brake rotor GMC CANYON 2015 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2015, Model line: CANYON, Model: GMC CANYON 2015Pages: 433, PDF Size: 4.61 MB

Page 351 of 433

Black plate (70,1)GMC Canyon Owner Manual (GMNA-Localizing-U.S./Canada-7587000) -

2015 - CRC - 3/17/15

10-70 Vehicle Care

Warning (Continued)

come off and cause a crash.

If any stud is damaged because

of a loose-running wheel, it could

be that all of the studs are

damaged. To be sure, replace all

studs on the wheel. If the stud

holes in a wheel have become

larger, the wheel could collapse in

operation. Replace any wheel if

its stud holes have become larger

or distorted in any way. Inspect

hubs and hub‐piloted wheels for

damage. Because of loose

running wheels, piloting pad

damage may occur and require

replacement of the entire hub, for

proper centering of the wheels.

When replacing studs, hubs,

wheel nuts or wheels, be sure to

use GM original equipment parts.

{Warning

Wheel nuts that are improperly or

incorrectly tightened can cause

the wheels to become loose or

come off. The wheel nuts should

be tightened with a torque wrench

to the proper torque specification

after replacing. Follow the torque

specification supplied by the

aftermarket manufacturer when

using accessory locking wheel

nuts. SeeCapacities and

Specifications on page 12-2 for

original equipment wheel nut

torque specifications.

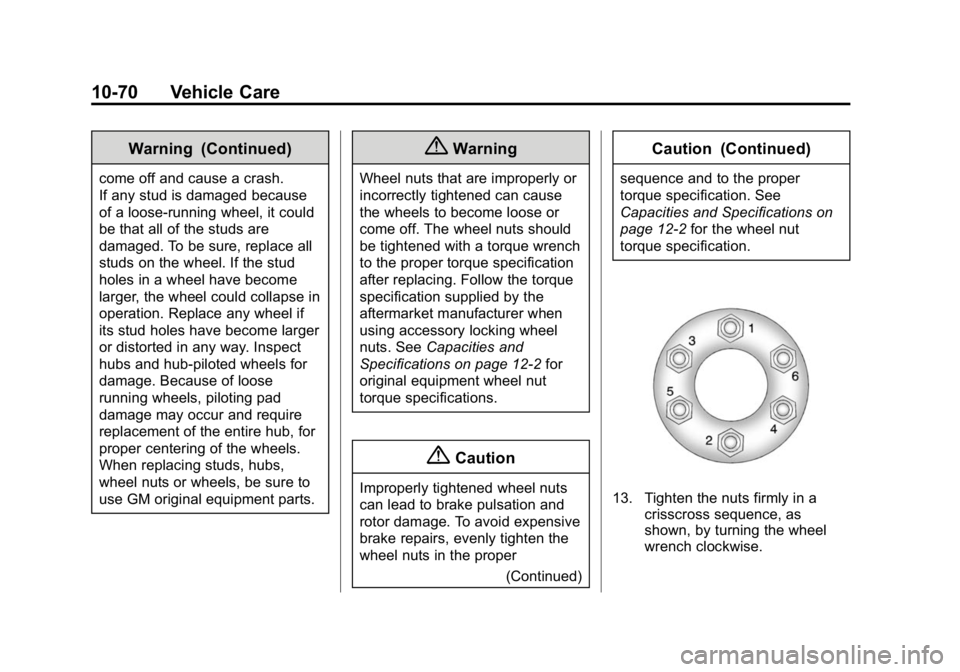

{Caution

Improperly tightened wheel nuts

can lead to brake pulsation and

rotor damage. To avoid expensive

brake repairs, evenly tighten the

wheel nuts in the proper

(Continued)

Caution (Continued)

sequence and to the proper

torque specification. See

Capacities and Specifications on

page 12-2for the wheel nut

torque specification.

13. Tighten the nuts firmly in a crisscross sequence, as

shown, by turning the wheel

wrench clockwise.

Page 368 of 433

Black plate (87,1)GMC Canyon Owner Manual (GMNA-Localizing-U.S./Canada-7587000) -

2015 - CRC - 3/17/15

Vehicle Care 10-87

{Caution

Chrome wheels and other chrome

trim may be damaged if the

vehicle is not washed after driving

on roads that have been sprayed

with magnesium, calcium,

or sodium chloride. These

chlorides are used on roads for

conditions such as ice and dust.

Always wash the chrome with

soap and water after exposure.

{Caution

To avoid surface damage, do not

use strong soaps, chemicals,

abrasive polishes, cleaners,

brushes, or cleaners that contain

acid on aluminum or

chrome-plated wheels. Use only

approved cleaners. Also, never

drive a vehicle with aluminum or

chrome-plated wheels through an(Continued)

Caution (Continued)

automatic car wash that uses

silicone carbide tire cleaning

brushes. Damage could occur

and the repairs would not be

covered by the vehicle warranty.

Brake System

Visually inspect brake lines and

hoses for proper hook-up, binding,

leaks, cracks, chafing, etc. Inspect

disc brake pads for wear and rotors

for surface condition. Inspect drum

brake linings/shoes for wear or

cracks. Inspect other brake parts,

including drums, wheel cylinders,

calipers, parking brake, master

cylinder, brake fluid reservoir,

vacuum pipes, electric vacuum

pump including bracket and vent

hose, if equipped.

Steering, Suspension, and

Chassis Components

Visually inspect steering,

suspension, and chassis

components for damaged, loose,

or missing parts or signs of wear at

least once a year.

Inspect power steering for proper

hook-up, binding, leaks, cracks,

chafing, etc.

Visually check constant velocity joint

boots and axle seals for leaks.

Body Component Lubrication

Lubricate all key lock cylinders,

hood hinges, liftgate hinges, steel

fuel door hinge, and power assist

step hinges, unless the components

are plastic. Applying silicone grease

on weatherstrips with a clean cloth

will make them last longer, seal

better, and not stick or squeak

Underbody Maintenance

At least twice a year, spring and fall,

use plain water to flush any

corrosive materials from the