trailer GMC SIERRA DENALI 2010 Service Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2010Pages: 550, PDF Size: 4.17 MB

Page 370 of 550

Driving On Grades

Reduce speed and shift to a lower gearbeforestarting

down a long or steep downgrade. If the transmission is

not shifted down, the brakes might get hot and no

longer work well.

Vehicles can tow in D (Drive). Shift the transmission to

a lower gear if the transmission shifts too often under

heavy loads and/or hilly conditions.

The tow/haul mode may be used if the transmission

shifts too often. See Tow/Haul Mode on page 3‑32.

When towing at high altitude on steep uphill grades,

consider the following: Engine coolant will boil at a

lower temperature than at normal altitudes. If the engine

is turned off immediately after towing at high altitude on

steep uphill grades, the vehicle may show signs similar

to engine overheating. To avoid this, let the engine run

while parked, preferably on level ground, with the

automatic transmission in P (Park) for a few minutes

before turning the engine off. If the overheat warning

comes on, see Engine Overheating on page 6‑34.

Parking on Hills

{WARNING:

Parking the vehicle on a hill with the trailer

attached can be dangerous. If something goes

wrong, the rig could start to move. People can be

injured, and both the vehicle and the trailer can be

damaged. When possible, always park the rig on

a flat surface.

If parking the rig on a hill: 1. Press the brake pedal, but do not shift into P (Park) yet. Turn the wheels into the curb if facing downhill

or into traffic if facing uphill.

2. Have someone place chocks under the trailer wheels.

3. When the wheel chocks are in place, release the regular brakes until the chocks absorb the load.

4. Reapply the brake pedal. Then apply the parking brake and shift into P (Park).

5. Release the brake pedal.

5-58

Page 371 of 550

{WARNING:

It can be dangerous to get out of the vehicle if the

shift lever is not fully in P (Park) with the parking

brake firmly set. The vehicle can roll.

If the engine has been left running, the vehicle

can move suddenly. You or others could be

injured. To be sure the vehicle will not move, even

when on fairly level ground, always put the shift

lever fully in P (Park) with the parking brake

firmly set.

Leaving After Parking on a Hill

1. Apply and hold the brake pedal.

2. Start the engine

3. Shift into a gear

4. Release the parking brake

5. Let up on the brake pedal.

6. Drive slowly until the trailer is clear of the chocks.

7. Stop and have someone pick up and store thechocks.

Maintenance When Trailer Towing

The vehicle needs service more often when pulling a

trailer. See this manual's Maintenance Schedule or

Index for more information. Things that are especially

important in trailer operation are automatic transmission

fluid, engine oil, axle lubricant, belts, cooling system

and brake system. It is a good idea to inspect these

before and during the trip.

Check periodically to see that all hitch nuts and bolts

are tight.

5-59

Page 372 of 550

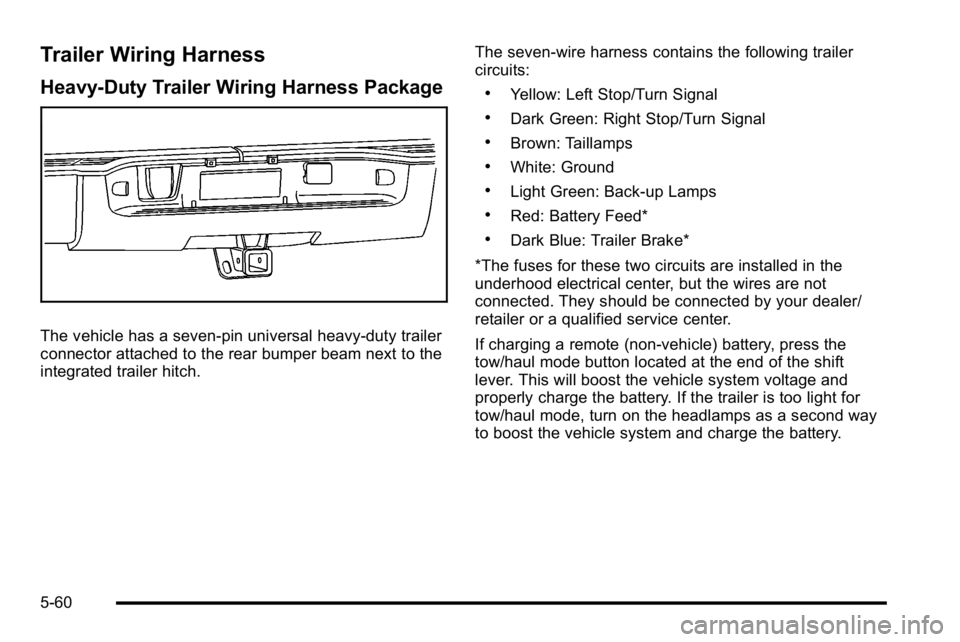

Trailer Wiring Harness

Heavy-Duty Trailer Wiring Harness Package

The vehicle has a seven-pin universal heavy-duty trailer

connector attached to the rear bumper beam next to the

integrated trailer hitch.The seven-wire harness contains the following trailer

circuits:

.Yellow: Left Stop/Turn Signal

.Dark Green: Right Stop/Turn Signal

.Brown: Taillamps

.White: Ground

.Light Green: Back-up Lamps

.Red: Battery Feed*

.Dark Blue: Trailer Brake*

*The fuses for these two circuits are installed in the

underhood electrical center, but the wires are not

connected. They should be connected by your dealer/

retailer or a qualified service center.

If charging a remote (non-vehicle) battery, press the

tow/haul mode button located at the end of the shift

lever. This will boost the vehicle system voltage and

properly charge the battery. If the trailer is too light for

tow/haul mode, turn on the headlamps as a second way

to boost the vehicle system and charge the battery.

5-60

Page 373 of 550

Electric Brake Control Wiring

Provisions

These wiring provisions are included with the vehicle as

part of the trailer wiring package. These provisions are

for an electric brake controller. The instrument panel

contains blunt cut wires near the data link connector for

the trailer brake controller. The harness contains the

following wires:

.Dark Blue: Brake Signal to Trailer Connector

.Red/Black: Battery

.Light Blue/White: Brake Switch

.White: Ground

It should be installed by your dealer/retailer or a

qualified service center.

If the vehicle is equipped with an ITBC, the blunt cuts

exist, but are not connected further in the harness. If an

aftermarket trailer brake controller is installed, the ITBC

must be disconnected. Do not power both ITBC and

aftermarket controllers to control the trailer brakes at the

same time.

Trailer Recommendations

Subtract the hitch loads from the Cargo Weight Rating

(CWR). CWR is the maximum weight of the load the

vehicle can carry. It does not include the weight of the

people inside, but you can figure about 150 lbs. (68 kg)

for each passenger. The total cargo load must not be

more than the vehicles CWR.

Weigh the vehicle with the trailer attached, so the

GVWR or GAWR are not exceeded. If using a

weight-distributing hitch, weigh the vehicle without the

spring bars in place.

The best performance is obtained by correctly

spreading out the weight of the load and choosing the

correct hitch and trailer brakes.

For more information see Towing a Trailer

on

page 5‑42.

5-61

Page 410 of 550

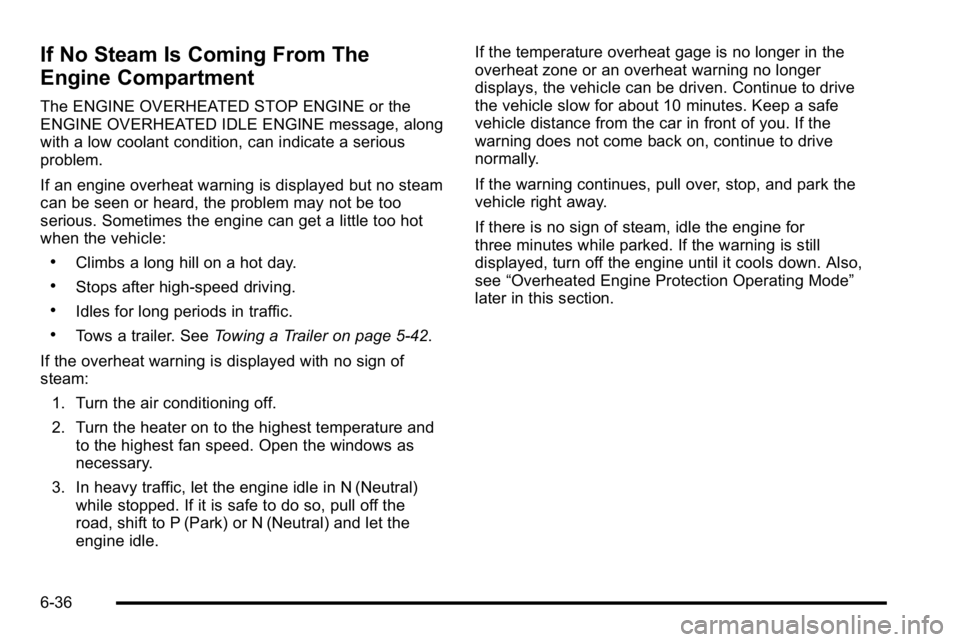

If No Steam Is Coming From The

Engine Compartment

The ENGINE OVERHEATED STOP ENGINE or the

ENGINE OVERHEATED IDLE ENGINE message, along

with a low coolant condition, can indicate a serious

problem.

If an engine overheat warning is displayed but no steam

can be seen or heard, the problem may not be too

serious. Sometimes the engine can get a little too hot

when the vehicle:

.Climbs a long hill on a hot day.

.Stops after high-speed driving.

.Idles for long periods in traffic.

.Tows a trailer. SeeTowing a Trailer on page 5‑42.

If the overheat warning is displayed with no sign of

steam: 1. Turn the air conditioning off.

2. Turn the heater on to the highest temperature and to the highest fan speed. Open the windows as

necessary.

3. In heavy traffic, let the engine idle in N (Neutral) while stopped. If it is safe to do so, pull off the

road, shift to P (Park) or N (Neutral) and let the

engine idle. If the temperature overheat gage is no longer in the

overheat zone or an overheat warning no longer

displays, the vehicle can be driven. Continue to drive

the vehicle slow for about 10 minutes. Keep a safe

vehicle distance from the car in front of you. If the

warning does not come back on, continue to drive

normally.

If the warning continues, pull over, stop, and park the

vehicle right away.

If there is no sign of steam, idle the engine for

three minutes while parked. If the warning is still

displayed, turn off the engine until it cools down. Also,

see

“Overheated Engine Protection Operating Mode”

later in this section.

6-36

Page 411 of 550

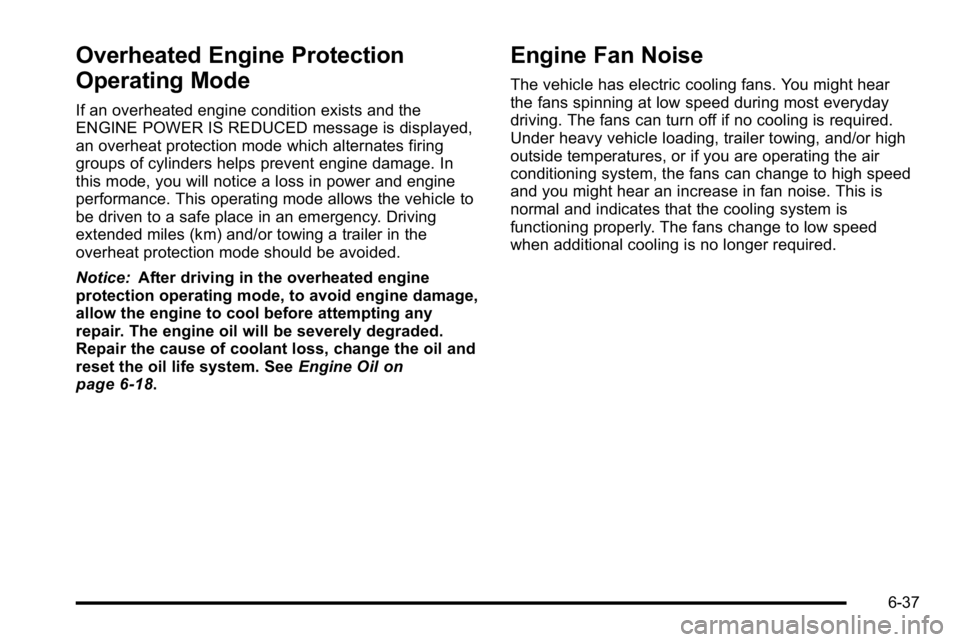

Overheated Engine Protection

Operating Mode

If an overheated engine condition exists and the

ENGINE POWER IS REDUCED message is displayed,

an overheat protection mode which alternates firing

groups of cylinders helps prevent engine damage. In

this mode, you will notice a loss in power and engine

performance. This operating mode allows the vehicle to

be driven to a safe place in an emergency. Driving

extended miles (km) and/or towing a trailer in the

overheat protection mode should be avoided.

Notice:After driving in the overheated engine

protection operating mode, to avoid engine damage,

allow the engine to cool before attempting any

repair. The engine oil will be severely degraded.

Repair the cause of coolant loss, change the oil and

reset the oil life system. See Engine Oil

on

page 6‑18.

Engine Fan Noise

The vehicle has electric cooling fans. You might hear

the fans spinning at low speed during most everyday

driving. The fans can turn off if no cooling is required.

Under heavy vehicle loading, trailer towing, and/or high

outside temperatures, or if you are operating the air

conditioning system, the fans can change to high speed

and you might hear an increase in fan noise. This is

normal and indicates that the cooling system is

functioning properly. The fans change to low speed

when additional cooling is no longer required.

6-37

Page 493 of 550

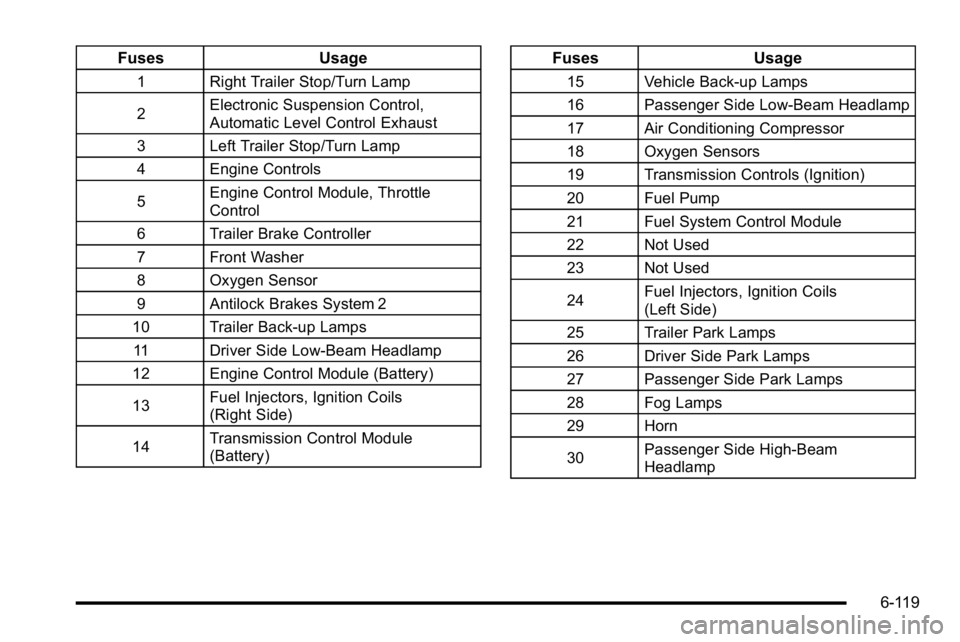

FusesUsage

1 Right Trailer Stop/Turn Lamp

2Electronic Suspension Control,

Automatic Level Control Exhaust

3 Left Trailer Stop/Turn Lamp

4 Engine Controls

5 Engine Control Module, Throttle

Control

6 Trailer Brake Controller

7 Front Washer

8 Oxygen Sensor

9 Antilock Brakes System 2

10 Trailer Back-up Lamps 11 Driver Side Low-Beam Headlamp

12 Engine Control Module (Battery)

13 Fuel Injectors, Ignition Coils

(Right Side)

14 Transmission Control Module

(Battery)

Fuses

Usage

15 Vehicle Back-up Lamps

16 Passenger Side Low-Beam Headlamp

17 Air Conditioning Compressor

18 Oxygen Sensors

19 Transmission Controls (Ignition)

20 Fuel Pump

21 Fuel System Control Module

22 Not Used

23 Not Used

24Fuel Injectors, Ignition Coils

(Left Side)

25 Trailer Park Lamps

26 Driver Side Park Lamps

27 Passenger Side Park Lamps

28 Fog Lamps

29 Horn

30 Passenger Side High-Beam

Headlamp

6-119

Page 495 of 550

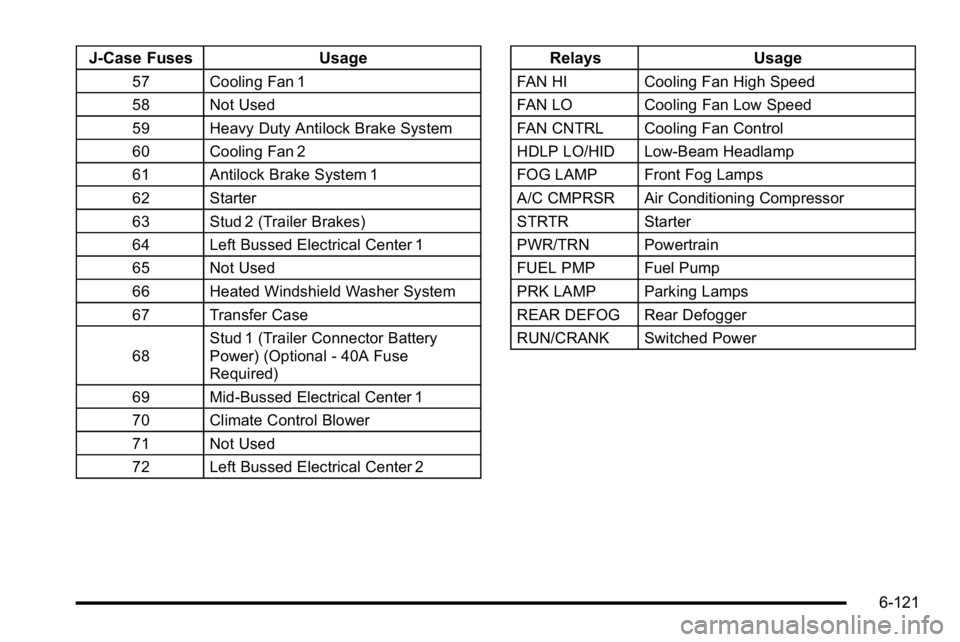

J-Case FusesUsage

57 Cooling Fan 1

58 Not Used

59 Heavy Duty Antilock Brake System

60 Cooling Fan 2

61 Antilock Brake System 1

62 Starter

63 Stud 2 (Trailer Brakes)

64 Left Bussed Electrical Center 1

65 Not Used

66 Heated Windshield Washer System

67 Transfer Case

68Stud 1 (Trailer Connector Battery

Power) (Optional - 40A Fuse

Required)

69 Mid-Bussed Electrical Center 1

70 Climate Control Blower

71 Not Used

72 Left Bussed Electrical Center 2

Relays Usage

FAN HI Cooling Fan High Speed

FAN LO Cooling Fan Low Speed

FAN CNTRL Cooling Fan Control

HDLP LO/HID Low-Beam Headlamp

FOG LAMP Front Fog Lamps

A/C CMPRSR Air Conditioning Compressor

STRTR Starter

PWR/TRN Powertrain

FUEL PMP Fuel Pump

PRK LAMP Parking Lamps

REAR DEFOG Rear Defogger

RUN/CRANK Switched Power

6-121

Page 502 of 550

First Engine Oil Change After Every

40 000 km/25,000 Miles

.Fuel system inspection for damage or leaks.

First Engine Oil Change After Every

80 000 km/50,000 Miles

.Engine air cleaner filter replacement. SeeEngine

Air Cleaner/Filter on page 6‑22.

.Automatic transmission fluid change (severe

service) for vehicles mainly driven in heavy city

traffic in hot weather, in hilly or mountainous

terrain, when frequently towing a trailer, or used for

taxi, police, or delivery service. See Automatic

Transmission Fluid on page 6‑24.

.Transfer case fluid change (severe service) for

vehicles mainly driven when frequently towing a

trailer, or used for taxi, police, or delivery service.

Check vent hose at transfer case for kinks and

proper installation. Check to be sure vent hose is

unobstructed, clear, and free of debris. During any maintenance, if a power washer is used to clean

mud and dirt from the underbody, care should be

taken to not directly spray the transfer case output

seals. High pressure water can overcome the seals

and contaminate the transfer case fluid.

Contaminated fluid will decrease the life of the

transfer case and should be replaced.

.Evaporative control system inspection. Check all

fuel and vapor lines and hoses for proper hook‐up,

routing, and condition. Check that the purge valve,

if the vehicle has one, works properly. Replace as

needed.

An Emission Control Service. The U.S.

Environmental Protection Agency or the California

Air Resources Board has determined that the

failure to perform this maintenance item will not

nullify the emission warranty or limit recall liability

prior to the completion of the vehicle's useful life.

We, however, urge that all recommended

maintenance services be performed at the

indicated intervals and the maintenance be

recorded.

7-6

Page 542 of 550

Headlamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55Aiming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

Daytime Running Lamps (DRL) . . . . . . . . . . . . . . . . . . . 4-11

Exterior Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Flash-to-Pass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

High/Low Beam Changer . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

On Reminder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Heated Seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17, 4-20 Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

High-Speed Operation, Tires . . . . . . . . . . . . . . . . . . . . . . 6-72

Highbeam On Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Highway Hypnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Hill and Mountain Roads . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Hood Checking Things Under . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

How to Wear Safety Belts Properly . . . . . . . . . . . . . . . . 2-16I

Ignition Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Infants and Young Children, Restraints . . . . . . . . . . . . 2-36

Inflation - Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-71

Instrument Panel Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Storage Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Instrument Panel Cluster . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Integrated Trailer Brake Control System (ITBC) . . . . 5-42

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

J

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

K

Keyless Entry Remote (RKE) System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Keyless Entry System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

i - 8