to raise the tire part

way up. Make sure the retainer is seated in the wheel

opening and the valve stem is pointed down.

Continue raising the tire, watch to make sure it

does not get caught on anything on the underbody.

If the tire does get caught, loosen two or three

turns and push and pull the tire and then retighten.

Repeat this procedure as many times as needed

to ensure proper stowage.

6. When the tire is properly seated to the underbody,

continue turning the wheel wrench clockwise until

you hear two clicks or feel it skip twice. You cannot

overtighten the cable.

6-98

Page 375 of 448

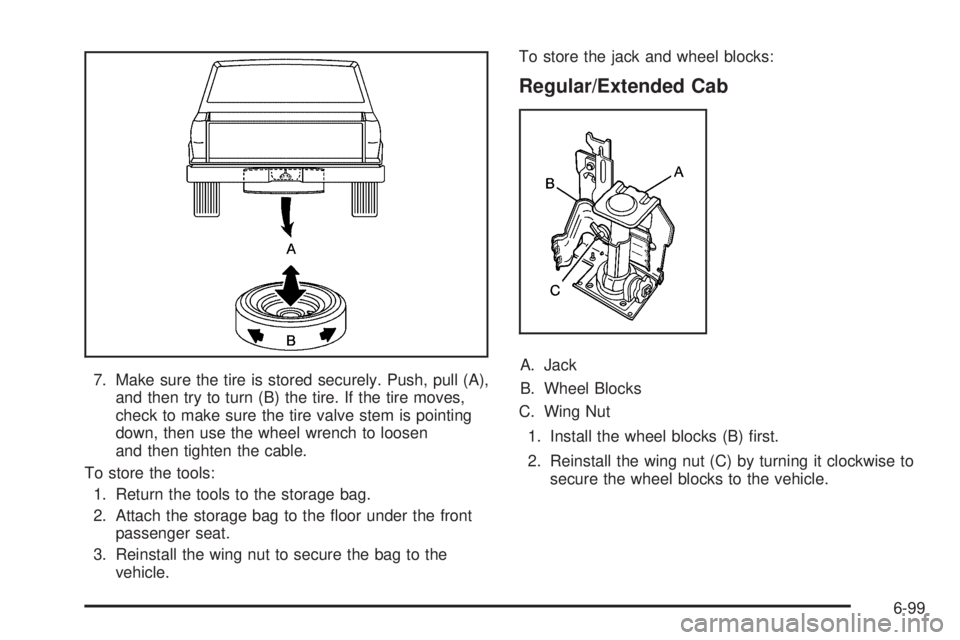

7. Make sure the tire is stored securely. Push, pull (A),

and then try to turn (B) the tire. If the tire moves,

check to make sure the tire valve stem is pointing

down, then use the wheel wrench to loosen

and then tighten the cable.

To store the tools:

1. Return the tools to the storage bag.

2. Attach the storage bag to the floor under the front

passenger seat.

3. Reinstall the wing nut to secure the bag to the

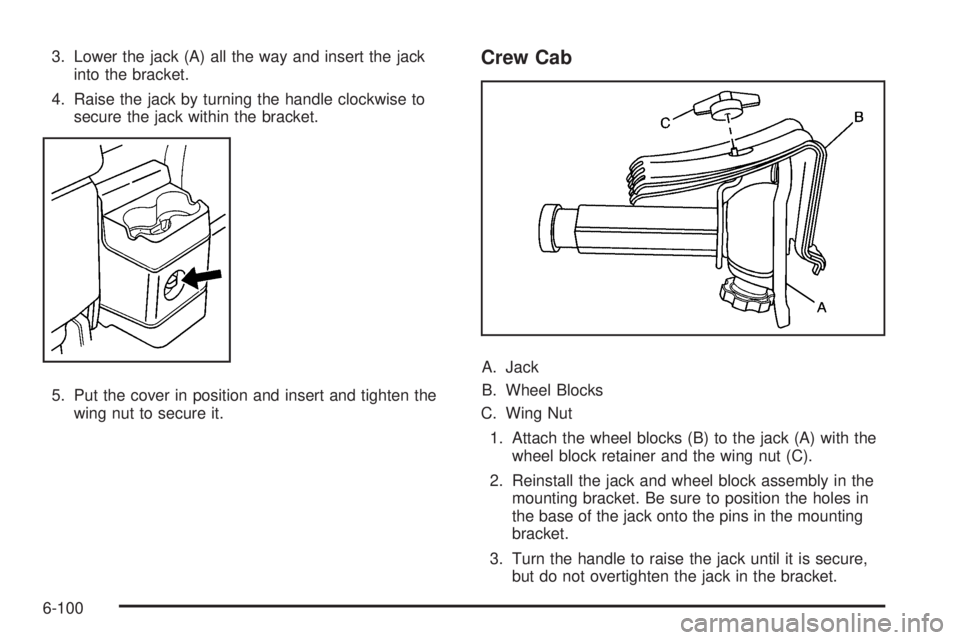

vehicle.To store the jack and wheel blocks:

Regular/Extended Cab

A. Jack

B. Wheel Blocks

C. Wing Nut

1. Install the wheel blocks (B) first.

2. Reinstall the wing nut (C) by turning it clockwise to

secure the wheel blocks to the vehicle.

6-99

Page 376 of 448

3. Lower the jack (A) all the way and insert the jack

into the bracket.

4. Raise the jack by turning the handle clockwise to

secure the jack within the bracket.

5. Put the cover in position and insert and tighten the

wing nut to secure it.Crew Cab

A. Jack

B. Wheel Blocks

C. Wing Nut

1. Attach the wheel blocks (B) to the jack (A) with the

wheel block retainer and the wing nut (C).

2. Reinstall the jack and wheel block assembly in the

mounting bracket. Be sure to position the holes in

the base of the jack onto the pins in the mounting

bracket.

3. Turn the handle to raise the jack until it is secure,

but do not overtighten the jack in the bracket.

6-100

Page 388 of 448

Engine Compartment Fuse Block

The engine compartment fuse block is located on the

driver side of the engine compartment. SeeEngine

Compartment Overview on page 6-12for more

information on location.To remove the cover, push in on the tab on the end of

the cover and lift. To reinstall the cover, line up the

tab and push down on the cover until the tab clicks

into place.

Notice:Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

6-112

Page 390 of 448

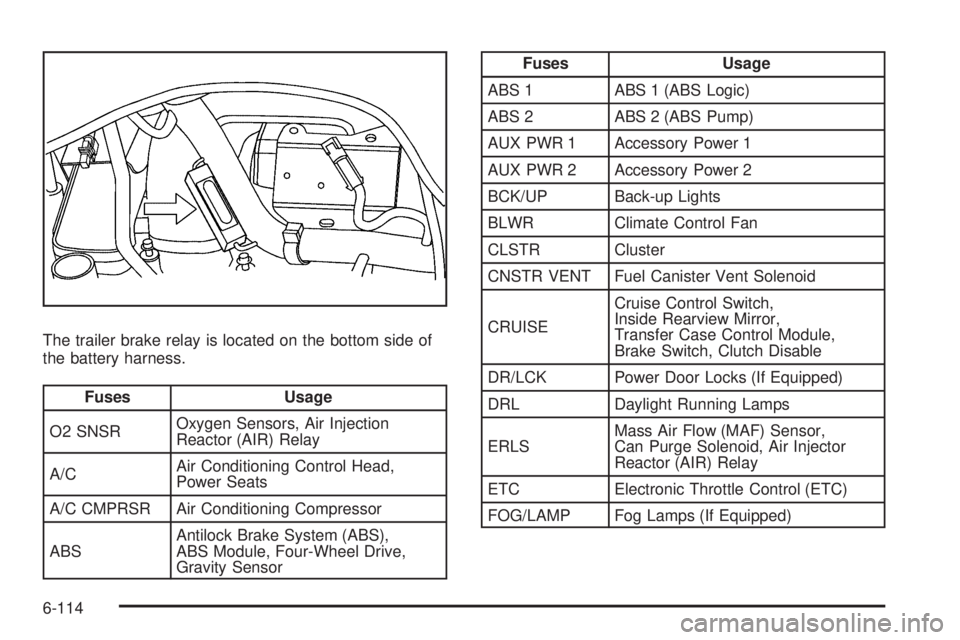

The trailer brake relay is located on the bottom side of

the battery harness.

Fuses Usage

O2 SNSROxygen Sensors, Air Injection

Reactor (AIR) Relay

A/CAir Conditioning Control Head,

Power Seats

A/C CMPRSR Air Conditioning Compressor

ABSAntilock Brake System (ABS),

ABS Module, Four-Wheel Drive,

Gravity Sensor

Fuses Usage

ABS 1 ABS 1 (ABS Logic)

ABS 2 ABS 2 (ABS Pump)

AUX PWR 1 Accessory Power 1

AUX PWR 2 Accessory Power 2

BCK/UP Back-up Lights

BLWR Climate Control Fan

CLSTR Cluster

CNSTR VENT Fuel Canister Vent Solenoid

CRUISECruise Control Switch,

Inside Rearview Mirror,

Transfer Case Control Module,

Brake Switch, Clutch Disable

DR/LCK Power Door Locks (If Equipped)

DRL Daylight Running Lamps

ERLSMass Air Flow (MAF) Sensor,

Can Purge Solenoid, Air Injector

Reactor (AIR) Relay

ETC Electronic Throttle Control (ETC)

FOG/LAMP Fog Lamps (If Equipped)

6-114

Page 400 of 448

•Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system must

be repaired and the fluid level checked.

•Engine air cleaner filter inspection (vehicles driven

in dusty conditions only). SeeEngine Air Cleaner/

Filter on page 6-20.

•Brake system inspection (or every 12 months,

whichever occurs first).

MaintenanceII

•Perform all services described in MaintenanceI.

•Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts

or signs of wear.

•Engine cooling system inspection. Visual inspection

of hoses, pipes, fittings, and clamps and

replacement, if needed.

•Windshield wiper blade inspection for wear, cracking,

or contamination and windshield and wiper blade

cleaning, if contaminated. SeeWindshield and Wiper

Blades on page 6-107. Worn or damaged wiper

blade replacement. SeeWindshield Wiper Blade

Replacement on page 6-55.

•Body hinges and latches, key lock cylinders, and

folding seat hardware lubrication. Lubricate hood

safety lever pivot and prop rod pivot and tailgate

latch bolt, handle assembly pivot points, and hinges.

SeeRecommended Fluids and Lubricants on

page 7-10. More frequent lubrication may be required

when vehicle is exposed to a corrosive environment.

Applying silicone grease on weatherstrips with a

clean cloth makes them last longer, seal better, and

not stick or squeak.

•Restraint system component check. SeeChecking

the Restraint Systems on page 2-81.

•Automatic transmission fluid level check and adding

fluid, if needed. SeeAutomatic Transmission Fluid

on page 6-21.

•Four-wheel drive vehicles: Transfer case fluid level

check and adding fluid, if needed.

•Engine air cleaner filter inspection. SeeEngine Air

Cleaner/Filter on page 6-20.

7-4

Page 401 of 448

Additional Required Services

At Each Fuel Stop

•

Engine oil level check. SeeEngine Oil on page 6-15.

•Engine coolant level check. SeeEngine Coolant on

page 6-29.

•Windshield washer fluid level check. SeeWindshield

Washer Fluid on page 6-38.

Once a Month

•

Tire inflation check. SeeIn�ation - Tire Pressure on

page 6-64.

•Tire wear inspection. SeeTire Inspection and

Rotation on page 6-71.

Once a Year

•

Starter switch check. SeeOwner Checks and

Services on page 7-8.

•Parking brake and automatic transmission P (Park)

mechanism check. SeeOwner Checks and

Services on page 7-8.

•Automatic transmission shiftlock control system

check. SeeOwner Checks and Services on

page 7-8.

•Ignition transmission lock check. SeeOwner

Checks and Services on page 7-8.

•Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. SeeCooling System on page 6-27.

•Exhaust system and nearby heat shields inspection

for loose or damaged components.

•Accelerator pedal check for damage, high effort, or

binding. Replace if needed.

First Engine Oil Change After Every

40 000 km/25,000 Miles

•

Fuel system inspection for damage or leaks.

7-5