brake rotor GMC YUKON 2006 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2006, Model line: YUKON, Model: GMC YUKON 2006Pages: 540, PDF Size: 3.14 MB

Page 461 of 540

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci�cation. SeeCapacities

and Specifications on page 5-114for wheel

nut torque speci�cation.

Notice:Improperly tightened wheel nuts can

lead to brake pulsation and rotor damage.

To avoid expensive brake repairs, evenly tighten

the wheel nuts in the proper sequence and to

the proper torque speci�cation. SeeCapacities

and Specifications on page 5-114for the wheel

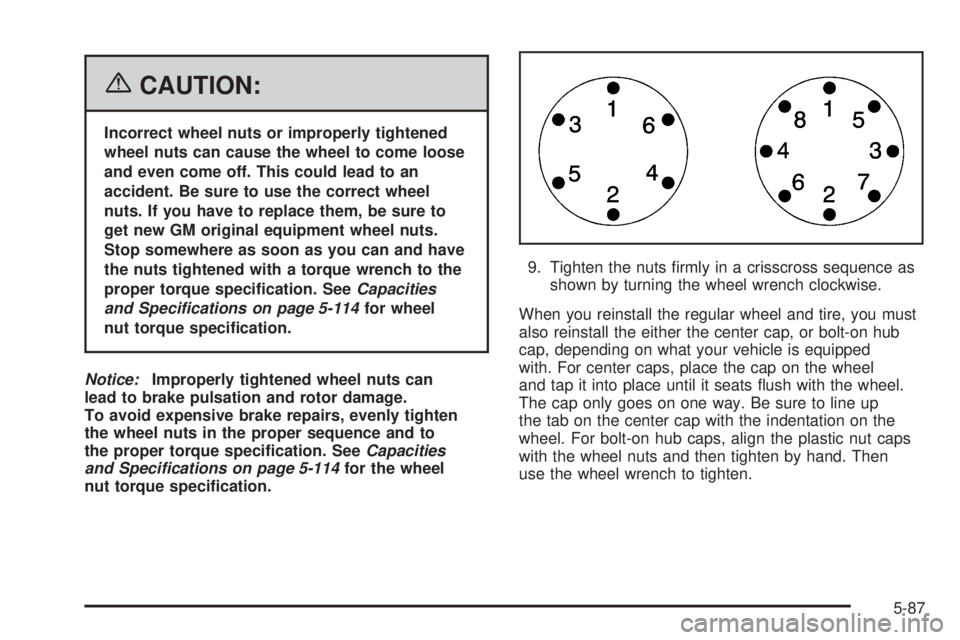

nut torque speci�cation.9. Tighten the nuts �rmly in a crisscross sequence as

shown by turning the wheel wrench clockwise.

When you reinstall the regular wheel and tire, you must

also reinstall the either the center cap, or bolt-on hub

cap, depending on what your vehicle is equipped

with. For center caps, place the cap on the wheel

and tap it into place until it seats �ush with the wheel.

The cap only goes on one way. Be sure to line up

the tab on the center cap with the indentation on the

wheel. For bolt-on hub caps, align the plastic nut caps

with the wheel nuts and then tighten by hand. Then

use the wheel wrench to tighten.

5-87

Page 498 of 540

Maintenance Footnotes

†The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

#Lubricate the front suspension, ball joints, steering

linkage, transmission shift linkage, and parking

brake cable guides. Ball joints should not be lubricated

unless their temperature is 10°F (-12°C) or higher,

or they could be damaged.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, cha�ng, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect other brake parts, including calipers,

parking brake, etc.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose, or missing parts,

signs of wear, or lack of lubrication. Inspect power

steering lines and hoses for proper hook-up, binding,

leaks, cracks, cha�ng, etc. Visually check constant

velocity joints, rubber boots, and axle seals for leaks.(c)Visually inspect hoses and have them replaced

if they are cracked, swollen, or deteriorated. Inspect all

pipes, �ttings, and clamps; replace with genuine GM

parts as needed. To help ensure proper operation,

a pressure test of the cooling system and pressure

cap and cleaning the outside of the radiator and

air conditioning condenser is recommended at least

once a year.

(d)Visually inspect wiper blades for wear or cracking.

Replace wiper blades that appear worn or damaged

or that streak or miss areas of the windshield.

(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors, and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken airbag

coverings, and have them repaired or replaced.

The airbag system does not need regular maintenance.

(f)Lubricate all key lock cylinders, hood latch

assembly, secondary latch, pivots, spring anchor,

release pawl, rear compartment hinges, outer liftgate

handle pivot points, rear door detent link, roller

mechanism, liftgate handle pivot points, latch bolt,

fuel door hinge, cargo door hinge, locks, and folding

seat hardware. More frequent lubrication may be

required when exposed to a corrosive environment.

6-8