clock GMC SIERRA DENALI 2015 User Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2015, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2015Pages: 439, PDF Size: 4.68 MB

Page 292 of 439

Black plate (21,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

Vehicle Care 10-21

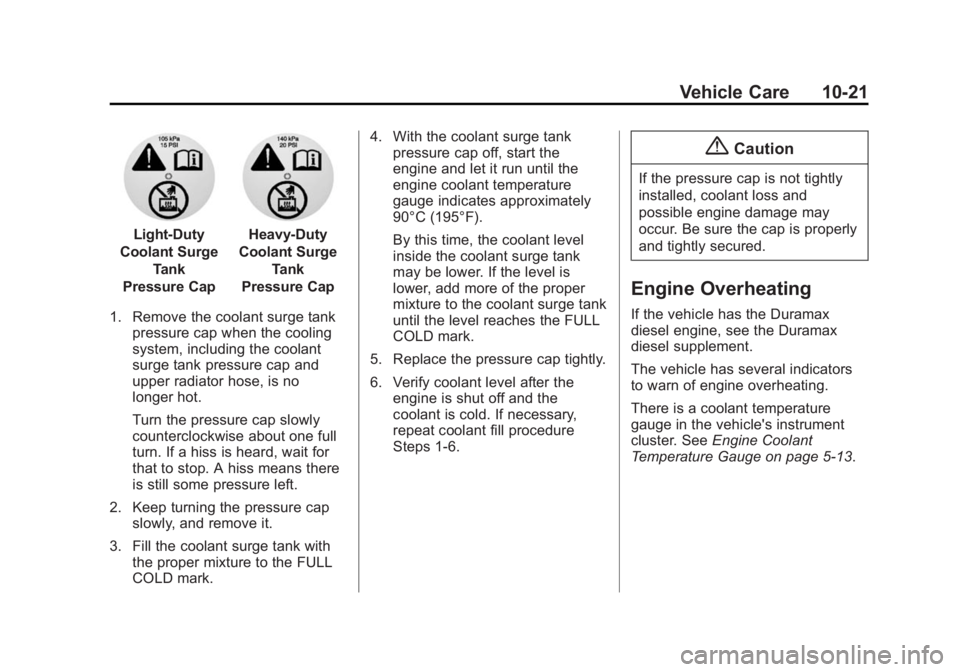

Light-Duty

Coolant Surge

Tank

Pressure Cap Heavy-Duty

Coolant Surge

Tank

Pressure Cap

1. Remove the coolant surge tank

pressure cap when the cooling

system, including the coolant

surge tank pressure cap and

upper radiator hose, is no

longer hot.

Turn the pressure cap slowly

counterclockwise about one full

turn. If a hiss is heard, wait for

that to stop. A hiss means there

is still some pressure left.

2. Keep turning the pressure cap

slowly, and remove it.

3. Fill the coolant surge tank with

the proper mixture to the FULL

COLD mark. 4. With the coolant surge tank

pressure cap off, start the

engine and let it run until the

engine coolant temperature

gauge indicates approximately

90°C (195°F).

By this time, the coolant level

inside the coolant surge tank

may be lower. If the level is

lower, add more of the proper

mixture to the coolant surge tank

until the level reaches the FULL

COLD mark.

5. Replace the pressure cap tightly.

6. Verify coolant level after the

engine is shut off and the

coolant is cold. If necessary,

repeat coolant fill procedure

Steps 1-6. { CautionIf the pressure cap is not tightly

installed, coolant loss and

possible engine damage may

occur. Be sure the cap is properly

and tightly secured.

Engine Overheating If the vehicle has the Duramax

diesel engine, see the Duramax

diesel supplement.

The vehicle has several indicators

to warn of engine overheating.

There is a coolant temperature

gauge in the vehicle's instrument

cluster. See Engine Coolant

Temperature Gauge on page 5-13 .

Page 308 of 439

Black plate (37,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

Vehicle Care 10-372. Remove the headlamp bulb

assembly cover by turning it

counterclockwise.

3. Turn the bulb socket

counterclockwise to remove it

from the headlamp assembly

and pull it straight out.

4. Unplug the electrical connector

from the old bulb by releasing

the clip on the bulb socket.

Turn Signal/Sidemarker/

Parking Lamp 1. Open the hood.

2. If replacing a bulb on the

passenger side, remove the

engine air cleaner.

3. Turn the bulb socket

counterclockwise to remove it

from the headlamp assembly

and pull it straight out.

4. Remove the bulb by pulling it

straight out of the bulb socket. Fog Lamps To replace the front fog lamp bulb:

1. Locate the fog lamp under the

front bumper.

2. Disconnect the electrical

connector from the fog lamp bulb

assembly by pressing the

connector release.

3. Remove the bulb from the

housing by squeezing the two

release tabs and pulling it

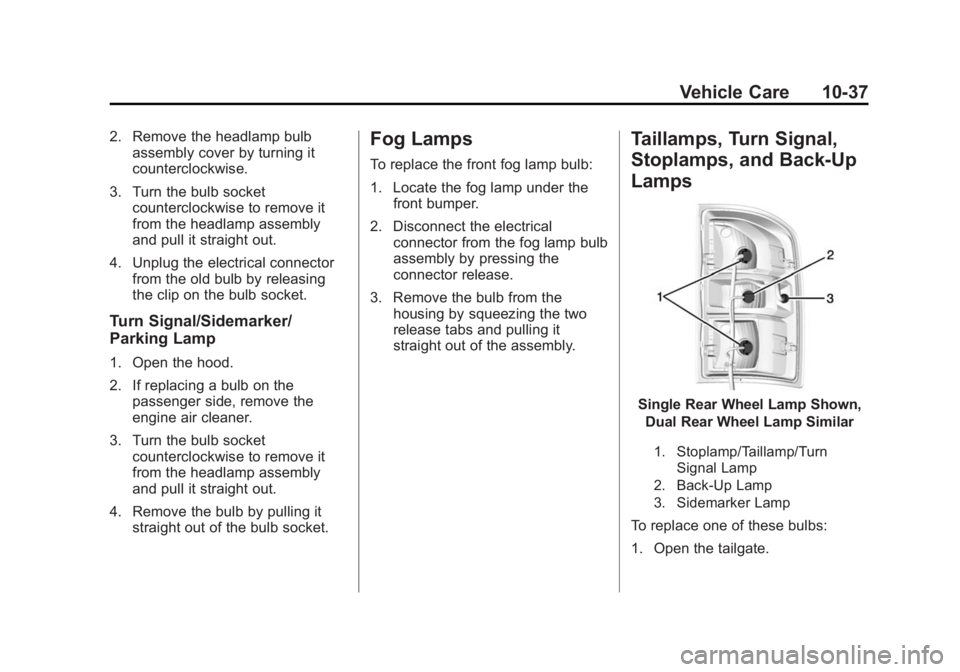

straight out of the assembly. Taillamps, Turn Signal,

Stoplamps, and Back-Up

Lamps

Single Rear Wheel Lamp Shown,

Dual Rear Wheel Lamp Similar

1. Stoplamp/Taillamp/Turn

Signal Lamp

2. Back-Up Lamp

3. Sidemarker Lamp

To replace one of these bulbs:

1. Open the tailgate.

Page 309 of 439

Black plate (38,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

10-38 Vehicle Care

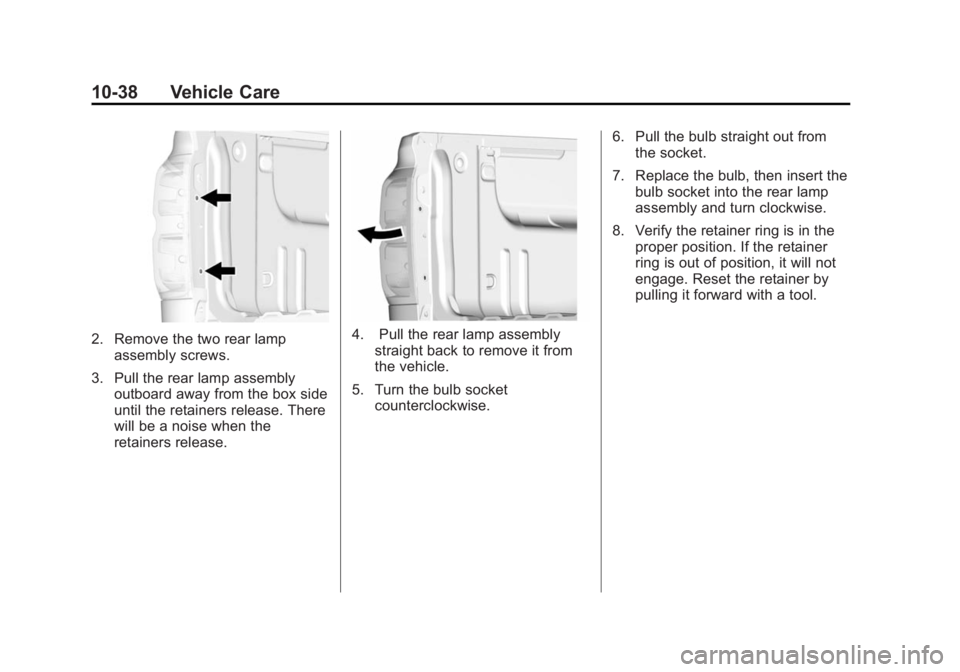

2. Remove the two rear lamp

assembly screws.

3. Pull the rear lamp assembly

outboard away from the box side

until the retainers release. There

will be a noise when the

retainers release. 4. Pull the rear lamp assembly

straight back to remove it from

the vehicle.

5. Turn the bulb socket

counterclockwise. 6. Pull the bulb straight out from

the socket.

7. Replace the bulb, then insert the

bulb socket into the rear lamp

assembly and turn clockwise.

8. Verify the retainer ring is in the

proper position. If the retainer

ring is out of position, it will not

engage. Reset the retainer by

pulling it forward with a tool.

Page 310 of 439

Black plate (39,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

Vehicle Care 10-39

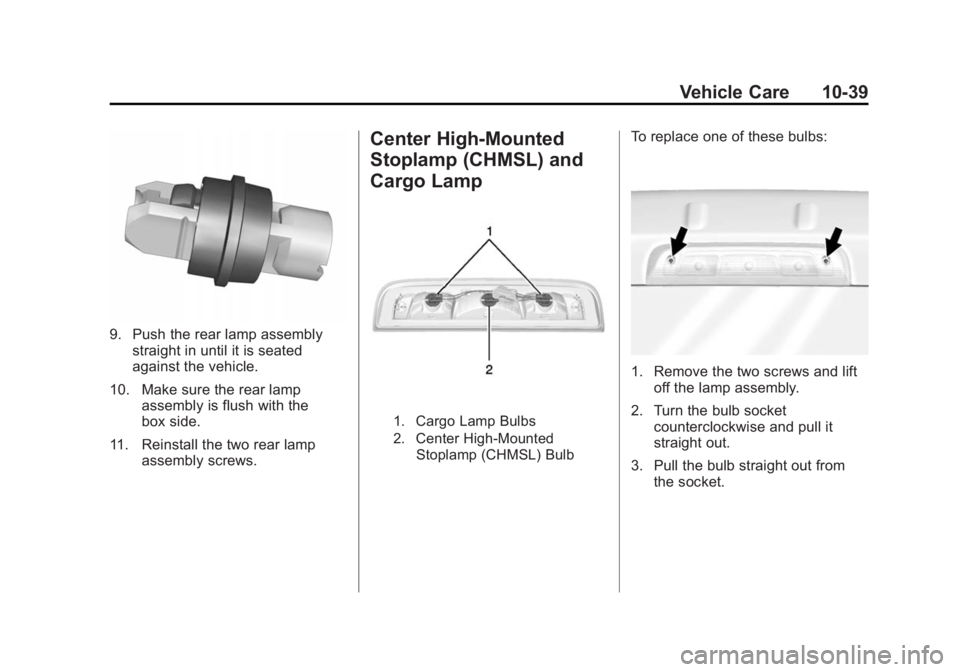

9. Push the rear lamp assembly

straight in until it is seated

against the vehicle.

10. Make sure the rear lamp

assembly is flush with the

box side.

11. Reinstall the two rear lamp

assembly screws. Center High-Mounted

Stoplamp (CHMSL) and

Cargo Lamp

1. Cargo Lamp Bulbs

2. Center High-Mounted

Stoplamp (CHMSL) Bulb To replace one of these bulbs:

1. Remove the two screws and lift

off the lamp assembly.

2. Turn the bulb socket

counterclockwise and pull it

straight out.

3. Pull the bulb straight out from

the socket.

Page 348 of 439

Black plate (77,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

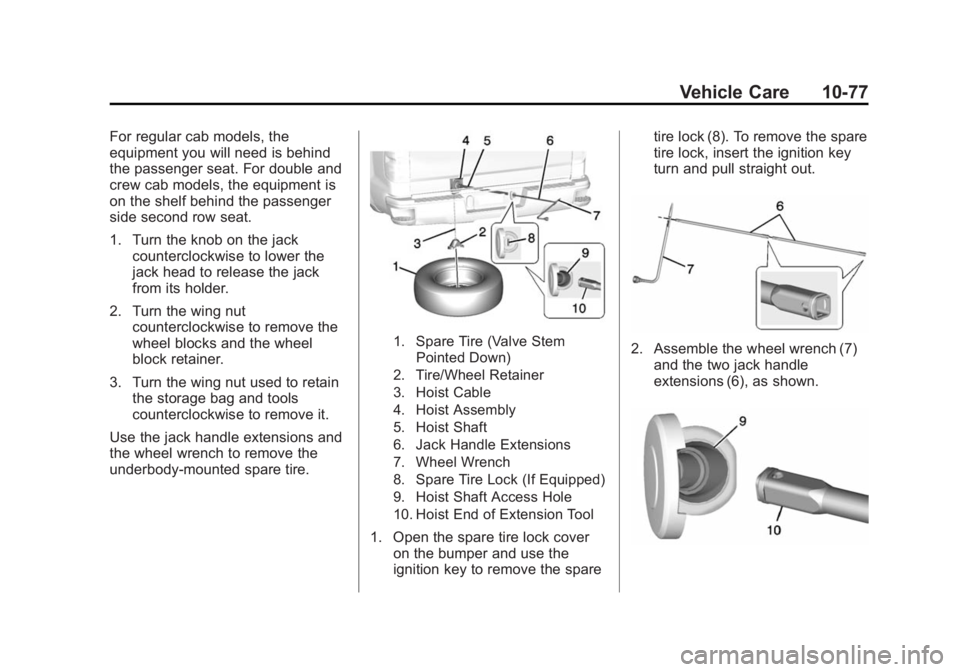

Vehicle Care 10-77For regular cab models, the

equipment you will need is behind

the passenger seat. For double and

crew cab models, the equipment is

on the shelf behind the passenger

side second row seat.

1. Turn the knob on the jack

counterclockwise to lower the

jack head to release the jack

from its holder.

2. Turn the wing nut

counterclockwise to remove the

wheel blocks and the wheel

block retainer.

3. Turn the wing nut used to retain

the storage bag and tools

counterclockwise to remove it.

Use the jack handle extensions and

the wheel wrench to remove the

underbody-mounted spare tire. 1. Spare Tire (Valve Stem

Pointed Down)

2. Tire/Wheel Retainer

3. Hoist Cable

4. Hoist Assembly

5. Hoist Shaft

6. Jack Handle Extensions

7. Wheel Wrench

8. Spare Tire Lock (If Equipped)

9. Hoist Shaft Access Hole

10. Hoist End of Extension Tool

1. Open the spare tire lock cover

on the bumper and use the

ignition key to remove the spare tire lock (8). To remove the spare

tire lock, insert the ignition key

turn and pull straight out.

2. Assemble the wheel wrench (7)

and the two jack handle

extensions (6), as shown.

Page 349 of 439

Black plate (78,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

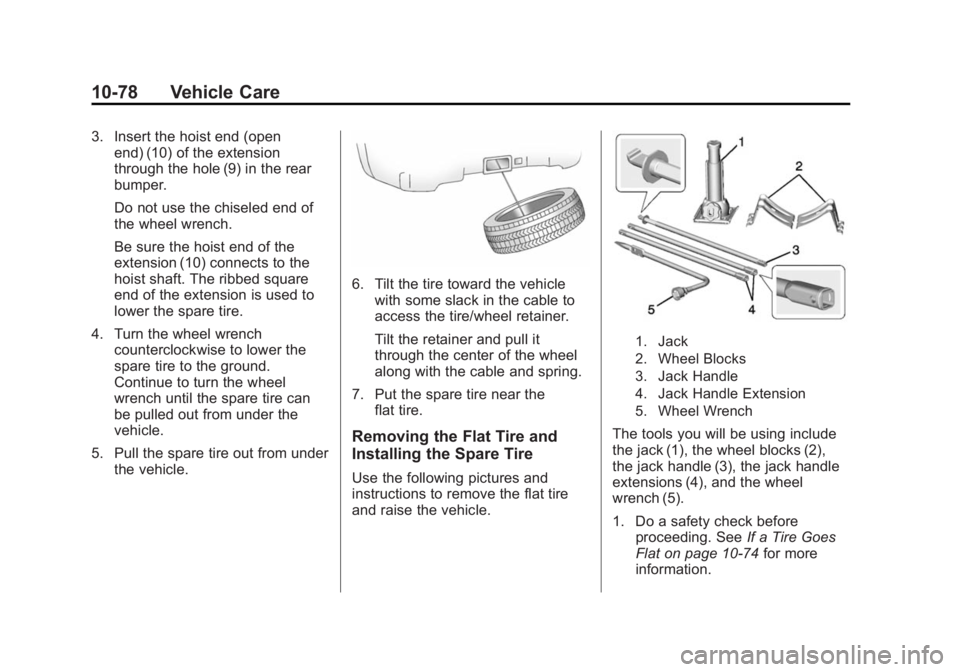

10-78 Vehicle Care 3. Insert the hoist end (open

end) (10) of the extension

through the hole (9) in the rear

bumper.

Do not use the chiseled end of

the wheel wrench.

Be sure the hoist end of the

extension (10) connects to the

hoist shaft. The ribbed square

end of the extension is used to

lower the spare tire.

4. Turn the wheel wrench

counterclockwise to lower the

spare tire to the ground.

Continue to turn the wheel

wrench until the spare tire can

be pulled out from under the

vehicle.

5. Pull the spare tire out from under

the vehicle. 6. Tilt the tire toward the vehicle

with some slack in the cable to

access the tire/wheel retainer.

Tilt the retainer and pull it

through the center of the wheel

along with the cable and spring.

7. Put the spare tire near the

flat tire.

Removing the Flat Tire and

Installing the Spare Tire

Use the following pictures and

instructions to remove the flat tire

and raise the vehicle. 1. Jack

2. Wheel Blocks

3. Jack Handle

4. Jack Handle Extension

5. Wheel Wrench

The tools you will be using include

the jack (1), the wheel blocks (2),

the jack handle (3), the jack handle

extensions (4), and the wheel

wrench (5).

1. Do a safety check before

proceeding. See If a Tire Goes

Flat on page 10-74 for more

information.

Page 350 of 439

Black plate (79,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

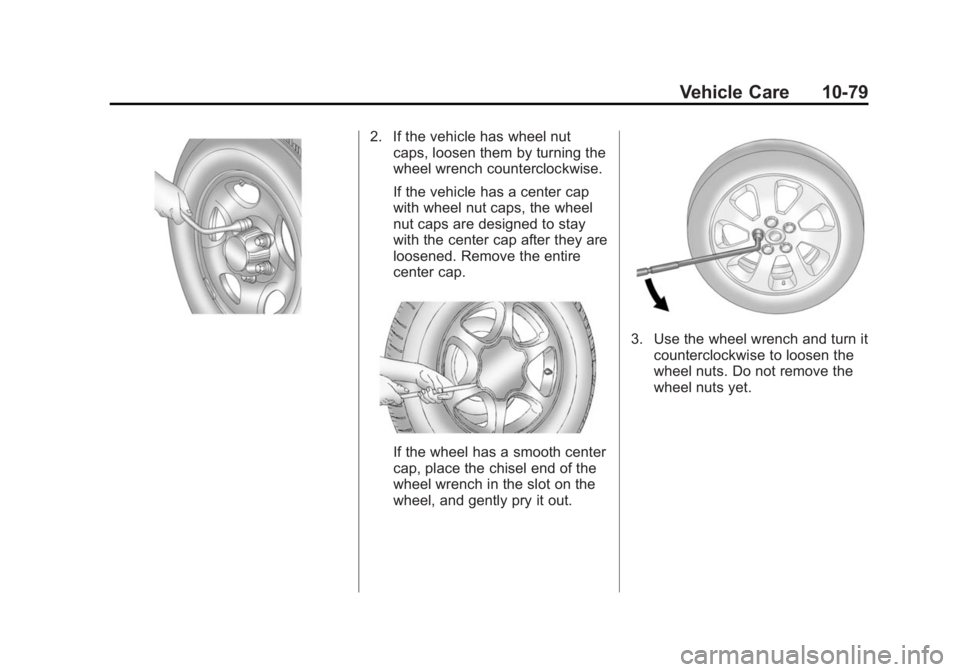

Vehicle Care 10-792. If the vehicle has wheel nut

caps, loosen them by turning the

wheel wrench counterclockwise.

If the vehicle has a center cap

with wheel nut caps, the wheel

nut caps are designed to stay

with the center cap after they are

loosened. Remove the entire

center cap.

If the wheel has a smooth center

cap, place the chisel end of the

wheel wrench in the slot on the

wheel, and gently pry it out. 3. Use the wheel wrench and turn it

counterclockwise to loosen the

wheel nuts. Do not remove the

wheel nuts yet.

Page 352 of 439

Black plate (81,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

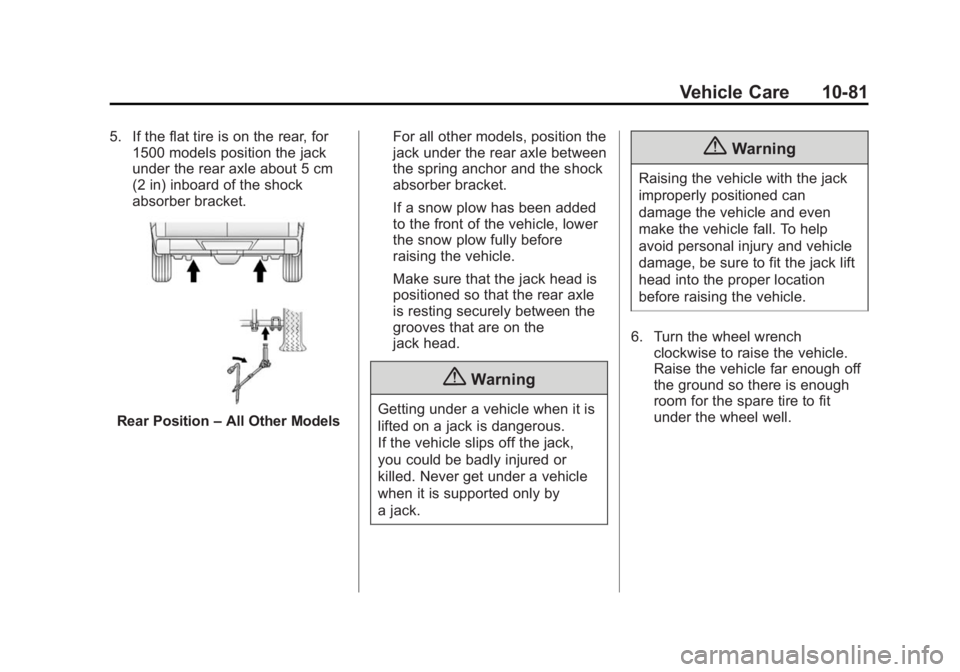

Vehicle Care 10-815. If the flat tire is on the rear, for

1500 models position the jack

under the rear axle about 5 cm

(2 in) inboard of the shock

absorber bracket.

Rear Position – All Other Models For all other models, position the

jack under the rear axle between

the spring anchor and the shock

absorber bracket.

If a snow plow has been added

to the front of the vehicle, lower

the snow plow fully before

raising the vehicle.

Make sure that the jack head is

positioned so that the rear axle

is resting securely between the

grooves that are on the

jack head.

{ Warning

Getting under a vehicle when it is

lifted on a jack is dangerous.

If the vehicle slips off the jack,

you could be badly injured or

killed. Never get under a vehicle

when it is supported only by

a jack. { WarningRaising the vehicle with the jack

improperly positioned can

damage the vehicle and even

make the vehicle fall. To help

avoid personal injury and vehicle

damage, be sure to fit the jack lift

head into the proper location

before raising the vehicle.

6. Turn the wheel wrench

clockwise to raise the vehicle.

Raise the vehicle far enough off

the ground so there is enough

room for the spare tire to fit

under the wheel well.

Page 353 of 439

Black plate (82,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

10-82 Vehicle Care

7. Remove all the wheel nuts and

take off the flat tire.

{ Warning

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose

after time. The wheel could come

off and cause an accident. When

changing a wheel, remove any

rust or dirt from places where the

wheel attaches to the vehicle. In

an emergency, a cloth or a paper

(Continued) Warning (Continued) towel can be used; however, use

a scraper or wire brush later to

remove all rust or dirt.

8. Remove any rust or dirt from the

wheel bolts, mounting surfaces,

and spare wheel.

9. Install the spare tire. { WarningNever use oil or grease on bolts

or nuts because the nuts might

come loose. The vehicle's wheel

could fall off, causing a crash.

10. Put the wheel nuts back on

with the rounded end of the

nuts toward the wheel.

11. Tighten each wheel nut by

hand. Then use the wheel

wrench to tighten the nuts until

the wheel is held against

the hub.

12. Turn the wheel wrench

counterclockwise to lower the

vehicle. Lower the jack

completely.

{ Warning

If wheel studs are damaged, they

can break. If all the studs on a

wheel broke, the wheel could

(Continued)

Page 354 of 439

Black plate (83,1)GMC 2015i Sierra Denali Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico-8431500) - 2015 - crc - 6/20/14

Vehicle Care 10-83Warning (Continued)come off and cause a crash.

If any stud is damaged because

of a loose-running wheel, it could

be that all of the studs are

damaged. To be sure, replace all

studs on the wheel. If the stud

holes in a wheel have become

larger, the wheel could collapse in

operation. Replace any wheel if

its stud holes have become larger

or distorted in any way. Inspect

hubs and hub ‐ piloted wheels for

damage. Because of loose

running wheels, piloting pad

damage may occur and require

replacement of the entire hub, for

proper centering of the wheels.

When replacing studs, hubs,

wheel nuts or wheels, be sure to

use GM original equipment parts. { WarningWheel nuts that are improperly or

incorrectly tightened can cause

the wheels to become loose or

come off. The wheel nuts should

be tightened with a torque wrench

to the proper torque specification

after replacing. Follow the torque

specification supplied by the

aftermarket manufacturer when

using accessory locking wheel

nuts. See Capacities and

Specifications on page 12-2 for

original equipment wheel nut

torque specifications.

{ Caution

Improperly tightened wheel nuts

can lead to brake pulsation and

rotor damage. To avoid expensive

brake repairs, evenly tighten the

wheel nuts in the proper

(Continued) Caution (Continued) sequence and to the proper

torque specification. See

Capacities and Specifications on

page 12-2 for the wheel nut

torque specification.

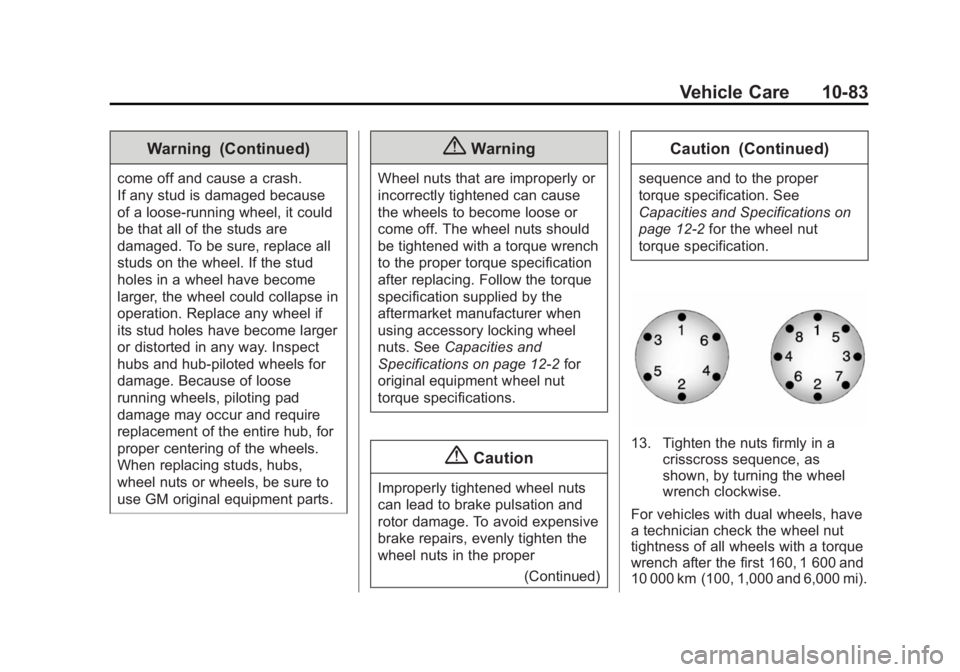

13. Tighten the nuts firmly in a

crisscross sequence, as

shown, by turning the wheel

wrench clockwise.

For vehicles with dual wheels, have

a technician check the wheel nut

tightness of all wheels with a torque

wrench after the first 160, 1 600 and

10 000 km (100, 1,000 and 6,000 mi).