load capacity GMC SIERRA 2009 User Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2009, Model line: SIERRA, Model: GMC SIERRA 2009Pages: 596, PDF Size: 3.25 MB

Page 392 of 596

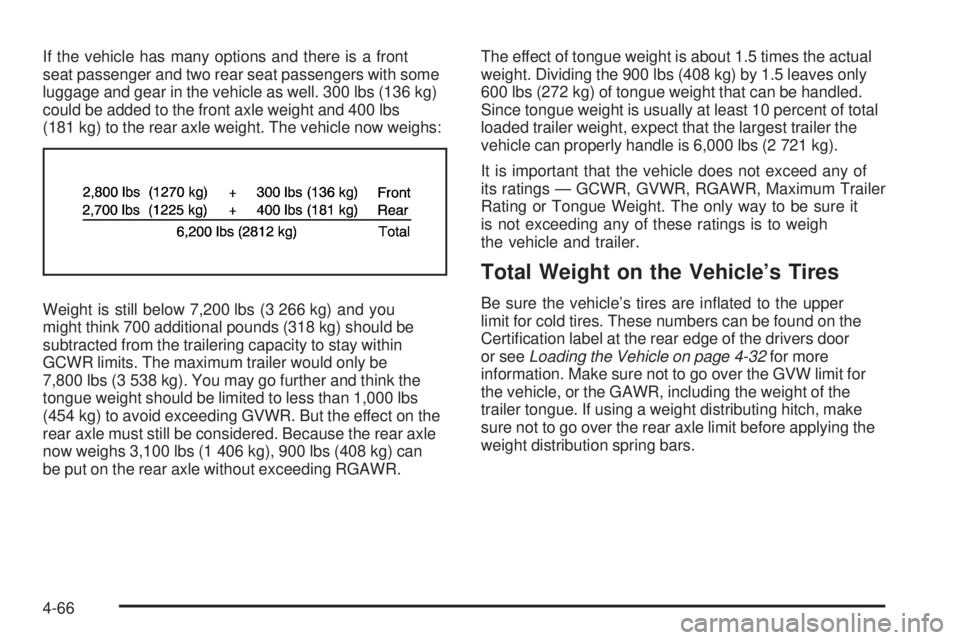

If the vehicle has many options and there is a front

seat passenger and two rear seat passengers with some

luggage and gear in the vehicle as well. 300 lbs (136 kg)

could be added to the front axle weight and 400 lbs

(181 kg) to the rear axle weight. The vehicle now weighs:

Weight is still below 7,200 lbs (3 266 kg) and you

might think 700 additional pounds (318 kg) should be

subtracted from the trailering capacity to stay within

GCWR limits. The maximum trailer would only be

7,800 lbs (3 538 kg). You may go further and think the

tongue weight should be limited to less than 1,000 lbs

(454 kg) to avoid exceeding GVWR. But the effect on the

rear axle must still be considered. Because the rear axle

now weighs 3,100 lbs (1 406 kg), 900 lbs (408 kg) can

be put on the rear axle without exceeding RGAWR.The effect of tongue weight is about 1.5 times the actual

weight. Dividing the 900 lbs (408 kg) by 1.5 leaves only

600 lbs (272 kg) of tongue weight that can be handled.

Since tongue weight is usually at least 10 percent of total

loaded trailer weight, expect that the largest trailer the

vehicle can properly handle is 6,000 lbs (2 721 kg).

It is important that the vehicle does not exceed any of

its ratings — GCWR, GVWR, RGAWR, Maximum Trailer

Rating or Tongue Weight. The only way to be sure it

is not exceeding any of these ratings is to weigh

the vehicle and trailer.

Total Weight on the Vehicle’s Tires

Be sure the vehicle’s tires are in�ated to the upper

limit for cold tires. These numbers can be found on the

Certi�cation label at the rear edge of the drivers door

or seeLoading the Vehicle on page 4-32for more

information. Make sure not to go over the GVW limit for

the vehicle, or the GAWR, including the weight of the

trailer tongue. If using a weight distributing hitch, make

sure not to go over the rear axle limit before applying the

weight distribution spring bars.

4-66

Page 480 of 596

(C) Aspect Ratio:A two-digit number that

indicates the tire height-to-width measurements.

For example, if the tire size aspect ratio is 75, as

shown in item C of the light truck (LT-Metric) tire

illustration, it would mean that the tire’s sidewall is

75 percent as high as it is wide.

(D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire. The

letter R means radial ply construction; the letter D

means diagonal or bias ply construction; and the

letter B means belted-bias ply construction.

(E) Rim Diameter

:Diameter of the wheel in

inches.

(F) Service Description

:The service description

indicates the load range and speed rating of a

tire. The load index represents the load carry

capacity a tire is certi�ed to carry. The load index

can range from 1 to 279. The speed rating is

the maximum speed a tire is certi�ed to carry a

load. Speed ratings range from A to Z.

Tire Terminology and De�nitions

Air Pressure:The amount of air inside the

tire pressing outward on each square inch of the

tire. Air pressure is expressed in pounds per

square inch (psi) or kilopascal (kPa).

Accessory Weight

:This means the combined

weight of optional accessories. Some examples of

optional accessories are, automatic transmission,

power steering, power brakes, power windows,

power seats, and air conditioning.

Aspect Ratio

:The relationship of a tire’s height

to its width.

Belt

:A rubber coated layer of cords that is

located between the plies and the tread. Cords

may be made from steel or other reinforcing

materials.

Bead

:The tire bead contains steel wires wrapped

by steel cords that hold the tire onto the rim.

Bias Ply Tire

:A pneumatic tire in which the plies

are laid at alternate angles less than 90 degrees

to the centerline of the tread.

5-70

Page 481 of 596

Cold Tire Pressure:The amount of air pressure in

a tire, measured in pounds per square inch (psi) or

kilopascals (kPa) before a tire has built up heat

from driving. SeeInflation - Tire Pressure on

page 5-73.

Curb Weight

:The weight of a motor vehicle with

standard and optional equipment including the

maximum capacity of fuel, oil, and coolant,

but without passengers and cargo.

DOT Markings

:A code molded into the sidewall

of a tire signifying that the tire is in compliance

with the U.S. Department of Transportation (DOT)

motor vehicle safety standards. The DOT code

includes the Tire Identi�cation Number (TIN),

an alphanumeric designator which can also identify

the tire manufacturer, production plant, brand,

and date of production.

GVWR

:Gross Vehicle Weight Rating.

SeeLoading the Vehicle on page 4-32.

GAWR FRT

:Gross Axle Weight Rating for the

front axle. SeeLoading the Vehicle on page 4-32.

GAWR RR

:Gross Axle Weight Rating for the

rear axle. SeeLoading the Vehicle on page 4-32.

Intended Outboard Sidewall

:The side of an

asymmetrical tire, that must always face outward

when mounted on a vehicle.Kilopascal (kPa)

:The metric unit for air pressure.

Light Truck (LT-Metric) Tire

:A tire used on

light duty trucks and some multipurpose passenger

vehicles.

Load Index

:An assigned number ranging from

1 to 279 that corresponds to the load carrying

capacity of a tire.

Maximum In�ation Pressure

:The maximum air

pressure to which a cold tire can be in�ated.

The maximum air pressure is molded onto the

sidewall.

Maximum Load Rating

:The load rating for a tire

at the maximum permissible in�ation pressure

for that tire.

Maximum Loaded Vehicle Weight

:The sum of

curb weight, accessory weight, vehicle capacity

weight, and production options weight.

Normal Occupant Weight

:The number of

occupants a vehicle is designed to seat multiplied

by 150 lbs (68 kg). SeeLoading the Vehicle on

page 4-32.

Occupant Distribution

:Designated seating

positions.

5-71

Page 482 of 596

Outward Facing Sidewall:The side of an

asymmetrical tire that has a particular side that

faces outward when mounted on a vehicle.

The side of the tire that contains a whitewall, bears

white lettering, or bears manufacturer, brand,

and/or model name molding that is higher

or deeper than the same moldings on the other

sidewall of the tire.

Passenger (P-Metric) Tire

:A tire used on

passenger cars and some light duty trucks and

multipurpose vehicles.

Recommended In�ation Pressure

:Vehicle

manufacturer’s recommended tire in�ation

pressure as shown on the tire placard. See

Inflation - Tire Pressure on page 5-73andLoading

the Vehicle on page 4-32.

Radial Ply Tire

:A pneumatic tire in which the

ply cords that extend to the beads are laid at

90 degrees to the centerline of the tread.

Rim

:A metal support for a tire and upon which

the tire beads are seated.

Sidewall

:The portion of a tire between the tread

and the bead.Speed Rating

:An alphanumeric code assigned to

a tire indicating the maximum speed at which a

tire can operate.

Traction

:The friction between the tire and the

road surface. The amount of grip provided.

Tread

:The portion of a tire that comes into

contact with the road.

Treadwear Indicators

:Narrow bands, sometimes

called wear bars, that show across the tread of

a tire when only 1/16 inch (1.6 mm) of tread

remains. SeeWhen It Is Time for New Tires on

page 5-83.

UTQGS (Uniform Tire Quality Grading

Standards)

:A tire information system that

provides consumers with ratings for a tire’s

traction, temperature, and treadwear. Ratings are

determined by tire manufacturers using

government testing procedures. The ratings are

molded into the sidewall of the tire. SeeUniform

Tire Quality Grading on page 5-86.

Vehicle Capacity Weight

:The number of

designated seating positions multiplied by 150 lbs

(68 kg) plus the rated cargo load. SeeLoading

the Vehicle on page 4-32.

5-72

Page 483 of 596

Vehicle Maximum Load on the Tire:Load on

an individual tire due to curb weight, accessory

weight, occupant weight, and cargo weight.

Vehicle Placard

:A label permanently attached

to a vehicle showing the vehicle’s capacity

weight and the original equipment tire size and

recommended in�ation pressure. See “Tire and

Loading Information Label” underLoading the

Vehicle on page 4-32.

In�ation - Tire Pressure

Tires need the correct amount of air pressure to

operate effectively.

Notice:Do not let anyone tell you that

under-in�ation or over-in�ation is all right.

It is not. If your tires do not have enough air

(under-in�ation), you can get the following:

Too much �exing

Too much heat

Tire overloading

Premature or irregular wear

Poor handling

Reduced fuel economyIf your tires have too much air (over-in�ation),

you can get the following:

Unusual wear

Poor handling

Rough ride

Needless damage from road hazards

A vehicle speci�c Tire and Loading Information

label is attached to your vehicle. This label shows

your vehicle’s original equipment tires and the

correct in�ation pressures for your tires when they

are cold. The recommended cold tire in�ation

pressure, shown on the label, is the minimum

amount of air pressure needed to support

your vehicle’s maximum load carrying capacity.

For additional information regarding how much

weight your vehicle can carry, and an example of

the Tire and Loading Information label, seeLoading

the Vehicle on page 4-32. How you load your

vehicle affects vehicle handling and ride comfort.

Never load your vehicle with more weight than it

was designed to carry.

When to Check

Check your tires once a month or more.

Do not forget to check the pressure of the spare

tire, if your vehicle has one. SeeSpare Tire

on page 5-113for additional information.

5-73

Page 499 of 596

Wheel Replacement

Replace any wheel that is bent, cracked, or badly rusted

or corroded. If wheel nuts keep coming loose, the wheel,

wheel bolts and wheel nuts should be replaced. If the

wheel leaks air, replace it (except some aluminum

wheels, which can sometimes be repaired). See your

dealer/retailer if any of these conditions exist.

Your dealer/retailer will know the kind of wheel you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset and be mounted

the same way as the one it replaces.

If you need to replace any of the wheels, wheel bolts,

wheel nuts or Tire Pressure Monitor System (TPMS)

sensors, replace them only with new GM original

equipment parts. This way, you will be sure to have the

right wheel, wheel bolts, wheel nuts, and TPMS sensors

for the vehicle.{CAUTION:

Using the wrong replacement wheels, wheel bolts,

or wheel nuts on your vehicle can be dangerous.

It could affect the braking and handling of your

vehicle, make your tires lose air and make you

lose control. You could have a collision in which

you or others could be injured. Always use the

correct wheel, wheel bolts, and wheel nuts for

replacement.

Notice:The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance, and tire or tire chain

clearance to the body and chassis.

Whenever a wheel, wheel bolt or wheel nut is replaced

on a dual wheel setup, check the wheel nut torque after

100, 1,000 and 6,000 miles (160, 1 600 and 10 000 km)

of driving. For proper torque, see “Wheel Nut Torque”

underCapacities and Specifications on page 5-129.

SeeChanging a Flat Tire on page 5-92for more

information.

5-89