change wheel GMC SIERRA 2001 User Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2001, Model line: SIERRA, Model: GMC SIERRA 2001Pages: 468, PDF Size: 3.2 MB

Page 325 of 468

5-19

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your hazard

warning flashers.

CAUTION:

Changing a tire can cause an injury. The vehicle

can slip off the jack and roll over you or other

people. You and they could be badly injured.

Find a level place to change your tire. To help

prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put an automatic transmission shift lever in

PARK (P) or shift a manual transmission

to FIRST (1) or REVERSE (R).

3. If you have a four

-wheel-drive vehicle,

be sure the transfer case is in a drive

gear

-- not in NEUTRAL.

CAUTION: (Continued)

CAUTION: (Continued)

4. Turn off the engine.

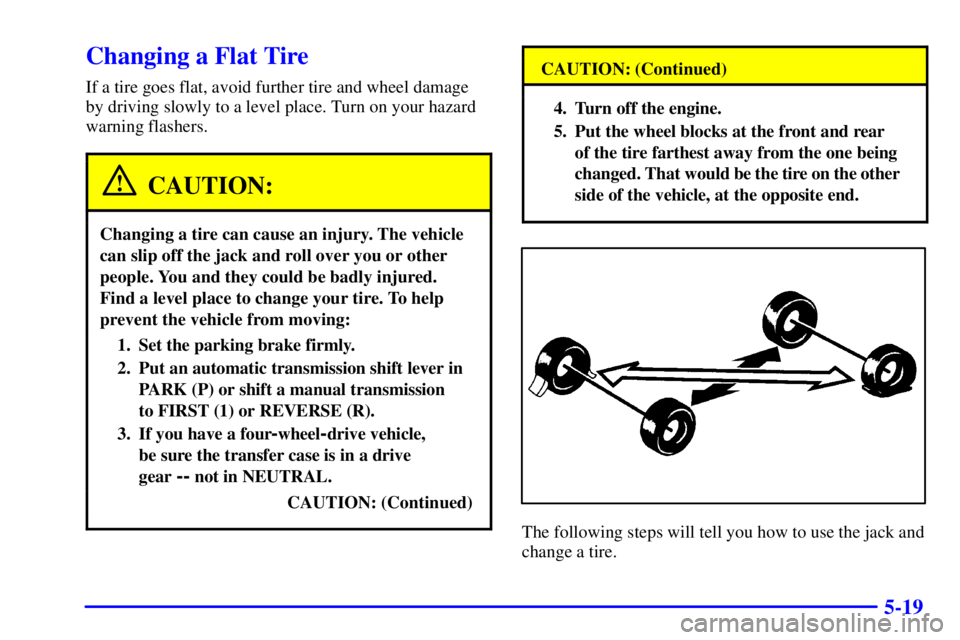

5. Put the wheel blocks at the front and rear

of the tire farthest away from the one being

changed. That would be the tire on the other

side of the vehicle, at the opposite end.

The following steps will tell you how to use the jack and

change a tire.

Page 334 of 468

5-28

CAUTION:

Rust or dirt on the wheel, or on the parts to

which it is fastened, can make the wheel nuts

become loose after a time. The wheel could come

off and cause an accident. When you change a

wheel, remove any rust or dirt from the places

where the wheel attaches to the vehicle. In an

emergency, you can use a cloth or a paper towel

to do this; but be sure to use a scraper or wire

brush later, if you need to, to get all the rust or

dirt off.

CAUTION:

Never use oil or grease on studs or nuts. If you

do, the nuts might come loose. Your wheel could

fall off, causing a serious accident.

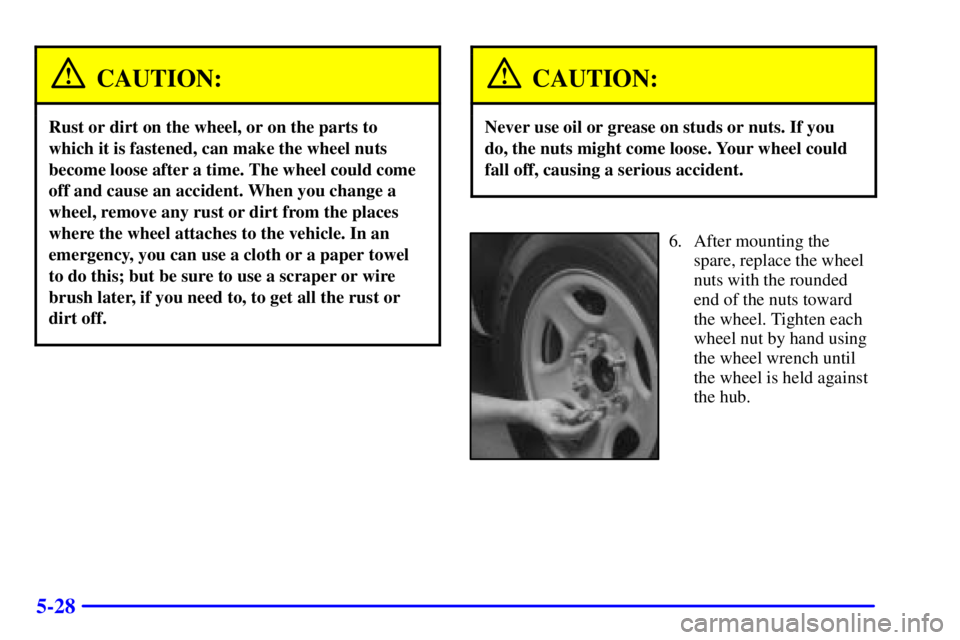

6. After mounting the

spare, replace the wheel

nuts with the rounded

end of the nuts toward

the wheel. Tighten each

wheel nut by hand using

the wheel wrench until

the wheel is held against

the hub.

Page 384 of 468

6-42

NOTICE:

Continuing to drive with worn-out brake pads

could result in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help prevent

brake pulsation. When tires are rotated, inspect brake

pads for wear and evenly tighten wheel nuts in the proper

sequence to GM torque specifications.

Brake linings should always be replaced as complete

axle sets.

See ªBrake System Inspectionº in Section 7 of this

manual under Part C ªPeriodic Maintenance Inspections.º

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in pedal

travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you make a brake stop, your disc brakes

adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together

if the vehicle is to have really good braking. Your

vehicle was designed and tested with top

-quality

GM brake parts. When you replace parts of your braking

system

-- for example, when your brake linings wear

down and you have to have new ones put in

-- be sure

you get new approved GM replacement parts. If you

don't, your brakes may no longer work properly.

For example, if someone puts in brake linings that

are wrong for your vehicle, the balance between your

front and rear brakes can change

-- for the worse.

The braking performance you've come to expect can

change in many other ways if someone puts in the

wrong replacement brake parts.

Page 397 of 468

6-55

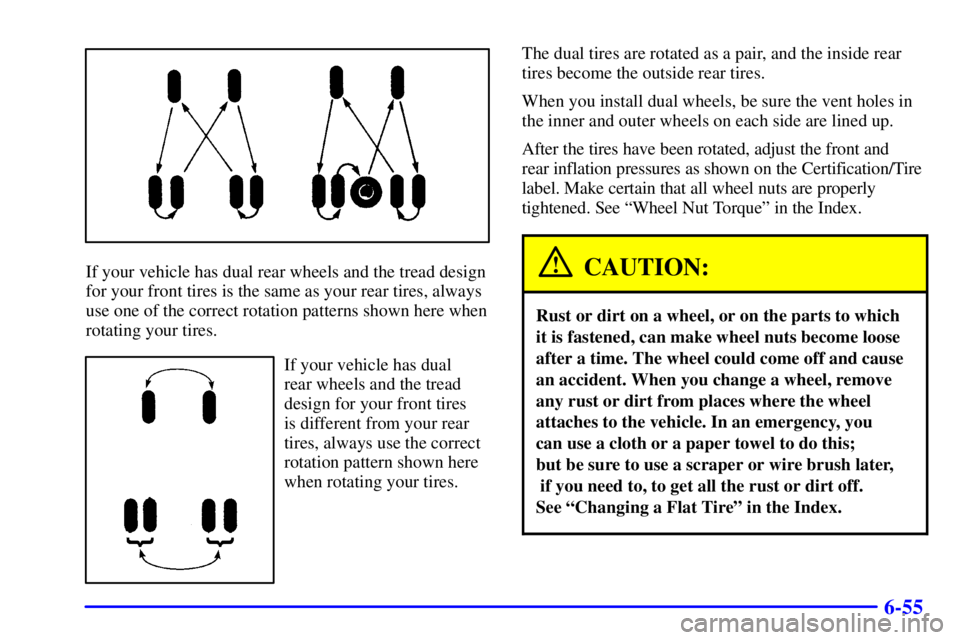

If your vehicle has dual rear wheels and the tread design

for your front tires is the same as your rear tires, always

use one of the correct rotation patterns shown here when

rotating your tires.

If your vehicle has dual

rear wheels and the tread

design for your front tires

is different from your rear

tires, always use the correct

rotation pattern shown here

when rotating your tires.The dual tires are rotated as a pair, and the inside rear

tires become the outside rear tires.

When you install dual wheels, be sure the vent holes in

the inner and outer wheels on each side are lined up.

After the tires have been rotated, adjust the front and

rear inflation pressures as shown on the Certification/Tire

label. Make certain that all wheel nuts are properly

tightened. See ªWheel Nut Torqueº in the Index.

CAUTION:

Rust or dirt on a wheel, or on the parts to which

it is fastened, can make wheel nuts become loose

after a time. The wheel could come off and cause

an accident. When you change a wheel, remove

any rust or dirt from places where the wheel

attaches to the vehicle. In an emergency, you

can use a cloth or a paper towel to do this;

but be sure to use a scraper or wire brush later,

if you need to, to get all the rust or dirt off.

See ªChanging a Flat Tireº in the Index.

Page 444 of 468

7-19 At Least Twice a Year

Restraint System Check

Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages are

working properly. Look for any other loose or damaged

safety belt system parts. If you see anything that might

keep a safety belt system from doing its job, have it

repaired. Have any torn or frayed safety belts replaced.

Also look for any opened or broken air bag coverings,

and have them repaired or replaced. (The air bag system

does not need regular maintenance.)

Wiper Blade Check

Inspect wiper blades for wear or cracking. Replace blade

inserts that appear worn or damaged or that streak or

miss areas of the windshield. Also see ªWiper Blades,

Cleaningº in the Index.Spare Tire Check

At least twice a year, after the monthly inflation check

of the spare tire determines that the spare is inflated to

the correct tire inflation pressure, make sure that the

spare tire is stored securely. Push, pull, and then try

to rotate or turn the tire. If it moves, use the wheel

wrench/ratchet to tighten the cable. See ªStoring the

Spare Tire and Toolsº in the Index.

Engine Air Cleaner Filter Restriction Indicator Check

Your vehicle has an indicator located on the air cleaner

in the engine compartment that lets you know when the

air cleaner filter is dirty and needs to be changed. Check

indicator at least twice a year or when your engine oil is

changed, whichever occurs first. See ªAir Cleanerº in

the Index for more information. Inspect your air cleaner

filter restriction indicator more often if the vehicle is

used in dusty areas or under off road conditions.

Page 449 of 468

7-24 Throttle System Inspection

Inspect the throttle system for interference or binding,

and for damaged or missing parts. Replace parts as

needed. Replace any components that have high effort

or excessive wear. Do not lubricate accelerator and

cruise control cables.

Transfer Case and Front Axle

(Four-Wheel Drive) Inspection

Every 12 months or at engine oil change intervals,

check front axle and transfer case and add lubricant

when necessary. A fluid loss could indicate a problem;

check and have it repaired, if needed. On manual

shift transfer case, oil the control lever pivot point.

Check vent hose at transfer case for kinks and proper

installation. More frequent lubrication may be required

on off

-road use.

Brake System Inspection

Inspect the complete system. Inspect brake lines and

hoses for proper hook

-up, binding, leaks, cracks,

chafing, etc. Inspect disc brake pads for wear and

rotors for surface condition. Inspect other brake parts,

including calipers, parking brake, etc. You may need to

have your brakes inspected more often if your driving

habits or conditions result in frequent braking.