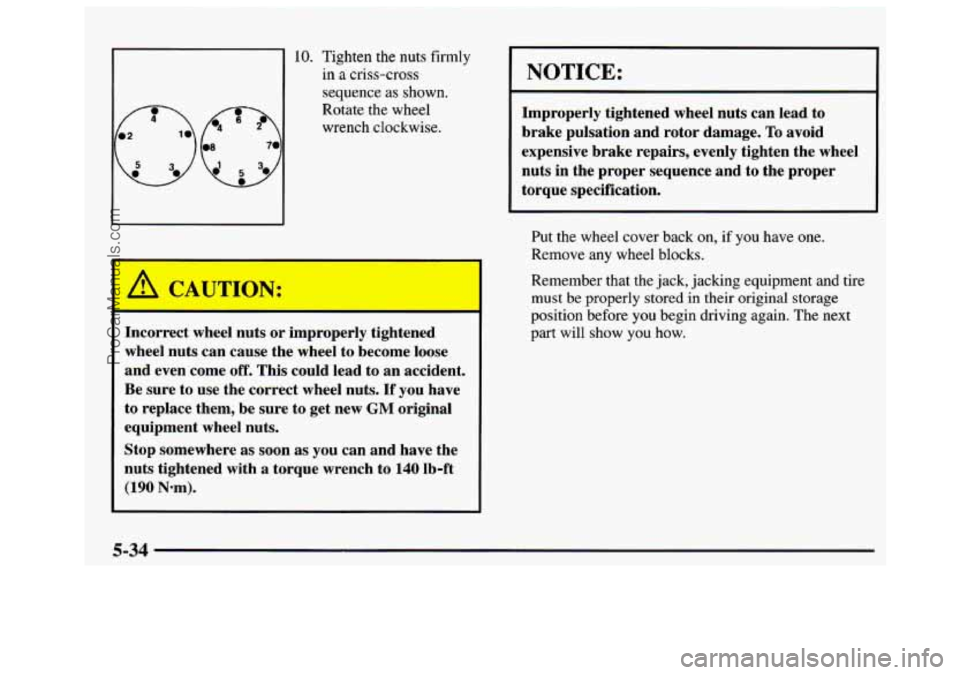

10. Tighten the nuts firmly

in a criss-cross

sequence as shown.

p

Rotate the wheel

wrench clockwise.

A CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to become loose

and even come

off. This could lead to an accident.

Be sure to use the correct wheel nuts.

If you have

to replace them, be sure to get new

GM original

equipment wheel nuts.

Stop somewhere as soon as

you can and have the

nuts tightened with a torque wrench to

140 lb-ft

(190 Nm).

NOTICE:

Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage.

To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification.

Put the wheel cover back on, if you have one.

Remove any wheel blocks.

Remember that the jack, jacking equipment and tire

must be properly stored

in their original storage

position before

you begin driving again. The next

part will

show you how.

5-34

ProCarManuals.com

Rear Axle Service

Check the gear lubricant level in the rear axle and add

if needed. See “Rear Axle” in the Index, A fluid loss

may indicate a problem. Check the axle and repair it

if needed.

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses

for proper hook-up, binding, leaks, cracks,

chafing,

etc. Inspect disc brake pads for wear and rotors

for surface condition.

Also inspect drum brake linings

for wear and cracks. Inspect other brake parts, including

drums, wheel cylinders, calipers, parking brake, etc.

Check parking brake adjustment.

You may need to have

your brakes inspected more often if your driving habits

or conditions result in frequent braking.

7-50

ProCarManuals.com