maintenance GMC SAVANA 2010 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SAVANA, Model: GMC SAVANA 2010Pages: 424, PDF Size: 2.4 MB

Page 285 of 424

How to Add Automatic Transmission

Fluid

Refer to the Maintenance Schedule to determine what

kind of transmission fluid to use. SeeRecommended

Fluids and Lubricants on page 7-11.

Using a funnel, add fluid down the transmission dipstick

tube only after checking the transmission fluid while it

is hot. A cold check is used only as a reference. If

the fluid level is low, add only enough of the proper fluid

to bring the level up to the HOT area for a hot check.

It does not take much fluid, generally less than one pint

(0.5 L). Do not overfill.

Notice:Use of the incorrect automatic transmission

�uid may damage the vehicle, and the damages

may not be covered by the vehicle’s warranty.

Always use the automatic transmission �uid listed

inRecommended Fluids and Lubricants on

page 7-11.

•After adding fluid, recheck the fluid level as

described under “How to Check Automatic

Transmission Fluid,” earlier in this section.

•When the correct fluid level is obtained, push the

dipstick back in all the way; then flip the handle

down to lock the dipstick in place.

Automatic Transmission Fluid

(6-Speed Transmission)

When to Check and Change Automatic

Transmission Fluid

It is usually not necessary to check the transmission

fluid level. The only reason for fluid loss is a

transmission leak or overheating the transmission. If a

small leak is suspected, use the following procedures to

check the fluid level. However, if there is a large leak,

then it may be necessary to have the vehicle towed to a

dealer/retailer service department and have it repaired

before driving the vehicle further.

Change the fluid and filter at the intervals listed in

Scheduled Maintenance on page 7-3, and be sure to

use the transmission fluid listed inRecommended Fluids

and Lubricants on page 7-11.

How to Check Automatic Transmission

Fluid

Because this operation can be difficult, it is

recommended to have this check done at the

dealer/retailer service department, which can monitor

the transmission temperature. The transmission

fluid level increases with temperature. To obtain a highly

accurate fluid level check, the transmission temperature

must be measured.

6-23

Page 288 of 424

How to Add Automatic Transmission

Fluid

Refer to the Maintenance Schedule to determine what

kind of transmission fluid to use. SeeRecommended

Fluids and Lubricants on page 7-11.

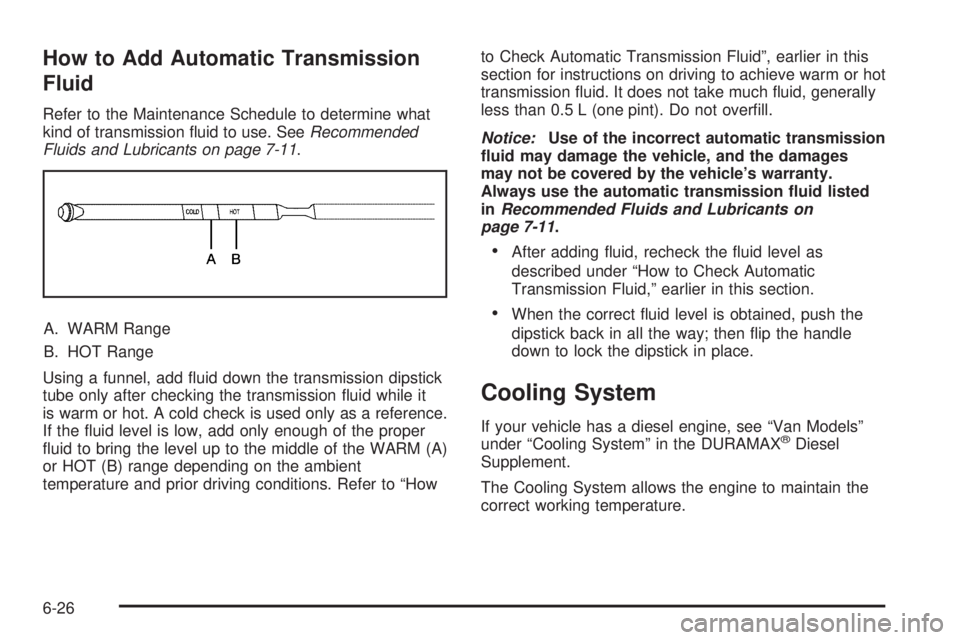

A. WARM Range

B. HOT Range

Using a funnel, add fluid down the transmission dipstick

tube only after checking the transmission fluid while it

is warm or hot. A cold check is used only as a reference.

If the fluid level is low, add only enough of the proper

fluid to bring the level up to the middle of the WARM (A)

or HOT (B) range depending on the ambient

temperature and prior driving conditions. Refer to “Howto Check Automatic Transmission Fluid”, earlier in this

section for instructions on driving to achieve warm or hot

transmission fluid. It does not take much fluid, generally

less than 0.5 L (one pint). Do not overfill.

Notice:Use of the incorrect automatic transmission

�uid may damage the vehicle, and the damages

may not be covered by the vehicle’s warranty.

Always use the automatic transmission �uid listed

inRecommended Fluids and Lubricants on

page 7-11.

•After adding fluid, recheck the fluid level as

described under “How to Check Automatic

Transmission Fluid,” earlier in this section.

•When the correct fluid level is obtained, push the

dipstick back in all the way; then flip the handle

down to lock the dipstick in place.

Cooling System

If your vehicle has a diesel engine, see “Van Models”

under “Cooling System” in the DURAMAX®Diesel

Supplement.

The Cooling System allows the engine to maintain the

correct working temperature.

6-26

Page 299 of 424

Brakes

Brake Fluid

The brake master cylinder

reservoir is filled with

DOT 3 brake fluid. See

Engine Compartment

Overview on page 6-14for

the location of the

reservoir.

There are only two reasons why the brake fluid level in

the reservoir might go down:

•The brake fluid level goes down because of normal

brake lining wear. When new linings are installed,

the fluid level goes back up.

•A fluid leak in the brake hydraulic system can also

cause a low fluid level. Have the brake hydraulic

system fixed, since a leak means that sooner

or later the brakes will not work well.Do not top off the brake fluid. Adding fluid does not

correct a leak. If fluid is added when the linings

are worn, there will be too much fluid when new brake

linings are installed. Add or remove brake fluid, as

necessary, only when work is done on the brake

hydraulic system.

{WARNING:

If too much brake fluid is added, it can spill on the

engine and/or fuel operated heater parts, if

equipped. If the vehicle has a diesel engine and a

fuel operated heater, see “Fuel Operated Heater

(FOH)” in the diesel engine supplement. The fluid

will burn if the engine is hot enough. You or others

could be burned, and the vehicle could be

damaged. Add brake fluid only when work is done

on the brake hydraulic system. See “Checking

Brake Fluid” in this section.

Refer to the Maintenance Schedule to determine when

to check the brake fluid. SeeScheduled Maintenance

on page 7-3.

6-37

Page 307 of 424

To disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the remote positive (+) terminal cover to its

original position.

All-Wheel Drive

Lubricant checks in this section also apply to these

vehicles. However, there are two additional systems that

need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeeScheduled

Maintenance on page 7-3.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the filler plug hole,

you’ll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the filler plug hole.

Use care not to overtighten the plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 7-11.

6-45

Page 308 of 424

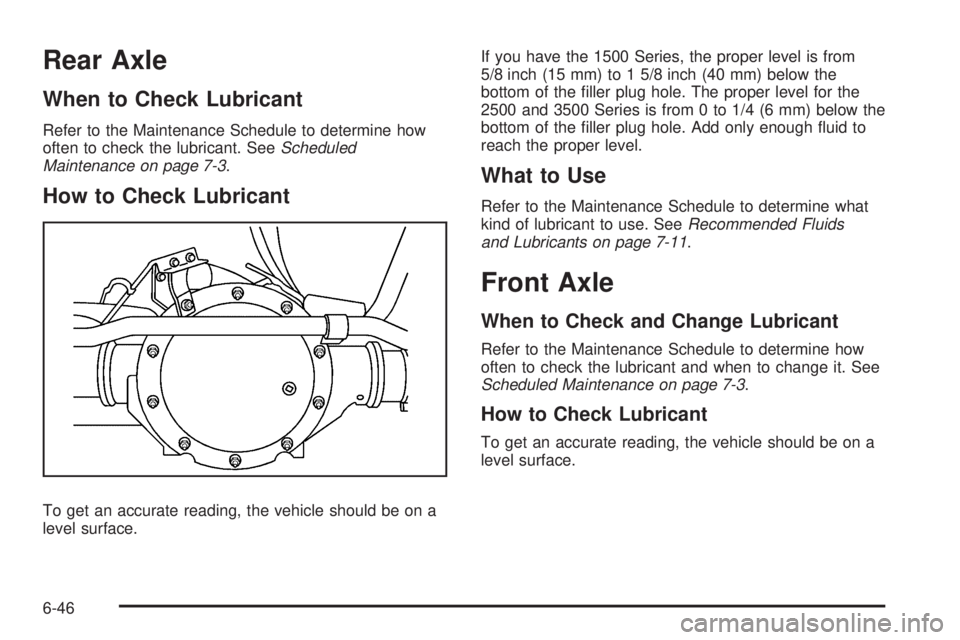

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeeScheduled

Maintenance on page 7-3.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If you have the 1500 Series, the proper level is from

5/8 inch (15 mm) to 1 5/8 inch (40 mm) below the

bottom of the filler plug hole. The proper level for the

2500 and 3500 Series is from 0 to 1/4 (6 mm) below the

bottom of the filler plug hole. Add only enough fluid to

reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 7-11.

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it. See

Scheduled Maintenance on page 7-3.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

6-46

Page 309 of 424

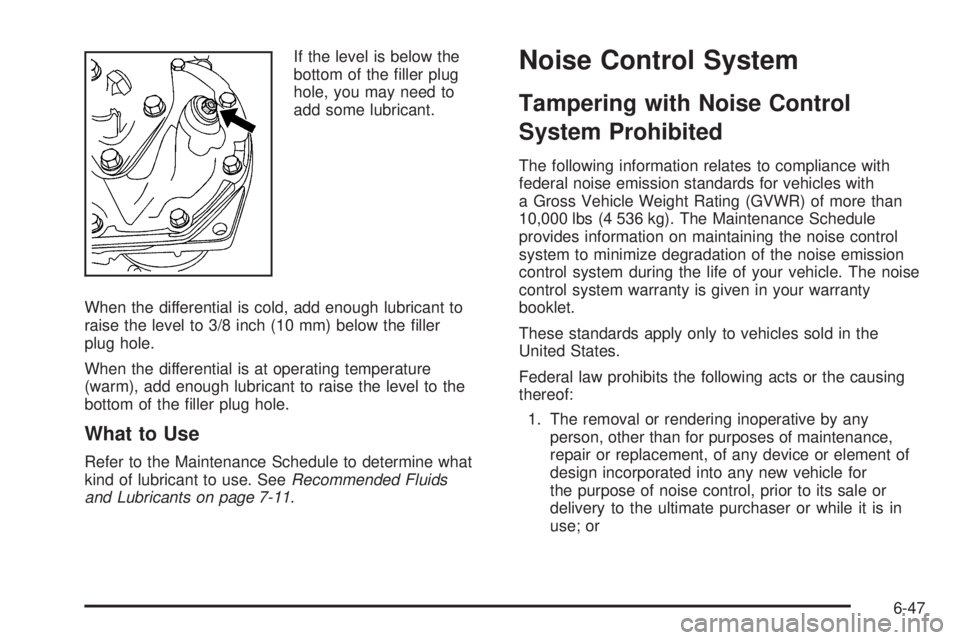

If the level is below the

bottom of the filler plug

hole, you may need to

add some lubricant.

When the differential is cold, add enough lubricant to

raise the level to 3/8 inch (10 mm) below the filler

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 7-11.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with

a Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty

booklet.

These standards apply only to vehicles sold in the

United States.

Federal law prohibits the following acts or the causing

thereof:

1. The removal or rendering inoperative by any

person, other than for purposes of maintenance,

repair or replacement, of any device or element of

design incorporated into any new vehicle for

the purpose of noise control, prior to its sale or

delivery to the ultimate purchaser or while it is in

use; or

6-47

Page 316 of 424

Windshield Wiper Blade

Replacement

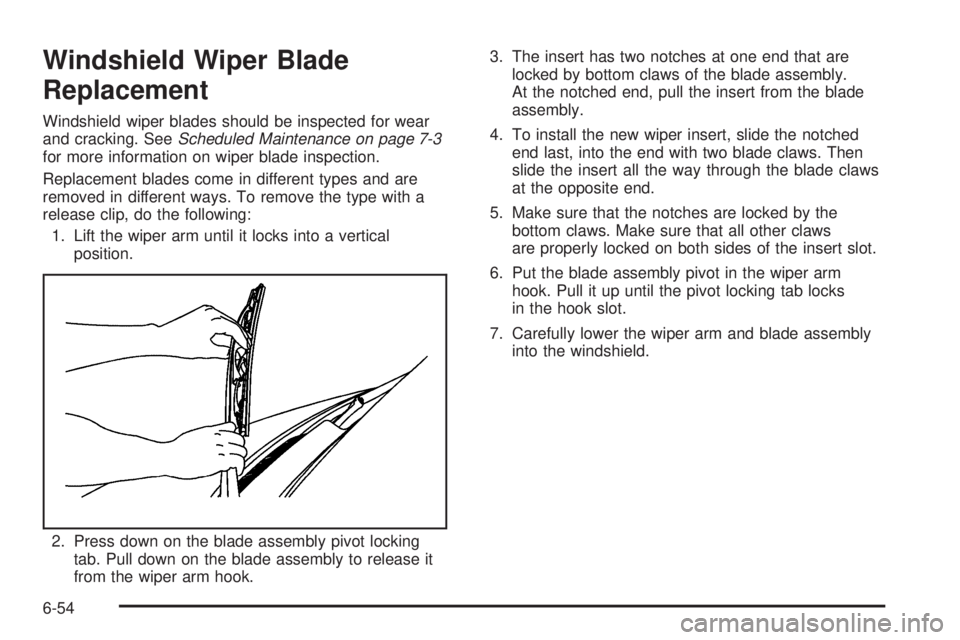

Windshield wiper blades should be inspected for wear

and cracking. SeeScheduled Maintenance on page 7-3

for more information on wiper blade inspection.

Replacement blades come in different types and are

removed in different ways. To remove the type with a

release clip, do the following:

1. Lift the wiper arm until it locks into a vertical

position.

2. Press down on the blade assembly pivot locking

tab. Pull down on the blade assembly to release it

from the wiper arm hook.3. The insert has two notches at one end that are

locked by bottom claws of the blade assembly.

At the notched end, pull the insert from the blade

assembly.

4. To install the new wiper insert, slide the notched

end last, into the end with two blade claws. Then

slide the insert all the way through the blade claws

at the opposite end.

5. Make sure that the notches are locked by the

bottom claws. Make sure that all other claws

are properly locked on both sides of the insert slot.

6. Put the blade assembly pivot in the wiper arm

hook. Pull it up until the pivot locking tab locks

in the hook slot.

7. Carefully lower the wiper arm and blade assembly

into the windshield.

6-54

Page 326 of 424

How to Check

Use a good quality pocket-type gage to check

tire pressure. You cannot tell if your tires are

properly inflated simply by looking at them. Radial

tires may look properly inflated even when they

are underinflated. Check the tire’s inflation

pressure when the tires are cold. Cold means your

vehicle has been sitting for at least three hours

or driven no more than 1 mile (1.6 km).

Remove the valve cap from the tire valve stem.

Press the tire gage firmly onto the valve to

get a pressure measurement. If the cold tire

inflation pressure matches the recommended

pressure on the Tire and Loading Information

label, no further adjustment is necessary. If the

pressure is low, add air until you reach the

recommended amount.

If you overfill the tire, release air by pushing on

the metal stem in the center of the tire valve.

Recheck the tire pressure with the tire gage.

Be sure to put the valve caps back on the valve

stems. They help prevent leaks by keeping out

dirt and moisture.

Dual Tire Operation

When the vehicle is new, or whenever a wheel, wheel

bolt or wheel nut is replaced, check the wheel nut torque

after 100, 1,000 and 6,000 miles (160, 1 600 and

10 000 km) of driving. For proper wheel nut tightening

information, see “Removing the Flat Tire and Installing

the Spare Tire” later in this section, underChanging

a Flat Tire on page 6-80. Also see “Wheel Nut Torque”

underCapacities and Speci�cations on page 6-110.

The outer tire on a dual wheel setup generally wears

faster than the inner tire. Your tires will wear more

evenly and last longer if you rotate the tires periodically.

SeeTire Inspection and Rotation on page 6-69. Also

seeScheduled Maintenance on page 7-3.

{WARNING:

If you operate your vehicle with a tire that is badly

underinflated, the tire can overheat. An overheated

tire can lose air suddenly or catch fire. You or

others could be injured. Be sure all tires (including

the spare) are properly inflated.

SeeTires on page 6-55andIn�ation - Tire Pressure on

page 6-63for more information on proper tire inflation.

6-64

Page 327 of 424

Tire Pressure Monitor System

The Tire Pressure Monitor System (TPMS) uses radio

and sensor technology to check tire pressure levels.

The TPMS sensors monitor the air pressure in

your vehicle’s tires and transmit tire pressure readings

to a receiver located in the vehicle.

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer

on the vehicle placard or tire inflation pressure label.

(If your vehicle has tires of a different size than the size

indicated on the vehicle placard or tire inflation

pressure label, you should determine the proper tire

inflation pressure for those tires.)

As an added safety feature, your vehicle has been

equipped with a tire pressure monitoring system (TPMS)

that illuminates a low tire pressure telltale when one

or more of your tires is significantly under-inflated.

Accordingly, when the low tire pressure telltale

illuminates, you should stop and check your tires as

soon as possible, and inflate them to the proper

pressure. Driving on a significantly under-inflated tire

causes the tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency and tire

tread life, and may affect the vehicle’s handling

and stopping ability.Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver’s responsibility to

maintain correct tire pressure, even if under-inflation has

not reached the level to trigger illumination of the

TPMS low tire pressure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator

is combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon

subsequent vehicle start-ups as long as the malfunction

exists.

When the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire

pressure as intended. TPMS malfunctions may occur for

a variety of reasons, including the installation of

replacement or alternate tires or wheels on the vehicle

that prevent the TPMS from functioning properly.

Always check the TPMS malfunction telltale after

replacing one or more tires or wheels on your vehicle to

ensure that the replacement or alternate tires and

wheels allow the TPMS to continue to function properly.

SeeTire Pressure Monitor Operation on page 6-66

for additional information.

6-65

Page 329 of 424

Your vehicle’s TPMS can warn you about a low tire

pressure condition but it does not replace normal

tire maintenance. SeeTire Inspection and Rotation on

page 6-69andTires on page 6-55.

Notice:Liquid tire sealants could damage the Tire

Pressure Monitor System (TPMS) sensors. Sensor

damage caused by using a tire sealant is not

covered by your warranty. Do not use liquid tire

sealants.

TPMS Malfunction Light and Message

The TPMS will not function properly if one or more of the

TPMS sensors are missing or inoperable. When the

system detects a malfunction, the low tire warning light

flashes for about one minute and then stays on for

the remainder of the ignition cycle. A DIC warning

message is also displayed. The low tire warning light

and DIC warning message come on at each ignition

cycle until the problem is corrected. Some of the

conditions that can cause the malfunction light and DIC

message to come on are:

•One of the road tires has been replaced with the

spare tire. The spare tire does not have a TPMS

sensor. The TPMS malfunction light and DIC

message should go off once you re-install the road

tire containing the TPMS sensor.

•The TPMS sensor matching process was started

but not completed or not completed successfully

after rotating the vehicle’s tires. The DIC message

and TPMS malfunction light should go off once

the TPMS sensor matching process is performed

successfully. See “TPMS Sensor Matching Process”

later in this section.

•One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your

dealer/retailer for service.

•Replacement tires or wheels do not match your

vehicle’s original equipment tires or wheels.

Tires and wheels other than those recommended

for your vehicle could prevent the TPMS from

functioning properly. SeeBuying New Tires on

page 6-73.

•Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or signal

a low tire condition. See your dealer/retailer for

service if the TPMS malfunction light and DIC message

comes on and stays on.

6-67