maintenance schedule GMC SIERRA 2010 User Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA, Model: GMC SIERRA 2010Pages: 630, PDF Size: 4.65 MB

Page 462 of 630

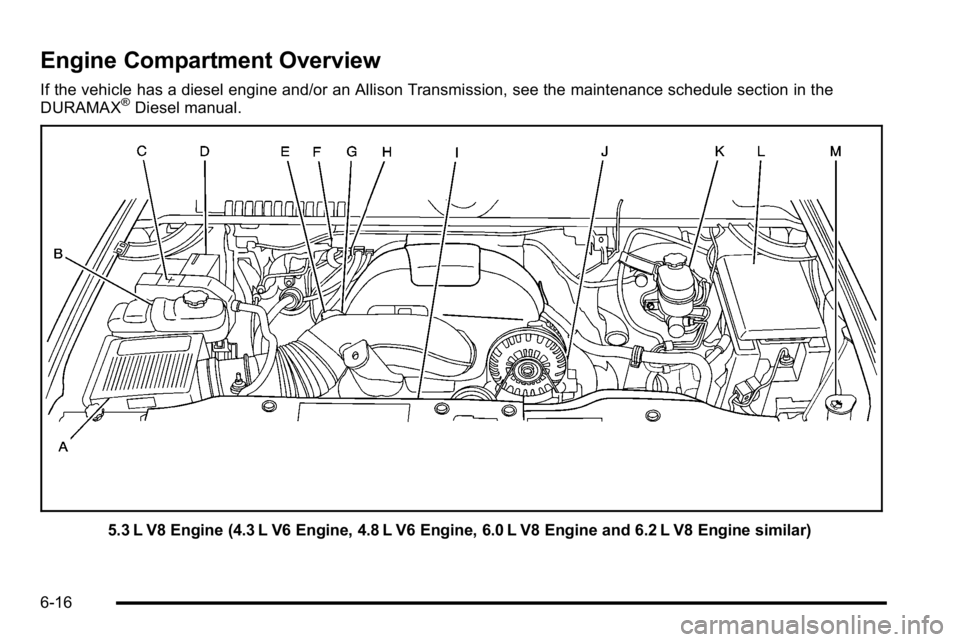

Engine Compartment Overview

If the vehicle has a diesel engine and/or an Allison Transmission, see the maintenance schedule section in the

DURAMAX®Diesel manual.

5.3 L V8 Engine (4.3 L V6 Engine, 4.8 L V6 Engine, 6.0 L V8 Engine and 6.2 L V8 Engine similar)

6-16

Page 468 of 630

When to Inspect the Engine Air

Cleaner/Filter

Inspect the air cleaner/filter at the MaintenanceII

intervals and replace it at the first oil change after each

50,000 mile (80 000 km) interval. See Scheduled

Maintenance

on page 7‑3for more information.

If driving on dusty/dirty conditions, inspect the filter at

each engine oil change.

How to Inspect the Engine Air

Cleaner/Filter

To inspect the air cleaner/filter, remove the engine

air cleaner/filter from the vehicle by following Steps 1

through 6. When the engine air cleaner/filter is

removed, lightly shake it to release loose dust and dirt.

If the engine air cleaner/filter remains caked with dirt, a

new filter is required. Never use compressed air to

clean the filter.

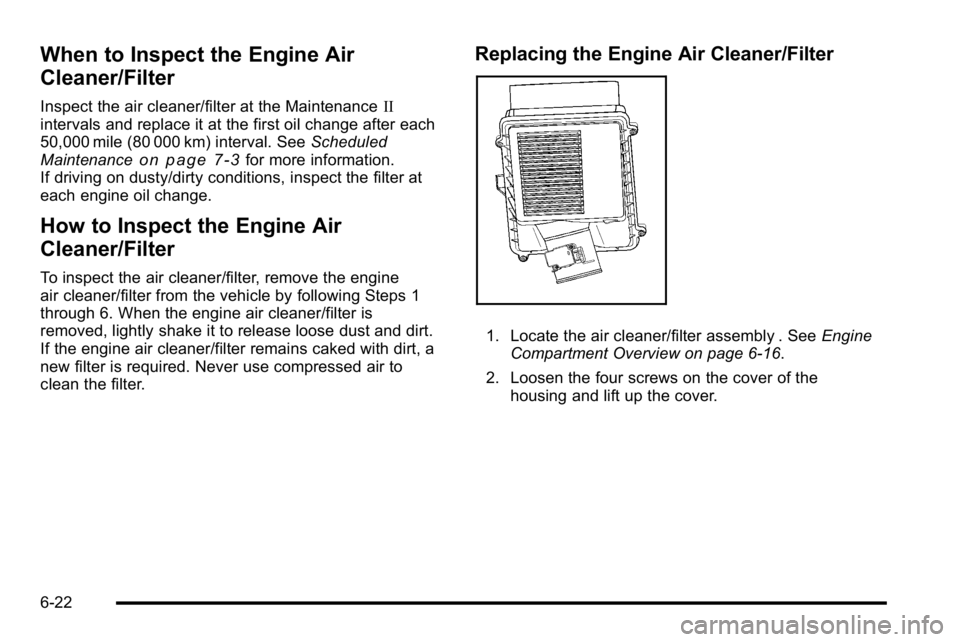

Replacing the Engine Air Cleaner/Filter

1. Locate the air cleaner/filter assembly . See Engine

Compartment Overview on page 6‑16.

2. Loosen the four screws on the cover of the housing and lift up the cover.

6-22

Page 469 of 630

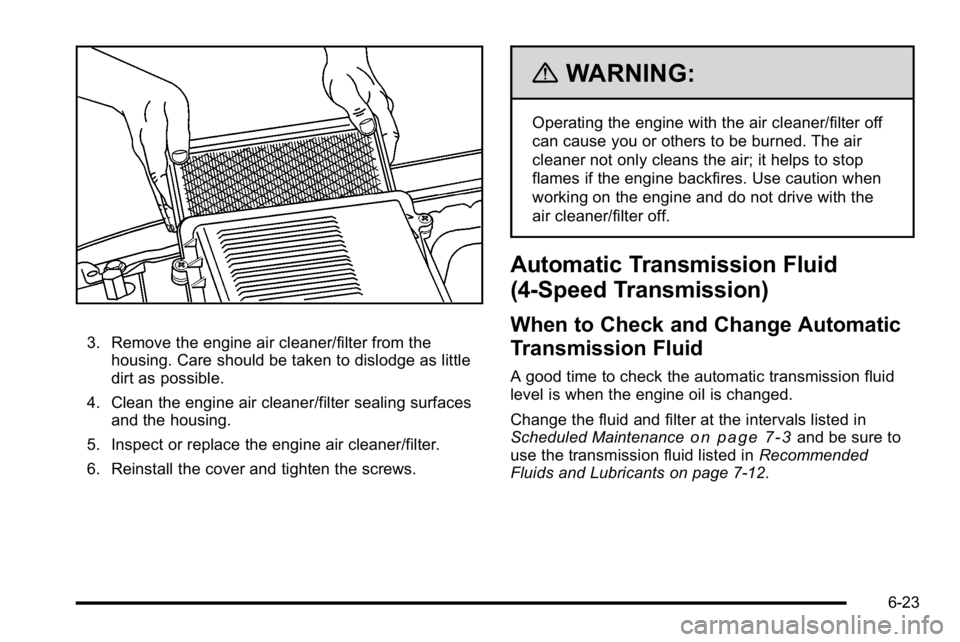

3. Remove the engine air cleaner/filter from thehousing. Care should be taken to dislodge as little

dirt as possible.

4. Clean the engine air cleaner/filter sealing surfaces and the housing.

5. Inspect or replace the engine air cleaner/filter.

6. Reinstall the cover and tighten the screws.

{WARNING:

Operating the engine with the air cleaner/filter off

can cause you or others to be burned. The air

cleaner not only cleans the air; it helps to stop

flames if the engine backfires. Use caution when

working on the engine and do not drive with the

air cleaner/filter off.

Automatic Transmission Fluid

(4-Speed Transmission)

When to Check and Change Automatic

Transmission Fluid

A good time to check the automatic transmission fluid

level is when the engine oil is changed.

Change the fluid and filter at the intervals listed in

Scheduled Maintenance

on page 7‑3and be sure to

use the transmission fluid listed in Recommended

Fluids and Lubricants on page 7‑12.

6-23

Page 472 of 630

How to Add Automatic Transmission

Fluid

Refer to the Maintenance Schedule to determine what

kind of transmission fluid to use. SeeRecommended

Fluids and Lubricants on page 7‑12.

Using a funnel, add fluid down the transmission dipstick

tube only after checking the transmission fluid while it is

hot. A cold check is used only as a reference. If the fluid

level is low, add only enough of the proper fluid to bring

the level up to the HOT area for a hot check. It does

not take much fluid, generally less than 0.5 Liter (1 Pint).

Do not overfill.

Notice: Use of the incorrect automatic transmission

fluid may damage the vehicle, and the damages may

not be covered by the vehicle's warranty. Always

use the automatic transmission fluid listed in

Recommended Fluids and Lubricants on page 7‑12.

.After adding fluid, recheck the fluid level as

described under “How to Check Automatic

Transmission Fluid,” earlier in this section.

.When the correct fluid level is obtained, push the

dipstick back in all the way; then flip the handle

down to lock the dipstick in place.

Automatic Transmission Fluid

(6-Speed Transmission)

When to Check and Change Automatic

Transmission Fluid

It is usually not necessary to check the transmission

fluid level. The only reason for fluid loss is a

transmission leak or overheating the transmission.

If you suspect a small leak, then use the following

checking procedures to check the fluid level. However,

if there is a large leak, then it may be necessary to have

the vehicle towed to a dealer/retailer service department

and have it repaired before driving the vehicle further.

Notice:Use of the incorrect automatic transmission

fluid may damage the vehicle, and the damages may

not be covered by the vehicle's warranty. Always

use the automatic transmission fluid listed in

Recommended Fluids and Lubricants on page 7‑12.

Change the fluid and filter at the intervals listed in the

Maintenance Schedule. See Scheduled Maintenance

on page 7‑3. Be sure to use the transmission fluid

listed in Recommended Fluids and Lubricantson

page 7‑12.

6-26

Page 486 of 630

Do not top off the brake fluid. Adding fluid does not

correct a leak. If fluid is added when the linings are

worn, there will be too much fluid when new brake

linings are installed. Add or remove brake fluid, as

necessary, only when work is done on the brake

hydraulic system.

{WARNING:

If too much brake fluid is added, it can spill on the

engine and burn, if the engine is hot enough. You

or others could be burned, and the vehicle could

be damaged. Add brake fluid only when work is

done on the brake hydraulic system. See

“Checking Brake Fluid”in this section.

Refer to the Maintenance Schedule to determine when

to check the brake fluid. See Scheduled Maintenance

on page 7‑3.

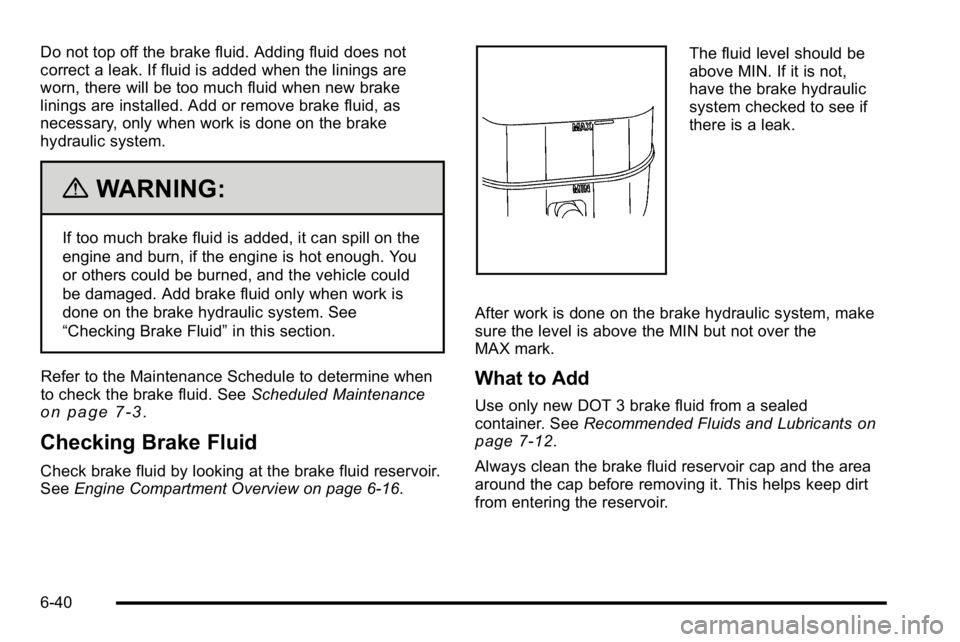

Checking Brake Fluid

Check brake fluid by looking at the brake fluid reservoir.

SeeEngine Compartment Overview on page 6‑16.

The fluid level should be

above MIN. If it is not,

have the brake hydraulic

system checked to see if

there is a leak.

After work is done on the brake hydraulic system, make

sure the level is above the MIN but not over the

MAX mark.

What to Add

Use only new DOT 3 brake fluid from a sealed

container. See Recommended Fluids and Lubricantson

page 7‑12.

Always clean the brake fluid reservoir cap and the area

around the cap before removing it. This helps keep dirt

from entering the reservoir.

6-40

Page 488 of 630

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to torque specifications in

Capacities and Specifications on page 6‑126.

If the vehicle has rear drum brakes, they do not have

wear indicators, but if a rear brake rubbing noise is

heard, have the rear brake linings inspected

immediately. Rear brake drums should be removed and

inspected each time the tires are removed for rotation or

changing. Drum brakes have an inspection hole to

inspect lining wear during scheduled maintenance.

When the front brake pads are replaced, have the rear

brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase in

pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every brake stop, the brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together if

the vehicle is to have really good braking. The vehicle

was designed and tested with top-quality brake parts.

When parts of the braking system are replaced—for

example, when the brake linings wear down and new

ones are installed —be sure to get new approved

replacement parts. If this is not done, the brakes might

not work properly. For example, if someone puts in

brake linings that are wrong for the vehicle, the balance

between the front and rear brakes can change —for the

worse. The braking performance expected can change

in many other ways if the wrong replacement brake

parts are installed.

6-42

Page 496 of 630

.For all 6.0L and 6.2L 2500HD Series applications,

the proper level is from 0 to 0.5 inches (0 mm to

13 mm) below the bottom of the filler plug hole,

located on the rear axle. Add only enough fluid to

reach the proper level.

.For all 6.6L DURAMAX DIESEL 2500HD Series

applications and all 3500 Series applications, the

proper level is from 0.6 inches to 0.8 inches

(17 mm to 21 mm) below the bottom of the filler

plug hole, located on the rear axle. Add only

enough fluid to reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids and

Lubricants on page 7‑12.

Four-Wheel Drive

Lubricant checks in this section also apply to these

vehicles.

Transfer Case

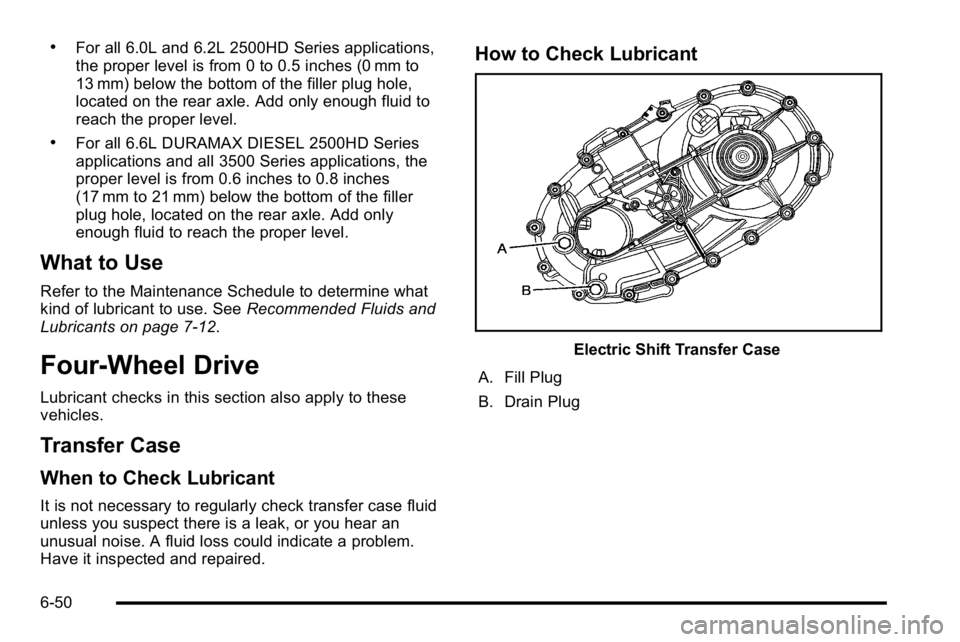

When to Check Lubricant

It is not necessary to regularly check transfer case fluid

unless you suspect there is a leak, or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

Electric Shift Transfer Case

A. Fill Plug

B. Drain Plug

6-50

Page 498 of 630

When to Change Lubricant

Refer to the Maintenance Schedule to determine how

often to change the lubricant. SeeScheduled

Maintenance on page 7‑3.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. See Recommended Fluids and

Lubricants on page 7‑12.

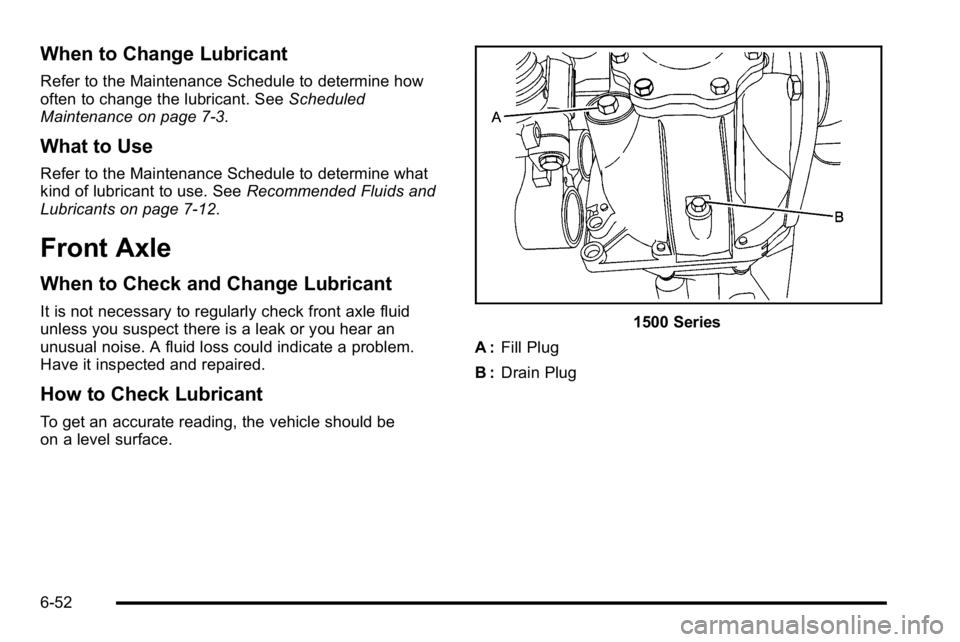

Front Axle

When to Check and Change Lubricant

It is not necessary to regularly check front axle fluid

unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

To get an accurate reading, the vehicle should be

on a level surface.

1500 Series

A : Fill Plug

B : Drain Plug

6-52

Page 499 of 630

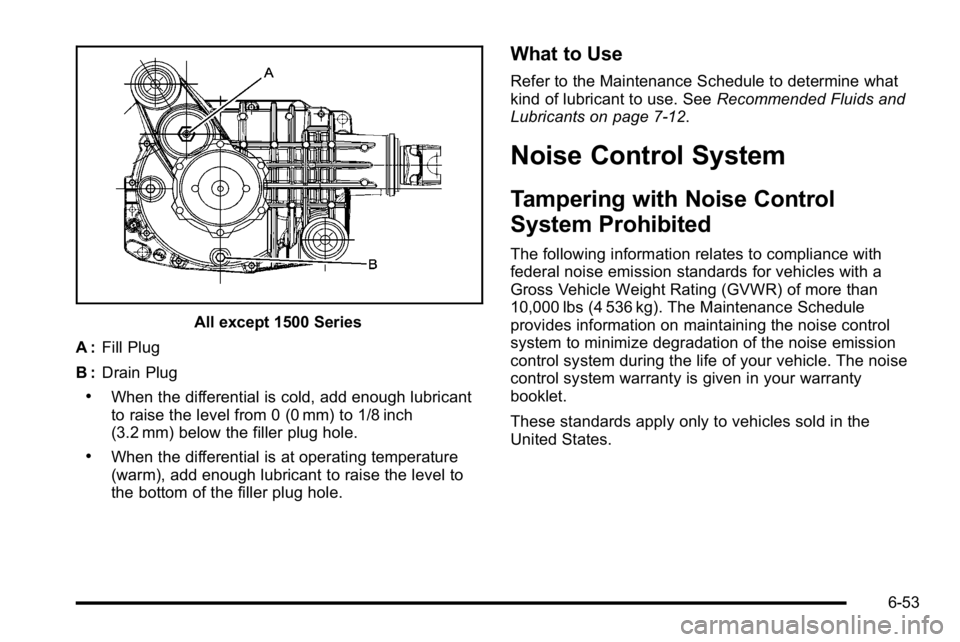

All except 1500 Series

A : Fill Plug

B : Drain Plug

.When the differential is cold, add enough lubricant

to raise the level from 0 (0 mm) to 1/8 inch

(3.2 mm) below the filler plug hole.

.When the differential is at operating temperature

(warm), add enough lubricant to raise the level to

the bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. See Recommended Fluids and

Lubricants on page 7‑12.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with a

Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty

booklet.

These standards apply only to vehicles sold in the

United States.

6-53

Page 509 of 630

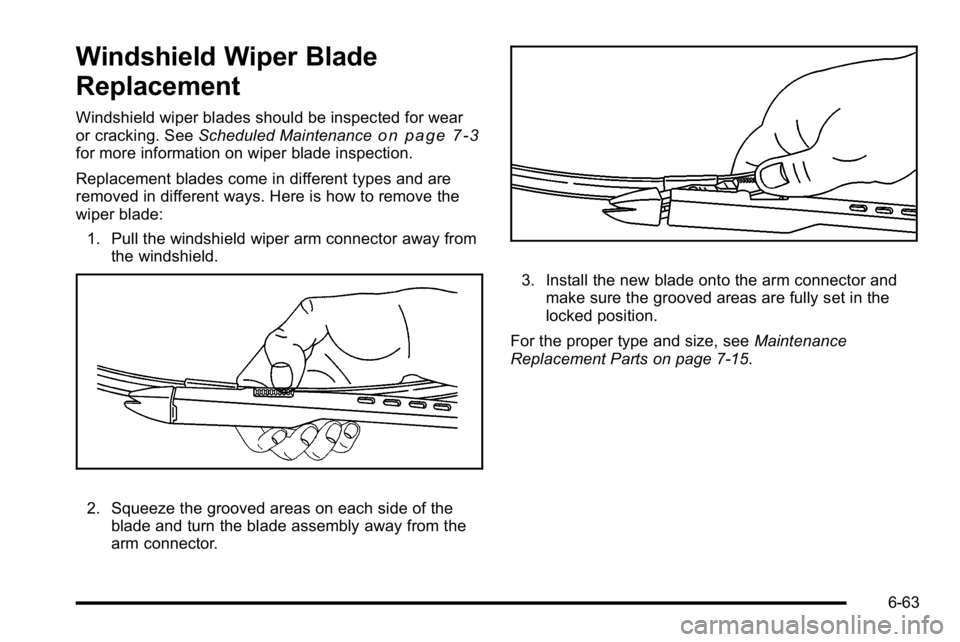

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

or cracking. SeeScheduled Maintenanceon page 7‑3for more information on wiper blade inspection.

Replacement blades come in different types and are

removed in different ways. Here is how to remove the

wiper blade:

1. Pull the windshield wiper arm connector away from the windshield.

2. Squeeze the grooved areas on each side of theblade and turn the blade assembly away from the

arm connector.

3. Install the new blade onto the arm connector and

make sure the grooved areas are fully set in the

locked position.

For the proper type and size, see Maintenance

Replacement Parts on page 7‑15.

6-63