key GMC SIERRA 2003 Service Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2003, Model line: SIERRA, Model: GMC SIERRA 2003Pages: 408, PDF Size: 2.58 MB

Page 327 of 408

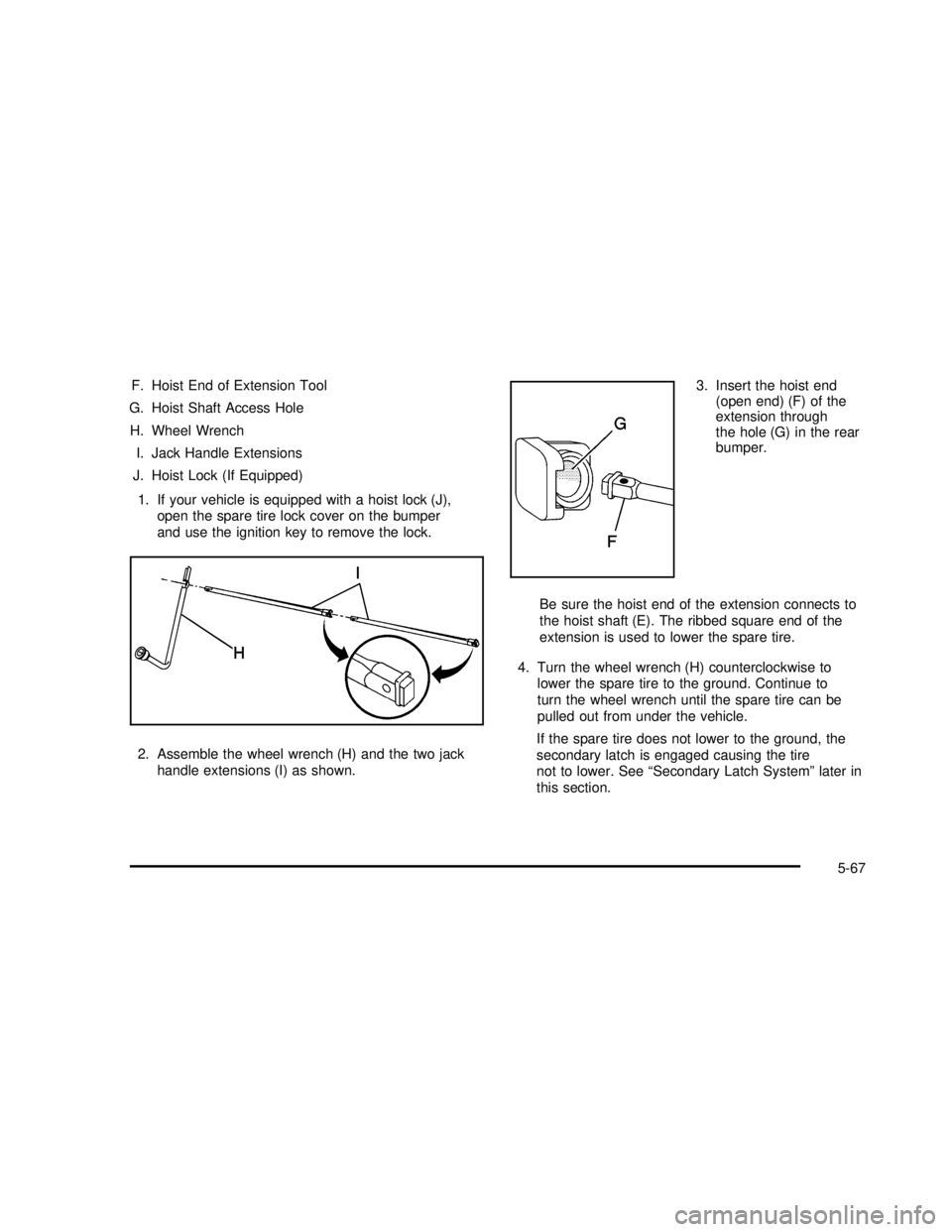

F. Hoist End of Extension Tool

G. Hoist Shaft Access Hole

H. Wheel Wrench

I. Jack Handle Extensions

J. Hoist Lock (If Equipped)

1. If your vehicle is equipped with a hoist lock (J),

open the spare tire lock cover on the bumper

and use the ignition key to remove the lock.

2. Assemble the wheel wrench (H) and the two jack

handle extensions (I) as shown.3. Insert the hoist end

(open end) (F) of the

extension through

the hole (G) in the rear

bumper.

Be sure the hoist end of the extension connects to

the hoist shaft (E). The ribbed square end of the

extension is used to lower the spare tire.

4. Turn the wheel wrench (H) counterclockwise to

lower the spare tire to the ground. Continue to

turn the wheel wrench until the spare tire can be

pulled out from under the vehicle.

If the spare tire does not lower to the ground, the

secondary latch is engaged causing the tire

not to lower. See“Secondary Latch System”later in

this section.

5-67

2003 - Sierra Denali

Page 371 of 408

Also look for any opened or broken air bag coverings,

and have them repaired or replaced. (The air bag

system does not need regular maintenance.)

Wiper Blade Check

Inspect wiper blades for wear or cracking. Replace

blade inserts that appear worn or damaged or that

streak or miss areas of the windshield. Also see

Cleaning the Outside of Your Vehicle on page 5-85.

Spare Tire Check

At least twice a year, after the monthly in�ation check of

the spare tire determines that the spare is in�ated to

the correct tire in�ation pressure, make sure that

the spare tire is stored securely. Push, pull, and then try

to rotate or turn the tire. If it moves, use the wheel

wrench/ratchet to tighten the cable. SeeChanging a Flat

Tire on page 5-65.

Weatherstrip Lubrication

Silicone grease on weatherstrips will make them last

longer, seal better, and not stick or squeak. Apply

silicone grease with a clean cloth. During very cold,

damp weather more frequent application may be

required. SeePart D: Recommended Fluids and

Lubricants on page 6-15.

Automatic Transmission Check

Check the transmission�uid level; add if needed. See

Automatic Transmission Fluid on page 5-20.A�uid loss

may indicate a problem. Check the system and repair

if needed.

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

speci�ed in Part D.

Body Lubrication Service

Lubricate all body door hinges, hood latch assembly,

secondary latch, pivots, spring anchor, release

pawl, tailgate hinge, tailgate linkage, tailgate handle

pivot points, latch bolt, fuel door hinge, locks and folding

seat hardware. Part D tells you what to use. More

frequent lubrication may be required when exposed to a

corrosive environment.

6-11

2003 - Sierra Denali

Page 372 of 408

Starter Switch Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-22if

necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. Try to start the engine in each gear. The starter

should work only in PARK (P) or NEUTRAL (N).

If the starter works in any other position, your

vehicle needs service.

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake. SeeParking Brake

on page 2-22if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the key to the RUN

position, but don’t start the engine. Without applying

the regular brake, try to move the shift lever out

of PARK (P) with normal effort. If the shift lever

moves out of PARK (P), your vehicle needs service.

6-12

2003 - Sierra Denali

Page 373 of 408

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition key to LOCK in each shift lever position.

The key should turn to LOCK only when the

shift lever is in PARK (P).

The key should come out only in LOCK.

Parking Brake and Automatic

Transmission Park (P) Mechanism

Check

{CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could be

injured and property could be damaged. Make

sure there is room in front of your vehicle in

case it begins to roll. Be ready to apply the

regular brake at once should the vehicle begin

to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake, set the

parking brake.

To check the parking brake’s holding ability: With

the engine running and transmission in NEUTRAL

(N), slowly remove foot pressure from the regular

brake pedal. Do this until the vehicle is held by the

parking brake only.

To check the PARK (P) mechanism’s holding

ability: With the engine running, shift to PARK (P).

Then release the parking brake followed by the

regular brake.

Underbody Flushing Service

At least every spring, use plain water to�ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

6-13

2003 - Sierra Denali

Page 376 of 408

Usage Fluid/Lubricant

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474, or equivalent).

Floor Shift

LinkageLubriplate Lubricant Aerosol (GM

Part No. U.S. 12346293, in Canada

992723, or equivalent) or lubricant

meeting requirements of NLGI #2

Category LB or GC-LB.

Chassis

LubricationChassis Lubricant (GM Part No.

U.S. 12377985, in Canada

88901242, or equivalent) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Front AxleSAE 75W-90 Synthetic Axle

Lubricant (GM Part No. U.S.

12378261, in Canada 10953455) or

equivalent meeting GM Speci�cation

9986115.

Rear Axle

(Steerable)Synthetic Axle Lubricant; use only

GM Part No. 12378557 (in Canada

88901362). Do not add friction

modi�er.

Transfer CaseDEXRON

®-III Automatic

Transmission Fluid.

Rear Driveline

Center SplineChassis Lubricant (GM Part No.

U.S. 12377985, in Canada

88901242, or equivalent) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Usage Fluid/Lubricant

Front Axle

Propshaft

SplineSpline Lubricant, Special Lubricant

(GM Part No. U.S. 12345879, in

Canada 10953511) or lubricant

meeting requirements of GM

9985830.

Hood HingesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474, or equivalent).

Body Door

Hinge Pins,

Tailgate Hinge

and Linkage,

Folding Seats

and Fuel Door

HingeMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474, or equivalent).

Tailgate Handle

Pivot Points,

Hinges, Latch

Bolt and

LinkageMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474, or equivalent).

Weatherstrip

ConditioningDielectric Silicone Grease (GM Part

No. U.S. 12345579, in Canada

10953014, or equivalent).

Weatherstrip

SqueaksSynthetic Grease with Te�on,

Superlube (GM Part No. U.S.

12371287, in Canada 10953437, or

equivalent).

6-16

2003 - Sierra Denali

Page 385 of 408

GM Mobility Program for Persons

with Disabilities

This program, available to

quali�ed applicants, can

reimburse you up to

$1,000 toward aftermarket

driver or passenger

adaptive equipment you

may require for your

vehicle (hand controls,

wheelchair/scooter

lifts, etc.).

This program can also provide you with free resource

information, such as area driver assessment centers and

mobility equipment installers. The program is available

for a limited period of time from the date of vehicle

purchase/lease. See your dealer for more details or call

the GM Mobility Assistance Center at 1-800-323-9935.

Text telephone (TTY) users, call 1-800-833-9935.

GM of Canada also has a Mobility Program. Call

1-800-GM-DRIVE (463-7483) for details. All TTY users

call 1-800-263-3830.

Roadside Assistance Program

GMC’s Roadside Assistance Provides stranded owners

with over-the-phone roadside repairs, location of the

nearest GMC dealer or the following special services:

Flat Tire Change:Installation of spare tire will be

covered at no charge (customer is responsible for repair

or replacement of tire).

Fuel Delivery:Delivery of enough fuel for the customer

to get to the nearest service station (up to $5.00)

will be covered.

Jump Start:No-start situations which require a battery

jump start will be covered at no charge.

Lock Out:Replacement keys or locksmith service will be

covered at no charge if you are unable to gain entry

into your vehicle. Delivery of the replacement key will be

covered within 10 miles (16 km).

Emergency Towing Service:Towing to the nearest GMC

dealer for warranty related disablements will be

covered.

Trip Routing:Custom-made, computerized highlighted

maps using the most direct or scenic route are provided

free of charge. Maps include points of interest and a

list of GMC dealers along the route. Also included is a

list of hotels along the route that are discounted

through affiliation with“Quest International.”Trip Routing

is available through Roadside Assistance by calling

7-5

2003 - Sierra Denali

Page 398 of 408

Instrument Panel

Cluster.......................................................3-25

Overview..................................................... 3-2

Instrument Panel Brightness Control..................3-15

Instrument Panel Fuse Block............................5-92

Interior Lamps................................................3-15

J

Jump Starting.................................................5-40

K

Key Lock Cylinders Service..............................6-11

Keyless Entry System....................................... 2-3

Keys............................................................... 2-2

L

Lamps

Exterior......................................................3-11

Interior.......................................................3-15

Lamps On Reminder.......................................3-13

Lap Belt........................................................1-22

Lap-Shoulder Belt...........................................1-12

LATCH System

Child Restraints...........................................1-42LATCH System (cont.)

Securing a Child Restraint Designed for

the LATCH System...................................1-45

Leaving Your Vehicle With the Engine Running......2-24

Light

Air Bag Off .................................................3-28

Air Bag Readiness.......................................3-27

Anti-Lock Brake System Warning...................3-35

Battery Warning..........................................3-33

Brake System Warning.................................3-34

Cruise Control.............................................3-40

Low Fuel Warning.......................................3-41

Malfunction Indicator....................................3-37

Passenger Air Bag Status Indicator................3-31

Safety Belt Reminder...................................3-27

Tow/Haul Mode ...........................................3-41

Loading Your Vehicle.......................................4-47

Loading Your Vehicle for Off-Road Driving..........4-19

Locking Rear Axle...........................................4-10

Locks

Door ........................................................... 2-6

Power Door.................................................. 2-7

Programmable Automatic Door Locks............... 2-7

Loss of Control...............................................4-16

LOW COOLANT LEVEL..................................3-52

Low Fuel Warning Light...................................3-41

Lumbar

Power Controls............................................. 1-3

8

2003 - Sierra Denali

Page 401 of 408

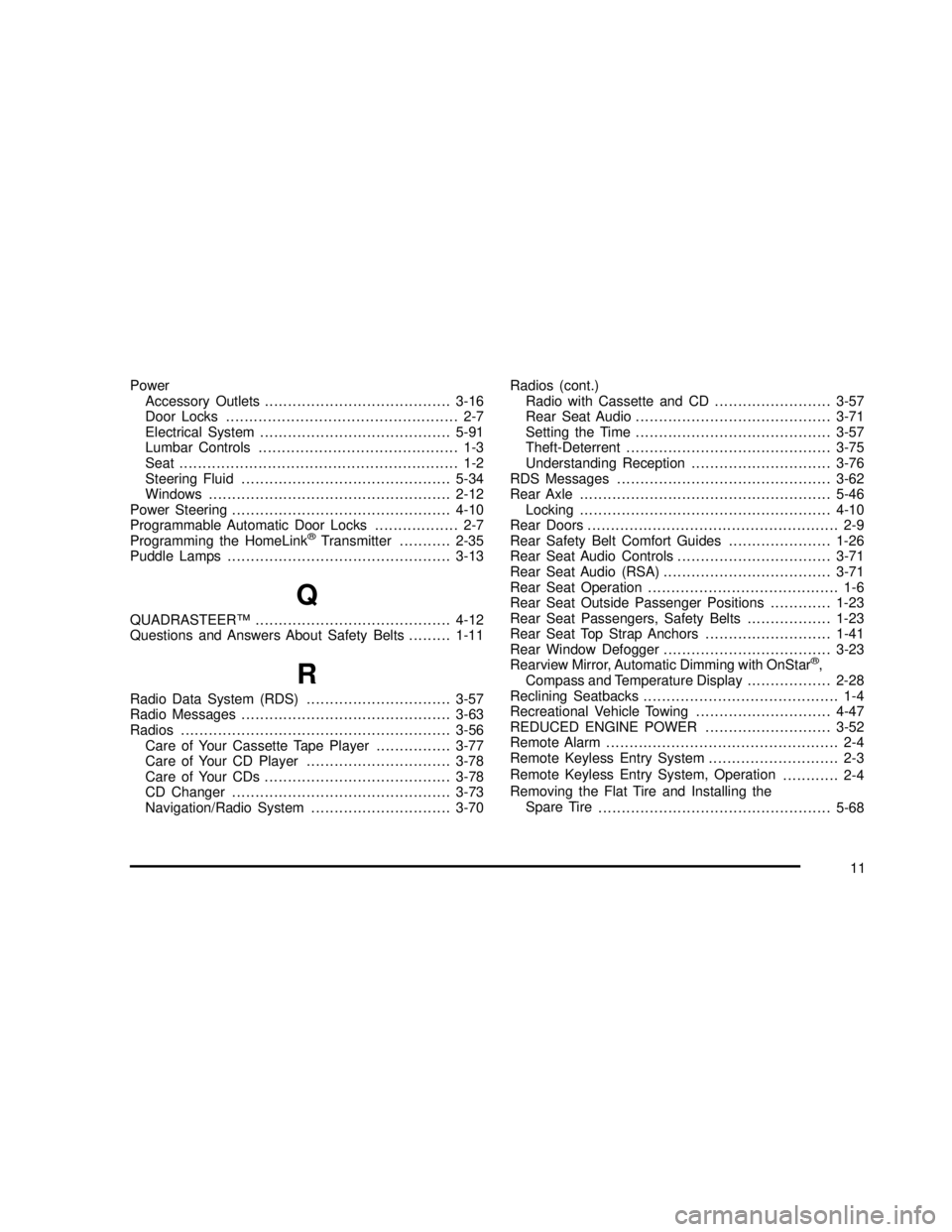

Power

Accessory Outlets........................................3-16

Door Locks.................................................. 2-7

Electrical System.........................................5-91

Lumbar Controls........................................... 1-3

Seat............................................................ 1-2

Steering Fluid.............................................5-34

Windows....................................................2-12

Power Steering...............................................4-10

Programmable Automatic Door Locks.................. 2-7

Programming the HomeLink

®Transmitter...........2-35

Puddle Lamps................................................3-13

Q

QUADRASTEER™..........................................4-12

Questions and Answers About Safety Belts.........1-11

R

Radio Data System (RDS)...............................3-57

Radio Messages.............................................3-63

Radios..........................................................3-56

Care of Your Cassette Tape Player................3-77

Care of Your CD Player...............................3-78

Care of Your CDs ........................................3-78

CD Changer...............................................3-73

Navigation/Radio System..............................3-70Radios (cont.)

Radio with Cassette and CD.........................3-57

Rear Seat Audio..........................................3-71

Setting the Time..........................................3-57

Theft-Deterrent............................................3-75

Understanding Reception..............................3-76

RDS Messages..............................................3-62

Rear Axle......................................................5-46

Locking......................................................4-10

Rear Doors...................................................... 2-9

Rear Safety Belt Comfort Guides......................1-26

Rear Seat Audio Controls.................................3-71

Rear Seat Audio (RSA)....................................3-71

Rear Seat Operation......................................... 1-6

Rear Seat Outside Passenger Positions.............1-23

Rear Seat Passengers, Safety Belts..................1-23

Rear Seat Top Strap Anchors...........................1-41

Rear Window Defogger....................................3-23

Rearview Mirror, Automatic Dimming with OnStar

®,

Compass and Temperature Display..................2-28

Reclining Seatbacks.......................................... 1-4

Recreational Vehicle Towing.............................4-47

REDUCED ENGINE POWER...........................3-52

Remote Alarm.................................................. 2-4

Remote Keyless Entry System............................ 2-3

Remote Keyless Entry System, Operation

............ 2-4

Removing the Flat Tire and Installing the

Spare Tire

..................................................5-68

11

2003 - Sierra Denali