clock GMC SAVANA PASSENGER 2009 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2009, Model line: SAVANA PASSENGER, Model: GMC SAVANA PASSENGER 2009Pages: 406, PDF Size: 2.34 MB

Page 293 of 406

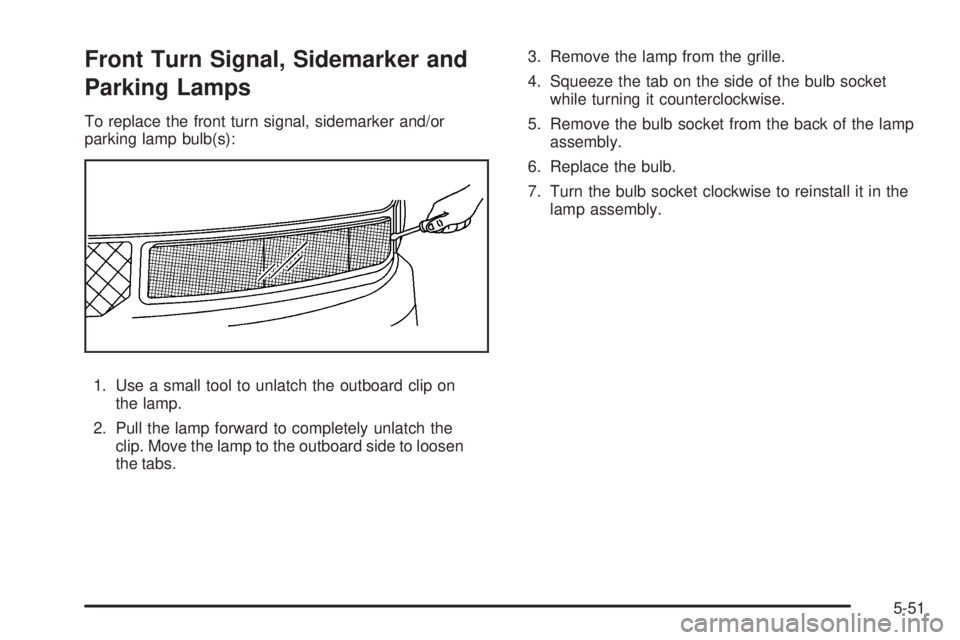

Front Turn Signal, Sidemarker and

Parking Lamps

To replace the front turn signal, sidemarker and/or

parking lamp bulb(s):

1. Use a small tool to unlatch the outboard clip on

the lamp.

2. Pull the lamp forward to completely unlatch the

clip. Move the lamp to the outboard side to loosen

the tabs.3. Remove the lamp from the grille.

4. Squeeze the tab on the side of the bulb socket

while turning it counterclockwise.

5. Remove the bulb socket from the back of the lamp

assembly.

6. Replace the bulb.

7. Turn the bulb socket clockwise to reinstall it in the

lamp assembly.

5-51

Page 294 of 406

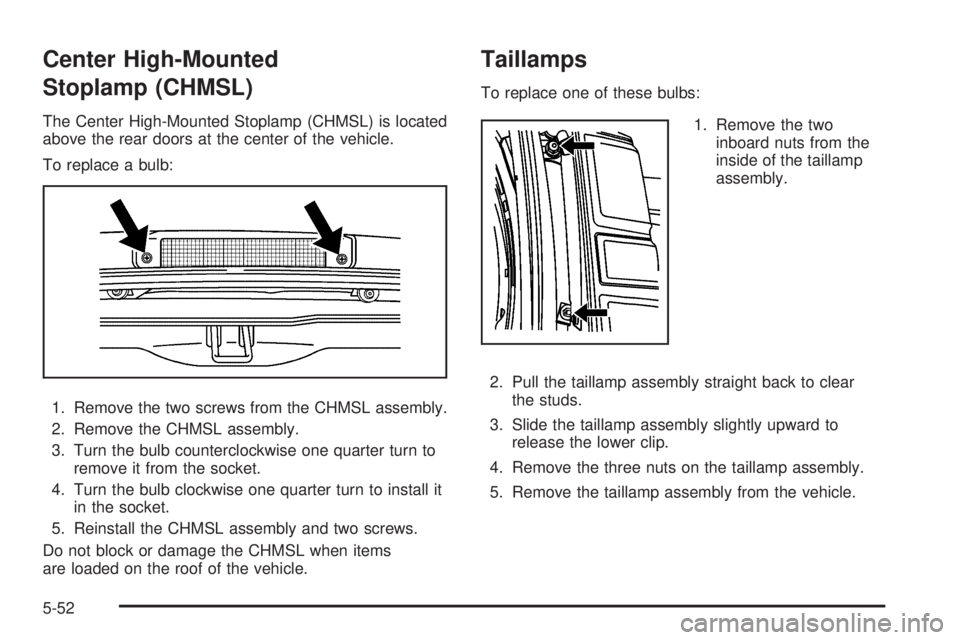

Center High-Mounted

Stoplamp (CHMSL)

The Center High-Mounted Stoplamp (CHMSL) is located

above the rear doors at the center of the vehicle.

To replace a bulb:

1. Remove the two screws from the CHMSL assembly.

2. Remove the CHMSL assembly.

3. Turn the bulb counterclockwise one quarter turn to

remove it from the socket.

4. Turn the bulb clockwise one quarter turn to install it

in the socket.

5. Reinstall the CHMSL assembly and two screws.

Do not block or damage the CHMSL when items

are loaded on the roof of the vehicle.

Taillamps

To replace one of these bulbs:

1. Remove the two

inboard nuts from the

inside of the taillamp

assembly.

2. Pull the taillamp assembly straight back to clear

the studs.

3. Slide the taillamp assembly slightly upward to

release the lower clip.

4. Remove the three nuts on the taillamp assembly.

5. Remove the taillamp assembly from the vehicle.

5-52

Page 295 of 406

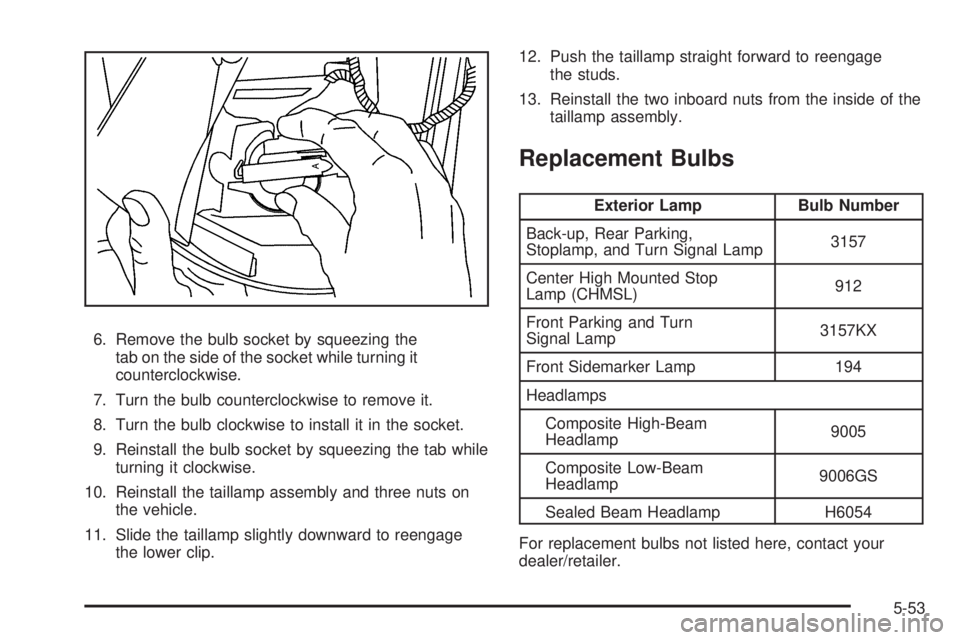

6. Remove the bulb socket by squeezing the

tab on the side of the socket while turning it

counterclockwise.

7. Turn the bulb counterclockwise to remove it.

8. Turn the bulb clockwise to install it in the socket.

9. Reinstall the bulb socket by squeezing the tab while

turning it clockwise.

10. Reinstall the taillamp assembly and three nuts on

the vehicle.

11. Slide the taillamp slightly downward to reengage

the lower clip.12. Push the taillamp straight forward to reengage

the studs.

13. Reinstall the two inboard nuts from the inside of the

taillamp assembly.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up, Rear Parking,

Stoplamp, and Turn Signal Lamp3157

Center High Mounted Stop

Lamp (CHMSL)912

Front Parking and Turn

Signal Lamp3157KX

Front Sidemarker Lamp 194

Headlamps

Composite High-Beam

Headlamp9005

Composite Low-Beam

Headlamp9006GS

Sealed Beam Headlamp H6054

For replacement bulbs not listed here, contact your

dealer/retailer.

5-53

Page 325 of 406

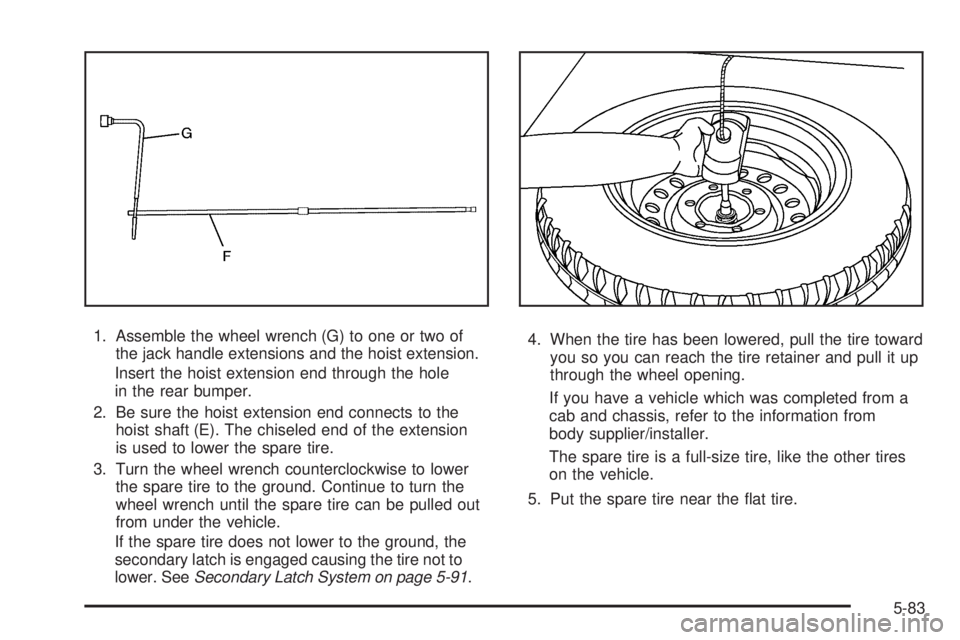

1. Assemble the wheel wrench (G) to one or two of

the jack handle extensions and the hoist extension.

Insert the hoist extension end through the hole

in the rear bumper.

2. Be sure the hoist extension end connects to the

hoist shaft (E). The chiseled end of the extension

is used to lower the spare tire.

3. Turn the wheel wrench counterclockwise to lower

the spare tire to the ground. Continue to turn the

wheel wrench until the spare tire can be pulled out

from under the vehicle.

If the spare tire does not lower to the ground, the

secondary latch is engaged causing the tire not to

lower. SeeSecondary Latch System on page 5-91.4. When the tire has been lowered, pull the tire toward

you so you can reach the tire retainer and pull it up

through the wheel opening.

If you have a vehicle which was completed from a

cab and chassis, refer to the information from

body supplier/installer.

The spare tire is a full-size tire, like the other tires

on the vehicle.

5. Put the spare tire near the flat tire.

5-83

Page 326 of 406

Removing the Flat Tire and

Installing the Spare Tire

If your vehicle has plastic wheel nut caps, loosen

them by turning the wheel wrench counterclockwise.

The wheel nut caps are designed to remain with

the center cap. Remove the center cap.

If the wheel has a smooth center piece, place the chisel

end of the wheel wrench in the slot on the wheel and

gently pry it out.

1. Do a safety check before proceeding. SeeChanging

a Flat Tire on page 5-80for more information.

2. Loosen all the wheel nuts with the wheel wrench.

Do not remove them yet.

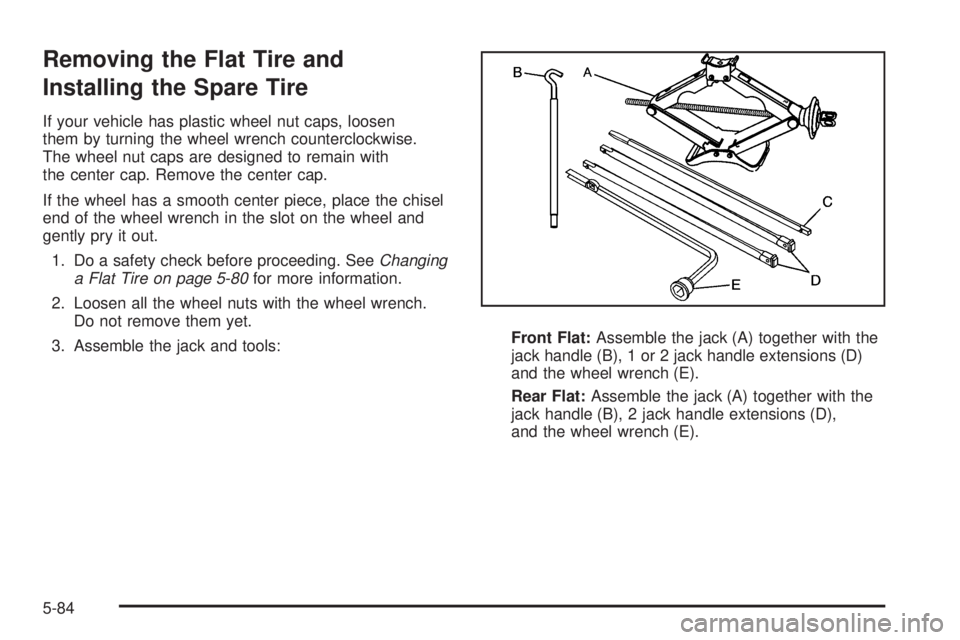

3. Assemble the jack and tools:Front Flat:Assemble the jack (A) together with the

jack handle (B), 1 or 2 jack handle extensions (D)

and the wheel wrench (E).

Rear Flat:Assemble the jack (A) together with the

jack handle (B), 2 jack handle extensions (D),

and the wheel wrench (E).

5-84

Page 329 of 406

{CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get under a

vehicle when it is supported only by a jack.

{CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even

make the vehicle fall. To help avoid personal injury

and vehicle damage, be sure to fit the jack lift

head into the proper location before raising the

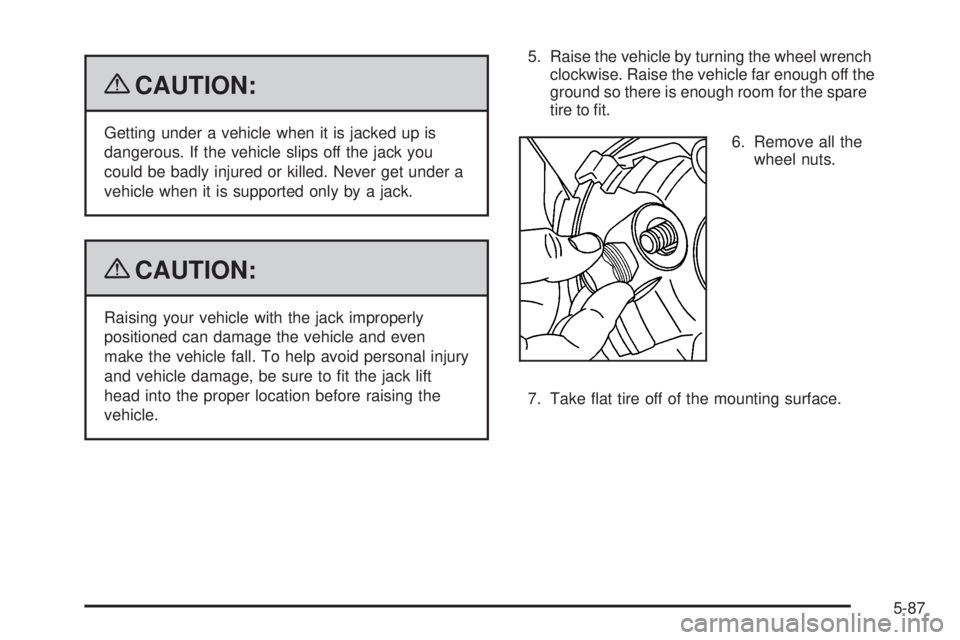

vehicle.5. Raise the vehicle by turning the wheel wrench

clockwise. Raise the vehicle far enough off the

ground so there is enough room for the spare

tire to fit.

6. Remove all the

wheel nuts.

7. Take flat tire off of the mounting surface.

5-87

Page 331 of 406

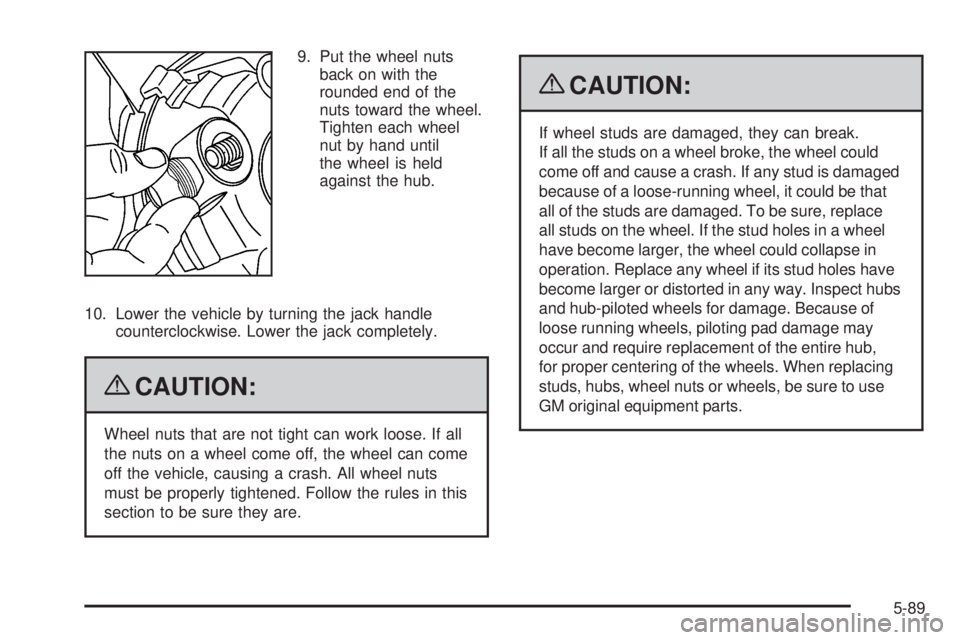

9. Put the wheel nuts

back on with the

rounded end of the

nuts toward the wheel.

Tighten each wheel

nut by hand until

the wheel is held

against the hub.

10. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{CAUTION:

Wheel nuts that are not tight can work loose. If all

the nuts on a wheel come off, the wheel can come

off the vehicle, causing a crash. All wheel nuts

must be properly tightened. Follow the rules in this

section to be sure they are.

{CAUTION:

If wheel studs are damaged, they can break.

If all the studs on a wheel broke, the wheel could

come off and cause a crash. If any stud is damaged

because of a loose-running wheel, it could be that

all of the studs are damaged. To be sure, replace

all studs on the wheel. If the stud holes in a wheel

have become larger, the wheel could collapse in

operation. Replace any wheel if its stud holes have

become larger or distorted in any way. Inspect hubs

and hub-piloted wheels for damage. Because of

loose running wheels, piloting pad damage may

occur and require replacement of the entire hub,

for proper centering of the wheels. When replacing

studs, hubs, wheel nuts or wheels, be sure to use

GM original equipment parts.

5-89

Page 332 of 406

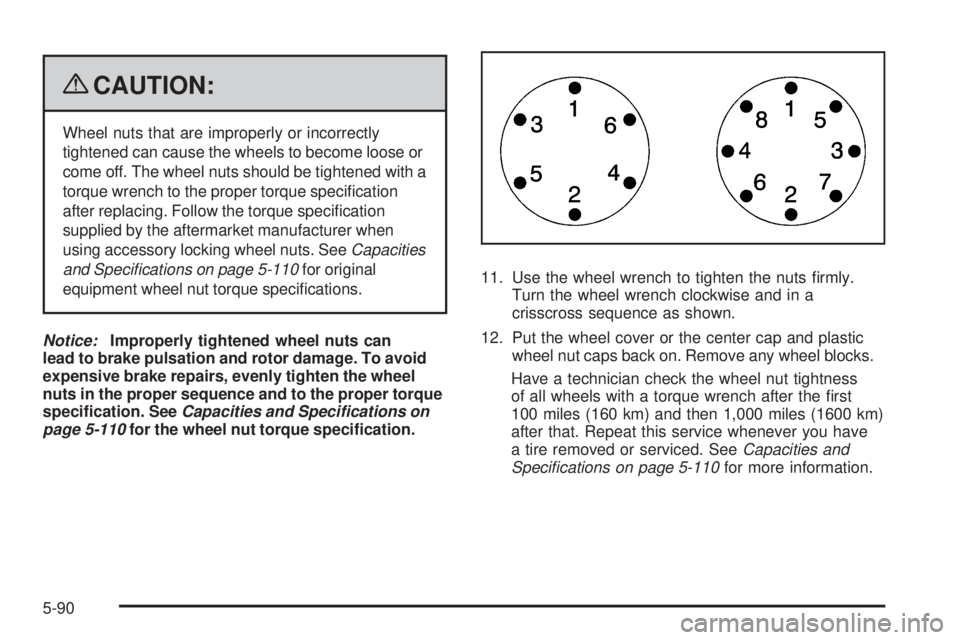

{CAUTION:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose or

come off. The wheel nuts should be tightened with a

torque wrench to the proper torque specification

after replacing. Follow the torque specification

supplied by the aftermarket manufacturer when

using accessory locking wheel nuts. SeeCapacities

and Specifications on page 5-110for original

equipment wheel nut torque specifications.

Notice:Improperly tightened wheel nuts can

lead to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

speci�cation. SeeCapacities and Specifications on

page 5-110for the wheel nut torque speci�cation.11. Use the wheel wrench to tighten the nuts firmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

12. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel blocks.

Have a technician check the wheel nut tightness

of all wheels with a torque wrench after the first

100 miles (160 km) and then 1,000 miles (1600 km)

after that. Repeat this service whenever you have

a tire removed or serviced. SeeCapacities and

Specifications on page 5-110for more information.

5-90

Page 334 of 406

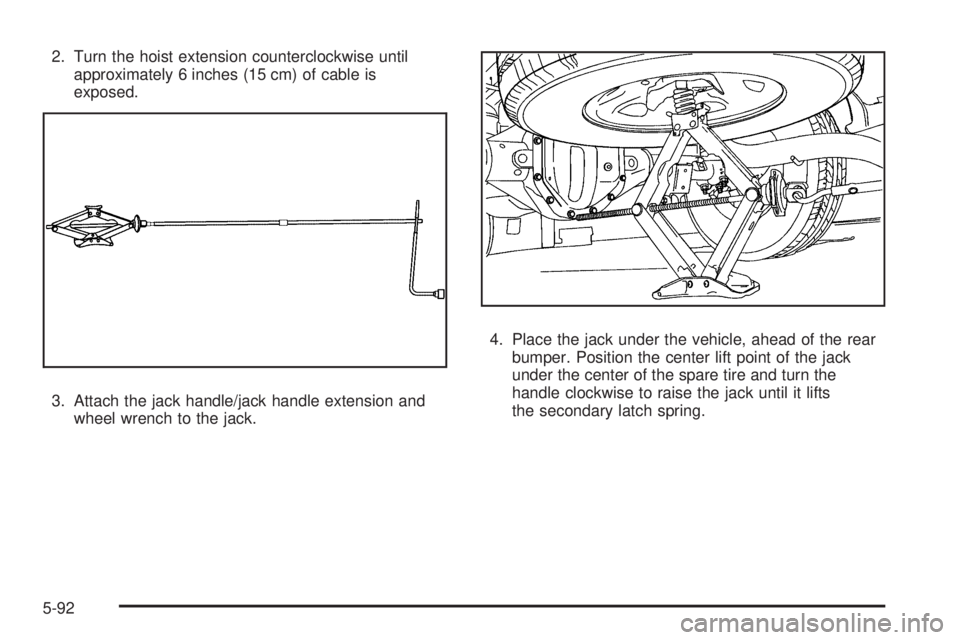

2. Turn the hoist extension counterclockwise until

approximately 6 inches (15 cm) of cable is

exposed.

3. Attach the jack handle/jack handle extension and

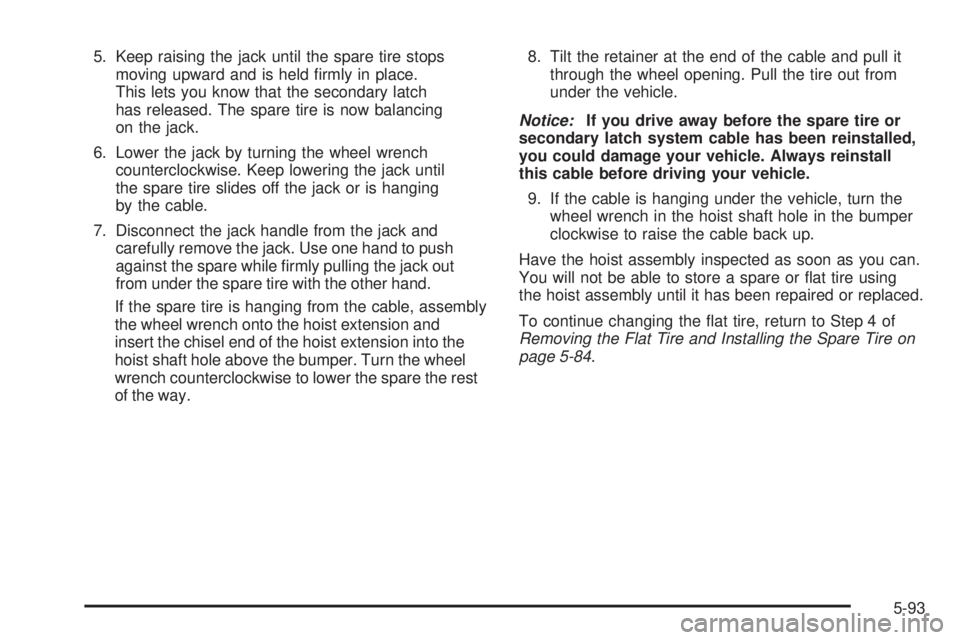

wheel wrench to the jack.4. Place the jack under the vehicle, ahead of the rear

bumper. Position the center lift point of the jack

under the center of the spare tire and turn the

handle clockwise to raise the jack until it lifts

the secondary latch spring.

5-92

Page 335 of 406

5. Keep raising the jack until the spare tire stops

moving upward and is held firmly in place.

This lets you know that the secondary latch

has released. The spare tire is now balancing

on the jack.

6. Lower the jack by turning the wheel wrench

counterclockwise. Keep lowering the jack until

the spare tire slides off the jack or is hanging

by the cable.

7. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push

against the spare while firmly pulling the jack out

from under the spare tire with the other hand.

If the spare tire is hanging from the cable, assembly

the wheel wrench onto the hoist extension and

insert the chisel end of the hoist extension into the

hoist shaft hole above the bumper. Turn the wheel

wrench counterclockwise to lower the spare the rest

of the way.8. Tilt the retainer at the end of the cable and pull it

through the wheel opening. Pull the tire out from

under the vehicle.

Notice:If you drive away before the spare tire or

secondary latch system cable has been reinstalled,

you could damage your vehicle. Always reinstall

this cable before driving your vehicle.

9. If the cable is hanging under the vehicle, turn the

wheel wrench in the hoist shaft hole in the bumper

clockwise to raise the cable back up.

Have the hoist assembly inspected as soon as you can.

You will not be able to store a spare or flat tire using

the hoist assembly until it has been repaired or replaced.

To continue changing the flat tire, return to Step 4 of

Removing the Flat Tire and Installing the Spare Tire on

page 5-84.

5-93