GMC SIERRA 2009 Owner's Manual

Manufacturer: GMC, Model Year: 2009, Model line: SIERRA, Model: GMC SIERRA 2009Pages: 596, PDF Size: 3.25 MB

Page 551 of 596

Maintenance Footnotes

This maintenance section applies to vehicles with a

gasoline engine. For diesel engine vehicles, see

the maintenance schedule section in the DURAMAX

®

Diesel manual.

†The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

#Lubricate the front suspension, steering linkage,

and parking brake cable guides. Control arm ball joints

on 2500/3500 series vehicles require lubrication but

should not be lubricated unless their temperature is

10°F (−12°C) or higher, or they could be damaged.

Control arm ball joints on 1500 series vehicles are

maintenance-free. Vehicles used under severe

commercial operating conditions require lubrication

on a regular basis every 3,000 miles (5 000 km).

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, chafing, etc. Inspect disc

brake pads for wear and rotors for surface condition.

Inspect drum brake linings/shoes for wear or cracks.

Inspect other brake parts, including drums, wheel

cylinders, calipers, parking brake, etc.(b)Visually inspect front and rear suspension and

steering system for damaged, loose or missing parts,

signs of wear or lack of lubrication. Inspect power

steering lines and hoses for proper hook-up, binding,

leaks, cracks, chafing, etc. Visually check constant

velocity joints, rubber boots, and axle seals for leaks.

(c)Visually inspect hoses and have them replaced if

they are cracked, swollen, or deteriorated. Inspect all

pipes, fittings and clamps; replace with genuine parts as

needed. To help ensure proper operation, a pressure test

of the cooling system and pressure cap and cleaning the

outside of the radiator and air conditioning condenser is

recommended at least once a year.

(d)Inspect wiper blades for wear, cracking, or

contamination. Clean the windshield and wiper blades,

if contaminated. Replace wiper blades that are worn or

damaged. See Windshield Wiper Blade Replacement

on page 5-64 and Windshield and Wiper Blades on

page 5-118 for more information.

(e)Make sure the safety belt reminder light and safety

belt assemblies are working properly. Look for any other

loose or damaged safety belt system parts. If you see

anything that might keep a safety belt system from doing

its job, have it repaired. Have any torn or frayed safety

belts replaced. Also see Checking the Restraint Systems

on page 1-90.

6-9

Page 552 of 596

(f)Lubricate all key lock cylinders, body door hinges,

hood latch assembly, secondary latch, pivots, spring

anchor, release pawl, tailgate hinges, tailgate linkage,

tailgate handle pivot points, latch bolt, fuel door hinge,

locks, and folding seat hardware. More frequent

lubrication may be required when exposed to a corrosive

environment. Applying silicone grease on weatherstrips

with a clean cloth will make them last longer, seal better,

and not stick or squeak.

(g)Check vent hose at transfer case for kinks and proper

installation. Check to be sure vent hose is unobstructed,

clear, and free of debris. During any maintenance, if a

power washer is used to clean mud and dirt from the

underbody, care should be taken to not directly spray the

transfer case output seals. High pressure water can

overcome the seals and contaminate the transfer case

fluid. Contaminated fluid will decrease the life of the

transfer case and should be replaced.

(h)Change automatic transmission fluid and filter if

the vehicle Gross Vehicle Weight Rating (GVWR) is over

8600 lbs or if the vehicle is mainly driven under one

or more of these conditions:

�In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

�In hilly or mountainous terrain.

�When doing frequent trailer towing.

�Uses such as found in taxi, police or delivery

service.(i)Drain, flush, and refill cooling system. This service

can be complex; you should have your dealer/retailer

perform this service. See Engine Coolant on page 5-29

for what to use. Inspect hoses. Clean radiator,

condenser, pressure cap, and filler neck. Pressure test

the cooling system and pressure cap.

(j)A fluid loss in any vehicle system could indicate a

problem. Have the system inspected and repaired and

the fluid level checked. Add fluid if needed.

(k)Inspect system. Check all fuel and vapor lines and

hoses for proper hook-up, routing, and condition. Check

that the purge valve, if the vehicle has one, works

properly. Replace as needed.

(l)Extreme Duty Service: Change transfer case fluid if

the vehicle is mainly driven off-road in four-wheel

drive. Vehicles used for farming, mining, forestry,

Department of Natural Resources (DNR), and snow

plowing occupations meet this definition.

(m)Severe Duty Service: Change transfer case fluid if

the vehicle is mainly driven under one or more of

these conditions:

�Frequent trailer towing.

�Taxi, police, or delivery service.

6-10

Page 553 of 596

(n)Vehicles with diesel engine or with GVWR above

10,000 lbs (4 536 kg) only: Inspect shields for damage or

looseness. Adjust or replace as required. This is a Noise

Emission Control Service. Applicable to vehicles sold in

the United States and recommended for vehicles sold in

Canada.

(p)If driving regularly under dusty conditions, inspect

the filter or change indicator (if equipped) at each engine

oil change.

(q)Visually inspect belt for fraying, excessive cracks, or

obvious damage. Replace belt if necessary.

Owner Checks and Services

These owner checks and services should be performed

at the intervals speci�ed to help ensure vehicle safety,

dependability, and emission control performance. Your

dealer/retailer can assist with these checks and services.

Be sure any necessary repairs are completed at once.

Whenever any �uids or lubricants are added to the

vehicle, make sure they are the proper ones, as shown

inRecommended Fluids and Lubricants on page 6-15.

At the First 100, 1,000 and

6,000 Miles (160, 1 600 and

10 000 km)

For vehicles with dual wheels, check dual wheel nut

torque. For proper torque, seeCapacities and

Specifications on page 5-129.

At Each Fuel Fill

It is important to perform these underhood checks at

each fuel fill.

Engine Oil Level Check

Notice:It is important to check the engine oil

regularly and keep it at the proper level. Failure to

keep the engine oil at the proper level can cause

damage to the engine not covered by the vehicle

warranty.

Check the engine oil level and add the proper oil if

necessary. SeeEngine Oil on page 5-15.

6-11

Page 554 of 596

Engine Coolant Level Check

Check the engine coolant level and add DEX-COOL®

coolant mixture if necessary. SeeEngine Coolant

on page 5-29.

Windshield Washer Fluid Level Check

Check the windshield washer �uid level in the windshield

washer �uid reservoir and add the proper �uid if

necessary.

At Least Once a Month

Tire In�ation Check

Inspect the vehicle’s tires and make sure they are

in�ated to the correct pressures. Do not forget to check

the spare tire. SeeInflation - Tire Pressure on page 5-73.

Check to make sure the spare tire is stored securely.

SeeChanging a Flat Tire on page 5-92.

Tire Wear Inspection

Tire rotation may be required for high mileage highway

drivers prior to the Engine Oil Life System service

noti�cation. Check the tires for wear and, if necessary,

rotate the tires. SeeTire Inspection and Rotation on

page 5-81.

At Least Once a Year

Starter Switch Check

{CAUTION:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough

room around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-50.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. Try to start the engine in each gear. The vehicle

should start only in P (Park) or N (Neutral). If the

vehicle starts in any other position, contact

your dealer/retailer for service.

6-12

Page 555 of 596

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough

room around the vehicle. It should be parked on a

level surface.

2. Firmly apply the parking brake. SeeParking Brake

on page 2-50.

Be ready to apply the regular brake immediately if

the vehicle begins to move.3. With the engine off, turn the ignition to ON/RUN,

but do not start the engine. Without applying the

regular brake, try to move the shift lever out

of P (Park) with normal effort. If the shift lever

moves out of P (Park), contact your dealer/retailer

for service.Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition to LOCK/OFF in each shift lever position.

The ignition should turn to LOCK/OFF only

when the shift lever is in P (Park).

The ignition key should come out only in

LOCK/OFF.

Contact your dealer/retailer if service is required.

6-13

Page 556 of 596

Parking Brake and Automatic

Transmission P (Park) Mechanism

Check

{CAUTION:

When you are doing this check, the vehicle could

begin to move. You or others could be injured and

property could be damaged. Make sure there is

room in front of the vehicle in case it begins to roll.

Be ready to apply the regular brake at once

should the vehicle begin to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake,

set the parking brake.

To check the parking brake’s holding ability:

With the engine running and the transmission

in N (Neutral), slowly remove foot pressure from

the regular brake pedal. Do this until the vehicle

is held by the parking brake only.

To check the P (Park) mechanism’s holding ability:

With the engine running, shift to P (Park). Then

release the parking brake followed by the regular

brake.

Contact your dealer/retailer if service is required.

Underbody Flushing Service

At least every spring, use plain water to �ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

6-14

Page 557 of 596

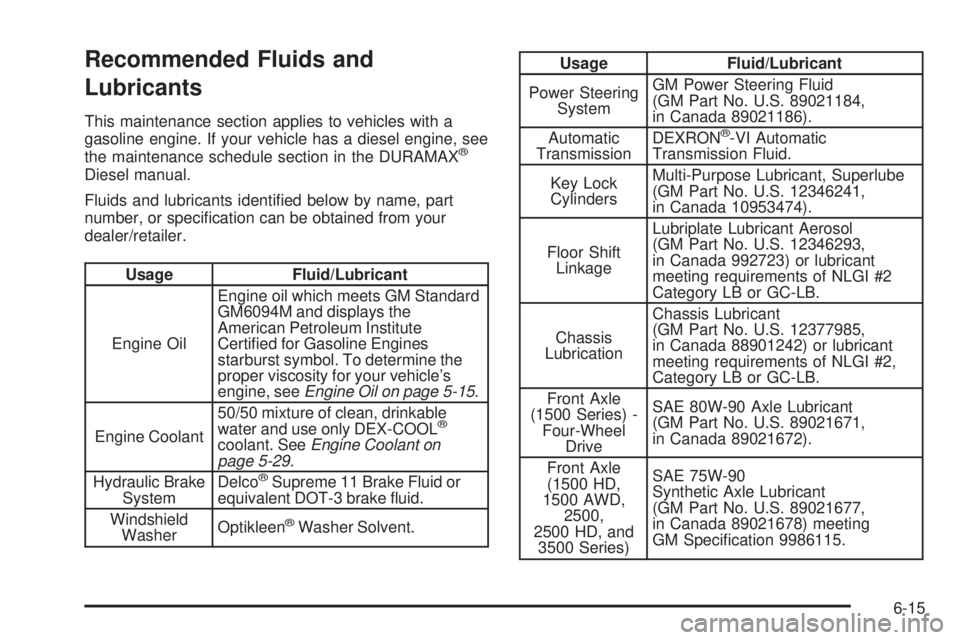

Recommended Fluids and

Lubricants

This maintenance section applies to vehicles with a

gasoline engine. If your vehicle has a diesel engine, see

the maintenance schedule section in the DURAMAX

®

Diesel manual.

Fluids and lubricants identi�ed below by name, part

number, or speci�cation can be obtained from your

dealer/retailer.

Usage Fluid/Lubricant

Engine OilEngine oil which meets GM Standard

GM6094M and displays the

American Petroleum Institute

Certi�ed for Gasoline Engines

starburst symbol. To determine the

proper viscosity for your vehicle’s

engine, seeEngine Oil on page 5-15.

Engine Coolant50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

coolant. SeeEngine Coolant on

page 5-29.

Hydraulic Brake

SystemDelco

®Supreme 11 Brake Fluid or

equivalent DOT-3 brake �uid.

Windshield

WasherOptikleen

®Washer Solvent.

Usage Fluid/Lubricant

Power Steering

SystemGM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Automatic

TransmissionDEXRON

®-VI Automatic

Transmission Fluid.

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Floor Shift

LinkageLubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2

Category LB or GC-LB.

Chassis

LubricationChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Front Axle

(1500 Series) -

Four-Wheel

DriveSAE 80W-90 Axle Lubricant

(GM Part No. U.S. 89021671,

in Canada 89021672).

Front Axle

(1500 HD,

1500 AWD,

2500,

2500 HD, and

3500 Series)SAE 75W-90

Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Speci�cation 9986115.

6-15

Page 558 of 596

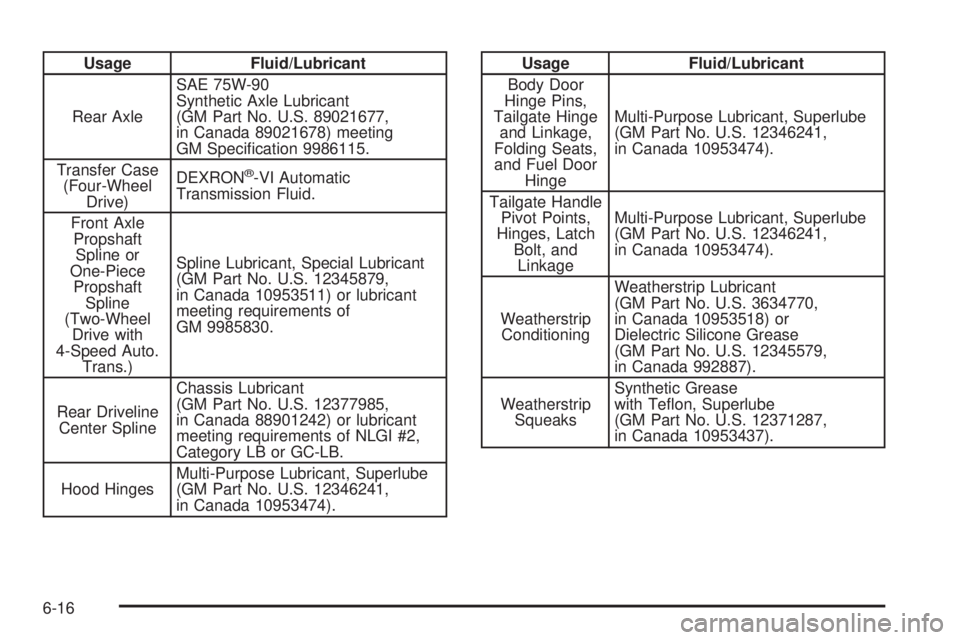

Usage Fluid/Lubricant

Rear AxleSAE 75W-90

Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Speci�cation 9986115.

Transfer Case

(Four-Wheel

Drive)DEXRON

®-VI Automatic

Transmission Fluid.

Front Axle

Propshaft

Spline or

One-Piece

Propshaft

Spline

(Two-Wheel

Drive with

4-Speed Auto.

Trans.)Spline Lubricant, Special Lubricant

(GM Part No. U.S. 12345879,

in Canada 10953511) or lubricant

meeting requirements of

GM 9985830.

Rear Driveline

Center SplineChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood HingesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Usage Fluid/Lubricant

Body Door

Hinge Pins,

Tailgate Hinge

and Linkage,

Folding Seats,

and Fuel Door

HingeMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Tailgate Handle

Pivot Points,

Hinges, Latch

Bolt, and

LinkageMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Weatherstrip

ConditioningWeatherstrip Lubricant

(GM Part No. U.S. 3634770,

in Canada 10953518) or

Dielectric Silicone Grease

(GM Part No. U.S. 12345579,

in Canada 992887).

Weatherstrip

SqueaksSynthetic Grease

with Te�on, Superlube

(GM Part No. U.S. 12371287,

in Canada 10953437).

6-16

Page 559 of 596

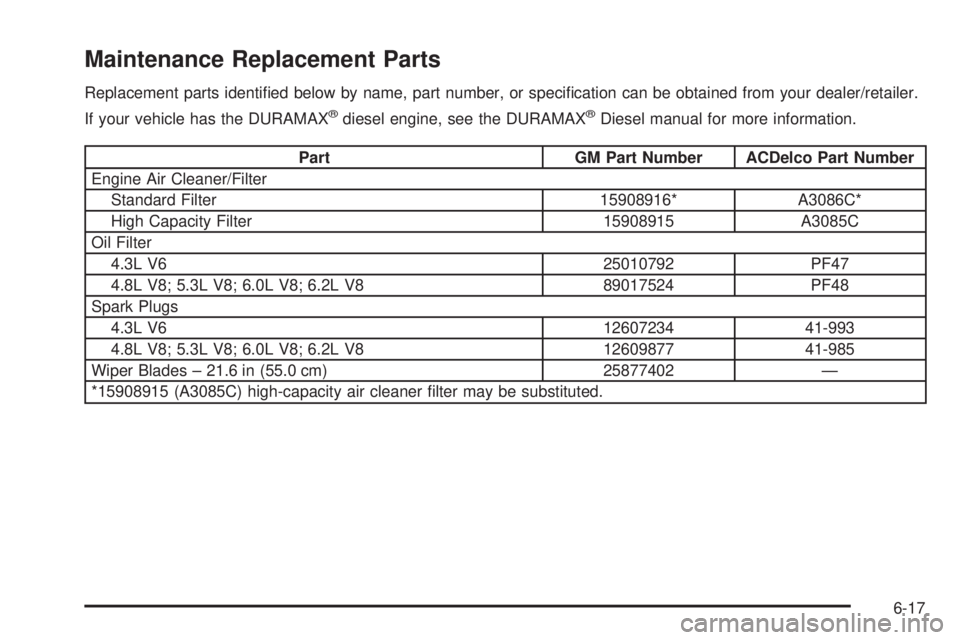

Maintenance Replacement Parts

Replacement parts identi�ed below by name, part number, or speci�cation can be obtained from your dealer/retailer.

If your vehicle has the DURAMAX

®diesel engine, see the DURAMAX®Diesel manual for more information.

Part GM Part Number ACDelco Part Number

Engine Air Cleaner/Filter

Standard Filter 15908916* A3086C*

High Capacity Filter 15908915 A3085C

Oil Filter

4.3L V6 25010792 PF47

4.8L V8; 5.3L V8; 6.0L V8; 6.2L V8 89017524 PF48

Spark Plugs

4.3L V6 12607234 41-993

4.8L V8; 5.3L V8; 6.0L V8; 6.2L V8 12609877 41-985

Wiper Blades – 21.6 in (55.0 cm) 25877402 —

*15908915 (A3085C) high-capacity air cleaner �lter may be substituted.

6-17

Page 560 of 596

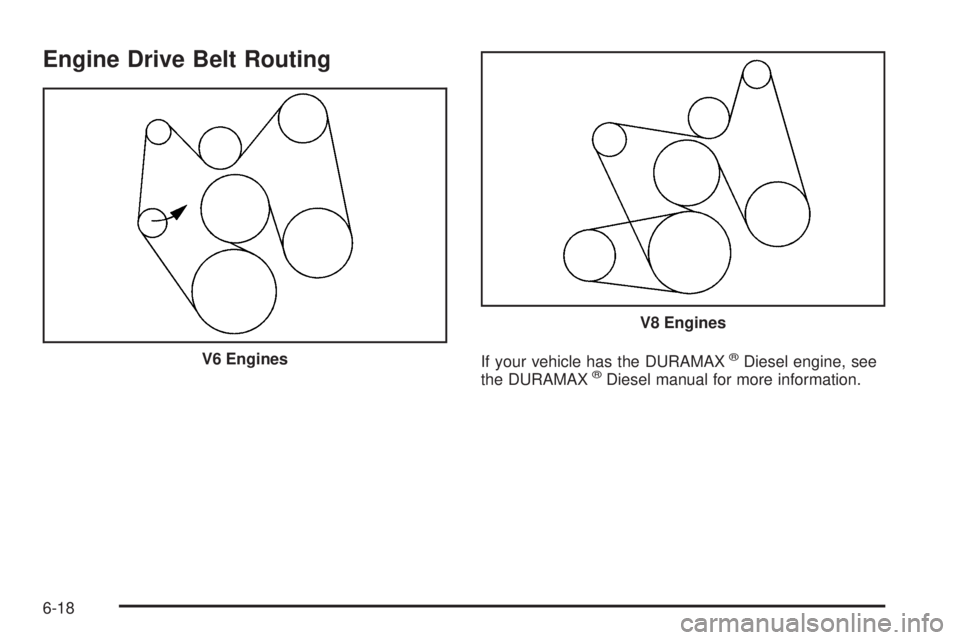

Engine Drive Belt Routing

If your vehicle has the DURAMAX®Diesel engine, see

the DURAMAX®Diesel manual for more information. V6 Engines

V8 Engines

6-18