lock GMC YUKON 2011 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2011, Model line: YUKON, Model: GMC YUKON 2011Pages: 528, PDF Size: 6.36 MB

Page 352 of 528

Black plate (72,1)GMC Yukon/Yukon XL Owner Manual - 2011

9-72 Driving and Operating

Filling the Tank

{WARNING

Fuel vapor burns violently and a

fuel fire can cause bad injuries.

To help avoid injuries to you and

others, read and follow all the

instructions on the fuel pump

island. Turn off the engine when

refueling. Do not smoke near fuel

or when refueling the vehicle. Do

not use cellular phones. Keep

sparks, flames, and smoking

materials away from fuel. Do not

leave the fuel pump unattended

when refueling the vehicle. This is

against the law in some places.

Do not re-enter the vehicle while

pumping fuel. Keep children away

from the fuel pump; never let

children pump fuel.

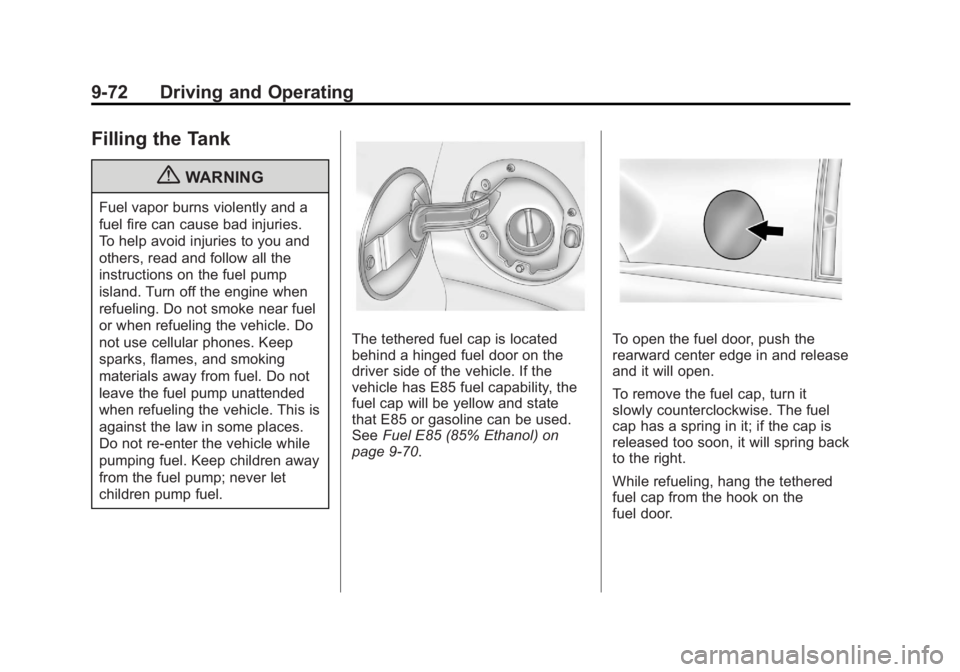

The tethered fuel cap is located

behind a hinged fuel door on the

driver side of the vehicle. If the

vehicle has E85 fuel capability, the

fuel cap will be yellow and state

that E85 or gasoline can be used.

SeeFuel E85 (85% Ethanol) on

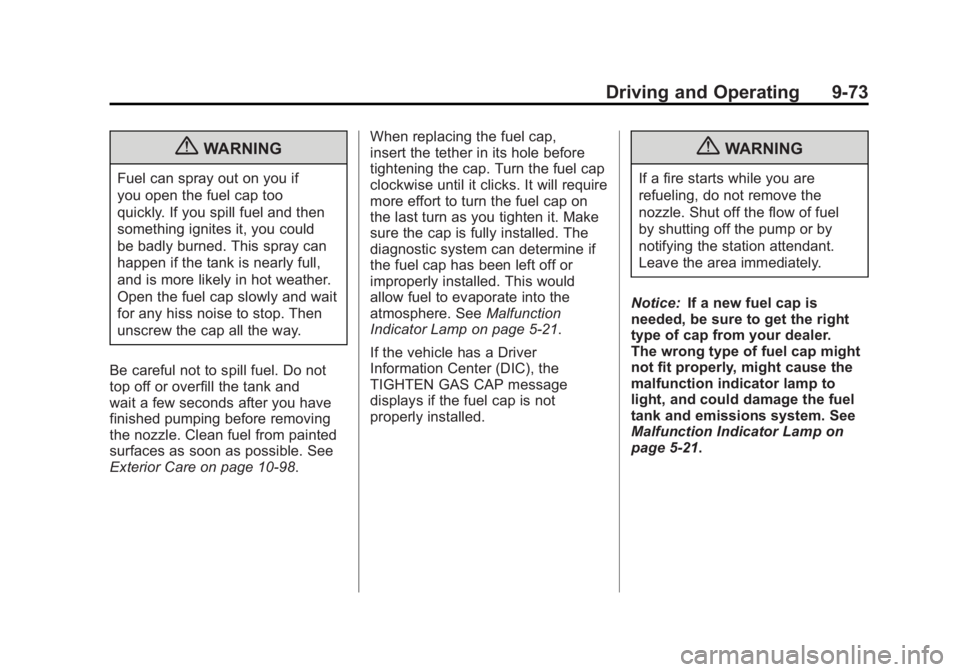

page 9‑70.To open the fuel door, push the

rearward center edge in and release

and it will open.

To remove the fuel cap, turn it

slowly counterclockwise. The fuel

cap has a spring in it; if the cap is

released too soon, it will spring back

to the right.

While refueling, hang the tethered

fuel cap from the hook on the

fuel door.

Page 353 of 528

Black plate (73,1)GMC Yukon/Yukon XL Owner Manual - 2011

Driving and Operating 9-73

{WARNING

Fuel can spray out on you if

you open the fuel cap too

quickly. If you spill fuel and then

something ignites it, you could

be badly burned. This spray can

happen if the tank is nearly full,

and is more likely in hot weather.

Open the fuel cap slowly and wait

for any hiss noise to stop. Then

unscrew the cap all the way.

Be careful not to spill fuel. Do not

top off or overfill the tank and

wait a few seconds after you have

finished pumping before removing

the nozzle. Clean fuel from painted

surfaces as soon as possible. See

Exterior Care on page 10‑98. When replacing the fuel cap,

insert the tether in its hole before

tightening the cap. Turn the fuel cap

clockwise until it clicks. It will require

more effort to turn the fuel cap on

the last turn as you tighten it. Make

sure the cap is fully installed. The

diagnostic system can determine if

the fuel cap has been left off or

improperly installed. This would

allow fuel to evaporate into the

atmosphere. See

Malfunction

Indicator Lamp on page 5‑21.

If the vehicle has a Driver

Information Center (DIC), the

TIGHTEN GAS CAP message

displays if the fuel cap is not

properly installed.

{WARNING

If a fire starts while you are

refueling, do not remove the

nozzle. Shut off the flow of fuel

by shutting off the pump or by

notifying the station attendant.

Leave the area immediately.

Notice: If a new fuel cap is

needed, be sure to get the right

type of cap from your dealer.

The wrong type of fuel cap might

not fit properly, might cause the

malfunction indicator lamp to

light, and could damage the fuel

tank and emissions system. See

Malfunction Indicator Lamp on

page 5‑21.

Page 368 of 528

Black plate (88,1)GMC Yukon/Yukon XL Owner Manual - 2011

9-88 Driving and Operating

This symbol is located on the Trailer

Brake Control Panel on vehicles

with an Integrated Trailer Brake

Control System. The power output

to the trailer brakes is based on the

amount of brake pressure being

applied by the vehicle’s brake

system. This available power output

to the trailer brakes can be adjusted

to a wide range of trailering

situations.

The ITBC system is integrated

with the vehicle’s brake, anti‐lock

brake and StabiliTrak systems.

In trailering conditions that cause

the vehicle’s anti‐lock brake or

StabiliTrak systems to activate,

power sent to the trailer's brakes

will be automatically adjusted to

minimize trailer wheel lock-up. This

does not imply that the trailer has

the StabiliTrak system. If the vehicle’s brake, anti‐lock

brake or StabiliTrak systems are

not functioning properly, the ITBC

system may not be fully functional

or may not function at all. Make

sure all of these systems are

fully operational to ensure full

functionality of the ITBC system.

The ITBC system is powered

through the vehicle's electrical

system. Turning the ignition off

will also turn off the ITBC system.

The ITBC system is fully functional

only when the ignition is in ON or

in RUN.

The ITBC system can only be used

with trailers with electric brakes.{WARNING

Connecting a trailer that is not

compatible with the ITBC system

may result in reduced or complete

loss of trailer braking. There

may be an increase in stopping

distance or trailer instability which

could result in personal injury or

damage to the vehicle, trailer,

or other property. An aftermarket

controller may be available for

use with trailers with surge,

air, or electric‐over‐hydraulic

trailer brake systems. To

determine the type of brakes

on the trailer and the availability

of controllers, check with your

trailer manufacturer or dealer.

Page 371 of 528

Black plate (91,1)GMC Yukon/Yukon XL Owner Manual - 2011

Driving and Operating 9-91

.There is a fault present in the

wiring to the electric trailer

brakes (a CHECK TRAILER

WIRING message will also be

displayed on the DIC).

.There is a fault in the ITBC

system (a SERVICE TRAILER

BRAKE SYSTEM message will

also be displayed in the DIC).

Manual Trailer Brake Apply

The Manual Trailer Brake Apply

Lever is located on the Trailer

Brake Control Panel and is used to

apply the trailer ’s electric brakes

independent of the vehicle’s brakes.

This lever is used in the Trailer Gain

Adjustment Procedure to properly

adjust the power output to the trailer

brakes. Sliding the lever to the left

will apply only the trailer brakes.

The power output to the trailer is

indicated in the Trailer Brake

Display Page in the DIC. If the

vehicle’s service brakes are applied while using the Manual Trailer Brake

Apply Lever, the trailer output power

will be the greater of the two.

The trailer and the vehicle's brake

lamps will come on when either

vehicle braking or manual trailer

brakes are applied.

Trailer Gain Adjustment Procedure

Trailer Gain should be set for a

specific trailering condition and

must be adjusted any time vehicle

loading, trailer loading or road

surface conditions change.

Setting the Trailer Gain properly

is needed for the best trailer

stopping performance. A trailer

that is over-gained may result in

locked trailer brakes. A trailer that

is under-gained may result in not

enough trailer braking. Both of these

conditions may result in poorer

stopping and stability of the vehicle

and trailer.

Use the following procedure to

correctly adjust Trailer Gain for each

towing condition:

1. Make sure the trailer brakes are

in proper working condition.

2. Connect a properly loaded trailer to the vehicle and make

all necessary mechanical and

electrical connections. See

Vehicle Load Limits on

page 9‑23 for more information.

3. After the electrical connection is made to a trailer equipped with

electric brakes:

.A TRAILER CONNECTED

message will be briefly

displayed on the DIC

display.

.The Trailer Brake Display

Page will appear on the

DIC showing TRAILER

GAIN and TRAILER

OUTPUT.

Page 372 of 528

Black plate (92,1)GMC Yukon/Yukon XL Owner Manual - 2011

9-92 Driving and Operating

.In the Trailer Output display

on the DIC,“- - - - - -“will

disappear if there is no

error present. Connecting

a trailer without electric

brakes will not clear the

six dashed lines.

4. Adjust the Trailer Gain by using the gain adjustment (+ / -)

buttons on the Trailer Brake

Control Panel.

5. Drive the vehicle with the trailer attached on a level road

surface representative of the

towing condition and free of

traffic at about 32 to 40 km/h

(20 to 25 mph) and fully apply

the Manual Trailer Brake Apply

lever.

Adjusting trailer gain at speeds

lower than 32 to 40 km/h

(20 to 25 mph) may result in an

incorrect gain setting. 6. Adjust the Trailer Gain to just

below the point of trailer wheel

lock-up, indicated by trailer

wheel squeal or tire smoke when

a trailer wheel locks.

Trailer wheel lock-up may not

occur if towing a heavily loaded

trailer. In this case, adjust the

Trailer Gain to the highest

allowable setting for the towing

condition.

7. Re-adjust Trailer Gain any time vehicle loading, trailer loading or

road surface conditions change

or if trailer wheel lock-up is

noticed at any time while towing

Other ITBC Related DIC Messages

In addition to displaying TRAILER

GAIN and TRAILER OUTPUT

through the DIC, trailer connection

and ITBC system status is displayed

in the DIC. TRAILER CONNECTED

–This

message will be briefly displayed

when a trailer with electric brakes is

first connected to the vehicle. This

message will automatically turn off

in about ten seconds. The driver

can also acknowledge this message

before it automatically turns off.

CHECK TRAILER WIRING –This

message will be displayed if:

1. The ITBC system first determines connection to a

trailer with electric brakes and

then the trailer harness becomes

disconnected from the vehicle.

If the disconnect occurs while

the vehicle is stationary, this

message will automatically

turn off in about thirty seconds.

This message will also turn off if

the driver acknowledges this

message off or if the trailer

harness is re-connected.

Page 379 of 528

Black plate (1,1)GMC Yukon/Yukon XL Owner Manual - 2011

Vehicle Care 10-1

Vehicle Care

General Information

General Information . . . . . . . . . . 10-2

CaliforniaProposition 65 Warning . . . . 10-3

California Perchlorate Materials Requirements . . . . 10-3

Accessories and Modifications . . . . . . . . . . . . . . . 10-3

Vehicle Checks

Doing Your OwnService Work . . . . . . . . . . . . . . . 10-4

Hood . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Engine Compartment Overview . . . . . . . . . . . . . . . . . . . 10-6

Engine Oil . . . . . . . . . . . . . . . . . . . 10-7

Engine Oil Life System . . . . . 10-10

Automatic Transmission Fluid . . . . . . . . . . . . . . . . . . . . . . 10-12

Engine Air Cleaner/Filter . . . . 10-15

Cooling System . . . . . . . . . . . . 10-16

Engine Coolant . . . . . . . . . . . . . 10-17

Engine Overheating . . . . . . . . 10-21 Overheated Engine

Protection

Operating Mode . . . . . . . . . . . 10-23

Engine Fan . . . . . . . . . . . . . . . . . 10-23

Power Steering Fluid . . . . . . . 10-24

Washer Fluid . . . . . . . . . . . . . . . 10-25

Brakes . . . . . . . . . . . . . . . . . . . . . 10-26

Brake Fluid . . . . . . . . . . . . . . . . . 10-27

Battery . . . . . . . . . . . . . . . . . . . . . 10-28

Four-Wheel Drive . . . . . . . . . . . 10-29

Front Axle . . . . . . . . . . . . . . . . . . 10-30

Rear Axle . . . . . . . . . . . . . . . . . . 10-31

Starter Switch Check . . . . . . . 10-32

Automatic Transmission Shift Lock Control Function

Check . . . . . . . . . . . . . . . . . . . . . 10-32

Ignition Transmission Lock Check . . . . . . . . . . . . . . . . . . . . . 10-33

Park Brake and P (Park) Mechanism Check . . . . . . . . 10-33

Wiper Blade Replacement . . . . . . . . . . . . . . 10-33

Glass Replacement . . . . . . . . 10-34

Headlamp Aiming

Headlamp Aiming . . . . . . . . . . 10-35

Bulb Replacement

Bulb Replacement . . . . . . . . . . 10-37

Halogen Bulbs . . . . . . . . . . . . . . 10-37

Taillamps, Turn Signal, Stoplamps, and Back-Up

Lamps . . . . . . . . . . . . . . . . . . . . 10-37

License Plate Lamp . . . . . . . . 10-38

Replacement Bulbs . . . . . . . . . 10-39

Electrical System

Electrical System Overload . . . . . . . . . . . . . . . . . . 10-39

Fuses and Circuit Breakers . . . . . . . . . . . . . . . . . . 10-40

Engine Compartment Fuse Block . . . . . . . . . . . . . . . . . . . . . 10-41

Instrument Panel Fuse Block . . . . . . . . . . . . . . . . . . . . . 10-45

Wheels and Tires

Tires . . . . . . . . . . . . . . . . . . . . . . . . 10-48

Tire Sidewall Labeling . . . . . . 10-50

Tire Designations . . . . . . . . . . . 10-52

Tire Terminology and

Definitions . . . . . . . . . . . . . . . . 10-53

Tire Pressure . . . . . . . . . . . . . . . 10-56

Tire Pressure Monitor System . . . . . . . . . . . . . . . . . . . 10-58

Page 381 of 528

Black plate (3,1)GMC Yukon/Yukon XL Owner Manual - 2011

Vehicle Care 10-3

California

Proposition 65 Warning

Most motor vehicles, including this

one, contain and/or emit chemicals

known to the State of California to

cause cancer and birth defects or

other reproductive harm. Engine

exhaust, many parts and systems,

many fluids, and some component

wear by-products contain and/or

emit these chemicals.

California Perchlorate

Materials Requirements

Certain types of automotive

applications, such as airbag

initiators, seat belt pretensioners,

and lithium batteries contained in

Remote Keyless Entry transmitters,

may contain perchlorate materials.

Special handling may be necessary.

For additional information, see

www.dtsc.ca.gov/hazardouswaste/

perchlorate.

Accessories and

Modifications

Adding non‐dealer accessories or

making modifications to the vehicle

can affect vehicle performance

and safety, including such things

as airbags, braking, stability, ride

and handling, emissions systems,

aerodynamics, durability, and

electronic systems like antilock

brakes, traction control, and stability

control. These accessories or

modifications could even cause

malfunction or damage not covered

by the vehicle warranty.

Damage to vehicle components

resulting from modifications or

the installation or use of non‐GM

certified parts, including control

module or software modifications, is

not covered under the terms of the

vehicle warranty and may affect

remaining warranty coverage for

affected parts.GM Accessories are designed to

complement and function with other

systems on the vehicle. Your GM

dealer can accessorize the vehicle

using genuine GM Accessories.

When you go to your GM dealer

and ask for GM Accessories, you

will know that GM-trained and

supported service technicians will

perform the work using genuine GM

Accessories.

Also, see

Adding Equipment to the

Airbag-Equipped Vehicle on

page 3‑52.

Page 385 of 528

Black plate (7,1)GMC Yukon/Yukon XL Owner Manual - 2011

Vehicle Care 10-7

A.Engine Air Cleaner/Filter on

page 10‑15.

B. Coolant Surge Tank and Pressure Cap. See Cooling

System on page 10‑16.

C. Remote Positive (+) Terminal. See Jump Starting on

page 10‑88.

D. Battery on page 10‑28.

E. Remote Negative (−) Terminal (Out of View). See Jump

Starting on page 10‑88.

F. Automatic Transmission Dipstick (Out of View). See

“Checking the Fluid Level”

under Automatic Transmission

Fluid on page 10‑12.

G. Engine Oil Fill Cap. See “When

to Add Engine Oil” under

Engine Oil on page 10‑7.

H. Engine Oil Dipstick (Out of View). See “Checking Engine

Oil” under Engine Oil on

page 10‑7. I. Engine Cooling Fan (Out of

View). See Cooling System on

page 10‑16.

J. Power Steering Fluid Reservoir. See Power Steering Fluid on

page 10‑24.

K. Brake Master Cylinder Reservoir. See “Brake

Fluid” under Brake Fluid on

page 10‑27.

L. Engine Compartment Fuse

Block on page 10‑41.

M. Windshield Washer Fluid Reservoir. See “Adding Washer

Fluid” under Washer Fluid on

page 10‑25.

If the vehicle is a hybrid, see

the hybrid supplement for more

information.Engine Oil

To ensure proper engine

performance and long life, careful

attention must be paid to engine

oil. Following these simple, but

important steps will help protect

your investment:

.Always use engine oil approved

to the proper specification and of

the proper viscosity grade. See

“Selecting the Right Engine Oil”

in this section.

.Check the engine oil level

regularly and maintain the

proper oil level. See “Checking

Engine Oil” and“When to Add

Engine Oil” in this section.

.Change the engine oil at the

appropriate time. See Engine Oil

Life System on page 10‑10.

.Always dispose of engine oil

properly. See “What to Do with

Used Oil” in this section.

Page 391 of 528

Black plate (13,1)GMC Yukon/Yukon XL Owner Manual - 2011

Vehicle Care 10-13

6. Using the TRANS TEMPreading, determine and

perform the appropriate check

procedure. If the TRANS TEMP

reading is not within the required

temperature ranges, allow the

vehicle to cool, or operate the

vehicle until the appropriate

transmission fluid temperature is

reached.

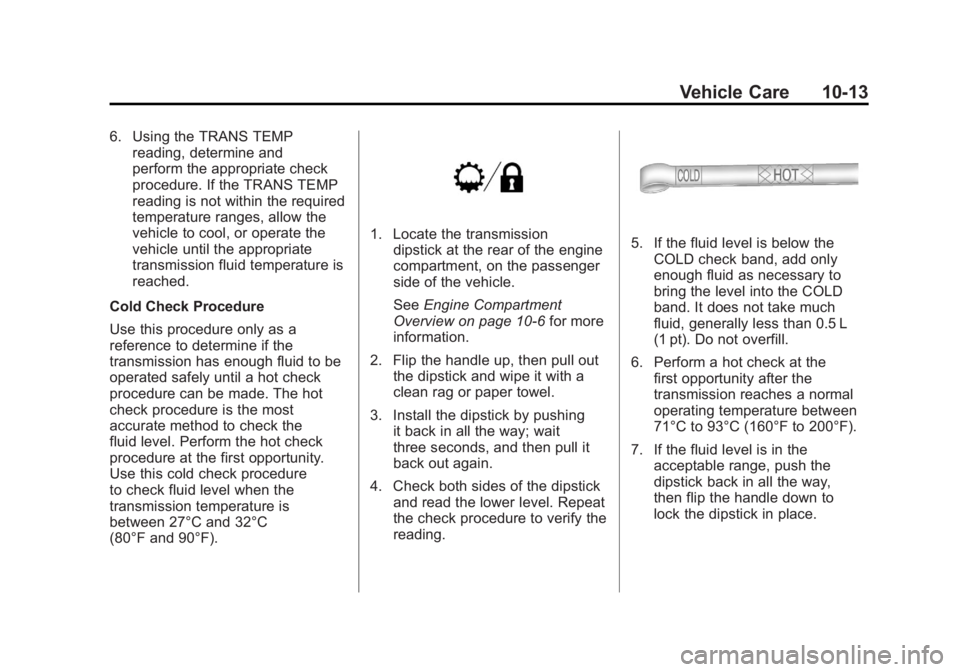

Cold Check Procedure

Use this procedure only as a

reference to determine if the

transmission has enough fluid to be

operated safely until a hot check

procedure can be made. The hot

check procedure is the most

accurate method to check the

fluid level. Perform the hot check

procedure at the first opportunity.

Use this cold check procedure

to check fluid level when the

transmission temperature is

between 27°C and 32°C

(80°F and 90°F).

1. Locate the transmission dipstick at the rear of the engine

compartment, on the passenger

side of the vehicle.

See Engine Compartment

Overview on page 10‑6 for more

information.

2. Flip the handle up, then pull out the dipstick and wipe it with a

clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way; wait

three seconds, and then pull it

back out again.

4. Check both sides of the dipstick and read the lower level. Repeat

the check procedure to verify the

reading.5. If the fluid level is below theCOLD check band, add only

enough fluid as necessary to

bring the level into the COLD

band. It does not take much

fluid, generally less than 0.5 L

(1 pt). Do not overfill.

6. Perform a hot check at the first opportunity after the

transmission reaches a normal

operating temperature between

71°C to 93°C (160°F to 200°F).

7. If the fluid level is in the acceptable range, push the

dipstick back in all the way,

then flip the handle down to

lock the dipstick in place.

Page 392 of 528

Black plate (14,1)GMC Yukon/Yukon XL Owner Manual - 2011

10-14 Vehicle Care

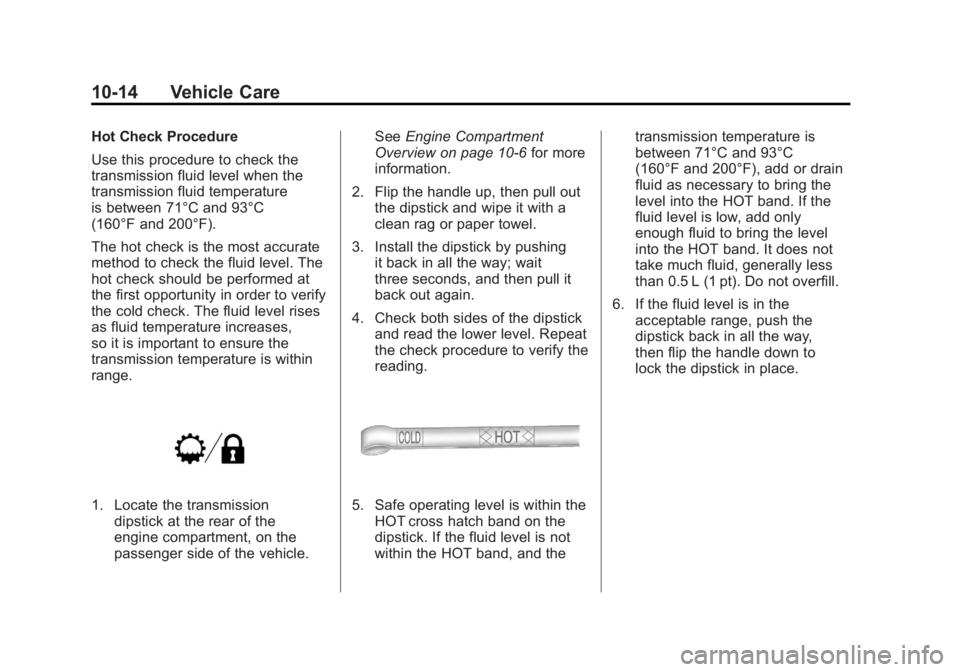

Hot Check Procedure

Use this procedure to check the

transmission fluid level when the

transmission fluid temperature

is between 71°C and 93°C

(160°F and 200°F).

The hot check is the most accurate

method to check the fluid level. The

hot check should be performed at

the first opportunity in order to verify

the cold check. The fluid level rises

as fluid temperature increases,

so it is important to ensure the

transmission temperature is within

range.

1. Locate the transmissiondipstick at the rear of the

engine compartment, on the

passenger side of the vehicle. See

Engine Compartment

Overview on page 10‑6 for more

information.

2. Flip the handle up, then pull out the dipstick and wipe it with a

clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way; wait

three seconds, and then pull it

back out again.

4. Check both sides of the dipstick and read the lower level. Repeat

the check procedure to verify the

reading.5. Safe operating level is within theHOT cross hatch band on the

dipstick. If the fluid level is not

within the HOT band, and the transmission temperature is

between 71°C and 93°C

(160°F and 200°F), add or drain

fluid as necessary to bring the

level into the HOT band. If the

fluid level is low, add only

enough fluid to bring the level

into the HOT band. It does not

take much fluid, generally less

than 0.5 L (1 pt). Do not overfill.

6. If the fluid level is in the acceptable range, push the

dipstick back in all the way,

then flip the handle down to

lock the dipstick in place.