trailer GMC ENVOY 2003 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2003, Model line: ENVOY, Model: GMC ENVOY 2003Pages: 442, PDF Size: 3.1 MB

Page 287 of 442

{CAUTION:

It can be dangerous to get out of your vehicle

if the shift lever is not fully in PARK (P) with

the parking brake ®rmly set. Your vehicle

can roll.

If you have left the engine running, the vehicle

can move suddenly. You or others could be

injured. To be sure your vehicle won't move,

even when you're on fairly level ground, use

the steps that follow.

Always put the shift lever fully in PARK (P)

with the parking brake ®rmly set.

If the transfer case on four-wheel drive

vehicles is in NEUTRAL, your vehicle will be

free to roll, even if your shift lever is in

PARK (P). So, be sure the transfer case is in a

drive gear Ð not in NEUTRAL.

See ªFour-Wheel Drive (Automatic Transfer

Case)º in the Index.

When You Are Ready to Leave After

Parking on a Hill

1. Apply your regular brakes and hold the pedal down

while you:

·start your engine,

·shift into a gear, and

·release the parking brake.

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the

chocks.

Maintenance When Trailer Towing

Your vehicle will need service more often when you're

pulling a trailer. See the Maintenance Schedule for more

on this. Things that are especially important in trailer

operation are automatic transmission ¯uid (don't over®ll),

engine oil, axle lubricant, belt(s), cooling system and

brake system. Each of these is covered in this manual,

and the Index will help you ®nd them quickly. If

you're trailering, it's a good idea to review these sections

before you start your trip.

Check periodically to see that all hitch nuts and bolts

are tight.

4-59

Page 288 of 442

Trailer Wiring Harness

Your vehicle may be equipped with the seven-wire

trailer towing harness. This harness has a seven-pin

universal heavy-duty trailer connector that is attached to

a bracket on the hitch platform.The seven-wire harness contains the following trailer

circuits:

·Yellow: Left Stop/Turn Signal

·Dark Green: Right Stop/Turn Signal

·Brown: Running Lamps

·White: Ground

·Light Green: Back-up Lamps

·Red: Battery Feed

·Dark Blue: Electric Brakes

If you need to tow a light-duty trailer with a standard

four-way round pin connector, an adapter connector is

available from your dealer.

Your vehicle may also be equipped with wiring for an

electric trailer brake controller. These wires are located

inside the vehicle on the driver's side under the

instrument panel. These wires should be connected to

an electric trailer brake controller by your dealer or

a quali®ed service center.

4-60

Page 309 of 442

To inspect or replace the ®lter and reset the indicator (if

equipped), do the following:

1. Remove the screws on the engine cleaner/®lter and

lift off the cover.

2. Remove the air cleaner/®lter from the housing. Care

should be taken to dislodge as little dirt as possible.

3. Install the new engine air cleaner/®lter.

4. Reinstall the cover and tighten the screws.

{CAUTION:

Operating the engine with the air cleaner/®lter

off can cause you or others to be burned. The

air cleaner not only cleans the air, it helps to

stop ¯ame if the engine back®res. If it isn't there

and the engine back®res, you could be burned.

Don't drive with it off, and be careful working on

the engine with the air cleaner/®lter off.

Notice:If the air cleaner/®lter is off, a back®re can

cause a damaging engine ®re. And, dirt can

easily get into your engine, which will damage it.

Always have the air cleaner/®lter in place when

you're driving.

Automatic Transmission Fluid

When to Check and Change

A good time to check your automatic transmission ¯uid

level is when the engine oil is changed.

Change both the ¯uid and ®lter every 50,000 miles

(83 000 km) if the vehicle is mainly driven under one or

more of these conditions:

·In heavy city traffic where the outside temperature

regularly reaches 90ÉF (32ÉC) or higher.

·In hilly or mountainous terrain.

·When doing frequent trailer towing.

·Uses such as found in taxi, police or delivery

service.

If you do not use your vehicle under any of these

conditions, change the ¯uid and ®lter every

100,000 miles (166 000 km).

5-21

Page 310 of 442

How to Check

Because this operation can be a little difficult, you may

choose to have this done at the dealership service

department.

If you do it yourself, be sure to follow all the instructions

here, or you could get a false reading on the dipstick.

Notice:Too much or too little ¯uid can damage

your transmission. Too much can mean that some

of the ¯uid could come out and fall on hot engine

part or exhaust system parts, starting a ®re.

Too little ¯uid could cause the transmission to

overheat. Be sure to get an accurate reading if you

check your transmission ¯uid.

Wait at least 30 minutes before checking the

transmission ¯uid level if you have been driving:

·When outside temperatures are above 90ÉF (32ÉC).

·At high speed for quite a while.

·In heavy traffic-especially in hot weather.

·While pulling a trailer.

To get the right reading, the ¯uid should be at normal

operating temperature, which is 180ÉF to 200ÉF

(82ÉC to 93ÉC).Get the vehicle warmed up by driving about 15 miles

(24 km) when outside temperatures are above 50ÉF

(10ÉC). If it's colder than 50ÉF (10ÉC), drive the vehicle

in THIRD (3) until the engine temperature gage

moves and then remains steady for 10 minutes.

A cold ¯uid check can be made after the vehicle has

been sitting for eight hours or more with the engine off,

but this is used only as a reference. Let the engine

run at idle for ®ve minutes if outside temperatures are

50ÉF (10ÉC) or more. If it's colder than 50ÉF (10ÉC), you

may have to idle the engine longer. Should the ¯uid

level be low during this cold check, you

mustcheck the

¯uid hot before adding ¯uid. Checking the ¯uid hot

will give you a more accurate reading of the ¯uid level.

Checking the Fluid Level

Prepare your vehicle as follows:

·Park your vehicle on a level place. Keep the engine

running.

·With the parking brake applied, place the shift lever

in PARK (P).

·With your foot on the brake pedal, move the shift

lever through each gear range, pausing for about

three seconds in each range. Then, position the shift

lever in PARK (P).

·Let the engine run at idle for three minutes or more.

5-22

Page 316 of 442

If No Steam Is Coming From Your

Engine

If you get an engine overheat warning but see or hear

no steam, the problem may not be too serious.

Sometimes the engine can get a little too hot when you:

·Climb a long hill on a hot day.

·Stop after high-speed driving.

·Idle for long periods in traffic.

·Tow a trailer.

If you get the overheat warning with no sign of steam,

try this for a minute or so:

1. In heavy traffic, let the engine idle in neutral while

stopped. If it is safe to do so, pull off the road,

shift to PARK (P) or NEUTRAL (N) and let

the engine idle.

2. Turn on your heater to full hot at the highest fan

speed and open the window as necessary.If you no longer have the overheat warning, you can

drive. Just to be safe, drive slower for about 10 minutes.

If the warning doesn't come back on, you can drive

normally.

If the warning continues and you have not stopped, pull

over, stop, and park your vehicle right away.

If there's still no sign of steam, you can push down the

accelerator until the engine speed is about twice as

fast as normal idle speed for at least three minutes while

you're parked. If you still have the warning,

turn off

the engine and get everyone out of the vehicleuntil it

cools down.

You may decide not to lift the hood but to get service

help right away.

5-28

Page 323 of 442

6. Start the engine and let it run until you can feel the

upper radiator hose getting hot. Watch out for the

engine cooling fan.

7. By this time, the coolant level inside the radiator

®ller neck may be lower. If the level is lower, add

more of the proper DEX-COOL

žcoolant mixture

through the ®ller neck until the level reaches

the base of the ®ller neck.

8. Then replace the pressure cap. At any time during

this procedure if coolant begins to ¯ow out of the

®ller neck, reinstall the pressure cap. Be sure

the pressure cap is hand-tight.

Engine Fan Noise

This vehicle has a clutched engine cooling fan. When

the clutch is engaged, the fan spins faster to provide

more air to cool the engine. In most everyday driving

conditions the clutch is not engaged. This improves fuel

economy and reduces fan noise. Under heavy vehicle

loading, trailer towing, and/or high outside temperatures,

the fan speed increases when the clutch engages. So

you may hear an increase in fan noise. This is

normal and should not be mistaken as the transmission

slipping or making extra shifts. It is merely the cooling

system functioning properly. The fan will slow down

when additional cooling is not required and the clutch

disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch disengages.

5-35

Page 381 of 442

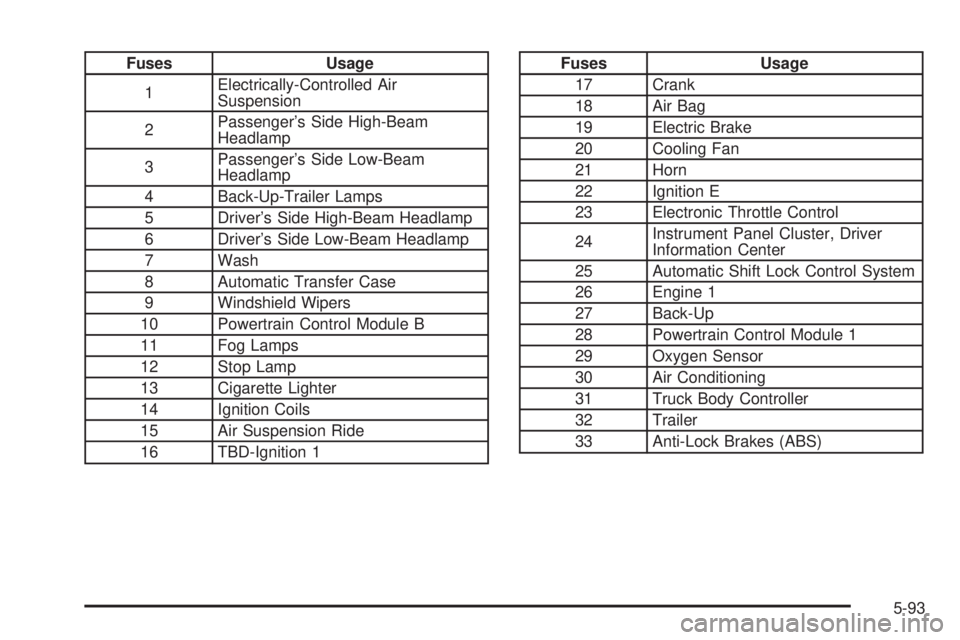

Fuses Usage

1Electrically-Controlled Air

Suspension

2Passenger's Side High-Beam

Headlamp

3Passenger's Side Low-Beam

Headlamp

4 Back-Up-Trailer Lamps

5 Driver's Side High-Beam Headlamp

6 Driver's Side Low-Beam Headlamp

7 Wash

8 Automatic Transfer Case

9 Windshield Wipers

10 Powertrain Control Module B

11 Fog Lamps

12 Stop Lamp

13 Cigarette Lighter

14 Ignition Coils

15 Air Suspension Ride

16 TBD-Ignition 1Fuses Usage

17 Crank

18 Air Bag

19 Electric Brake

20 Cooling Fan

21 Horn

22 Ignition E

23 Electronic Throttle Control

24Instrument Panel Cluster, Driver

Information Center

25 Automatic Shift Lock Control System

26 Engine 1

27 Back-Up

28 Powertrain Control Module 1

29 Oxygen Sensor

30 Air Conditioning

31 Truck Body Controller

32 Trailer

33 Anti-Lock Brakes (ABS)

5-93

Page 382 of 442

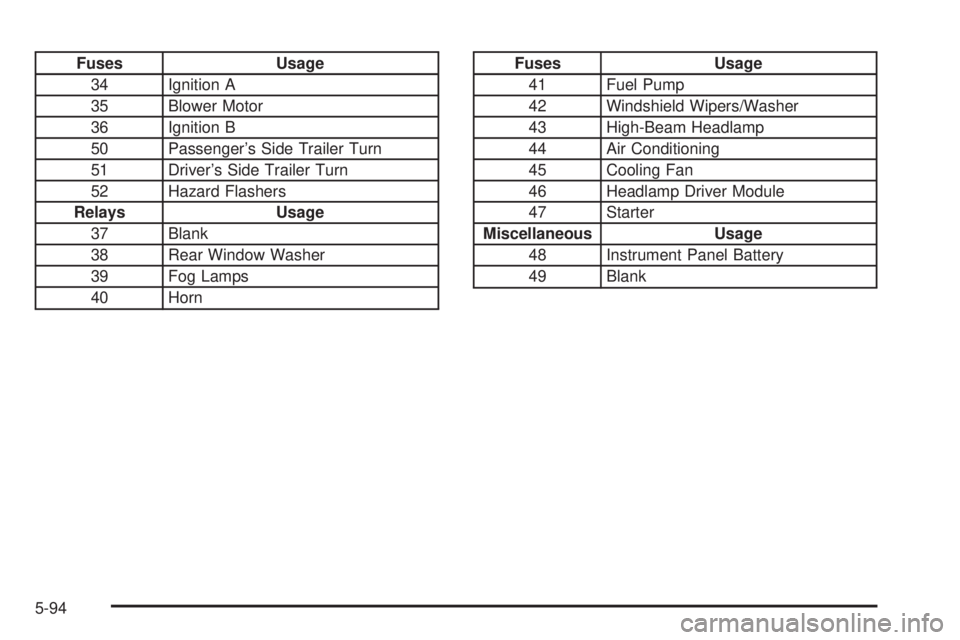

Fuses Usage

34 Ignition A

35 Blower Motor

36 Ignition B

50 Passenger's Side Trailer Turn

51 Driver's Side Trailer Turn

52 Hazard Flashers

Relays Usage

37 Blank

38 Rear Window Washer

39 Fog Lamps

40 HornFuses Usage

41 Fuel Pump

42 Windshield Wipers/Washer

43 High-Beam Headlamp

44 Air Conditioning

45 Cooling Fan

46 Headlamp Driver Module

47 Starter

Miscellaneous Usage

48 Instrument Panel Battery

49 Blank

5-94

Page 384 of 442

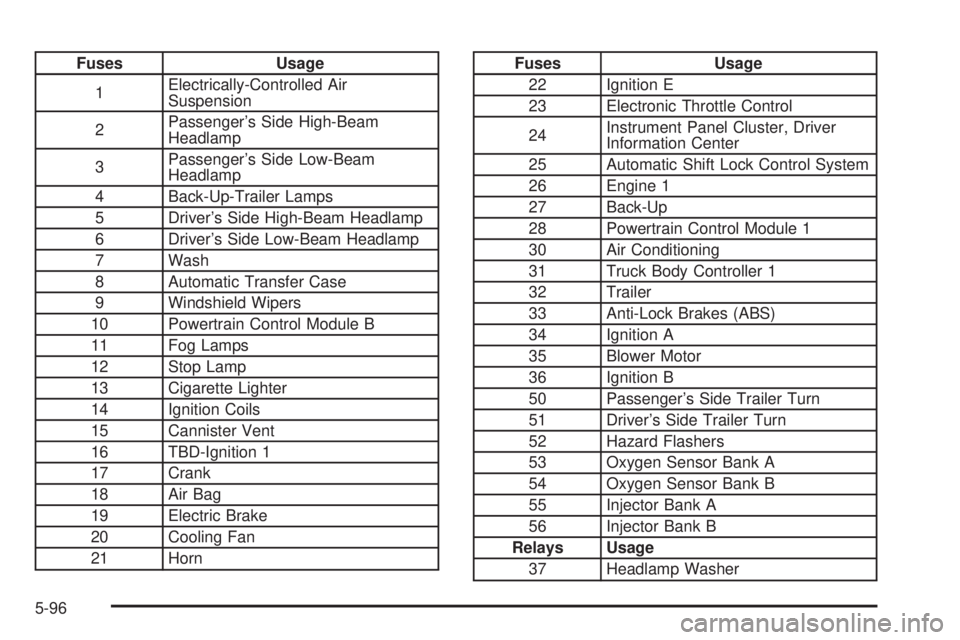

Fuses Usage

1Electrically-Controlled Air

Suspension

2Passenger's Side High-Beam

Headlamp

3Passenger's Side Low-Beam

Headlamp

4 Back-Up-Trailer Lamps

5 Driver's Side High-Beam Headlamp

6 Driver's Side Low-Beam Headlamp

7 Wash

8 Automatic Transfer Case

9 Windshield Wipers

10 Powertrain Control Module B

11 Fog Lamps

12 Stop Lamp

13 Cigarette Lighter

14 Ignition Coils

15 Cannister Vent

16 TBD-Ignition 1

17 Crank

18 Air Bag

19 Electric Brake

20 Cooling Fan

21 HornFuses Usage

22 Ignition E

23 Electronic Throttle Control

24Instrument Panel Cluster, Driver

Information Center

25 Automatic Shift Lock Control System

26 Engine 1

27 Back-Up

28 Powertrain Control Module 1

30 Air Conditioning

31 Truck Body Controller 1

32 Trailer

33 Anti-Lock Brakes (ABS)

34 Ignition A

35 Blower Motor

36 Ignition B

50 Passenger's Side Trailer Turn

51 Driver's Side Trailer Turn

52 Hazard Flashers

53 Oxygen Sensor Bank A

54 Oxygen Sensor Bank B

55 Injector Bank A

56 Injector Bank B

Relays Usage

37 Headlamp Washer

5-96

Page 387 of 442

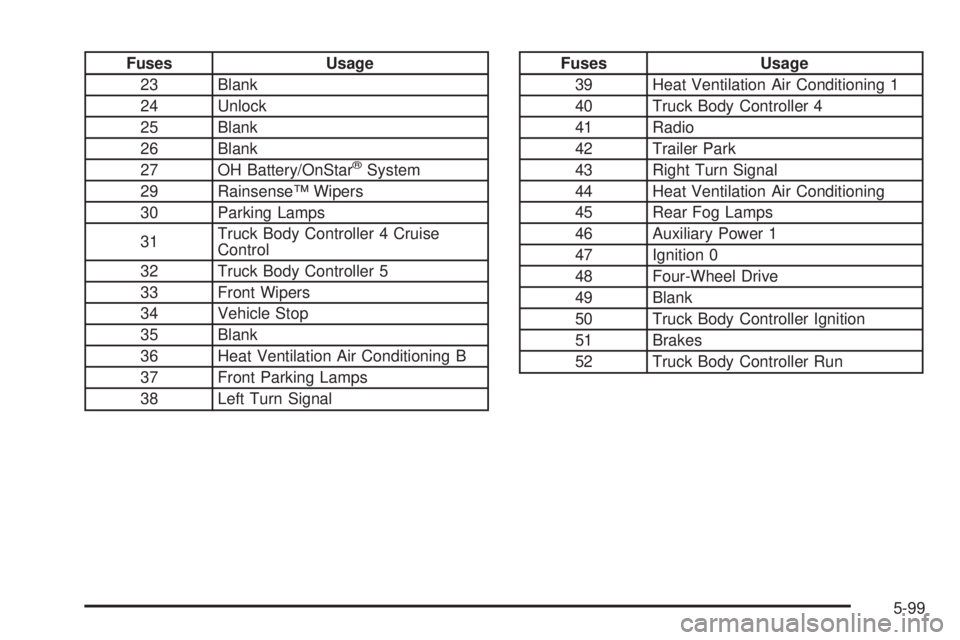

Fuses Usage

23 Blank

24 Unlock

25 Blank

26 Blank

27 OH Battery/OnStar

žSystem

29 RainsenseŸ Wipers

30 Parking Lamps

31Truck Body Controller 4 Cruise

Control

32 Truck Body Controller 5

33 Front Wipers

34 Vehicle Stop

35 Blank

36 Heat Ventilation Air Conditioning B

37 Front Parking Lamps

38 Left Turn Signal

Fuses Usage

39 Heat Ventilation Air Conditioning 1

40 Truck Body Controller 4

41 Radio

42 Trailer Park

43 Right Turn Signal

44 Heat Ventilation Air Conditioning

45 Rear Fog Lamps

46 Auxiliary Power 1

47 Ignition 0

48 Four-Wheel Drive

49 Blank

50 Truck Body Controller Ignition

51 Brakes

52 Truck Body Controller Run

5-99