light GMC SAVANA 2019 Manual PDF

[x] Cancel search | Manufacturer: GMC, Model Year: 2019, Model line: SAVANA, Model: GMC SAVANA 2019Pages: 373, PDF Size: 5.58 MB

Page 225 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

224 Driving and Operating

Trailer Wiring Harness

Basic Trailer Wiring

If the vehicle is not equipped with a

trailer connector on the rear bumper,

a seven-wire trailering harness is

tied to the vehicle’s frame. The

harness requires the installation of a

trailer connector, which is available

through your dealer.

Use only a round, seven-wire

connector with flat blade terminals

meeting SAE J2863 specifications

for proper electrical connectivity.

The seven-wire harness contains

the following trailer circuits:Stop/Turn

Signal Left* Yellow

Stop/Turn

Signal Right* Dark Green

Tail/Parking

Lamps** Brown

Reverse

Lamps** Light Green Battery Feed Red/Black

Ground White

Electric Trailer

Brake

Dark Blue

*If the vehicle is a cutaway with

trailer provisions, a 15 amp fuse

will be shared for both left/stop

trailer turn and right/stop trailer

turn signals. However, the

cutaway lighting connector will

have a 10 amp fuse for each

signal.

**If the vehicle is a cutaway with

trailer provisions, a 15 amp fuse

will be shared for trailer park

lamps and cutaway rear lighting

connector park lamps. Also, a

10 amp fuse will be shared for

trailer back-up lamps and cutaway

rear lighting connector back-up

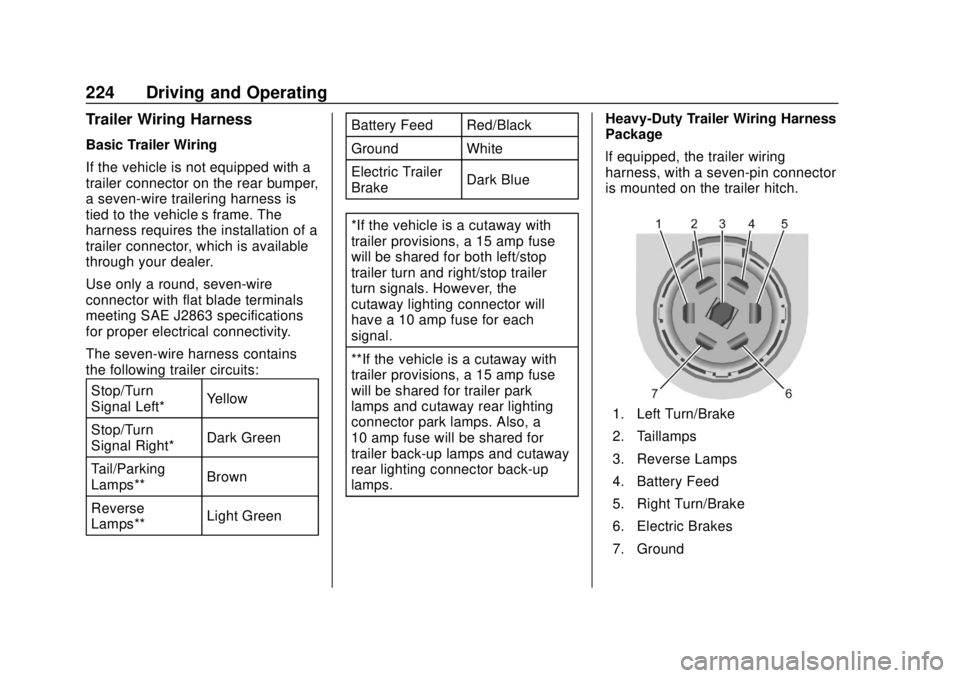

lamps. Heavy-Duty Trailer Wiring Harness

Package

lf equipped, the trailer wiring

harness, with a seven-pin connector

is mounted on the trailer hitch.

1. Left Turn/Brake

2. Taillamps

3. Reverse Lamps

4. Battery Feed

5. Right Turn/Brake

6. Electric Brakes

7. Ground

Page 226 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

Driving and Operating 225

Electric Brake Control Wiring

Provisions

If the vehicle is not equipped with

an integrated trailer brake controller,

and the trailer has electric brakes, a

trailer brake controller needs to be

installed on the vehicle. The brake

controller should be installed by

your dealer or a qualified service

center.

If equipped, wiring provisions for an

aftermarket electric trailer brake

controller are included with the

vehicle as part of the trailer wiring

package. The harness contains the

following circuits:Electric Trailer

Brakes Dark Blue

Battery Feed Red/White

Brake Apply

Signal Light Blue

Ground Black

There are four blunt cut wires under

the floor carpeting in front of the

brake pedal. It will be necessary to have a technician connect the

12-volt power to the engine

compartment fuse block.

Refer to the aftermarket electric

trailer brake controller owner's

manual to determine wire color

coding of the electric trailer brake

controller. The wire colors on the

brake controller may be different

from the vehicle.

Trailer Lamps

Always check all trailer lamps are

working at the beginning of each

trip, and periodically on longer trips.

Turn Signals When Towing a

Trailer

When properly connected, the trailer

turn signals will illuminate to indicate

the vehicle is turning, changing

lanes, or stopping. When towing a

trailer, the arrows on the instrument

cluster will illuminate even if the

trailer is not properly connected or

the bulbs are burned out.

Tow/Haul Mode

Tow/Haul assists when pulling a

heavy trailer or a large or heavy

load. For instructions on how to

enter Tow/Haul mode, see

Tow/Haul

Mode 0190.

Tow/Haul Mode is designed to be

most effective when the vehicle and

trailer combined weight is at least

75% of the vehicle's Gross

Combined Weight Rating (GCWR).

See “Trailer Weight ”under Trailer

Towing 0215.

Tow/Haul Mode is most useful when

towing a heavy trailer or carrying a

large or heavy load:

. through rolling terrain

. in stop-and-go traffic

. in busy parking lots

Operating the vehicle in Tow/Haul

Mode when lightly loaded or not

towing will not cause damage;

however, it is not recommended and

may result in unpleasant engine and

transmission driving characteristics

and reduced fuel economy.

Page 227 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

226 Driving and Operating

Trailer Sway

Control (TSC)

Vehicles with StabiliTrak/Electronic

Stability Control (ESC) have a

Trailer Sway Control (TSC) feature.

Trailer sway is unintended

side-to-side motion of a trailer while

towing. If the vehicle is towing a

trailer and the TSC detects that

sway is increasing, the vehicle

brakes are selectively applied at

each wheel, to help reduce

excessive trailer sway. If equipped

with the Integrated Trailer Brake

Control (ITBC) system, and the

trailer has an electric brake system,

StabiliTrak/ESC may also apply the

trailer brakes.

If TSC is enabled, the Traction

Control System (TCS)/StabiliTrak/

ESC warning light will flash on the

instrument cluster. Reduce vehicle

speed by gradually removing your

foot from the accelerator. If trailer

sway continues, StabiliTrak/ESC

can reduce engine torque to help

slow the vehicle. TSC will not

function if StabiliTrak/ESC is turned

off. SeeTraction Control/Electronic

Stability Control 0192.

{Warning

Trailer sway can result in a crash

and in serious injury or death,

even if the vehicle is equipped

with TSC.

(Continued)

Warning (Continued)

If the trailer begins to sway,

reduce vehicle speed by

gradually removing your foot from

the accelerator. Then pull over to

check the trailer and vehicle to

help correct possible causes,

including an improperly or

overloaded trailer, unrestrained

cargo, improper trailer hitch

configuration, or improperly

inflated or incorrect vehicle or

trailer tires. SeeTowing

Equipment 0222 for trailer ratings

and hitch setup

recommendations.

Trailer Tires

Special Trailer (ST) tires differ from

vehicle tires. Trailer tires are

designed with stiff sidewalls to help

prevent sway and to support heavy

loads. These features can make it

difficult to determine if the trailer tire

pressures are low only based on a

visual inspection.

Page 240 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

Vehicle Care 239

suspected, use the following

procedures to check the fluid level.

However, if there is a large leak, it

may be necessary to have the

vehicle towed to a dealer and have

it repaired before driving the vehicle

further.

Change the fluid and filter at the

intervals listed inMaintenance

Schedule 0319, and be sure to use

the transmission fluid listed in

Recommended Fluids and

Lubricants 0327.

How to Check Automatic

Transmission Fluid

Because this operation can be

difficult, it is recommended to have

this check done at your dealer,

which can monitor the transmission

temperature. The transmission fluid

level increases with temperature. To

obtain a highly accurate fluid level

check, the transmission temperature

must be measured.

If it is decided to check the fluid

level, be sure to follow all the

instructions here, or a false reading

on the dipstick may occur.

Caution

Too much or too little fluid can

damage the transmission. Too

much can mean that some of the

fluid could come out and fall on

hot engine parts or exhaust

system parts, starting a fire. Too

little fluid could cause the

transmission to overheat. Be sure

to get an accurate reading if

checking the transmission fluid.

Wait at least 30 minutes with the

engine off, before checking the

transmission fluid level if the vehicle

has been driven:

. In hot weather, when outside

temperatures are above 32 °C

(90 °F).

. The vehicle is heavily loaded.

. At high speed for quite a while in

hot weather.

. In heavy traffic and hot weather.

. While pulling a trailer. After driving under these conditions,

a hot check can be performed. The

fluid should be hot, which is 71 °C to

93 °C (160 °F to 200 °F).

A cold fluid level check can be

performed after the vehicle has

been sitting for eight hours or more

with the engine off, but this is used

only as a reference. Let the engine

run at idle for five minutes if the

outside temperature is between

15 °C to 32 °C (60 °F to 90 °F).

Should the fluid level be low during

this cold check, the fluid must be

checked warm or hot before adding

fluid. If the outside temperature is

colder than 15 °C (60 °F) or hotter

than 32 °C (90 °F), a cold check

cannot be performed.

A warm fluid level check can be

performed by driving the vehicle

under lightly loaded conditions and

outside temperatures between 10 °C

to 27 °C (50 °F to 80 °F). The

vehicle should be driven for at least

24 km (15 mi) before performing a

warm check. Checking the fluid

Page 241 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

240 Vehicle Care

warm or hot will give a more

accurate reading of the fluid level

than a cold check.

Because the vehicle is equipped

with a high-efficiency air-to-oil

cooler, the transmission fluid

temperature may not reach the

required hot fluid level checking

temperature under normal lightly

loaded driving vehicle conditions.

Checking the Fluid Level

Prepare the vehicle:1. Park the vehicle on a level place. Keep the engine

running.

2. With the parking brake applied, place the shift lever in P (Park).

3. With a foot on the brake pedal, move the shift lever through

each gear range, pausing for

about three seconds in each

range. When M is reached,

move the selector from M1

through M3. Then, position the

shift lever in P (Park).

4. Let the engine run at idle for two minutes or more. Then, without shutting off the

engine, use the steps that follow.

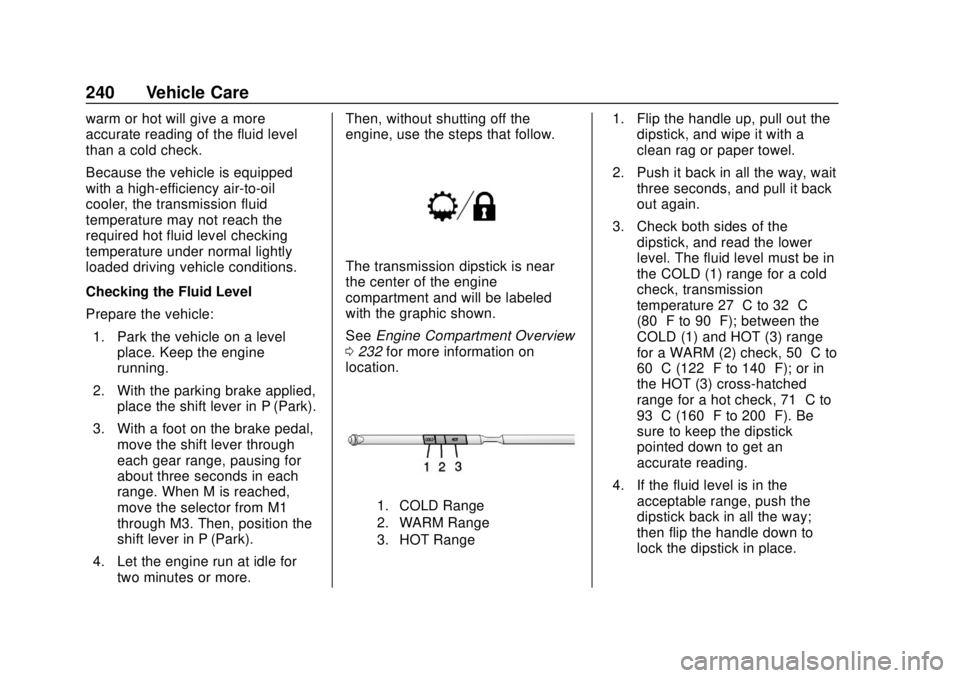

The transmission dipstick is near

the center of the engine

compartment and will be labeled

with the graphic shown.

See

Engine Compartment Overview

0 232 for more information on

location.

1. COLD Range

2. WARM Range

3. HOT Range

1. Flip the handle up, pull out the dipstick, and wipe it with a

clean rag or paper towel.

2. Push it back in all the way, wait three seconds, and pull it back

out again.

3. Check both sides of the dipstick, and read the lower

level. The fluid level must be in

the COLD (1) range for a cold

check, transmission

temperature 27 °C to 32 °C

(80 °F to 90 °F); between the

COLD (1) and HOT (3) range

for a WARM (2) check, 50 °C to

60 °C (122 °F to 140 °F); or in

the HOT (3) cross-hatched

range for a hot check, 71 °C to

93 °C (160 °F to 200 °F). Be

sure to keep the dipstick

pointed down to get an

accurate reading.

4. If the fluid level is in the acceptable range, push the

dipstick back in all the way;

then flip the handle down to

lock the dipstick in place.

Page 243 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

242 Vehicle Care

Caution

Use of the incorrect automatic

transmission fluid may damage

the vehicle, and the damage may

not be covered by the vehicle

warranty. Always use the correct

automatic transmission fluid. See

Recommended Fluids and

Lubricants0327.

Change the fluid and filter at the

scheduled maintenance intervals

listed in Maintenance Schedule

0 319. Be sure to use the

transmission fluid listed in

Recommended Fluids and

Lubricants 0327.

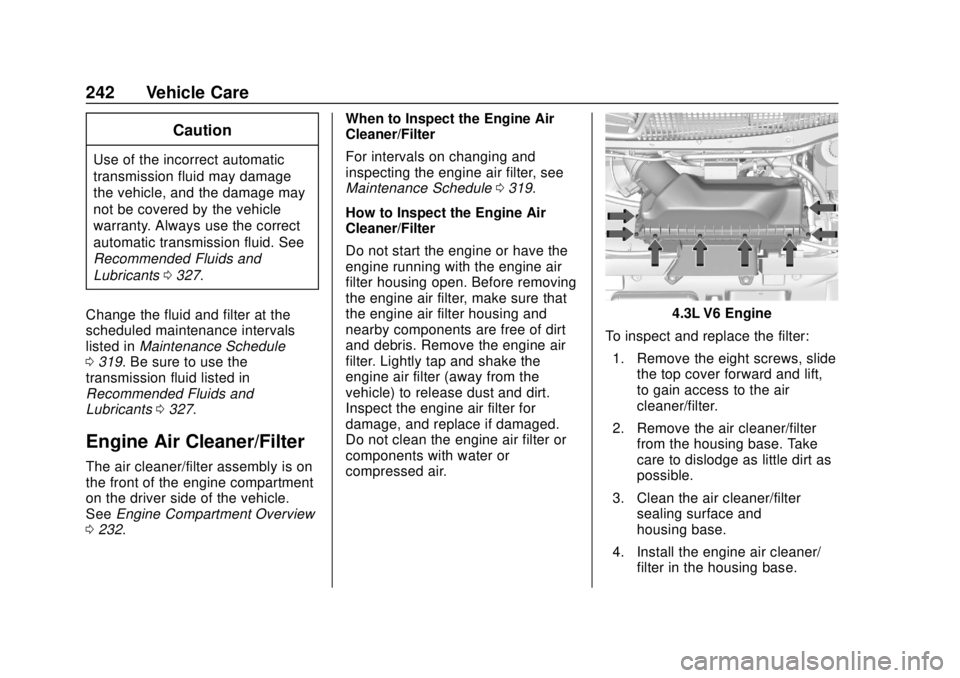

Engine Air Cleaner/Filter

The air cleaner/filter assembly is on

the front of the engine compartment

on the driver side of the vehicle.

See Engine Compartment Overview

0 232. When to Inspect the Engine Air

Cleaner/Filter

For intervals on changing and

inspecting the engine air filter, see

Maintenance Schedule

0319.

How to Inspect the Engine Air

Cleaner/Filter

Do not start the engine or have the

engine running with the engine air

filter housing open. Before removing

the engine air filter, make sure that

the engine air filter housing and

nearby components are free of dirt

and debris. Remove the engine air

filter. Lightly tap and shake the

engine air filter (away from the

vehicle) to release dust and dirt.

Inspect the engine air filter for

damage, and replace if damaged.

Do not clean the engine air filter or

components with water or

compressed air.

4.3L V6 Engine

To inspect and replace the filter: 1. Remove the eight screws, slide the top cover forward and lift,

to gain access to the air

cleaner/filter.

2. Remove the air cleaner/filter from the housing base. Take

care to dislodge as little dirt as

possible.

3. Clean the air cleaner/filter sealing surface and

housing base.

4. Install the engine air cleaner/ filter in the housing base.

Page 252 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

Vehicle Care 251

Caution

.Do not use washer fluid that

contains any type of water

repellent coating. This can

cause the wiper blades to

chatter or skip.

. Do not use engine coolant

(antifreeze) in the

windshield washer. It can

damage the windshield

washer system and paint.

. Do not mix water with

ready-to-use washer fluid.

Water can cause the

solution to freeze and

damage the washer fluid

tank and other parts of the

washer system.

. When using concentrated

washer fluid, follow the

manufacturer instructions for

adding water.

. Fill the washer fluid tank

only three-quarters full when

it is very cold. This allows

(Continued)

Caution (Continued)

for fluid expansion if

freezing occurs, which could

damage the tank if it is

completely full.

Brakes

Disc brake pads have built-in wear

indicators that make a high-pitched

warning sound when the brake pads

are worn and new pads are needed.

The sound can come and go or can

be heard all the time when the

vehicle is moving, except when

applying the brake pedal firmly.

{Warning

The brake wear warning sound

means that soon the brakes will

not work well. That could lead to

a crash. When the brake wear

warning sound is heard, have the

vehicle serviced.

Caution

Continuing to drive with worn-out

brake pads could result in costly

brake repair.

Some driving conditions or climates

can cause a brake squeal when the

brakes are first applied or lightly

applied. This does not mean

something is wrong with the brakes.

Properly torqued wheel nuts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear and

evenly tighten wheel nuts in the

proper sequence to torque

specifications. See Capacities and

Specifications 0332.

Brake pads should be replaced as

complete sets.

Brake Pedal Travel

See your dealer if the brake pedal

does not return to normal height,

or if there is a rapid increase in

pedal travel. This could be a sign

that brake service may be required.

Page 253 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

252 Vehicle Care

Replacing Brake System Parts

Always replace brake system parts

with new, approved replacement

parts. If this is not done, the brakes

may not work properly. The braking

performance expected can change

in many other ways if the wrong

replacement brake parts are

installed or if parts are improperly

installed.

Brake Fluid

The brake master cylinder reservoir

is filled with DOT 3 brake fluid. See

Engine Compartment Overview

0232 for the location of the

reservoir.

There are only two reasons why the

brake fluid level in the reservoir may

go down: .

Normal brake lining wear. When

new linings are installed, the

fluid level goes back up.

. A fluid leak in the brake

hydraulic system. Have the

brake hydraulic system fixed.

With a leak, the brakes will not

work well.

Always clean the brake fluid

reservoir cap and the area around

the cap before removing it.

Do not top off the brake fluid.

Adding fluid does not correct a leak.

If fluid is added when the linings are

worn, there will be too much fluid

when new brake linings are

installed. Add or remove fluid, as

necessary, only when work is done

on the brake hydraulic system.

{Warning

If too much brake fluid is added, it

can spill on the engine and burn,

if the engine is hot enough. You

or others could be burned, and

the vehicle could be damaged. (Continued)

Warning (Continued)

Add brake fluid only when work is

done on the brake hydraulic

system.

When the brake fluid falls to a low

level, the brake warning light comes

on. See Brake System Warning

Light 0109.

Brake fluid absorbs water over time.

Replace brake fluid at the specified

intervals to prevent increased

stopping distance. See Maintenance

Schedule 0319.

Checking Brake Fluid

Check brake fluid by looking at the

brake fluid reservoir. See Engine

Compartment Overview 0232.

Page 262 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

Vehicle Care 261

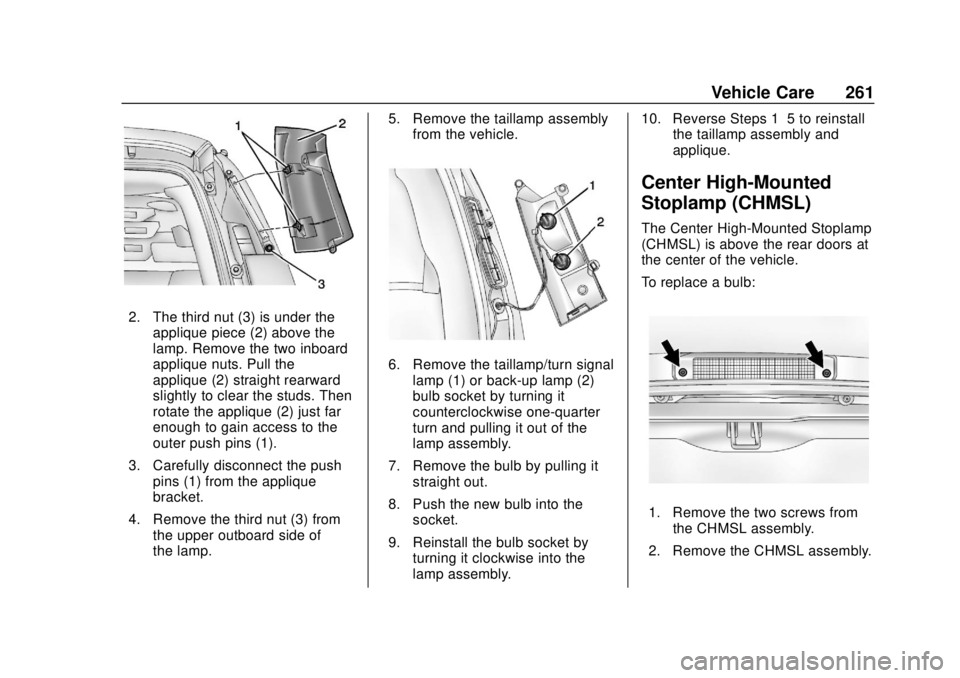

2. The third nut (3) is under theapplique piece (2) above the

lamp. Remove the two inboard

applique nuts. Pull the

applique (2) straight rearward

slightly to clear the studs. Then

rotate the applique (2) just far

enough to gain access to the

outer push pins (1).

3. Carefully disconnect the push pins (1) from the applique

bracket.

4. Remove the third nut (3) from the upper outboard side of

the lamp. 5. Remove the taillamp assembly

from the vehicle.

6. Remove the taillamp/turn signallamp (1) or back-up lamp (2)

bulb socket by turning it

counterclockwise one-quarter

turn and pulling it out of the

lamp assembly.

7. Remove the bulb by pulling it straight out.

8. Push the new bulb into the socket.

9. Reinstall the bulb socket by turning it clockwise into the

lamp assembly. 10. Reverse Steps 1–5 to reinstall

the taillamp assembly and

applique.

Center High-Mounted

Stoplamp (CHMSL)

The Center High-Mounted Stoplamp

(CHMSL) is above the rear doors at

the center of the vehicle.

To replace a bulb:

1. Remove the two screws fromthe CHMSL assembly.

2. Remove the CHMSL assembly.

Page 267 of 373

GMC Savana Owner Manual (GMNA-Localizing-U.S./Canada-12146167) -

2019 - CRC - 11/26/18

266 Vehicle Care

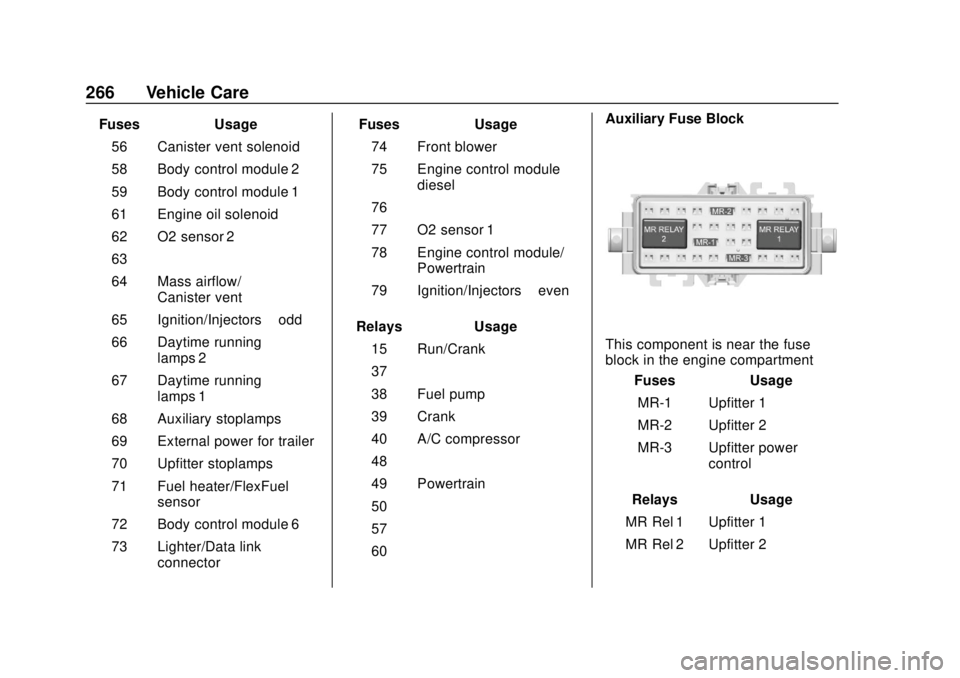

FusesUsage

56 Canister vent solenoid

58 Body control module 2

59 Body control module 1

61 Engine oil solenoid

62 O2 sensor 2

63 –

64 Mass airflow/ Canister vent

65 Ignition/Injectors –odd

66 Daytime running lamps 2

67 Daytime running lamps 1

68 Auxiliary stoplamps

69 External power for trailer

70 Upfitter stoplamps

71 Fuel heater/FlexFuel sensor

72 Body control module 6

73 Lighter/Data link connector Fuses

Usage

74 Front blower

75 Engine control module diesel

76 –

77 O2 sensor 1

78 Engine control module/ Powertrain

79 Ignition/Injectors –even

Relays Usage

15 Run/Crank

37 –

38 Fuel pump

39 Crank

40 A/C compressor

48 –

49 Powertrain

50 –

57 –

60 – Auxiliary Fuse Block

This component is near the fuse

block in the engine compartment

Fuses Usage

MR-1 Upfitter 1

MR-2 Upfitter 2

MR-3 Upfitter power control

Relays Usage

MR Rel 1 Upfitter 1

MR Rel 2 Upfitter 2