lock GMC YUKON 2010 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: YUKON, Model: GMC YUKON 2010Pages: 614, PDF Size: 3.55 MB

Page 538 of 614

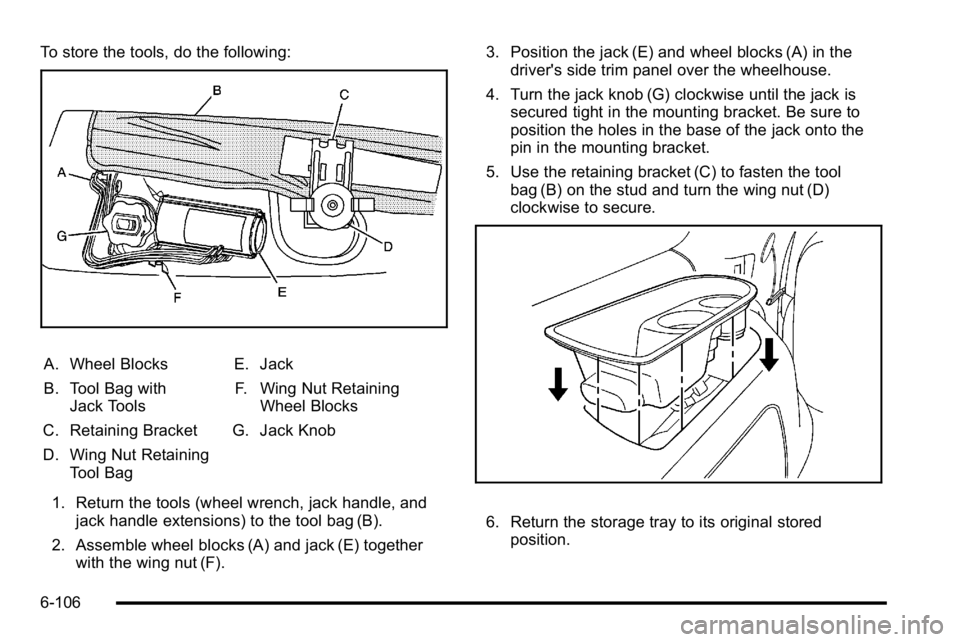

To store the tools, do the following:

A. Wheel Blocks

B. Tool Bag withJack Tools

C. Retaining Bracket

D. Wing Nut Retaining Tool Bag E. Jack

F. Wing Nut Retaining Wheel Blocks

G. Jack Knob

1. Return the tools (wheel wrench, jack handle, and jack handle extensions) to the tool bag (B).

2. Assemble wheel blocks (A) and jack (E) together with the wing nut (F). 3. Position the jack (E) and wheel blocks (A) in the

driver's side trim panel over the wheelhouse.

4. Turn the jack knob (G) clockwise until the jack is secured tight in the mounting bracket. Be sure to

position the holes in the base of the jack onto the

pin in the mounting bracket.

5. Use the retaining bracket (C) to fasten the tool bag (B) on the stud and turn the wing nut (D)

clockwise to secure.

6. Return the storage tray to its original storedposition.

6-106

Page 551 of 614

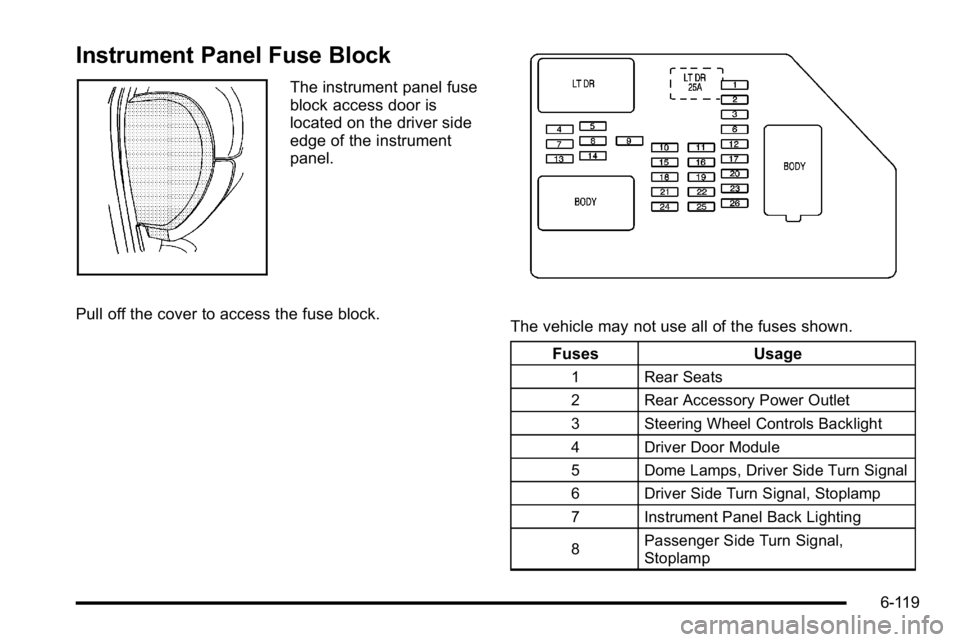

Instrument Panel Fuse Block

The instrument panel fuse

block access door is

located on the driver side

edge of the instrument

panel.

Pull off the cover to access the fuse block.

The vehicle may not use all of the fuses shown. Fuses Usage

1 Rear Seats

2 Rear Accessory Power Outlet

3 Steering Wheel Controls Backlight

4 Driver Door Module

5 Dome Lamps, Driver Side Turn Signal

6 Driver Side Turn Signal, Stoplamp

7 Instrument Panel Back Lighting

8 Passenger Side Turn Signal,

Stoplamp

6-119

Page 552 of 614

FusesUsage

9Passenger Door Module, Driver

Unlock

10 Power Door Lock 2 (Unlock Feature) 11 Power Door Lock 2 (Lock Feature)

12 Stoplamps, Center-High Mounted

Stoplamp

13 Rear Climate Controls

14 Power Mirror

15 Body Control Module (BCM)

16 Accessory Power Outlets

17 Interior Lamps

18 Power Door Lock 1 (Unlock Feature)

19 Rear Seat Entertainment

20 Ultrasonic Rear Parking Assist,

Power Liftgate

21 Power Door Lock 1 (Lock Feature)

Fuses Usage

22 Driver Information Center (DIC)

23 Rear Wiper

24 Cooled Seats

25Driver Seat Module, Remote Keyless

Entry System

26 Driver Power Door Lock

(Unlock Feature)

Circuit Breaker

Usage

LT DRDriver Side Power Window Circuit

Breaker

Harness

Connector Usage

LT DR Driver Door Harness Connection

BODY Harness Connector

BODY Harness Connector

6-120

Page 553 of 614

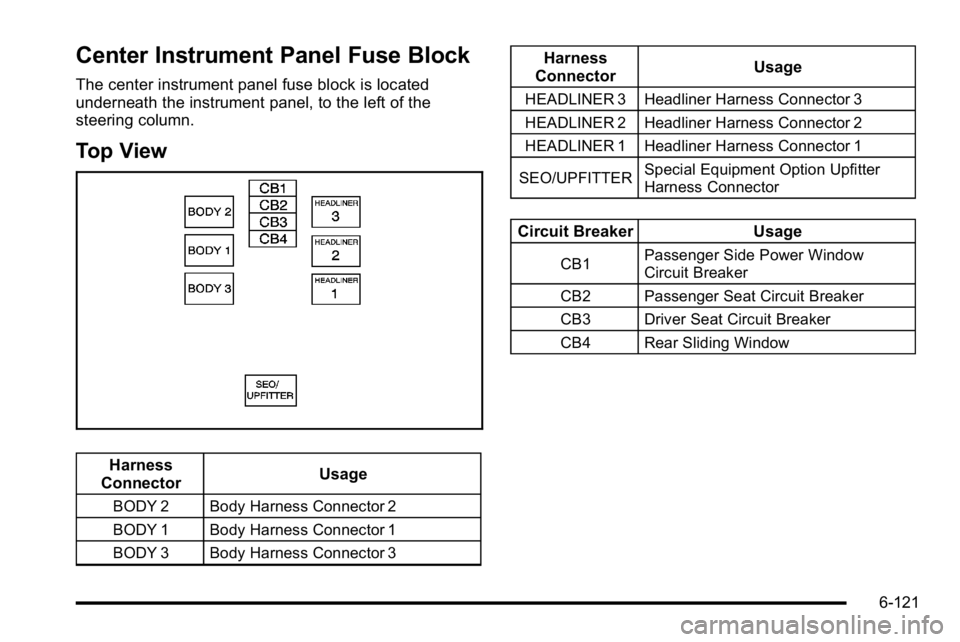

Center Instrument Panel Fuse Block

The center instrument panel fuse block is located

underneath the instrument panel, to the left of the

steering column.

Top View

Harness

Connector Usage

BODY 2 Body Harness Connector 2

BODY 1 Body Harness Connector 1

BODY 3 Body Harness Connector 3

Harness

Connector Usage

HEADLINER 3 Headliner Harness Connector 3

HEADLINER 2 Headliner Harness Connector 2

HEADLINER 1 Headliner Harness Connector 1

SEO/UPFITTER Special Equipment Option Upfitter

Harness Connector

Circuit Breaker

Usage

CB1Passenger Side Power Window

Circuit Breaker

CB2 Passenger Seat Circuit Breaker

CB3 Driver Seat Circuit Breaker

CB4 Rear Sliding Window

6-121

Page 554 of 614

Underhood Fuse Block

The underhood fuse block is located in the engine

compartment, on the driver side of the vehicle.

Lift the cover for access to the fuse/relay block.

If the vehicle is a Two-mode Hybrid, see the Two-mode

Hybrid manual for more information.

Notice:Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

To remove fuses, hold the end of the fuse between your

thumb and index finger and pull straight out.

Fuses Usage

1 Right Trailer Stop/Turn Lamp

2Electronic Stability Suspension

Control, Automatic Level Control

Exhaust

3 Left Trailer Stop/Turn Lamp

4 Engine Controls

6-122

Page 555 of 614

FusesUsage

5Engine Control Module,

Throttle Control

6 Trailer Brake Controller

7 Front Washer

8 Oxygen Sensors

9 Antilock Brakes System 2

10 Trailer Back-up Lamps 11 Driver Side Low-Beam Headlamp

12 Engine Control Module (Battery)

13 Fuel Injectors, Ignition Coils

(Right Side)

14 Transmission Control Module

(Battery)

15 Vehicle Back-up Lamps

16 Passenger Side Low-Beam Headlamp

17 Air Conditioning Compressor

18 Oxygen Sensors

Fuses Usage

19 Transmission Controls (Ignition)

20 Fuel Pump

21 Fuel System Control Module

22 Headlamp Washer

23 Rear Windshield Washer

24Fuel Injectors, Ignition Coils

(Left Side)

25 Trailer Park Lamps

26 Driver Side Park Lamps

27 Passenger Side Park Lamps

28 Fog Lamps

29 Horn

30 Passenger Side High-Beam

Headlamp

31 Daytime Running Lamps (DRL)

32 Driver Side High-Beam Headlamp

33 Daytime Running Lamps 2

6-123

Page 557 of 614

J-Case FusesUsage

57 Cooling Fan 1

58 Automatic Level Control Compressor

59 Heavy Duty Antilock Braking System

60 Cooling Fan 2

61 Antilock Brake System 1

62 Starter

63 Stud 2 (Trailer Brakes)

64 Left Bussed Electrical Center 1

65 Electric Running Boards

66 Heated Windshield Washer System

67 Transfer Case

68Stud 1 (Trailer Connector Battery

Power)

69 Mid-Bussed Electrical Center 1

70 Climate Control Blower

71 Power Liftgate Module

72 Left Bussed Electrical Center 2

Relays Usage

FAN HI Cooling Fan High Speed

FAN LO Cooling Fan Low Speed

FAN CNTRL Cooling Fan Control

HDLP LO/HID Low-Beam Headlamp

FOG LAMP Front Fog Lamps

A/C CMPRSR Air Conditioning Compressor

STRTR Starter

PWR/TRN Powertrain

FUEL PMP Fuel Pump

PRK LAMP Parking Lamps

REAR DEFOG Rear Defogger

RUN/CRANK Switched Power

6-125

Page 559 of 614

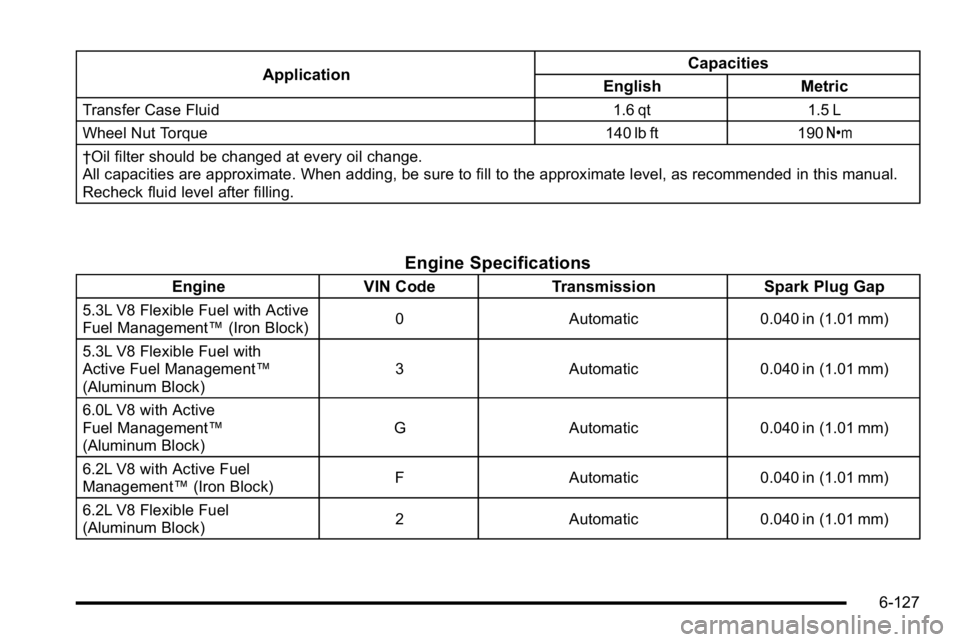

ApplicationCapacities

English Metric

Transfer Case Fluid 1.6 qt1.5 L

Wheel Nut Torque 140 lb ft190Y

†Oil filter should be changed at every oil change.

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this manual.

Recheck fluid level after filling.

Engine Specifications

Engine VIN CodeTransmission Spark Plug Gap

5.3L V8 Flexible Fuel with Active

Fuel Management™(Iron Block) 0 Automatic 0.040 in (1.01 mm)

5.3L V8 Flexible Fuel with

Active Fuel Management™

(Aluminum Block) 3 Automatic 0.040 in (1.01 mm)

6.0L V8 with Active

Fuel Management™

(Aluminum Block) G Automatic 0.040 in (1.01 mm)

6.2L V8 with Active Fuel

Management™ (Iron Block) F Automatic 0.040 in (1.01 mm)

6.2L V8 Flexible Fuel

(Aluminum Block) 2 Automatic 0.040 in (1.01 mm)

6-127

Page 565 of 614

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield

and wiper blade cleaning, if contaminated. See

Windshield, Backglass, and Wiper Blades

on

page 6‑114. Worn or damaged wiper blade

replacement. See Windshield Wiper Blade

Replacement on page 6‑61.

.Body hinges and latches, key lock cylinders,

folding seat hardware, and liftgate hinges,

linkage, and handle pivot points lubrication.

See Recommended Fluids and Lubricants

on

page 7‑11. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them

last longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑101.

.Automatic transmission fluid level check

and adding fluid, if needed. See Automatic

Transmission Fluid (4-Speed Transmission)

on

page 6‑24or Automatic Transmission Fluid

(6-Speed Transmission) on page 6‑27.

.Four‐wheel drive vehicles: Transfer case fluid level

check and adding fluid, if needed.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑22.

Additional Required Services

At Each Fuel Stop

.Engine oil level check. See Engine Oilon

page 6‑18.

.Engine coolant level check. See Engine Coolanton page 6‑32.

.Windshield washer fluid level check.

SeeWindshield Washer Fluid on page 6‑41.

Once a Month

.Tire inflation check. See Inflation - Tire Pressureon page 6‑72.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑78.

Once a Year

.Starter switch check. See Owner Checks and

Services on page 7‑9.

.Parking brake and automatic transmission P (Park)

mechanism check. See Owner Checks and

Services on page 7‑9.

7-5

Page 566 of 614

.Automatic transmission shiftlock control system

check. SeeOwner Checks and Serviceson

page 7‑9.

.Ignition transmission lock check. See Owner

Checks and Services on page 7‑9.

.Hood and liftgate gas strut support service.

Visually inspect gas strut for signs of wear,

corrosion, cracks, loss of lubricant, or other

damage. Check the hold open ability of gas strut.

Replace as necessary with genuine parts from

your dealer.

.Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. See Cooling System

on

page 6‑30.

.Exhaust system and nearby heat shields

inspection for loose or damaged components.

.Accelerator pedal check for damage, high effort,

or binding. Replace if needed.

First Engine Oil Change After Every

40 000 km/25,000 Miles

.Fuel system inspection for damage or leaks.

First Engine Oil Change After Every

80 000 km/50,000 Miles

.Engine air cleaner filter replacement. See Engine

Air Cleaner/Filter on page 6‑22.

.Automatic transmission fluid change (severe

service) for vehicles with Gross Vehicle Weight

Rating (GVWR) over 3 901 kg (8,600 lbs) or mainly

driven in heavy city traffic in hot weather, in hilly

or mountainous terrain, when frequently towing a

trailer, or used for taxi, police, or delivery service.

See Automatic Transmission Fluid (4-Speed

Transmission)

on page 6‑24or Automatic

Transmission Fluid (6-Speed Transmission)on

page 6‑27.

.Four‐wheel drive only: Transfer case fluid change

(severe service) for vehicles mainly driven when

frequently towing a trailer, or used for taxi, police,

or delivery service. Check vent hose at transfer

case for kinks and proper installation. Check to

be sure vent hose is unobstructed, clear, and free

of debris. During any maintenance, if a power

washer is used to clean mud and dirt from the

underbody, care should be taken to not directly

spray the transfer case output seals. High pressure

water can overcome the seals and contaminate

the transfer case fluid. Contaminated fluid will

decrease the life of the transfer case and should

be replaced.

7-6