cooling GMC ENVOY 2003 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2003, Model line: ENVOY, Model: GMC ENVOY 2003Pages: 442, PDF Size: 3.1 MB

Page 323 of 442

6. Start the engine and let it run until you can feel the

upper radiator hose getting hot. Watch out for the

engine cooling fan.

7. By this time, the coolant level inside the radiator

®ller neck may be lower. If the level is lower, add

more of the proper DEX-COOL

žcoolant mixture

through the ®ller neck until the level reaches

the base of the ®ller neck.

8. Then replace the pressure cap. At any time during

this procedure if coolant begins to ¯ow out of the

®ller neck, reinstall the pressure cap. Be sure

the pressure cap is hand-tight.

Engine Fan Noise

This vehicle has a clutched engine cooling fan. When

the clutch is engaged, the fan spins faster to provide

more air to cool the engine. In most everyday driving

conditions the clutch is not engaged. This improves fuel

economy and reduces fan noise. Under heavy vehicle

loading, trailer towing, and/or high outside temperatures,

the fan speed increases when the clutch engages. So

you may hear an increase in fan noise. This is

normal and should not be mistaken as the transmission

slipping or making extra shifts. It is merely the cooling

system functioning properly. The fan will slow down

when additional cooling is not required and the clutch

disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch disengages.

5-35

Page 349 of 442

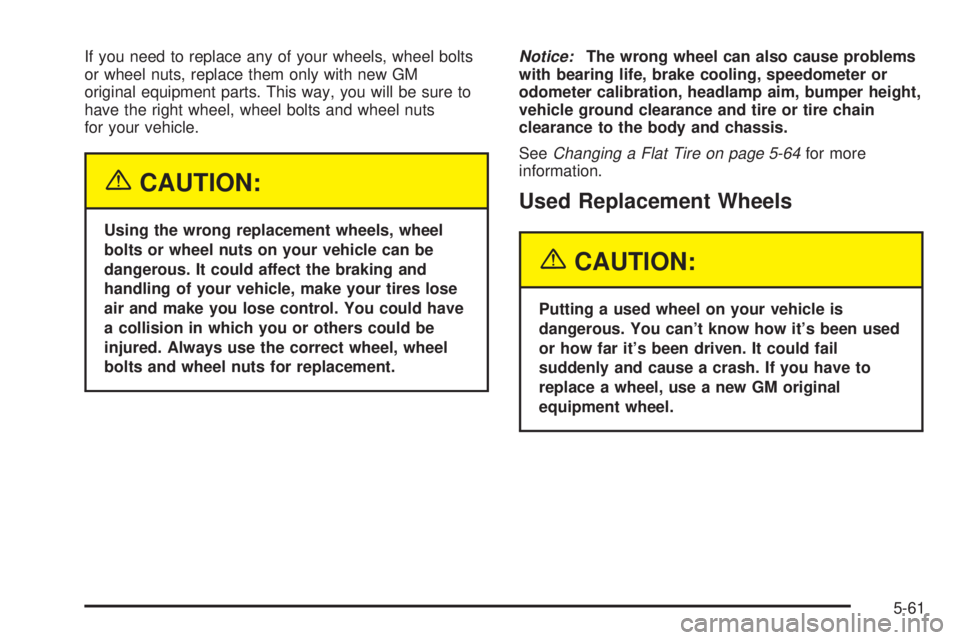

If you need to replace any of your wheels, wheel bolts

or wheel nuts, replace them only with new GM

original equipment parts. This way, you will be sure to

have the right wheel, wheel bolts and wheel nuts

for your vehicle.

{CAUTION:

Using the wrong replacement wheels, wheel

bolts or wheel nuts on your vehicle can be

dangerous. It could affect the braking and

handling of your vehicle, make your tires lose

air and make you lose control. You could have

a collision in which you or others could be

injured. Always use the correct wheel, wheel

bolts and wheel nuts for replacement.

Notice:The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance and tire or tire chain

clearance to the body and chassis.

See

Changing a Flat Tire on page 5-64for more

information.

Used Replacement Wheels

{CAUTION:

Putting a used wheel on your vehicle is

dangerous. You can't know how it's been used

or how far it's been driven. It could fail

suddenly and cause a crash. If you have to

replace a wheel, use a new GM original

equipment wheel.

5-61

Page 381 of 442

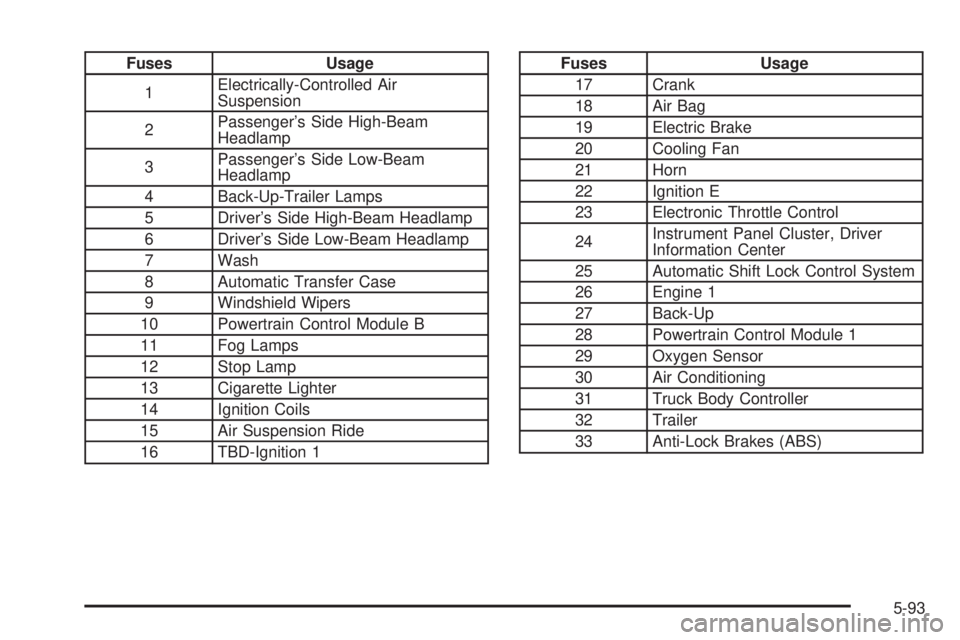

Fuses Usage

1Electrically-Controlled Air

Suspension

2Passenger's Side High-Beam

Headlamp

3Passenger's Side Low-Beam

Headlamp

4 Back-Up-Trailer Lamps

5 Driver's Side High-Beam Headlamp

6 Driver's Side Low-Beam Headlamp

7 Wash

8 Automatic Transfer Case

9 Windshield Wipers

10 Powertrain Control Module B

11 Fog Lamps

12 Stop Lamp

13 Cigarette Lighter

14 Ignition Coils

15 Air Suspension Ride

16 TBD-Ignition 1Fuses Usage

17 Crank

18 Air Bag

19 Electric Brake

20 Cooling Fan

21 Horn

22 Ignition E

23 Electronic Throttle Control

24Instrument Panel Cluster, Driver

Information Center

25 Automatic Shift Lock Control System

26 Engine 1

27 Back-Up

28 Powertrain Control Module 1

29 Oxygen Sensor

30 Air Conditioning

31 Truck Body Controller

32 Trailer

33 Anti-Lock Brakes (ABS)

5-93

Page 382 of 442

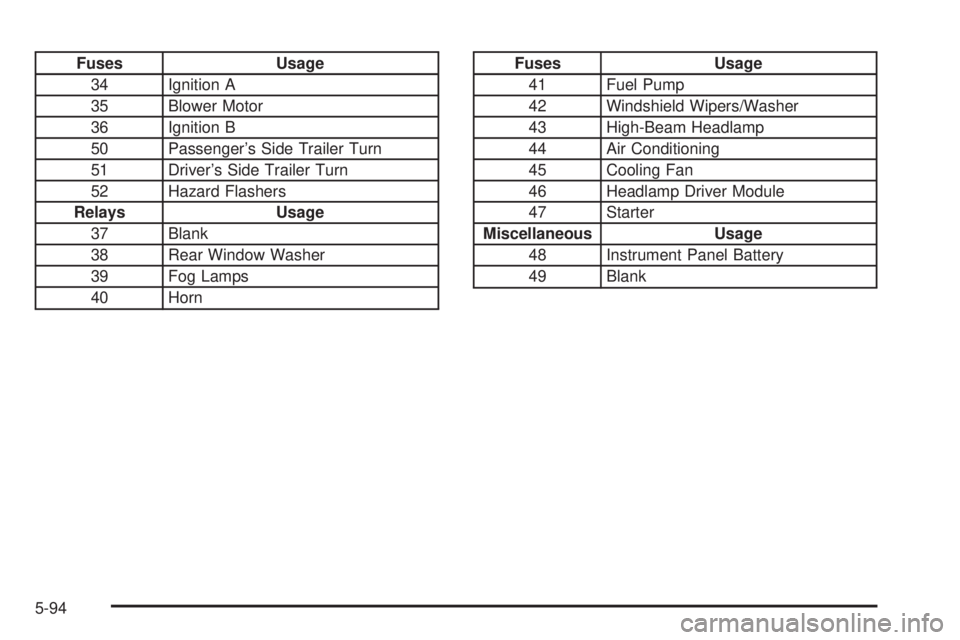

Fuses Usage

34 Ignition A

35 Blower Motor

36 Ignition B

50 Passenger's Side Trailer Turn

51 Driver's Side Trailer Turn

52 Hazard Flashers

Relays Usage

37 Blank

38 Rear Window Washer

39 Fog Lamps

40 HornFuses Usage

41 Fuel Pump

42 Windshield Wipers/Washer

43 High-Beam Headlamp

44 Air Conditioning

45 Cooling Fan

46 Headlamp Driver Module

47 Starter

Miscellaneous Usage

48 Instrument Panel Battery

49 Blank

5-94

Page 384 of 442

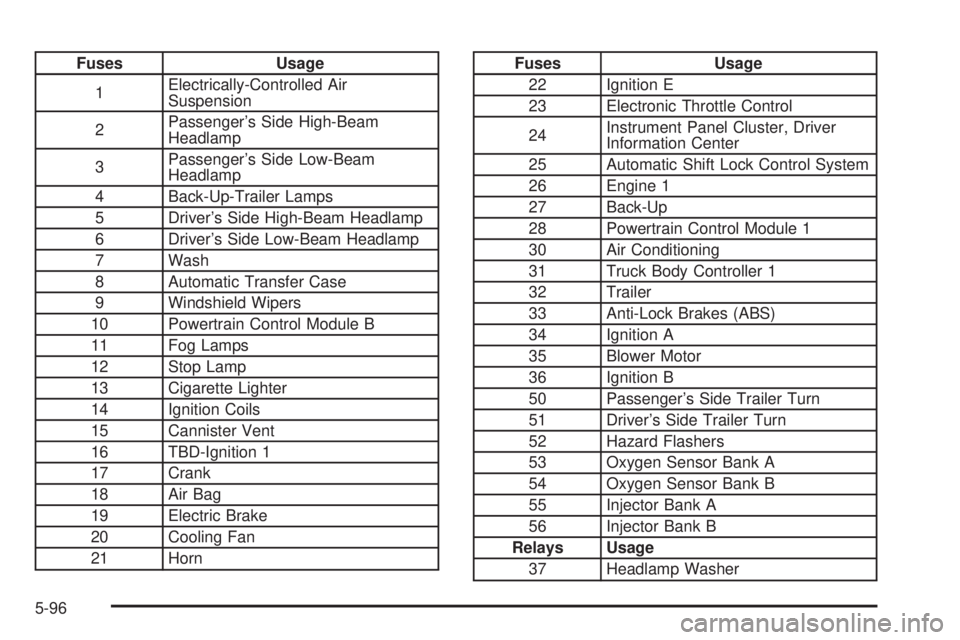

Fuses Usage

1Electrically-Controlled Air

Suspension

2Passenger's Side High-Beam

Headlamp

3Passenger's Side Low-Beam

Headlamp

4 Back-Up-Trailer Lamps

5 Driver's Side High-Beam Headlamp

6 Driver's Side Low-Beam Headlamp

7 Wash

8 Automatic Transfer Case

9 Windshield Wipers

10 Powertrain Control Module B

11 Fog Lamps

12 Stop Lamp

13 Cigarette Lighter

14 Ignition Coils

15 Cannister Vent

16 TBD-Ignition 1

17 Crank

18 Air Bag

19 Electric Brake

20 Cooling Fan

21 HornFuses Usage

22 Ignition E

23 Electronic Throttle Control

24Instrument Panel Cluster, Driver

Information Center

25 Automatic Shift Lock Control System

26 Engine 1

27 Back-Up

28 Powertrain Control Module 1

30 Air Conditioning

31 Truck Body Controller 1

32 Trailer

33 Anti-Lock Brakes (ABS)

34 Ignition A

35 Blower Motor

36 Ignition B

50 Passenger's Side Trailer Turn

51 Driver's Side Trailer Turn

52 Hazard Flashers

53 Oxygen Sensor Bank A

54 Oxygen Sensor Bank B

55 Injector Bank A

56 Injector Bank B

Relays Usage

37 Headlamp Washer

5-96

Page 385 of 442

Fuses Usage

38 Rear Window Washer

39 Fog Lamps

40 Horn

41 Fuel Pump

42 Windshield Wipers/Washer

43 High-Beam Headlamp

44 Air Conditioning

45 Cooling Fan

46 Headlamp Driver Module

47 Starter

58 Ignition 1

Miscellaneous Usage

48 Instrument Panel BatteryRear Underseat Fuse Block

L6 Engine

5-97

Page 390 of 442

Capacities and Speci®cations

Capacities and Speci®cations

Engine VIN Code Transmission Spark Plug Gap Firing Order

ªVORTECŸ º 4200 L6 S M300.042 inches

(1.07 mm)1±5-3±6±2±4

ªVORTECŸ º 5300 V8 P M300.060 inches

(1.52 mm)1±8±7±2±6±5±4±3

ApplicationL6 Engine V8 Engine

English Metric English Metric

Wheel Nut Torque 100 lb ft 140Y100 lb ft 140Y

Cooling System

Envoy 13.9 quarts 13.1 L Ð Ð

Envoy XL 15.2 quarts 14.4 L 17.9 quarts 17.0 L

Air Conditioning Refrigerant R/134a

Envoy 1.9 lbs. 0.9 kg Ð Ð

Envoy XL 2.8 lbs. 1.27 kg 2.8 lbs. 1.27 kg

Engine Oil with Filter 7.0 quarts 6.6 L 6.0 quarts 5.7 L

5-102

Page 393 of 442

Maintenance Schedule......................................6-2

Introduction...................................................6-2

Your Vehicle and the Environment....................6-2

Maintenance Requirements..............................6-2

How This Section is Organized.........................6-3

Part A: Scheduled Maintenance Services...........6-4

Using Your Maintenance Schedule....................6-4

Scheduled Maintenance...................................6-5

Part B: Owner Checks and Services................6-11

At Each Fuel Fill..........................................6-11

At Least Once a Month.................................6-11

At Least Twice a Year...................................6-12At Least Once a Year...................................6-13

Part C: Periodic MaintenanceInspections.........6-16

Steering, Suspension and Front Drive Axle

Boot and Seal Inspection............................6-16

Exhaust System Inspection............................6-16

Fuel System Inspection..................................6-16

Engine Cooling System Inspection...................6-17

Transfer Case and Front Axle (Four-Wheel

Drive) Inspection.......................................6-17

Brake System Inspection................................6-17

Part D: Recommended Fluids and Lubricants. . . .6-18

Part E: Maintenance Record...........................6-20

Section 6 Maintenance Schedule

6-1

Page 402 of 442

100,000 Miles (166 000 km)

qV8 Engine Only: Inspect spark plug wires.An

Emission Control Service.

qReplace spark plugs.An Emission Control Service.

qChange automatic transmission ¯uid and ®lter if

the vehicle is mainly driven under one or more

of these conditions:

þ In heavy city traffic where the outside

temperature regularly reaches 90ÉF (32ÉC) or

higher.

þ In hilly or mountainous terrain.

þ When doing frequent trailer towing.

þ Uses such as found in taxi, police or delivery

service.

qIf you haven't used your vehicle under severe service

conditions listed previously and, therefore, haven't

changed your automatic transmission ¯uid, change

both the ¯uid and ®lter

qAutomatic Transfer Case Only: Change transfer case

¯uid.

qV8 Engine Only: Inspect Positive Crankcase

Ventilation (PCV) valve.

An Emission Control Service.

150,000 Miles (240 000 km)

qDrain, ¯ush and re®ll cooling system (or every

60 months since last service, whichever occurs ®rst).

See

Engine Coolant on page 5-24for what to use.

Inspect hoses. Clean radiator, condenser, pressure

cap and neck. Pressure test the cooling system

and pressure cap.

An Emission Control Service.

qInspect engine accessory drive belt.An Emission

Control Service.

6-10

Page 409 of 442

Engine Cooling System Inspection

Inspect the hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

®ttings and clamps; replace as needed. Clean the

outside of the radiator and air conditioning condenser.

To help ensure proper operation, a pressure test of

the cooling system and pressure cap is recommended

at least once a year.

Transfer Case and Front Axle

(Four-Wheel Drive) Inspection

Every 12 months or at engine oil change intervals,

check front axle and transfer case and add lubricant

when necessary. A ¯uid loss could indicate a problem;

check and have it repaired, if needed. Check vent

hose at transfer case for kinks and proper installation.

More frequent lubrication may be required on

off-road use.

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook-up, binding, leaks, cracks,

cha®ng, etc. Inspect disc brake pads for wear and rotors

for surface condition. Inspect other brake parts,

including calipers, parking brake, etc. Check parking

brake adjustment. You may need to have your brakes

inspected more often if your driving habits or

conditions result in frequent braking.

6-17