GMC YUKON DENALI 2002 Owners Manual

YUKON DENALI 2002

GMC

GMC

https://www.carmanualsonline.info/img/44/57885/w960_57885-0.png

GMC YUKON DENALI 2002 Owners Manual

Trending: service indicator, rear view mirror, center console, open hood, steering wheel, adding oil, ABS

Page 281 of 407

5-22

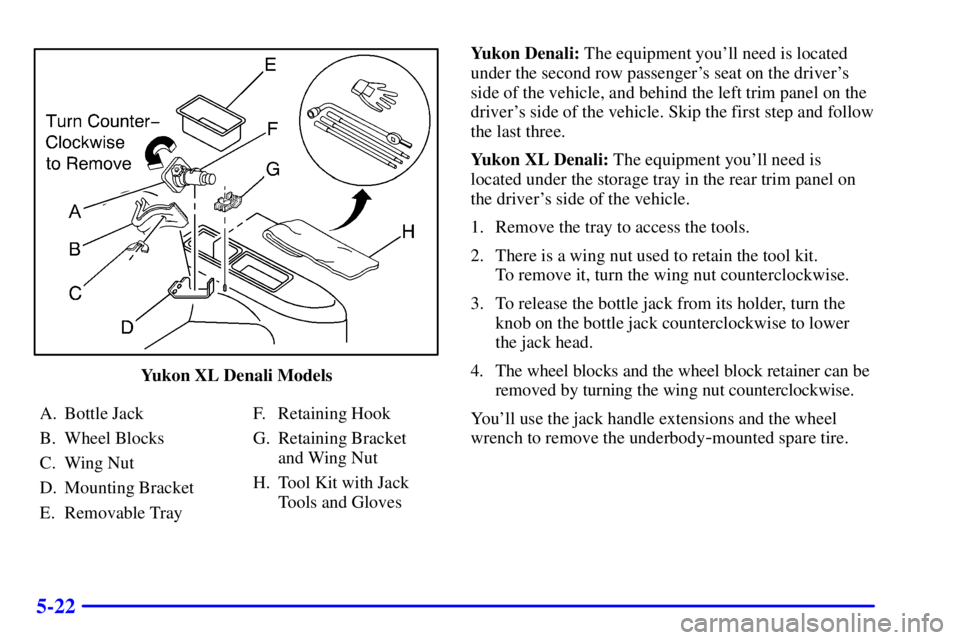

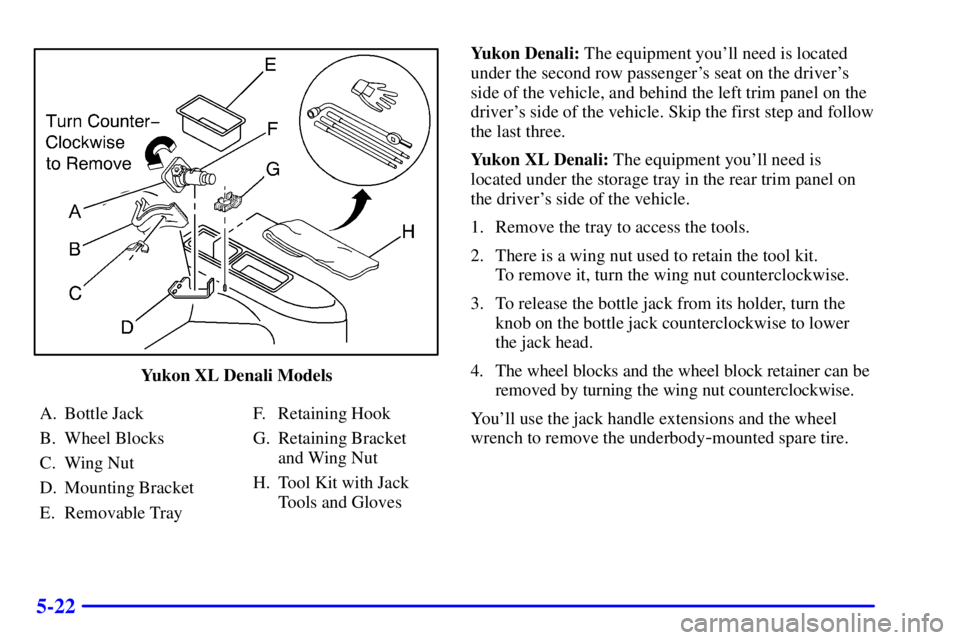

Yukon XL Denali Models

A. Bottle Jack

B. Wheel Blocks

C. Wing Nut

D. Mounting Bracket

E. Removable TrayF. Retaining Hook

G. Retaining Bracket

and Wing Nut

H. Tool Kit with Jack

Tools and GlovesYukon Denali: The equipment you'll need is located

under the second row passenger's seat on the driver's

side of the vehicle, and behind the left trim panel on the

driver's side of the vehicle. Skip the first step and follow

the last three.

Yukon XL Denali: The equipment you'll need is

located under the storage tray in the rear trim panel on

the driver's side of the vehicle.

1. Remove the tray to access the tools.

2. There is a wing nut used to retain the tool kit.

To remove it, turn the wing nut counterclockwise.

3. To release the bottle jack from its holder, turn the

knob on the bottle jack counterclockwise to lower

the jack head.

4. The wheel blocks and the wheel block retainer can be

removed by turning the wing nut counterclockwise.

You'll use the jack handle extensions and the wheel

wrench to remove the underbody

-mounted spare tire.

Page 282 of 407

5-23

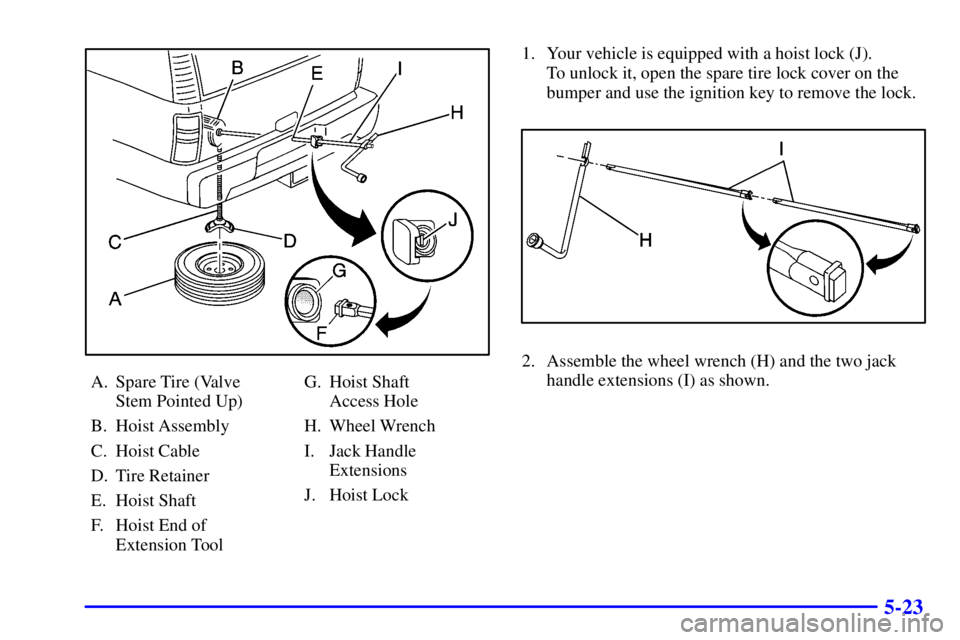

A. Spare Tire (Valve

Stem Pointed Up)

B. Hoist Assembly

C. Hoist Cable

D. Tire Retainer

E. Hoist Shaft

F. Hoist End of

Extension ToolG. Hoist Shaft

Access Hole

H. Wheel Wrench

I. Jack Handle

Extensions

J. Hoist Lock1. Your vehicle is equipped with a hoist lock (J).

To unlock it, open the spare tire lock cover on the

bumper and use the ignition key to remove the lock.

2. Assemble the wheel wrench (H) and the two jack

handle extensions (I) as shown.

Page 283 of 407

5-24

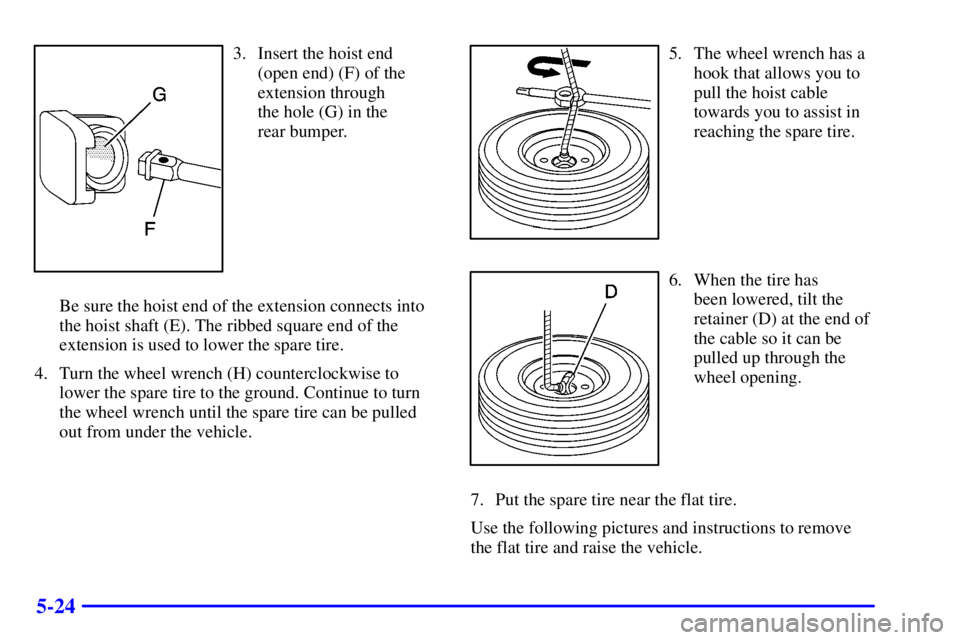

3. Insert the hoist end

(open end) (F) of the

extension through

the hole (G) in the

rear bumper.

Be sure the hoist end of the extension connects into

the hoist shaft (E). The ribbed square end of the

extension is used to lower the spare tire.

4. Turn the wheel wrench (H) counterclockwise to

lower the spare tire to the ground. Continue to turn

the wheel wrench until the spare tire can be pulled

out from under the vehicle.5. The wheel wrench has a

hook that allows you to

pull the hoist cable

towards you to assist in

reaching the spare tire.

6. When the tire has

been lowered, tilt the

retainer (D) at the end of

the cable so it can be

pulled up through the

wheel opening.

7. Put the spare tire near the flat tire.

Use the following pictures and instructions to remove

the flat tire and raise the vehicle.

Page 284 of 407

5-25

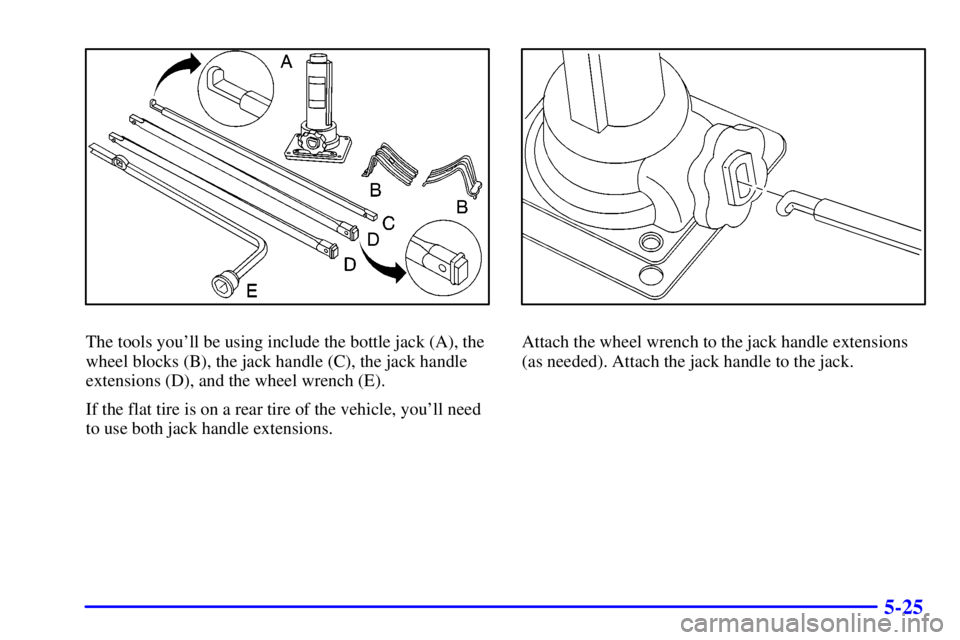

The tools you'll be using include the bottle jack (A), the

wheel blocks (B), the jack handle (C), the jack handle

extensions (D), and the wheel wrench (E).

If the flat tire is on a rear tire of the vehicle, you'll need

to use both jack handle extensions.Attach the wheel wrench to the jack handle extensions

(as needed). Attach the jack handle to the jack.

Page 285 of 407

5-26

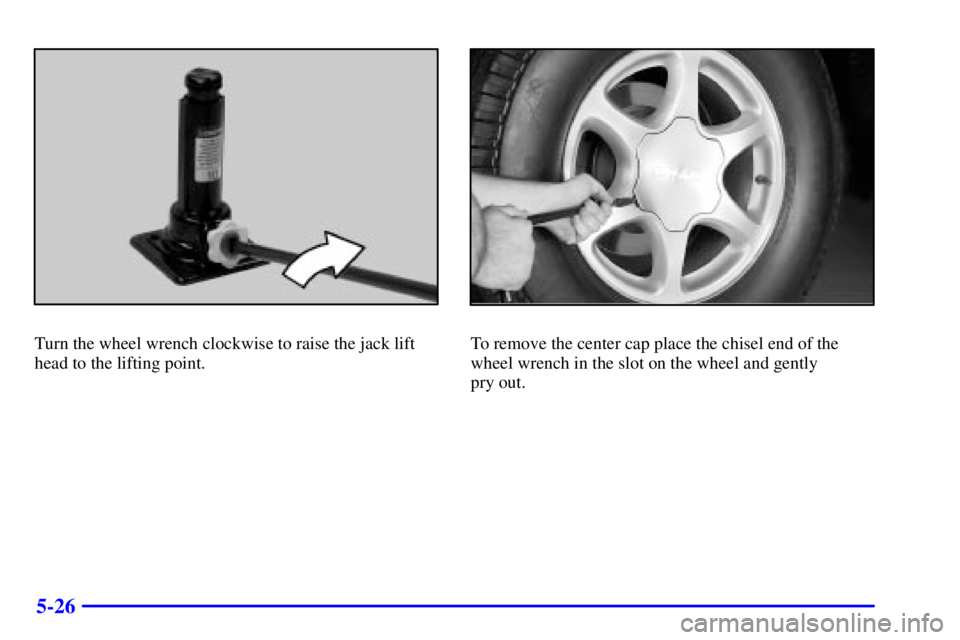

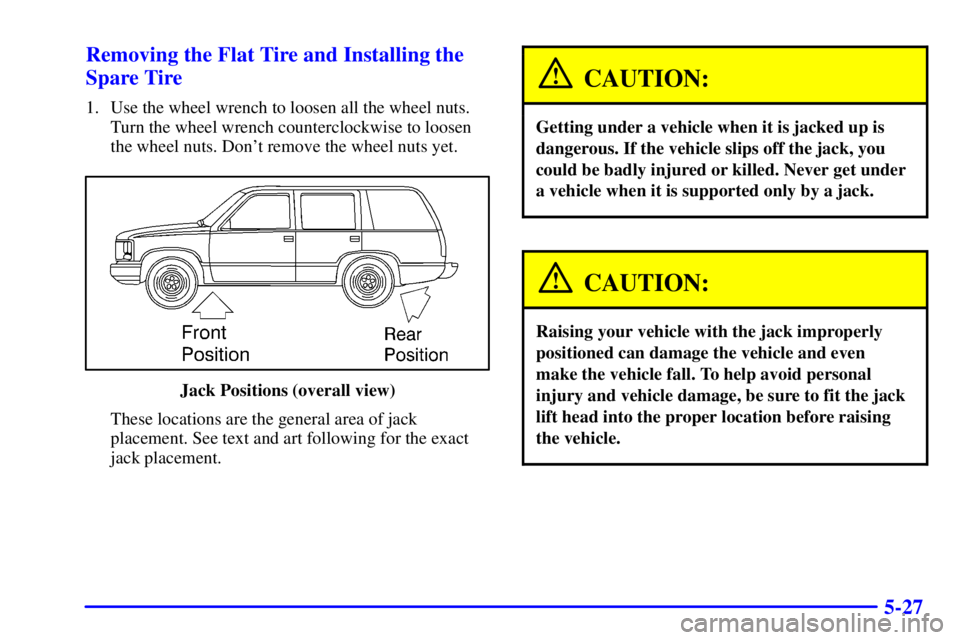

Turn the wheel wrench clockwise to raise the jack lift

head to the lifting point.To remove the center cap place the chisel end of the

wheel wrench in the slot on the wheel and gently

pry out.

Page 286 of 407

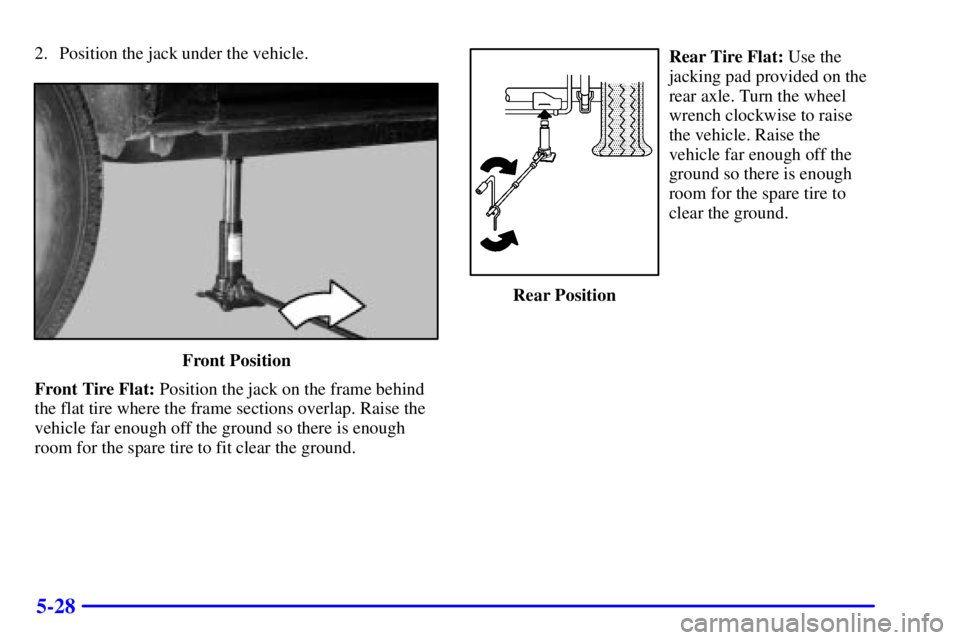

5-27 Removing the Flat Tire and Installing the

Spare Tire

1. Use the wheel wrench to loosen all the wheel nuts.

Turn the wheel wrench counterclockwise to loosen

the wheel nuts. Don't remove the wheel nuts yet.

Jack Positions (overall view)

These locations are the general area of jack

placement. See text and art following for the exact

jack placement.

CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack, you

could be badly injured or killed. Never get under

a vehicle when it is supported only by a jack.

CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even

make the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to fit the jack

lift head into the proper location before raising

the vehicle.

Page 287 of 407

5-28

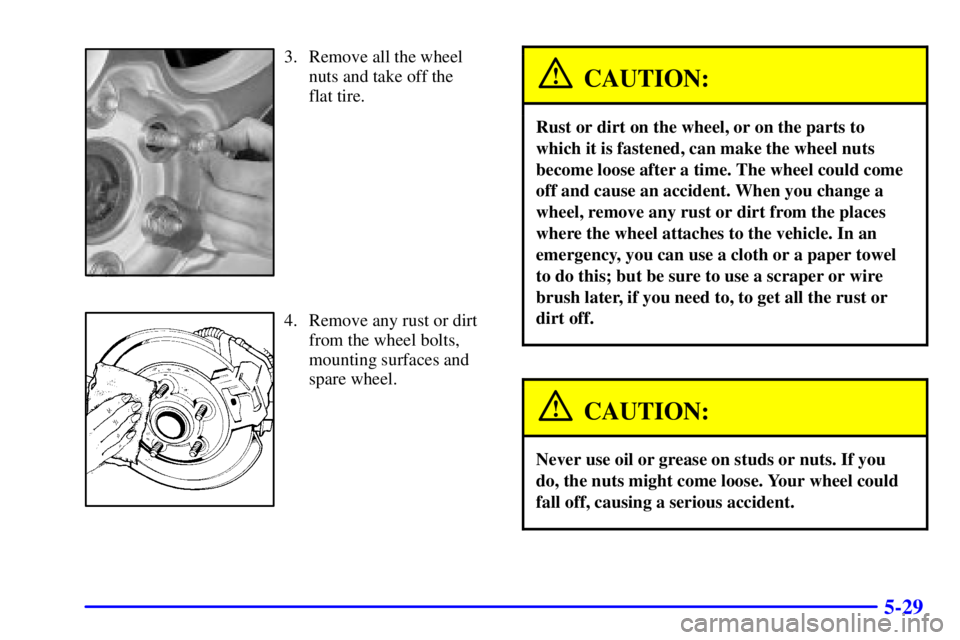

2. Position the jack under the vehicle.

Front Position

Front Tire Flat: Position the jack on the frame behind

the flat tire where the frame sections overlap. Raise the

vehicle far enough off the ground so there is enough

room for the spare tire to fit clear the ground.

Rear Tire Flat: Use the

jacking pad provided on the

rear axle. Turn the wheel

wrench clockwise to raise

the vehicle. Raise the

vehicle far enough off the

ground so there is enough

room for the spare tire to

clear the ground.

Rear Position

Page 288 of 407

5-29

3. Remove all the wheel

nuts and take off the

flat tire.

4. Remove any rust or dirt

from the wheel bolts,

mounting surfaces and

spare wheel.

CAUTION:

Rust or dirt on the wheel, or on the parts to

which it is fastened, can make the wheel nuts

become loose after a time. The wheel could come

off and cause an accident. When you change a

wheel, remove any rust or dirt from the places

where the wheel attaches to the vehicle. In an

emergency, you can use a cloth or a paper towel

to do this; but be sure to use a scraper or wire

brush later, if you need to, to get all the rust or

dirt off.

CAUTION:

Never use oil or grease on studs or nuts. If you

do, the nuts might come loose. Your wheel could

fall off, causing a serious accident.

Page 289 of 407

5-30

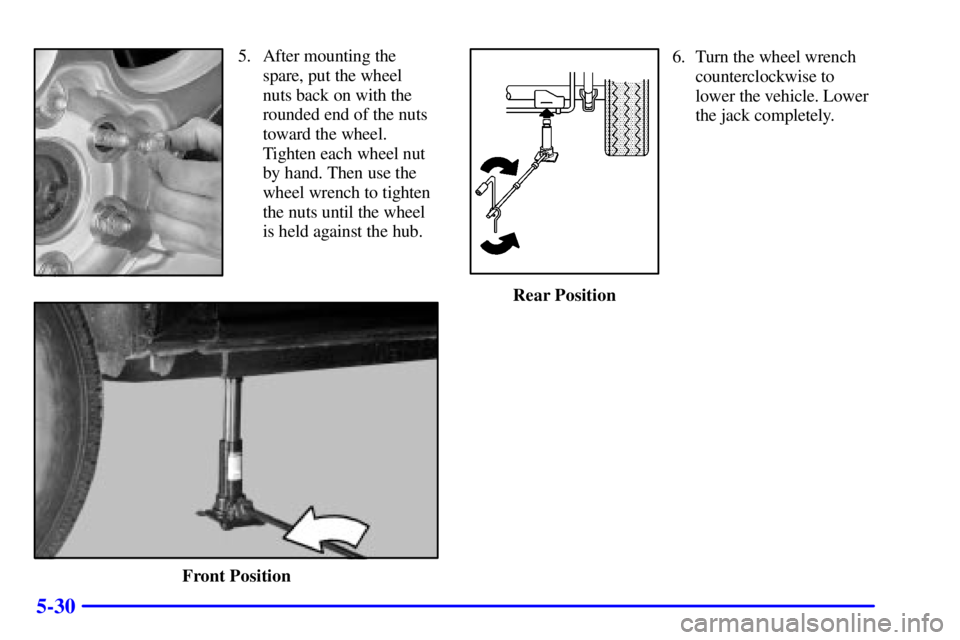

5. After mounting the

spare, put the wheel

nuts back on with the

rounded end of the nuts

toward the wheel.

Tighten each wheel nut

by hand. Then use the

wheel wrench to tighten

the nuts until the wheel

is held against the hub.

Front Position

6. Turn the wheel wrench

counterclockwise to

lower the vehicle. Lower

the jack completely.

Rear Position

Page 290 of 407

5-31

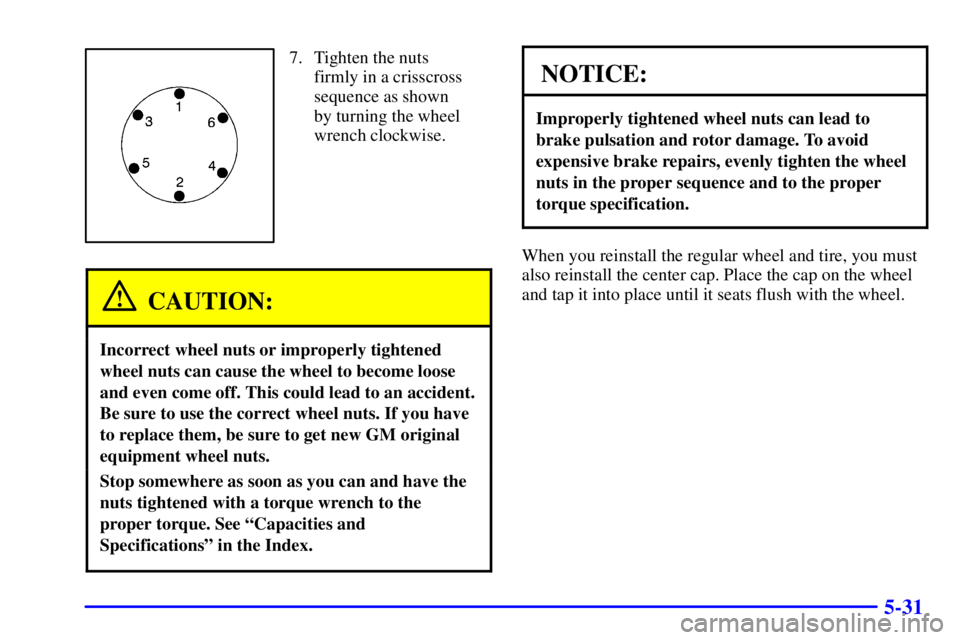

7. Tighten the nuts

firmly in a crisscross

sequence as shown

by turning the wheel

wrench clockwise.

CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to become loose

and even come off. This could lead to an accident.

Be sure to use the correct wheel nuts. If you have

to replace them, be sure to get new GM original

equipment wheel nuts.

Stop somewhere as soon as you can and have the

nuts tightened with a torque wrench to the

proper torque. See ªCapacities and

Specificationsº in the Index.

NOTICE:

Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification.

When you reinstall the regular wheel and tire, you must

also reinstall the center cap. Place the cap on the wheel

and tap it into place until it seats flush with the wheel.

Trending: battery capacity, lug pattern, wiper blades, trip computer, service, coolant, jump cable