brake GMC JIMMY 2005 Manual PDF

[x] Cancel search | Manufacturer: GMC, Model Year: 2005, Model line: JIMMY, Model: GMC JIMMY 2005Pages: 432, PDF Size: 2.65 MB

Page 339 of 432

{CAUTION:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without

the appropriate safety equipment and training.

The jack provided with your vehicle is

designed only for changing a �at tire. If it is

used for anything else, you or others could be

badly injured or killed if the vehicle slips off

the jack. Use the jack provided with your

vehicle only for changing a �at tire.

If a tire goes �at, the next part shows how to use your

jacking equipment to change a �at tire safely.

Changing a Flat Tire

If a tire goes �at, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your

hazard warning �ashers.

{CAUTION:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you

or other people. You and they could be badly

injured or even killed. Find a level place to

change your tire. To help prevent the vehicle

from moving:

1. Set the parking brake �rmly.

2. Put an automatic transmission shift lever in

PARK (P), or shift a manual transmission to

FIRST (1) or REVERSE (R).

3. Turn off the engine and do not restart while

the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

Put the wheel blocks at the front and rear of the

tire farthest away from the one being changed.

That would be the tire on the other side, at the

opposite end of the vehicle.

5-67

Page 347 of 432

9. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci�cation. SeeCapacities

and Specifications on page 5-95for wheel nut

torque speci�cation.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. SeeCapacities and

Specifications on page 5-95for the wheel nut torque

speci�cation.

5-75

Page 364 of 432

Fuse Usage

6 Steering Wheel Radio Controls

7Headlamps Switch, Body Control

Module, Headlamp Relay

8Courtesy Lamps, Battery Run-Down

Protection

9Heating, Ventilation, Air Cooling

Control Head (Manual)

10 Turn Signal

11 Cluster, Engine Control Module

12 Interior Lights

13 Auxiliary Power

14 Power Locks Motor

154WD Switch, Engine Controls (VCM,

PCM, Transmission)

16 Supplemental In�atable Restraint

17 Front Wiper

18 Steering Wheel Radio Controls

19 Radio, Battery

20 Ampli�er

21Heating, Ventilation, Air Cooling

(Manual), Heating,Ventilation, Air

Cooling (Automatic), Heating,

Ventilation, Air Cooling Sensors

(Automatic)

22 Anti-Lock BrakesFuse Usage

23 Rear Wiper

24 Radio, Ignition

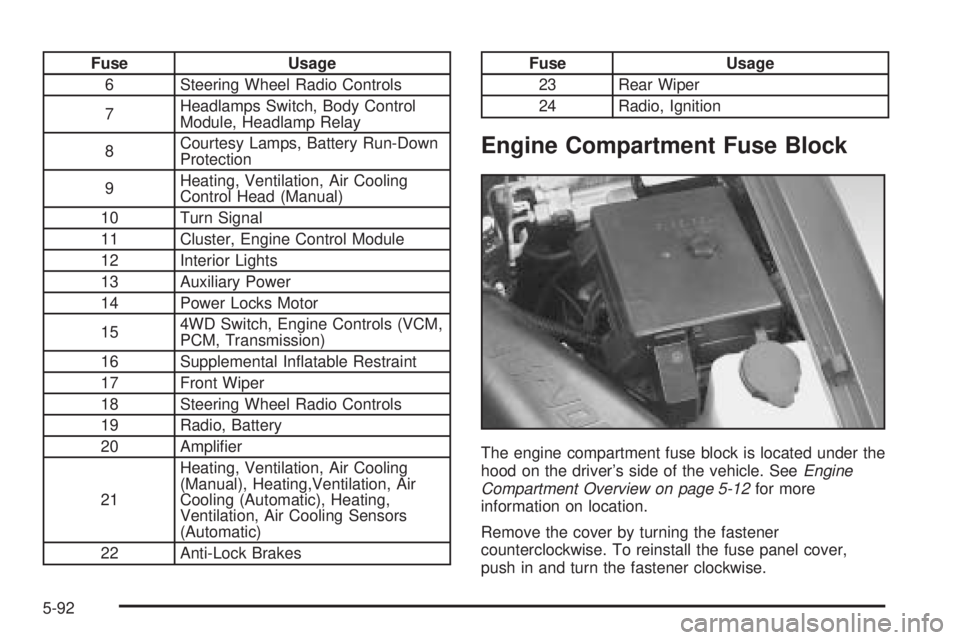

Engine Compartment Fuse Block

The engine compartment fuse block is located under the

hood on the driver’s side of the vehicle. SeeEngine

Compartment Overview on page 5-12for more

information on location.

Remove the cover by turning the fastener

counterclockwise. To reinstall the fuse panel cover,

push in and turn the fastener clockwise.

5-92

Page 365 of 432

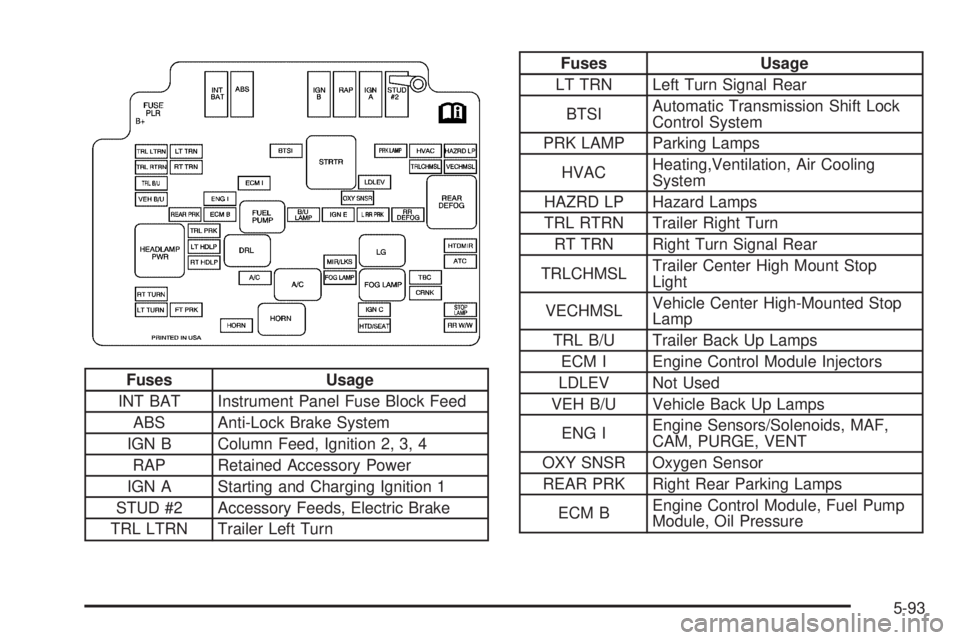

Fuses Usage

INT BAT Instrument Panel Fuse Block Feed

ABS Anti-Lock Brake System

IGN B Column Feed, Ignition 2, 3, 4

RAP Retained Accessory Power

IGN A Starting and Charging Ignition 1

STUD #2 Accessory Feeds, Electric Brake

TRL LTRN Trailer Left Turn

Fuses Usage

LT TRN Left Turn Signal Rear

BTSIAutomatic Transmission Shift Lock

Control System

PRK LAMP Parking Lamps

HVACHeating,Ventilation, Air Cooling

System

HAZRD LP Hazard Lamps

TRL RTRN Trailer Right Turn

RT TRN Right Turn Signal Rear

TRLCHMSLTrailer Center High Mount Stop

Light

VECHMSLVehicle Center High-Mounted Stop

Lamp

TRL B/U Trailer Back Up Lamps

ECM I Engine Control Module Injectors

LDLEV Not Used

VEH B/U Vehicle Back Up Lamps

ENG IEngine Sensors/Solenoids, MAF,

CAM, PURGE, VENT

OXY SNSR Oxygen Sensor

REAR PRK Right Rear Parking Lamps

ECM BEngine Control Module, Fuel Pump

Module, Oil Pressure

5-93

Page 369 of 432

Maintenance Schedule......................................6-2

Introduction...................................................6-2

Maintenance Requirements..............................6-2

Your Vehicle and the Environment....................6-2

How This Section is Organized.........................6-3

Part A: Scheduled Maintenance Services...........6-4

Using Your Maintenance Schedule....................6-4

Selecting the Right Schedule...........................6-5

Short Trip/City Scheduled Maintenance..............6-6

Long Trip/Highway Scheduled Maintenance......6-18

Part B: Owner Checks and Services................6-26

At Each Fuel Fill..........................................6-26

At Least Once a Month.................................6-26

At Least Twice a Year...................................6-27

At Least Once a Year...................................6-28Part C: Periodic Maintenance Inspections.........6-31

Steering, Suspension and Front Drive

Axle Boot and Seal Inspection....................6-31

Exhaust System Inspection............................6-31

Fuel System Inspection..................................6-31

Engine Cooling System Inspection...................6-31

Throttle System Inspection.............................6-32

Transfer Case and Front Axle (Four-Wheel

Drive) Inspection.......................................6-32

Brake System Inspection................................6-32

Part D: Recommended Fluids and Lubricants. . . .6-33

Normal Maintenance Replacement Parts..........6-35

Part E: Maintenance Record...........................6-36

Section 6 Maintenance Schedule

6-1

Page 375 of 432

Footnotes

†The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

#Lubricate the front suspension, ball joints, steering

linkage, parking brake cable guides, propshaft splines,

universal joints and brake pedal springs.

+A good time to check your brakes is during tire

rotation. See Brake System Inspection on page 6-32.

**Drive axle service. See Part D: Recommended Fluids

and Lubricants on page 6-33for proper lubricant to use:

Check �uid level and add �uid as needed. If driving in

dusty areas or when towing a trailer, drain �uid and

re�ll every 15,000 miles (25 000 km).

If your vehicle has a locking differential, drain �uid

and re�ll at �rst engine oil change.

More frequent lubrication may be required for

heavy-duty or off-road use.

3,000 Miles (5 000 km)

❑Change engine oil and �lter (or every 3 months,

whichever occurs �rst).An Emission Control Service.

❑Lubricate chassis components (or every 3 months,

whichever occurs �rst).(See footnote #.)

❑Check rear/front axle �uid level and add �uid as

needed. Check constant velocity joints and axle seals

for leaking.(See footnote **.)

6,000 Miles (10 000 km)

❑Change engine oil and �lter (or every 3 months,

whichever occurs �rst).An Emission Control Service.

❑Lubricate chassis components (or every 3 months,

whichever occurs �rst).(See footnote #.)

❑Check rear/front axle �uid level and add �uid as

needed. Check constant velocity joints and axle seals

for leaking.(See footnote **.)

❑Rotate tires. SeeTire Inspection and Rotation on

page 5-60for proper rotation pattern and additional

information.(See footnote +.)

6-7

Page 386 of 432

Long Trip/Highway Scheduled

Maintenance

The services shown in this schedule up to 100,000 miles

(166 000 km) should be repeated after 100,000 miles

(166 000 km) at the same intervals for the life of

this vehicle. The services shown at 150,000 miles

(240 000 km) should be repeated at the same interval

after 150,000 miles (240 000 km) for the life of this

vehicle.

SeePart B: Owner Checks and Services on page 6-26

andPart C: Periodic Maintenance Inspections on

page 6-31.

Footnotes

†The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

#Lubricate the front suspension, ball joints, steering

linkage, parking brake cable guides, propshaft splines,

universal joints and brake pedal springs.

+A good time to check your brakes is during tire

rotation. See Brake System Inspection on page 6-32.

**Drive axle service. See Part D: Recommended Fluids

and Lubricants on page 6-33for proper lubricant to use.

Check �uid level and add �uid as needed.

If your vehicle has a locking differential, drain �uid

and re�ll at �rst engine oil change.

6-18

Page 396 of 432

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

speci�ed in Part D.

Body Lubrication Service

Lubricate all hood hinges, hood latch assembly,

secondary latch, pivots, spring anchor, release pawl,

door hinges, fuel door hinge, endgate hinges, outer

tailgate handle pivot points, tailgate hinges, tailgate

mounted spare tire (if equipped), glove box and console

doors, moving seat hardware and folding seat

hardware. Part D tells you what to use. More frequent

lubrication may be required when exposed to a corrosive

environment.

Starter Switch Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-36if

necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. On automatic transmission vehicles, try to start the

engine in each gear. The starter should work only

in PARK (P) or NEUTRAL (N). If the starter works in

any other position, your vehicle needs service.

On manual transmission vehicles, put the shift lever

in NEUTRAL (N), push the clutch down halfway and

try to start the engine. The starter should work only

when the clutch is pushed down all the way to the

�oor. If the starter works when the clutch is not

pushed all the way down, your vehicle needs service.

6-28

Page 397 of 432

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake, SeeParking Brake

on page 2-36if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the ignition to RUN, but do

not start the engine. Without applying the regular

brake, try to move the shift lever out of PARK (P)

with normal effort. If the shift lever moves out

of PARK (P), your vehicle needs service.

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition to LOCK in each shift lever position.

With an automatic transmission, the ignition should

turn to LOCK only when the shift lever is in

PARK (P).

With a manual transmission, the ignition should turn

to LOCK only when you press the key release

button.

On all vehicles, the key should come out only in LOCK.

6-29

Page 398 of 432

Parking Brake and Automatic

Transmission Park (P)

Mechanism Check

{CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could be

injured and property could be damaged. Make

sure there is room in front of your vehicle in

case it begins to roll. Be ready to apply the

regular brake at once should the vehicle begin

to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake, set the

parking brake.

To check the parking brake’s holding ability: With

the engine running and transmission in

NEUTRAL (N), slowly remove foot pressure form

the regular brake pedal. Do this until the vehicle is

held by the parking brake only.

To check the PARK (P) mechanism’s holding ability:

With the engine running, shift to PARK (P). Then

release the parking brake followed by the

regular brake.

Underbody Flushing Service

At least every spring, use plain water to �ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

6-30