stop start GMC SAVANA 2009 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2009, Model line: SAVANA, Model: GMC SAVANA 2009Pages: 404, PDF Size: 2.35 MB

Page 239 of 404

Towing a trailer requires a certain amount of experience.

Get to know the rig before setting out for the open

road. Get acquainted with the feel of handling and

braking with the added weight of the trailer. And always

keep in mind that the vehicle you are driving is now

longer and not as responsive as the vehicle is by itself.

Before starting, check all trailer hitch parts and

attachments, safety chains, electrical connectors, lamps,

tires and mirror adjustments. If the trailer has electric

brakes, start the vehicle and trailer moving and then

apply the trailer brake controller by hand to be sure the

brakes are working. This checks the electrical connection

at the same time.

During the trip, check occasionally to be sure that the

load is secure, and that the lamps and any trailer brakes

are still working.

Following Distance

Stay at least twice as far behind the vehicle ahead as

you would when driving the vehicle without a trailer.

This can help to avoid situations that require heavy

braking and sudden turns.

Passing

More passing distance is needed when towing a trailer.

Because the rig is longer, it is necessary to go much

farther beyond the passed vehicle before returning to

the lane.

Backing Up

Hold the bottom of the steering wheel with one hand.

Then, to move the trailer to the left, move that hand

to the left. To move the trailer to the right, move your

hand to the right. Always back up slowly and, if possible,

have someone guide you.

Making Turns

Notice:Making very sharp turns while trailering

could cause the trailer to come in contact with the

vehicle. The vehicle could be damaged. Avoid

making very sharp turns while trailering.

When turning with a trailer, make wider turns than

normal. Do this so the trailer will not strike soft shoulders,

curbs, road signs, trees or other objects. Avoid jerky or

sudden maneuvers. Signal well in advance.

Turn Signals When Towing a Trailer

The arrows on the instrument panel flash whenever

signaling a turn or lane change. Properly hooked up, the

trailer lamps also flash, telling other drivers the vehicle

is turning, changing lanes or stopping.

When towing a trailer, the arrows on the instrument panel

flash for turns even if the bulbs on the trailer are burned

out. For this reason you may think other drivers are

seeing the signal when they are not. It is important to

check occasionally to be sure the trailer bulbs are still

working.

4-35

Page 241 of 404

3. When the wheel chocks are in place, release the

brake pedal until the chocks absorb the load.

4. Reapply the brake pedal. Then apply the parking

brake and shift into P (Park) for vehicles with an

automatic transmission or into gear for vehicles with

a manual transmission.

5. Release the brake pedal.

Leaving After Parking on a Hill

1. Apply and hold the brake pedal while you:

•start the engine,

•shift into a gear, and

•release the parking brake.

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the

chocks.

Maintenance When Trailer Towing

The vehicle needs service more often when pulling a

trailer. See this manual’s Maintenance Schedule or Index

for more information. Things that are especially important

in trailer operation are automatic transmission fluid,

engine oil, axle lubricant, belts, cooling system and brake

system. It is a good idea to inspect these before and

during the trip.

Check periodically to see that all hitch nuts and bolts

are tight.

Trailer Wiring Harness

The optional heavy-duty trailer wiring package includes

a wiring harness, with a seven-pin connector at the

rear of the vehicle and a four-wire harness assembly

under the driver side of the instrument panel. The

four-wire harness assembly comes without a connector.

If the vehicle does not have a trailer hitch, the

seven-wire harness assembly with connector is taped

together and located in a frame pocket at the driver side

rear left corner of the frame.

4-37

Page 243 of 404

Service............................................................5-3

Accessories and Modifications..........................5-3

California Proposition 65 Warning.....................5-4

California Perchlorate Materials Requirements......5-4

Doing Your Own Service Work.........................5-4

Adding Equipment to the Outside of the

Vehicle......................................................5-5

Fuel................................................................5-5

Gasoline Octane............................................5-6

Gasoline Specifications....................................5-6

California Fuel...............................................5-6

Additives.......................................................5-7

Fuel E85 (85% Ethanol)..................................5-8

Fuels in Foreign Countries...............................5-9

Filling the Tank............................................5-10

Filling a Portable Fuel Container.....................5-12

Checking Things Under the Hood....................5-12

Hood Release..............................................5-13

Engine Compartment Overview.......................5-14

Engine Oil...................................................5-15

Engine Oil Life System..................................5-18

Engine Air Cleaner/Filter................................5-20

Automatic Transmission Fluid.........................5-21

Cooling System............................................5-24

Engine Coolant.............................................5-25Radiator Pressure Cap..................................5-31

Engine Overheating.......................................5-31

Engine Fan Noise.........................................5-33

Power Steering Fluid.....................................5-34

Windshield Washer Fluid................................5-35

Brakes........................................................5-36

Battery........................................................5-39

Jump Starting...............................................5-40

All-Wheel Drive..............................................5-44

Rear Axle

.......................................................5-45

Front Axle......................................................5-46

Noise Control System.....................................5-47

Tampering with Noise Control System

Prohibited.................................................5-47

Bulb Replacement..........................................5-48

Halogen Bulbs..............................................5-48

Headlamps..................................................5-48

Front Turn Signal, Sidemarker and

Parking Lamps..........................................5-50

Center High-Mounted

Stoplamp (CHMSL)....................................5-51

Taillamps.....................................................5-51

Replacement Bulbs.......................................5-52

Windshield Wiper Blade Replacement..............5-53

Section 5 Service and Appearance Care

5-1

Page 253 of 404

To remove the fuel cap, turn it slowly counterclockwise.

While refueling, hang the tethered fuel cap from the

hook on the fuel door.

{CAUTION:

Fuel can spray out on you if you open the fuel cap

too quickly. If you spill fuel and then something

ignites it, you could be badly burned. This spray

can happen if the tank is nearly full, and is more

likely in hot weather. Open the fuel cap slowly and

wait for any hiss noise to stop. Then unscrew the

cap all the way.

Be careful not to spill fuel. Do not top off or overfill the

tank and wait a few seconds after you have finished

pumping before removing the nozzle. Clean fuel

from painted surfaces as soon as possible.

SeeWashing Your Vehicle on page 5-99.When replacing the fuel cap, turn it clockwise until it

clicks. Make sure the cap is fully installed. The diagnostic

system can determine if the fuel cap has been left off or

improperly installed. This would allow fuel to evaporate

into the atmosphere. SeeMalfunction Indicator Lamp on

page 3-36.{CAUTION:

If a fire starts while you are refueling, do not

remove the nozzle. Shut off the flow of fuel by

shutting off the pump or by notifying the station

attendant. Leave the area immediately.

Notice:If you need a new fuel cap, be sure to

get the right type. Your dealer/retailer can get one

for you. If you get the wrong type, it may not �t

properly. This may cause the malfunction indicator

lamp to light and may damage the fuel tank and

emissions system. SeeMalfunction Indicator Lamp

on page 3-36.

5-11

Page 275 of 404

If the temperature overheat gage is no longer in the

overheat zone or an overheat warning no longer

displays, the vehicle can be driven. Continue to drive

the vehicle slow for about 10 minutes. Keep a safe

vehicle distance from the car in front of you. If the

warning does not come back on, continue to drive

normally.

If the warning continues, pull over, stop, and park the

vehicle right away.

If there is still no sign of steam, push down the

accelerator until the engine speed is about twice

as fast as normal idle speed for at least three minutes

while you are parked. If you still have the warning, turn

off the engine until it cools down.

You may decide not to lift the hood but to get service

help right away.Engine Fan Noise

Your vehicle has a clutched engine cooling fan.

When the clutch is engaged, the fan spins faster to

provide more air to cool the engine. In most everyday

driving conditions, the fan is spinning slower and the

clutch is not fully engaged. This improves fuel economy

and reduces fan noise. Under heavy vehicle loading,

trailer towing, and/or high outside temperatures, the fan

speed increases as the clutch more fully engages, so you

may hear an increase in fan noise. This is normal and

should not be mistaken as the transmission slipping or

making extra shifts. It is merely the cooling system

functioning properly. The fan will slow down when

additional cooling is not required and the clutch partially

disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch partially

disengages.

5-33

Page 306 of 404

Tire Pressure Monitor System

The Tire Pressure Monitor System (TPMS) uses radio

and sensor technology to check tire pressure levels.

The TPMS sensors monitor the air pressure in

your vehicle’s tires and transmit tire pressure

readings to a receiver located in the vehicle.

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer

on the vehicle placard or tire inflation pressure label.

(If your vehicle has tires of a different size than the

size indicated on the vehicle placard or tire inflation

pressure label, you should determine the proper

tire inflation pressure for those tires.)

As an added safety feature, your vehicle has been

equipped with a tire pressure monitoring system (TPMS)

that illuminates a low tire pressure telltale when one

or more of your tires is significantly under-inflated.

Accordingly, when the low tire pressure telltale

illuminates, you should stop and check your tires

as soon as possible, and inflate them to the proper

pressure. Driving on a significantly under-inflated

tire causes the tire to overheat and can lead to tire

failure. Under-inflation also reduces fuel efficiency

and tire tread life, and may affect the vehicle’s handling

and stopping ability.Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver’s responsibility to

maintain correct tire pressure, even if under-inflation

has not reached the level to trigger illumination of

the TPMS low tire pressure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon

subsequent vehicle start-ups as long as the malfunction

exists.

When the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire

pressure as intended. TPMS malfunctions may occur

for a variety of reasons, including the installation of

replacement or alternate tires or wheels on the vehicle

that prevent the TPMS from functioning properly. Always

check the TPMS malfunction telltale after replacing one

or more tires or wheels on your vehicle to ensure that

the replacement or alternate tires and wheels allow the

TPMS to continue to function properly.

SeeTire Pressure Monitor Operation on page 5-65for

additional information.

5-64

Page 309 of 404

•One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your

dealer/retailer for service.

•Replacement tires or wheels do not match your

vehicle’s original equipment tires or wheels. Tires

and wheels other than those recommended for your

vehicle could prevent the TPMS from functioning

properly. SeeBuying New Tires on page 5-72.

•Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or

signal a low tire condition. See your dealer/retailer for

service if the TPMS malfunction light and DIC message

comes on and stays on.

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you rotate your vehicle’s tires or replace one

or more of the TPMS sensors, the identification codes

will need to be matched to the new tire/wheel position.

The sensors are matched to the tire/wheel positions in

the following order: driver side front tire, passenger side

front tire, passenger side rear tire, and driver side rear tire

using a TPMS diagnostic tool. See your dealer/retailer for

service.

The TPMS sensors can also be matched to each

tire/wheel position by increasing or decreasing the tire’s

air pressure. If increasing the tire’s air pressure, do not

exceed the maximum inflation pressure indicated on the

tire’s sidewall.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gage, or a key.

You have two minutes to match the first tire/wheel

position, and five minutes overall to match all four

tire/wheel positions. If it takes longer than two minutes, to

match the first tire and wheel, or more than five minutes

to match all four tire and wheel positions the matching

process stops and you need to start over.

5-67

Page 333 of 404

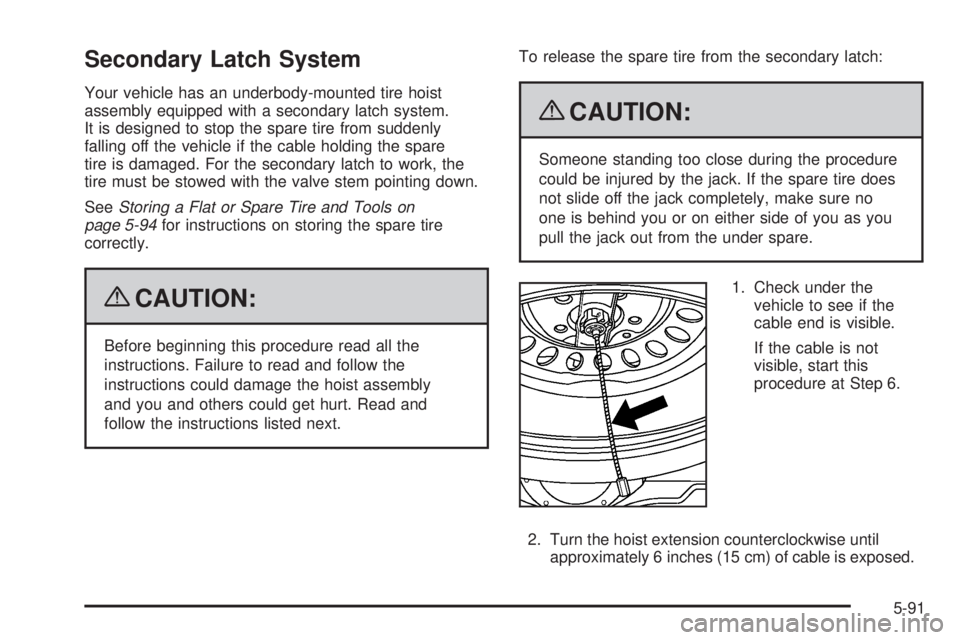

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system.

It is designed to stop the spare tire from suddenly

falling off the vehicle if the cable holding the spare

tire is damaged. For the secondary latch to work, the

tire must be stowed with the valve stem pointing down.

SeeStoring a Flat or Spare Tire and Tools on

page 5-94for instructions on storing the spare tire

correctly.

{CAUTION:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed next.To release the spare tire from the secondary latch:

{CAUTION:

Someone standing too close during the procedure

could be injured by the jack. If the spare tire does

not slide off the jack completely, make sure no

one is behind you or on either side of you as you

pull the jack out from the under spare.

1. Check under the

vehicle to see if the

cable end is visible.

If the cable is not

visible, start this

procedure at Step 6.

2. Turn the hoist extension counterclockwise until

approximately 6 inches (15 cm) of cable is exposed.

5-91