height GMC SIERRA 2011 User Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2011, Model line: SIERRA, Model: GMC SIERRA 2011Pages: 594, PDF Size: 6.55 MB

Page 455 of 594

Black plate (31,1)GMC Sierra Owner Manual - 2011

Vehicle Care 10-31

Some driving conditions or climates

can cause a brake squeal when

the brakes are first applied or

lightly applied. This does not mean

something is wrong with the brakes.

Properly torqued wheel nuts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear and

evenly tighten wheel nuts in

the proper sequence to torque

specifications inCapacities and

Specifications on page 12‑2.

If the vehicle has rear drum brakes,

they do not have wear indicators,

but if a rear brake rubbing noise is

heard, have the rear brake linings

inspected immediately. Rear brake

drums should be removed and

inspected each time the tires are

removed for rotation or changing. Drum brakes have an inspection

hole to inspect lining wear during

scheduled maintenance. When

the front brake pads are replaced,

have the rear brakes inspected, too.

Brake linings should always be

replaced as complete axle sets.

Brake Pedal Travel

See your dealer if the brake pedal

does not return to normal height,

or if there is a rapid increase in

pedal travel. This could be a

sign that brake service might

be required.

Brake Adjustment

Every time the brakes are applied,

with or without the vehicle moving,

the brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is

complex. Its many parts have to be

of top quality and work well together

if the vehicle is to have really good

braking. The vehicle was designed

and tested with top-quality brake

parts. When parts of the braking

system are replaced, be sure to get

new, approved replacement parts.

If this is not done, the brakes might

not work properly. For example,

installing disc brake pads that

are wrong for the vehicle, can

change the balance between the

front and rear brakes

—for the

worse. The braking performance

expected can change in many

other ways if the wrong replacement

brake parts are installed.

Page 467 of 594

Black plate (43,1)GMC Sierra Owner Manual - 2011

Vehicle Care 10-43

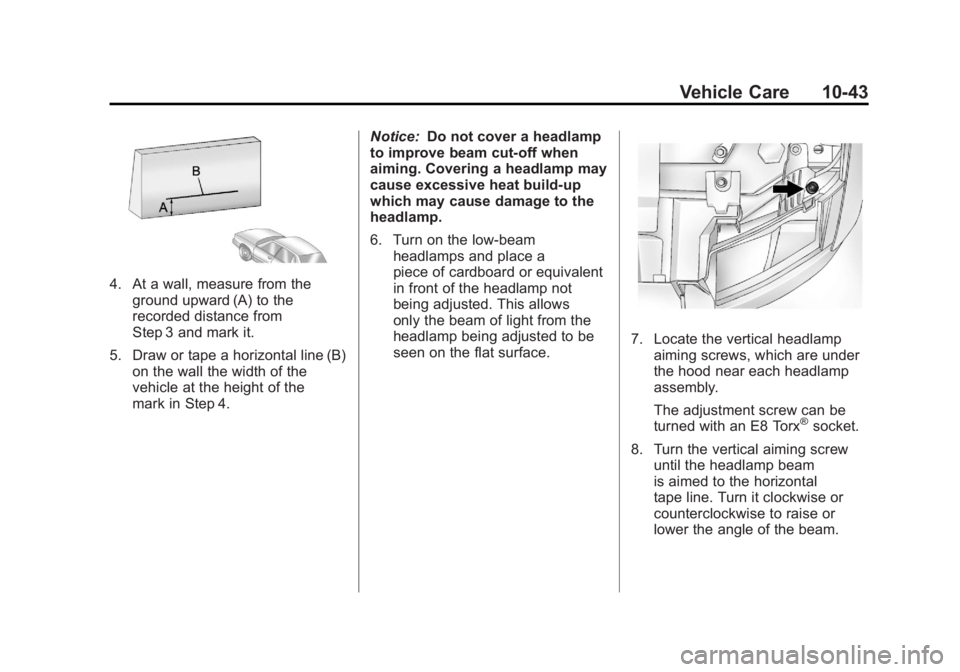

4. At a wall, measure from theground upward (A) to the

recorded distance from

Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the

vehicle at the height of the

mark in Step 4. Notice:

Do not cover a headlamp

to improve beam cut-off when

aiming. Covering a headlamp may

cause excessive heat build-up

which may cause damage to the

headlamp.

6. Turn on the low-beam

headlamps and place a

piece of cardboard or equivalent

in front of the headlamp not

being adjusted. This allows

only the beam of light from the

headlamp being adjusted to be

seen on the flat surface.

7. Locate the vertical headlampaiming screws, which are under

the hood near each headlamp

assembly.

The adjustment screw can be

turned with an E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam

is aimed to the horizontal

tape line. Turn it clockwise or

counterclockwise to raise or

lower the angle of the beam.

Page 482 of 594

Black plate (58,1)GMC Sierra Owner Manual - 2011

10-58 Vehicle Care

20‐Inch Tires

If your vehicle has the optional

20‐inch P275/55R20 size tires,

they are classified as touring

tires and are designed for

on road use. The low‐profile,

wide tread design is not

recommended for“off‐road”

driving or commercial uses

such as snow plowing. See

Off-Road Driving on page 9‑7

and Adding a Snow Plow

or Similar Equipment on

page 9‑125 for additional

information.

Notice: If the vehicle has

low‐profile tires, they are more

susceptible to damage from

road hazards or curb impact

than standard profile tires. Tire and/or wheel assembly

damage can occur when

coming into contact with

road hazards like, potholes,

or sharp edged objects,

or when sliding into a curb.

The vehicle warranty does

not cover this type of damage.

Keep tires set to the correct

inflation pressure and, when

possible avoid contact with

curbs, potholes, and other

road hazards.

Tire Sidewall Labeling

Useful information about a

tire is molded into the sidewall.

The following illustrations are

examples of a typical P‐Metric

and a LT‐Metric tire sidewall.

Passenger (P‐Metric) Tire

(A) Tire Size:The tire size

code is a combination of letters

and numbers used to define a

particular tire's width, height,

aspect ratio, construction type,

and service description. See the

“Tire Size” illustration later in this

section for more detail.

Page 483 of 594

Black plate (59,1)GMC Sierra Owner Manual - 2011

Vehicle Care 10-59

(B) TPC Spec (Tire

Performance Criteria

Specification)

:Original

equipment tires designed to

GM's specific tire performance

criteria have a TPC specification

code molded onto the sidewall.

GM's TPC specifications meet

or exceed all federal safety

guidelines.

(C) DOT (Department

of Transportation)

:The

Department of Transportation

(DOT) code indicates that

the tire is in compliance

with the U.S. Department of

Transportation Motor Vehicle

Safety Standards.

(D) Tire Identification Number

(TIN)

:The letters and numbers

following DOT code are the Tire

Identification Number (TIN). The

TIN shows the manufacturer and

plant code, tire size, and date

the tire was manufactured. The TIN is molded onto both

sides of the tire, although only

one side may have the date of

manufacture.

(E) Tire Ply Material

:The type

of cord and number of plies in

the sidewall and under the tread.

(F) Uniform Tire Quality

Grading (UTQG)

:Tire

manufacturers are required

to grade tires based on three

performance factors: treadwear,

traction, and temperature

resistance. For more

information, see Uniform Tire

Quality Grading on page 10‑80.

(G) Maximum Cold Inflation

Load Limit

:Maximum load

that can be carried and the

maximum pressure needed

to support that load. For

information on recommended

tire pressure see Tire Pressure

on page 10‑66 andVehicle

Load Limits on page 9‑25.

Light Truck (LT-Metric) Tire

(A) Tire Size:The tire size

code is a combination of letters

and numbers used to define

a particular tire's width, height,

aspect ratio, construction type,

and service description. See the

“Tire Size” illustration later in this

section for more detail.

Page 485 of 594

Black plate (61,1)GMC Sierra Owner Manual - 2011

Vehicle Care 10-61

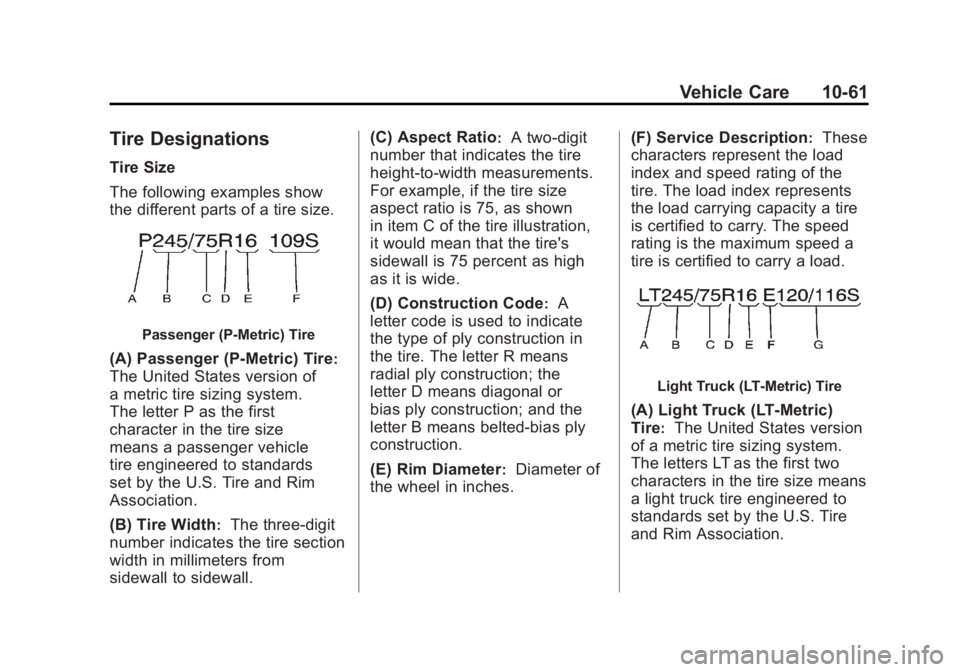

Tire Designations

Tire Size

The following examples show

the different parts of a tire size.

Passenger (P‐Metric) Tire

(A) Passenger (P‐Metric) Tire:

The United States version of

a metric tire sizing system.

The letter P as the first

character in the tire size

means a passenger vehicle

tire engineered to standards

set by the U.S. Tire and Rim

Association.

(B) Tire Width

:The three‐digit

number indicates the tire section

width in millimeters from

sidewall to sidewall. (C) Aspect Ratio

:A two‐digit

number that indicates the tire

height‐to‐width measurements.

For example, if the tire size

aspect ratio is 75, as shown

in item C of the tire illustration,

it would mean that the tire's

sidewall is 75 percent as high

as it is wide.

(D) Construction Code

:A

letter code is used to indicate

the type of ply construction in

the tire. The letter R means

radial ply construction; the

letter D means diagonal or

bias ply construction; and the

letter B means belted‐bias ply

construction.

(E) Rim Diameter

:Diameter of

the wheel in inches. (F) Service Description

:These

characters represent the load

index and speed rating of the

tire. The load index represents

the load carrying capacity a tire

is certified to carry. The speed

rating is the maximum speed a

tire is certified to carry a load.

Light Truck (LT‐Metric) Tire

(A) Light Truck (LT‐Metric)

Tire

:The United States version

of a metric tire sizing system.

The letters LT as the first two

characters in the tire size means

a light truck tire engineered to

standards set by the U.S. Tire

and Rim Association.

Page 486 of 594

Black plate (62,1)GMC Sierra Owner Manual - 2011

10-62 Vehicle Care

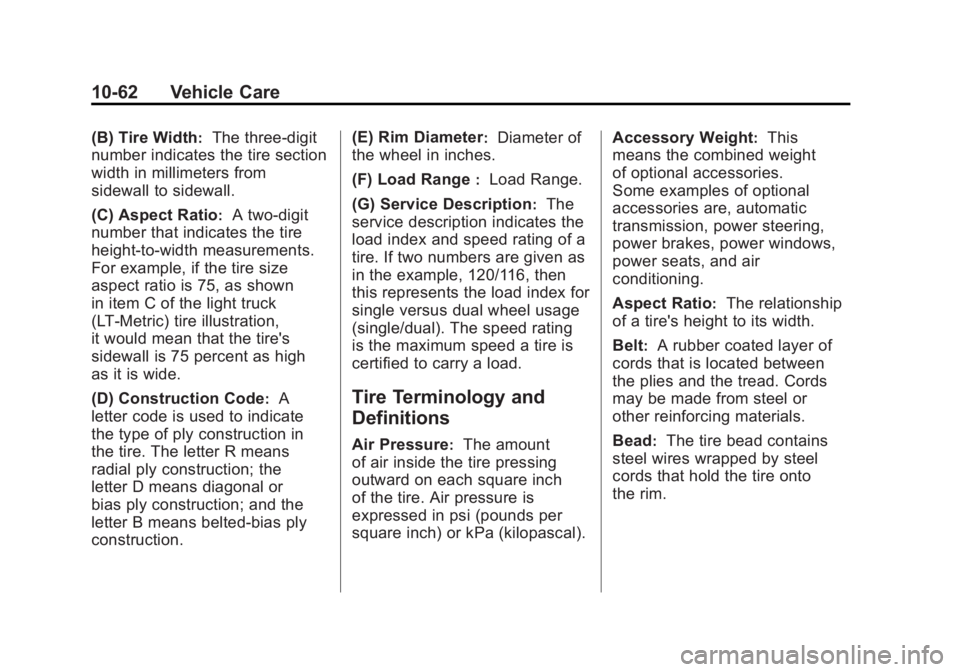

(B) Tire Width:The three‐digit

number indicates the tire section

width in millimeters from

sidewall to sidewall.

(C) Aspect Ratio

:A two‐digit

number that indicates the tire

height‐to‐width measurements.

For example, if the tire size

aspect ratio is 75, as shown

in item C of the light truck

(LT‐Metric) tire illustration,

it would mean that the tire's

sidewall is 75 percent as high

as it is wide.

(D) Construction Code

:A

letter code is used to indicate

the type of ply construction in

the tire. The letter R means

radial ply construction; the

letter D means diagonal or

bias ply construction; and the

letter B means belted‐bias ply

construction. (E) Rim Diameter

:Diameter of

the wheel in inches.

(F) Load Range

:Load Range.

(G) Service Description

:The

service description indicates the

load index and speed rating of a

tire. If two numbers are given as

in the example, 120/116, then

this represents the load index for

single versus dual wheel usage

(single/dual). The speed rating

is the maximum speed a tire is

certified to carry a load.

Tire Terminology and

Definitions

Air Pressure:The amount

of air inside the tire pressing

outward on each square inch

of the tire. Air pressure is

expressed in psi (pounds per

square inch) or kPa (kilopascal). Accessory Weight

:This

means the combined weight

of optional accessories.

Some examples of optional

accessories are, automatic

transmission, power steering,

power brakes, power windows,

power seats, and air

conditioning.

Aspect Ratio

:The relationship

of a tire's height to its width.

Belt

:A rubber coated layer of

cords that is located between

the plies and the tread. Cords

may be made from steel or

other reinforcing materials.

Bead

:The tire bead contains

steel wires wrapped by steel

cords that hold the tire onto

the rim.

Page 506 of 594

Black plate (82,1)GMC Sierra Owner Manual - 2011

10-82 Vehicle Care

Wheel Replacement

Replace any wheel that is bent,

cracked, or badly rusted or

corroded. If wheel nuts keep coming

loose, the wheel, wheel bolts and

wheel nuts should be replaced.

If the wheel leaks air, replace it

(except some aluminum wheels,

which can sometimes be repaired).

See your dealer if any of these

conditions exist.

Your dealer will know the kind of

wheel you need.

Each new wheel should have

the same load-carrying capacity,

diameter, width, offset and be

mounted the same way as the

one it replaces.

If you need to replace any of the

wheels, wheel bolts, wheel nuts

or Tire Pressure Monitor System

(TPMS) sensors, replace them only

with new GM original equipment

parts. This way, you will be sure to

have the right wheel, wheel bolts,

wheel nuts, and TPMS sensors for

the vehicle.{WARNING

Using the wrong replacement

wheels, wheel bolts, or wheel

nuts can be dangerous. It could

affect the braking and handling

of the vehicle. Tires can lose air,

and cause loss of control, causing

a crash. Always use the correct

wheel, wheel bolts, and wheel

nuts for replacement.

Notice: The wrong wheel

can also cause problems with

bearing life, brake cooling,

speedometer or odometer

calibration, headlamp aim,

bumper height, vehicle ground

clearance, and tire or tire chain

clearance to the body and

chassis. Whenever a wheel, wheel

bolt or wheel nut is replaced

on a dual wheel setup, check

the wheel nut torque after

160, 1 600 and 10 000 km

(100, 1,000 and 6,000 miles)

of driving. For proper torque,

see

“Wheel Nut Torque” under

Capacities and Specifications on

page 12‑2.

See If a Tire Goes Flat on

page 10‑84 for more information.

Used Replacement Wheels

{WARNING

Replacing a wheel with a used

one is dangerous. How it has

been used or how far it has been

driven may be unknown. It could

fail suddenly and cause a crash.

When replacing wheels, use a

new GM original equipment

wheel.