flat tire GMC SAVANA 2006 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2006, Model line: SAVANA, Model: GMC SAVANA 2006Pages: 394, PDF Size: 2.56 MB

Page 250 of 394

Tires..............................................................5-52

Tire Sidewall Labeling...................................5-53

Tire Terminology and Definitions.....................5-56

Inflation - Tire Pressure.................................5-59

Dual Tire Operation.......................................5-60

Tire Inspection and Rotation...........................5-61

When It Is Time for New Tires.......................5-63

Buying New Tires.........................................5-63

Different Size Tires and Wheels......................5-65

Uniform Tire Quality Grading..........................5-65

Wheel Alignment and Tire Balance..................5-67

Wheel Replacement......................................5-67

Tire Chains..................................................5-68

If a Tire Goes Flat........................................5-69

Changing a Flat Tire.....................................5-70

Removing the Spare Tire and Tools................5-71

Removing the Flat Tire and Installing

the Spare Tire..........................................5-74

Secondary Latch System...............................5-79

Storing a Flat or Spare Tire and Tools............5-82

Spare Tire...................................................5-83

Appearance Care............................................5-84

Cleaning the Inside of Your Vehicle.................5-84

Fabric/Carpet...............................................5-85

Instrument Panel, Vinyl, and Other

Plastic Surfaces........................................5-86Care of Safety Belts......................................5-86

Weatherstrips...............................................5-86

Washing Your Vehicle...................................5-87

Cleaning Exterior Lamps/Lenses.....................5-87

Finish Care..................................................5-87

Windshield and Wiper Blades.........................5-88

Aluminum Wheels.........................................5-89

Tires...........................................................5-89

Sheet Metal Damage.....................................5-90

Finish Damage.............................................5-90

Underbody Maintenance................................5-90

Chemical Paint Spotting.................................5-90

Vehicle Care/Appearance Materials..................5-91

Vehicle Identi�cation......................................5-92

Vehicle Identification Number (VIN).................5-92

Service Parts Identification Label.....................5-92

Electrical System............................................5-93

Add-On Electrical Equipment..........................5-93

Headlamp Wiring..........................................5-93

Windshield Wiper Fuses................................5-93

Fuses and Circuit Breakers............................5-93

Floor Console Fuse Block..............................5-94

Engine Compartment Fuse Block....................5-95

Capacities and Speci�cations..........................5-98

Section 5 Service and Appearance Care

5-2

Page 308 of 394

How to Check

Use a good quality pocket-type gage to check tire

pressure. You cannot tell if your tires are properly

inflated simply by looking at them. Radial tires may look

properly inflated even when they’re underinflated.

Check the tire’s inflation pressure when the tires are

cold. Cold means your vehicle has been sitting for

at least three hours or driven no more than 1 mile

(1.6 km).

Remove the valve cap from the tire valve stem. Press

the tire gage firmly onto the valve to get a pressure

measurement. If the cold tire inflation pressure matches

the recommended pressure on the tire and loading

information label, no further adjustment is necessary. If

the pressure is low, add air until you reach the

recommended amount.

If you overfill the tire, release air by pushing on the

metal stem in the center of the tire valve. Recheck the

tire pressure with the tire gage.

Be sure to put the valve caps back on the valve stems.

They help prevent leaks by keeping out dirt and

moisture.

Dual Tire Operation

When the vehicle is new, or whenever a wheel, wheel

bolt or wheel nut is replaced, check the wheel nut torque

after 100, 1,000 and 6,000 miles (160, 1 600 and

10 000 km) of driving. For proper wheel nut tightening

information, see “Removing the Flat Tire and Installing

the Spare Tire” later in this section, underChanging

a Flat Tire on page 5-70. Also see “Wheel Nut Torque”

underCapacities and Speci�cations on page 5-98.

The outer tire on a dual wheel setup generally wears

faster than the inner tire. Your tires will wear more

evenly and last longer if you rotate the tires periodically.

SeeTire Inspection and Rotation on page 5-61. Also

seeScheduled Maintenance (Gasoline Engine) on

page 6-4.

{CAUTION:

If you operate your vehicle with a tire that is

badly underin�ated, the tire can overheat. An

overheated tire can lose air suddenly or catch

�re. You or others could be injured. Be sure all

tires (including the spare) are properly in�ated.

SeeTires on page 5-52andIn�ation - Tire Pressure on

page 5-59for more information on proper tire inflation.

5-60

Page 309 of 394

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. SeeWhen It Is Time

for New Tires on page 5-63andWheel Replacement

on page 5-67for more information.

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves,

use the ratchet/wheel wrench to tighten the cable. See

Changing a Flat Tire on page 5-70.

If your vehicle has dual rear wheels, also seeDual Tire

Operation on page 5-60.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The first rotation

is the most important. SeeScheduled Maintenance

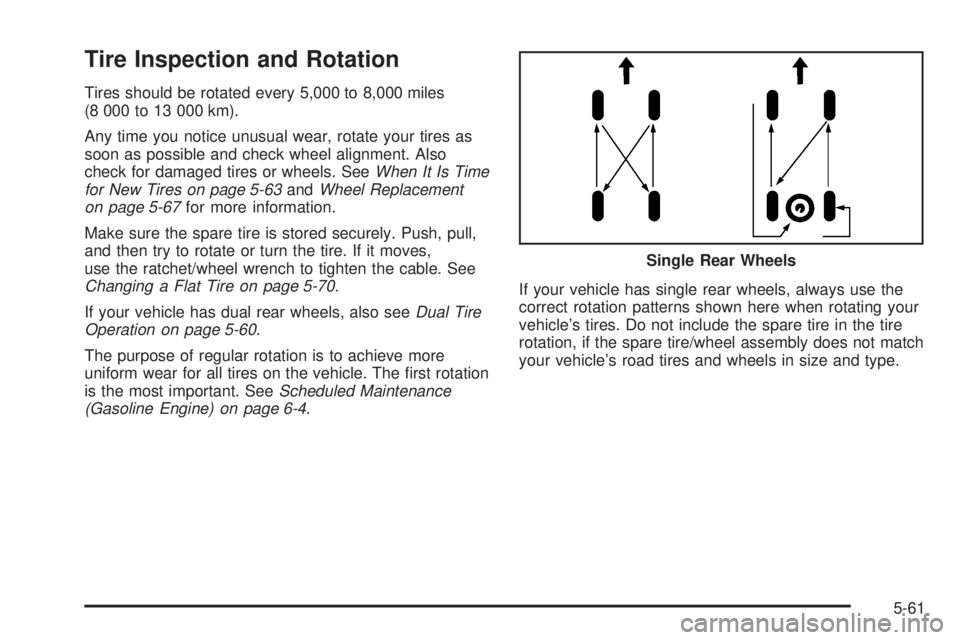

(Gasoline Engine) on page 6-4.If your vehicle has single rear wheels, always use the

correct rotation patterns shown here when rotating your

vehicle’s tires. Do not include the spare tire in the tire

rotation, if the spare tire/wheel assembly does not match

your vehicle’s road tires and wheels in size and type.Single Rear Wheels

5-61

Page 310 of 394

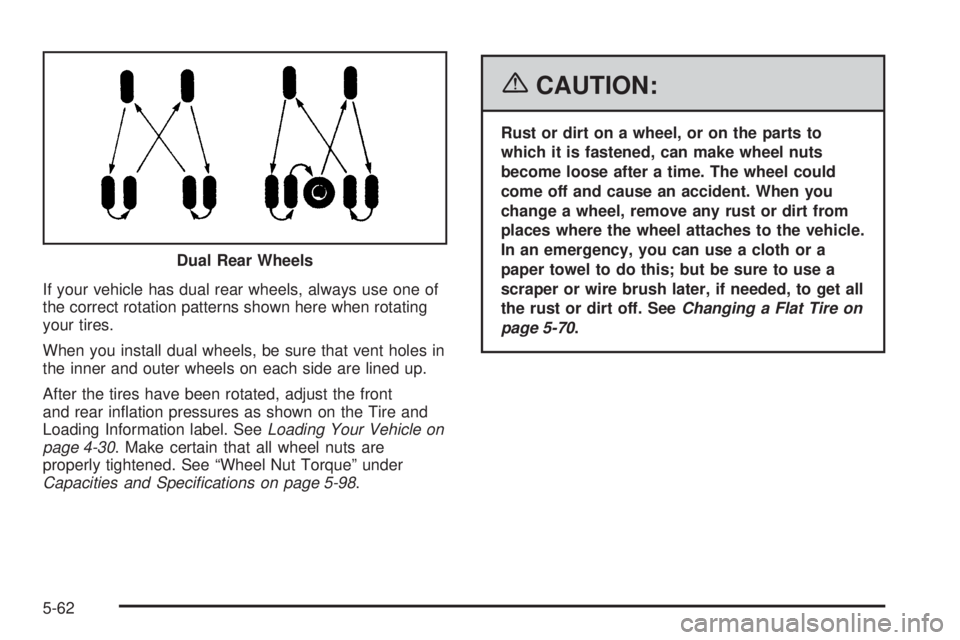

If your vehicle has dual rear wheels, always use one of

the correct rotation patterns shown here when rotating

your tires.

When you install dual wheels, be sure that vent holes in

the inner and outer wheels on each side are lined up.

After the tires have been rotated, adjust the front

and rear inflation pressures as shown on the Tire and

Loading Information label. SeeLoading Your Vehicle on

page 4-30. Make certain that all wheel nuts are

properly tightened. See “Wheel Nut Torque” under

Capacities and Speci�cations on page 5-98.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if needed, to get all

the rust or dirt off. SeeChanging a Flat Tire on

page 5-70. Dual Rear Wheels

5-62

Page 316 of 394

SeeChanging a Flat Tire on page 5-70for more

information.

Used Replacement Wheels

{CAUTION:

Putting a used wheel on your vehicle is

dangerous. You cannot know how it has been

used or how far it has been driven. It could fail

suddenly and cause a crash. If you have to

replace a wheel, use a new GM original

equipment wheel.

Tire Chains

{CAUTION:

If your vehicle has dual wheels or P235/75R16,

P245/75R16 or LT245/75R16 size tires, do not

use tire chains. They can damage your vehicle

because there is not enough clearance. Tire

chains used on a vehicle without the proper

amount of clearance can cause damage to the

brakes, suspension, or other vehicle parts. The

area damaged by the tire chains could cause

you to lose control of your vehicle and you or

others may be injured in a crash.

Use another type of traction device only if its

manufacturer recommends it for use on your

vehicle and tire size combination and road

conditions. Follow that manufacturer’s

instructions. To help avoid damage to your

vehicle, drive slowly, readjust or remove the

device if it is contacting your vehicle, and do

not spin the vehicle’s wheels.

If you do �nd traction devices that will �t,

install them on the rear tires.

5-68

Page 317 of 394

Notice:If your vehicle does not have dual wheels

and is equipped with a tire size other than

P235/75R16, P245/75R16 or LT245/75R16, use tire

chains only where legal and only when you

must. Use chains that are the proper size for your

tires. Install them on the tires of the rear axle. Do not

use chains on the tires of the front axle. Tighten

them as tightly as possible with the ends securely

fastened. Drive slowly and follow the chain

manufacturer’s instructions. If you can hear the

chains contacting your vehicle, stop and retighten

them. If the contact continues, slow down until

it stops. Driving too fast or spinning the wheels with

chains on will damage your vehicle.

If a Tire Goes Flat

It is unusual for a tire to blowout while you are driving,

especially if you maintain your vehicle’s tires properly.

If air goes out of a tire, it is much more likely to leak out

slowly. But if you should ever have a blowout, here

are a few tips about what to expect and what to do:

If a front tire fails, the flat tire will create a drag that pulls

the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blowout remove your foot from

the accelerator pedal. Get the vehicle under control

by steering the way you want the vehicle to go. It may

be very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.

{CAUTION:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without

the appropriate safety equipment and training.

The jack provided with your vehicle is

designed only for changing a �at tire. If it is

used for anything else, you or others could be

badly injured or killed if the vehicle slips off

the jack. Use the jack provided with your

vehicle only for changing a �at tire.

If a tire goes flat, the next part shows how to use the

jacking equipment to change a flat tire safely.

5-69

Page 318 of 394

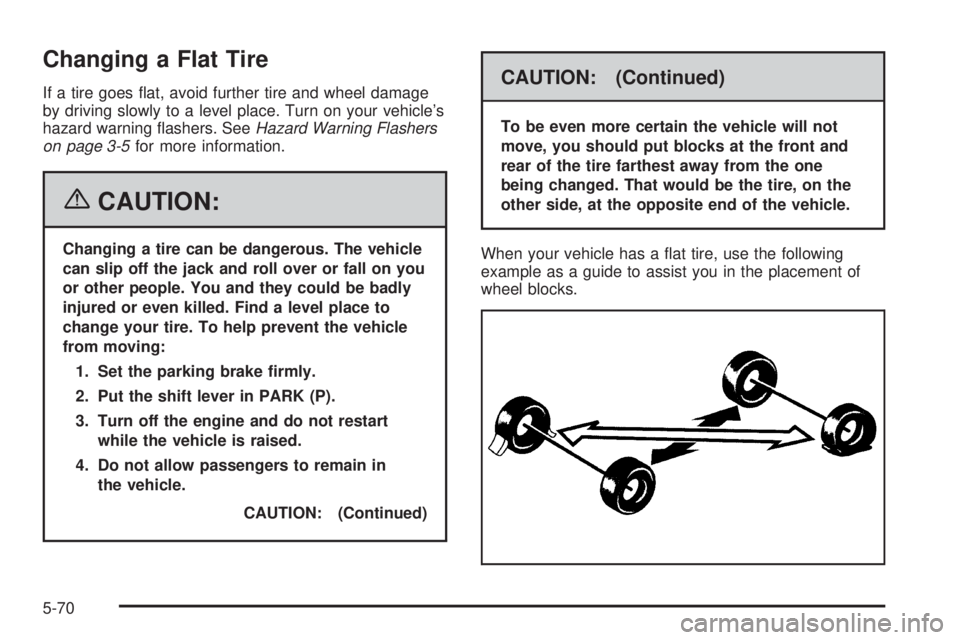

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your vehicle’s

hazard warning flashers. SeeHazard Warning Flashers

on page 3-5for more information.

{CAUTION:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you

or other people. You and they could be badly

injured or even killed. Find a level place to

change your tire. To help prevent the vehicle

from moving:

1. Set the parking brake �rmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine and do not restart

while the vehicle is raised.

4. Do not allow passengers to remain in

the vehicle.

CAUTION: (Continued)

CAUTION: (Continued)

To be even more certain the vehicle will not

move, you should put blocks at the front and

rear of the tire farthest away from the one

being changed. That would be the tire, on the

other side, at the opposite end of the vehicle.

When your vehicle has a flat tire, use the following

example as a guide to assist you in the placement of

wheel blocks.

5-70

Page 322 of 394

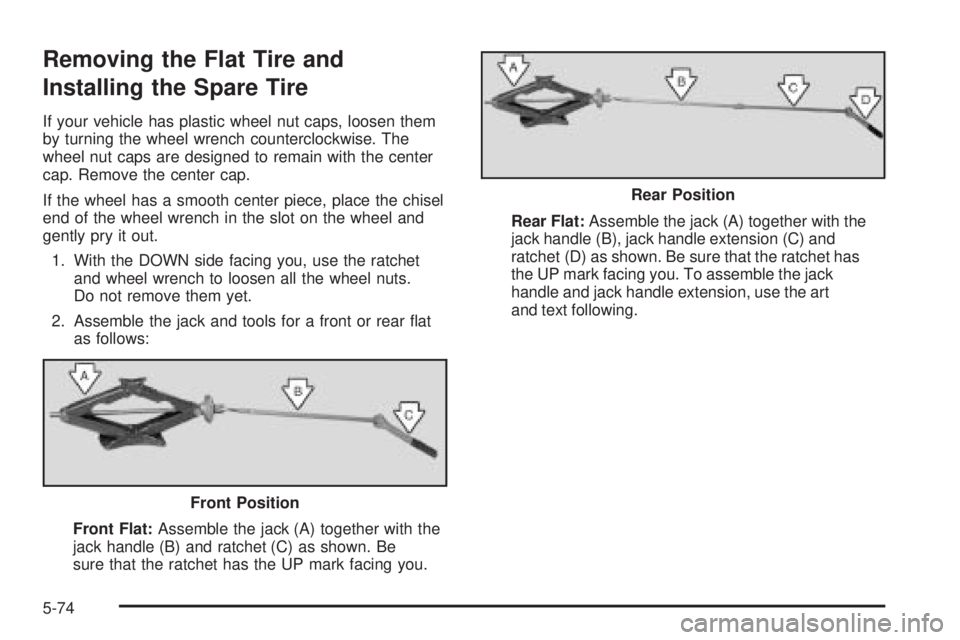

Removing the Flat Tire and

Installing the Spare Tire

If your vehicle has plastic wheel nut caps, loosen them

by turning the wheel wrench counterclockwise. The

wheel nut caps are designed to remain with the center

cap. Remove the center cap.

If the wheel has a smooth center piece, place the chisel

end of the wheel wrench in the slot on the wheel and

gently pry it out.

1. With the DOWN side facing you, use the ratchet

and wheel wrench to loosen all the wheel nuts.

Do not remove them yet.

2. Assemble the jack and tools for a front or rear flat

as follows:

Front Flat:Assemble the jack (A) together with the

jack handle (B) and ratchet (C) as shown. Be

sure that the ratchet has the UP mark facing you.Rear Flat:Assemble the jack (A) together with the

jack handle (B), jack handle extension (C) and

ratchet (D) as shown. Be sure that the ratchet has

the UP mark facing you. To assemble the jack

handle and jack handle extension, use the art

and text following.

Front Position

Rear Position

5-74

Page 327 of 394

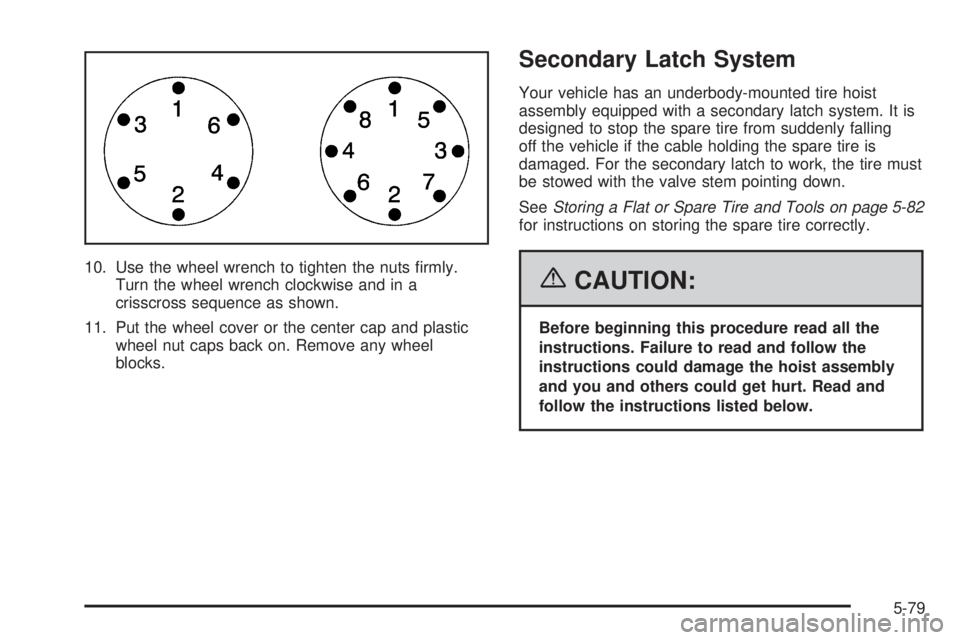

10. Use the wheel wrench to tighten the nuts firmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

11. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel

blocks.

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system. It is

designed to stop the spare tire from suddenly falling

off the vehicle if the cable holding the spare tire is

damaged. For the secondary latch to work, the tire must

be stowed with the valve stem pointing down.

SeeStoring a Flat or Spare Tire and Tools on page 5-82

for instructions on storing the spare tire correctly.

{CAUTION:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed below.

5-79

Page 329 of 394

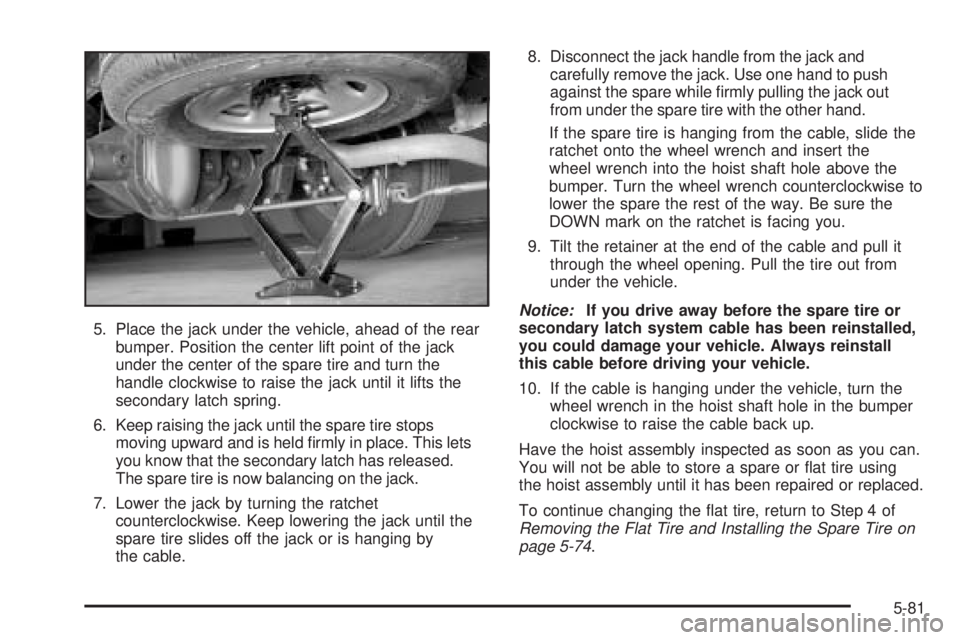

5. Place the jack under the vehicle, ahead of the rear

bumper. Position the center lift point of the jack

under the center of the spare tire and turn the

handle clockwise to raise the jack until it lifts the

secondary latch spring.

6. Keep raising the jack until the spare tire stops

moving upward and is held firmly in place. This lets

you know that the secondary latch has released.

The spare tire is now balancing on the jack.

7. Lower the jack by turning the ratchet

counterclockwise. Keep lowering the jack until the

spare tire slides off the jack or is hanging by

the cable.8. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push

against the spare while firmly pulling the jack out

from under the spare tire with the other hand.

If the spare tire is hanging from the cable, slide the

ratchet onto the wheel wrench and insert the

wheel wrench into the hoist shaft hole above the

bumper. Turn the wheel wrench counterclockwise to

lower the spare the rest of the way. Be sure the

DOWN mark on the ratchet is facing you.

9. Tilt the retainer at the end of the cable and pull it

through the wheel opening. Pull the tire out from

under the vehicle.

Notice:If you drive away before the spare tire or

secondary latch system cable has been reinstalled,

you could damage your vehicle. Always reinstall

this cable before driving your vehicle.

10. If the cable is hanging under the vehicle, turn the

wheel wrench in the hoist shaft hole in the bumper

clockwise to raise the cable back up.

Have the hoist assembly inspected as soon as you can.

You will not be able to store a spare or flat tire using

the hoist assembly until it has been repaired or replaced.

To continue changing the flat tire, return to Step 4 of

Removing the Flat Tire and Installing the Spare Tire on

page 5-74.

5-81